Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Pentruder 6-12HF

- Page 1 Operator’s manual ® Pentruder 6-12HF wall saw ® Pentpak high frequency power pack...

-

Page 2: Table Of Contents

Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 1 Operator’s manual for ® Pentruder 6-12HF-wall saw and ® Pentpak high frequency power pack Version: 1.9 Date: 2012-03-05 Support & Service document Original instructions Copyright © 1997-2012 Tractive AB. -

Page 3: Introduction

Pentruder 6-12HF. We are confident that your investment in this equipment and its many design features will enhance your companies’ competitive edge and profitability! The first section of this manual, page 1-2, contains the table of contents and an introduction of the machine. -

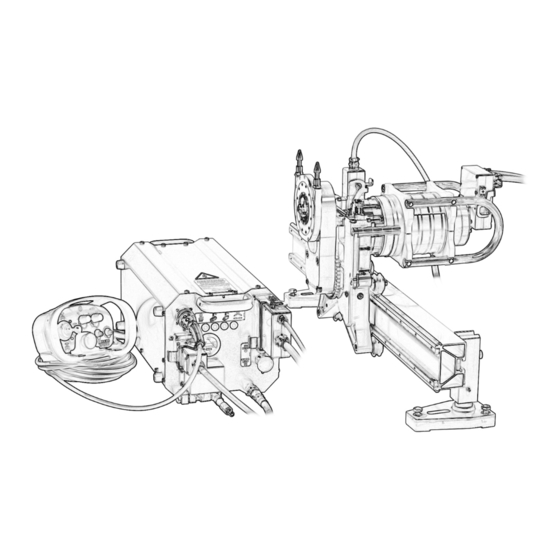

Page 4: Description Of The Machine

The Pentruder 6-12HF is the overall most efficient machine for concrete cutting in it’s size available on the market today. When the overall efficiency of the system is evaluated, all aspects of the work must be considered. - Page 5 Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 4 For optimum accessibility the saw arm can be rotated through 360 degrees in either direction. The saw head accepts an 800 mm (32”) saw blade free from the wall.

- Page 6 Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 5 Pos G. Travel and feed motors are protected within the chassis body. No electric parts except for connectors are exposed to dirt. Pos H. Travel and feed transmission is by means of planetary gear transmission and a self blocking worm gear transmission.

-

Page 7: Quick Disconnect Coupling For Mounting Of The Saw Blade (Patent)

This is the most important criteria when our machines are designed. Pentruder 6-12HF is equipped with a patented quick disconnect coupling for the saw blade. The intention with this coupling is primarily to enhance safety and handling. A unique patented coupling for the blade flange enhances safety and simplifies awkward set-up’s considerably,... -

Page 8: Tracks And Brackets

Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 7 Tracks and brackets The tracks and the brackets are designed to provide high levels of rigidity and stability for the lowest possible weight. The design is unique in the sense that it allows the guide rollers on the saw head to be aligned above each other, in the same plane as for the cut. -

Page 9: Blade Guard

Because of the lightweight design it is more likely that the operator will choose to use the blade guards on all jobs – this has not always been so! The guards on the Pentruder 6-12 HF are so convenient and lightweight they should always be used. It is a basic requirement for safe handling of the machine. -

Page 10: Pentpak High Frequency (Hf)-Power Pack

Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 9 Pentpak high frequency (HF)-power pack The Pentpak high frequency (HF-)power pack is designed to a new and unique concept. The electronic units are especially designed for the Pentpak and the power pack is one of the most compact designs on the market. -

Page 11: Intended Use Of The Pentruder 6-12Hf And Pentpak Hf-Power Pack

Intended use of the Pentruder 6-12HF and Pentpak HF-power pack Pentruder 6-12HF is intended to be used together with a Pentpak HF-power pack and may only be used for cutting of concrete and similar materials. It is our expressed recommendation that the machine not be used for cutting in any other materials. - Page 12 Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 11 Warning! A saw blade rotates at up to 60 m/s peripheral speed, i.e. over 200 km/hour (120 mph). The energy stored in such a blade is considerable, and it is always important that the machine always is mounted according to the instructions given in this manual, and that the blade guard always is fitted.

-

Page 13: Getting Started

Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 12 Getting started Preparations before commencing work. Certain preparations must be done before starting work. Cleaning: The machine should be carefully cleaned and all functions checked and are found normal before use of the machine. - Page 14 Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 13 Water seal on saw head: In the saw arm, there is a rotating shaft with seals used to feed the water into the centre of the spindle and further to both sides of the blade flange.

-

Page 15: Preparation And Mounting Of Track Feet And Tracks

Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 14 Preparation and mounting of track feet and tracks Bolts for fastening: The track feet and the tracks should be mounted in such a way that they can not become detached when the machine is working, or at sudden changes in load on the anchor bolts. - Page 16 Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 15 Adjusting the height of the track feet. The height of the fork can be adjusted totally 12 mm by turning the fork CW or CCW, to compensate for irregularities on the wall. Please be sure that the fork is not threaded all the way out before the track is mounted.

