Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Stahl SH 3

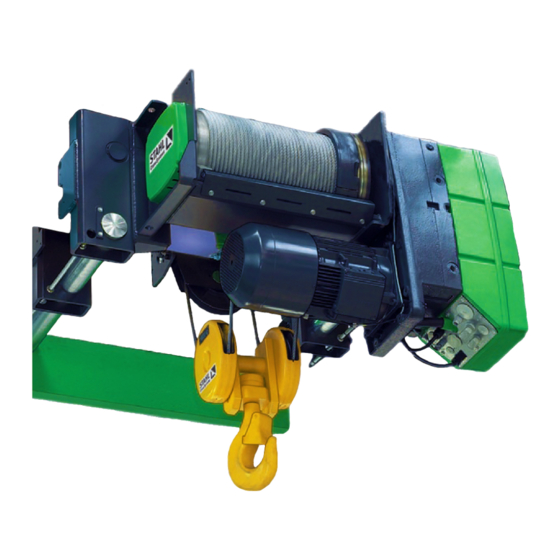

- Page 1 Wire Rope Hoists _ Operating and Maintenance Instructions...

- Page 2 Fundamental information You have purchased a product manufactured by STAHL CraneSystems GmbH. This wire rope hoist has been constructed in compliance with the applicable standards and regulations. Inspect hoist for damage caused in transit immediately upon delivery. Report damage caused in transit and after consulting the manufacturer/supplier repair or have repaired before installation and commissioning.

-

Page 3: Table Of Contents

Contents Safety instructions Symbols ........................... 4 Operating instructions ....................4 Use for intended purpose ..................... 5 Safety-conscious operation..................5 Organisational safety precautions................5 General regulations ....................... 6 Installation, commissioning, maintenance and repairs .......... 6 Warranty.......................... 6 Periodic tests........................6 1.10 After sales service......................6 Getting to know the wire rope hoist .............................. -

Page 4: Safety Instructions

1 Safety instructions 1.1 Symbols Transport The wire rope hoist is delivered on a special pallet. This enables the hoist to be loaded and unloaded safely with a fork-lift truck. If the wire rope hoist is to be transported suspended, it must be attached by the suspension lugs provided, see sketch. -

Page 5: Use For Intended Purpose

1 Safety instructions 1.3 Use for intended purpose • Wire rope hoists are intended for lifting freely movable and guided loads that cannot tilt. Depending on their design, they are for stationary or mobile use. If loads are to be towed horizontally, or in the case of guided loads, automatic opera- tion, continual deadweight or constantly repeated hoisting motions, the individual application must be assessed. -

Page 6: General Regulations

1 Safety instructions 1.6 General regulations • Safety regulations and accident prevention regulations. • National regulations 1.7 Installation, commissioning, • Installation, commissioning, maintenance and repairs may be carried out by quali- fied persons only, see page 2. maintenance and repairs •... -

Page 7: Getting To Know The Wire Rope Hoist

2 Seilzug kennen lernen The modular concept of our series of wire rope hoists permits a multitude of variations on the basis of series components. Our certified quality assurance system to DIN ISO 9001/EN 29001 guarantees consistently high quality. If you have any questions, for example on hoists modified to customers’ specific applications, please contact one of our branches or subsidiaries. -

Page 8: Installation

(Rope drum torque) must therefore be torsion resistant. • If the rope lead-off is not vertical, the shearing forces arising must be taken up by a SH 3: M = 0.5 x F x 126 mm support bar. SH 4: M = 0.5 x F x 167 mm... -

Page 9: Fleet Angles

3 Installation Fleet angles 3.2.1 Feet at bottom SH 3 1/1, 2/2 SH 4 SH 5 SH 3 SH 4 SH 6 α1 4° 5° 8° 8° α2 23° 13° 20° 18° α3 27° 30° 30° 30° α4 74° 73°... - Page 10 3 Installation 3.2.3 Fleet angles The rope guide must be adjusted to the fleet angle. Observe also the radial rope exit Type angle γ. γ° γ SH 3 53° SH 4 60° SH 5 53° SH 6 53° 3.2.4 Angles of installation •...

-

Page 11: Trolleys/Crabs

3.3 Trolleys/crabs 3.3.1 Monorail trolley (KE-S33 - 76) with SH 3, SH 4, SH 5, SHR 6, SH 6 wire rope hoists • Check flange width "B" and clearance "c" against table 1 and set trolley to beam width if necessary. - Page 12 3 Installation Drive shaft for trolley drive (trolley KE-S76) • The drive shaft is suitable for girder flange widths "B" from 124 to ≤220, >221 to ≤400 and >401 to 500 mm; see table 2, page 11 for length "L". •...