-

Page 17: Mounting The Saw Head On The Track

Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 16 Mounting the saw head on the track The saw head runs on the track on four conical rollers. The upper rollers are fitted on eccentric shafts, opened and locked by turning the handles. -

Page 18: Quick Disconnect Coupling For Hf-Motor On Saw Head

Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 17 Quick disconnect coupling for HF-motor on saw head To reduce the weight of the parts that must be handled by the operator, the saw head is basically divided in the saw head unit and the drive motor. -

Page 19: Quick Disconnect Coupling For The Saw Blade

Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 18 Quick disconnect coupling for the saw blade Function principle: The saw blade is fitted on a blade flange by means of an outer collar and clamped by means of a special centre screw, or, for flush cutting, on a special flush cutting flange by means of 6 countersunk screws and nuts. -

Page 20: How To Fit A Blade On A Standard Blade Flange

Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 19 Warning! The drive dogs on the machine spindle and blade flange bust be completely in mesh before the clamping screw is tightened to prevent damage to the coupling. Failure to follow this instruction may result in coupling overload and a failure can lead to serious personal injury or death. -

Page 21: How To Fit A Blade On A Flush Cutting Flange

How to fit a blade on a flush cutting flange: The Pentruder 6-12HF is a powerful machine. This means the blades which are fitted for flush cutting must be properly fixed to the machine. When a blade is fitted to a flush cutting flange, it is... -

Page 22: Mounting The Blade With Flange On The Machine Spindle

Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 21 Mounting the blade with flange on the machine spindle If the procedure described above is followed, the blade and flange are now ready to be fitted on to the machine spindle with the quick coupling. -

Page 23: Peripheral Cutting Speed And Spindle Speed

The Pentruder 6-12HF is equipped with a 2-speed gearbox to give optimum power for different conditions and size of blade. In combination with alteration of the frequency from the power pack a useful speed range from approximately 550 to 1200 RPM is available. - Page 24 Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 23 Peripheral cutting speed and spindle speed in metres / second for different blade diameters, @ 400Hz: (Set potentiometer at 90% on the remote control) Gear Ø...

-

Page 25: How To Shift Gears In The 2-Speed Gearbox

Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 24 How to shift gears in the 2-speed gearbox: Gears may only be shifted when the power cord is disconnected from the HF-motor. The gear selection knob is placed below the HF-motor. -

Page 26: Mounting The Blade Guard

A prerequisite to achieve any level of protection is that the guard is fitted to the machine at all times. For the 6-12HF the guards are available in three different sizes, Ø 800 (32”) , Ø 1000 (40”), and Ø 1200 (48”) for normal and flush cutting. Fully covering “parallel” blade guards are also available for use together with a parallel blade guard guide. -

Page 27: Preparing The Power Pack

Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 26 Preparing the power pack Positioning: The power pack should be positioned away from where the sawing takes place and should be kept dry at all times. It should preferably be placed on a flat surface. - Page 28 Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 27 Connecting to remote control: The power pack may be disconnected from the mains when the remote control is connected. The multi pin connector must be in the correct position with the notch pointing upwards for the clamping ring to close.

-

Page 29: Led Type Warning Lights On The Power Pack

Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 28 Starting the power pack: Connect all cords, big diameter orange colour cord to HF-motor, small diameter orange colour cord to feed and travel motors, grey remote control cord to the power pack and lastly a 380 –... - Page 30 Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 29 LED type warning lights on the power pack There are four red warning LED:s on the Pentpak. Below is an explanation of the respective functions.

- Page 31 Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 30 LED indicating status for the HF-motor Pentpak is powered, but the green start button on the Pentpak button has not yet been pressed. A test is made for the can-bus to the HF-motor and the chassis.

- Page 32 Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 31 LED indicating status for the feed and travel drive system Pentpak is powered, but the green start button on the Pentpak button has not yet been pressed.

-

Page 33: Remote Control Unit

Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 32 Remote control unit The remote control unit is connected to the power pack through a Cannon connector. It is not possible to control any functions on the power pack unless the remote control is connected to the power pack. - Page 34 Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 33 Switch for water valve: Move the switch forward to start and stop the water flow through the machine. The water flow will be switched on automatically when the blade is started.

-

Page 35: Maintenance

Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 34 Maintenance For the Pentruder 6-12HF / Pentpak HF-power pack remain in a condition which is safe for operation at all times, certain maintenance is needed. Please read the instructions below carefully before any service work is commenced. - Page 36 Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 35 Oil change in the travel and arm feed worm gear transmission: This oil should be changed every 80 hours of operation when service is done to the machine. The travel worm gear transmission is filled with 60 ml and the arm feed worm gear transmission with 60 ml of Omega 680 oil.

- Page 37 Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 36 Water seal on saw head: In the saw arm, there is a swivel to feed the water into the centre of the spindle and further to both sides of the blade flange. Two seals seal off the water which is fed through the spindle quick disconnect screw, and on through the pull stud at the front of the spindle.

- Page 38 Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 37 Service on the rotating blade guard flange: The blade guard holding flange consists of a nylon flange bolted to the saw arm. Around the nylon flange there is an aluminium outer flange that rotates with the blade guard as the arm rotates.

-

Page 39: Technical Data Pentruder 6-12Hf - Hf-Wall Saw

Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 38 Technical data Pentruder 6-12HF - HF-wall saw Pentruder 6-12HF Saw blade diameter max.: 1200 mm (48”) Max cutting depth with 515 mm (20.3”), Blade radius minus 85 mm (3.35”) 1200 (48”) blade:... -

Page 40: Technical Data Pentpak Hf Power Pack

Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 39 Technical data Pentpak HF power pack Pentpak 418 / 422 / 427 Pentpak 200* / 218 / 222 Input voltage: 380 – 480 V 200 – 230 V Input frequency: 50 –... -

Page 41: Declaration Of Conformity

Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 40 Declaration of Conformity We, Tractive AB declare that the machine Manufacturer: Tractive AB Gjutargatan 54 78170 Borlänge Sweden Category: High Frequency Power Pack Make: Pentpak... - Page 42 Operators manual for the Pentruder 6-12HF and Pentpak HF-power pack – Original instructions Page 41 Declaration of conformity We, Tractive AB declare that the machine Manufacturer: Tractive AB Gjutargatan 54 78170 Borlänge Sweden Category: High Frequency Wall Saw Make: Pentruder...

Need help?

Do you have a question about the 6-12HF and is the answer not in the manual?

Questions and answers