-

Page 13: Ue-S4 Monorail Trolley

3 Installation 3.3.2Monorail trolley (UE-S4) with SH 4, SH 5 1/1 wire rope hoists (single fall) • Check flange width "B" and clearance "c±2" against the table and set trolley to beam width if necessary. Ensure that the connection piece (square tube) (6) is in the centre (of dimension "c") between the trolley side cheeks ("z1"... -

Page 14: Ue-S776 Monorail Trolley

3 Installation 3.3.3Monorail trolley (UE-S776) with SH 6, 4/1 wire rope hoists (four-fall) • Check flange width "B" and clearance "c±2" against the table and set trolley to beam width if necessary. Ensure that the connection piece (square tube) (6) is in the centre (of dimension "c") between the trolley side cheeks ("z1"... - Page 15 3 Installation Drive shaft for trolley drive (trolley UE-S776) • The drive shaft is suitable for girder flange widths "B" from 185 to 500 mm, see table for length "L". • Insert drive shaft (1) into the two drive pinions (6) from the counterweight side, then assemble spacer tube (3) and adjusting ring (4).

-

Page 16: Dke-S Articulated Trolley

3 Installation 3.4 Articulated trolley with SH 3, SH 4, SH 5 wire rope hoists (DKE-S4 / DKE-S6) • Check flange width "B" and clearance "c" against the table and set trolley to beam width if necessary. Ensure that the connection piece (square tube) (6) is in the centre (of dimension "c") between the trolley side cheeks ("z1"... - Page 17 3 Installation Drive shaft for travel drive (DKE-S4 / DKE-S6) Trolleys with one travel drive • Mount a drive shaft of a length (L) suitable for the beam width (B) • Fit lockwashers (S) acc. to dimension L4 • The mounting position of the drive shaft does not change over the corresponding beam range (B).

- Page 18 3 Installation End stops • Mount end stops with rubber buffers at end of runway. E max ØD Type Order no. PA 50/200 01 740 24 27 0 PA 50/300 3200 01 740 25 27 0 PA 50/500 01 740 26 27 0 PA 63/200 01 740 27 27 0 PA 63/300...

-

Page 19: Double Rail Crab

3 Installation 3.5 Double rail crab (OE-S ) • Check track gauge Spw on crab and rail. • L1 max - L1 min = 5 mm, see sketch. • Check lateral play between rail and flange, see sketch. • Bolt rubber buffers to crab or runway end stop. •... -

Page 20: Travel Limit Switches

3 Installation 3.6 Travel limit switch 3.6.1 Monorail trolley The travel limit switches (optional) are mounted on the trolley. 3.6.2 Double rail crab The travel limit switch assembly is supplied ready-wired but not mounted and must be secured to the towing arm for the power supply. The switching contacts are designed for control current. -

Page 21: Electrical Equipment

3 Installation 3.7 Electrical equipment For the sake of safety, have the wire rope hoist connected by a skilled electrician (see page 2). Observe the relevant safety and accident prevention regulations! 3.7.1 Supply cables • As fixed installed cables: NYY, NYM •... - Page 22 3 Installation 3.7.8 Overload cut-off Description of system • prevents an overload being lifted. If an overload has been established, the load can only be lowered. The switch is set in the factory. Corrections are only permissible in special cases, see page 57. In certain applications, wire rope hoists may also be used without an overload cut- off.

-

Page 23: Hoists With Frequency Converter

3 Installation 3.7.9 Connecting to mains • Compare existing mains voltage and frequency with the information on the rating plate. • Route cables into the hoist connection box through the cable glands. • Connect according to the circuit diagrams supplied. Measure control voltage. -

Page 24: Reeving Rope

3 Installation 3.9 Reeving rope The wire rope is wound onto the drum in the factory. If not, see page 50, "Replacing wire rope". If the bottom hook block is not fitted, proceed as follows: • Gripper pliers hold the rope securely. •... - Page 25 3 Installation Reeving rope (SH3 - SH6) Reeve the rope as shown in the schematic drawings and attach the end of the rope at the rope anchorage. Caution! The bottom hook block must hang horizontal (./2-1) SH3 - SH5 2/2-1 4/2-1 8/2-1 SH3 - SH5...

- Page 26 • Secure loose end of rope with rope clamp (3) approx. 50 mm from the end of the rope. See table for tightening torque. • Max. projection of rope wedge SH 3 - SH 4 x = 6mm ; SH 5 - 6 x = 15mm max.

- Page 27 3 Installation Rope anchorage (SH3 - SH5) Length L SH 3 SH 4 SH 5 SH3.. 216 241 SH4.. 265 290 SH5.. 334 366 4/2-1 SH3.. 216 241 SH4.. 265 290 SH5.. 334 366 Length L SH 3 SH 4...

- Page 28 3 Installation Rope anchorage(SH6) SH 6 Length L L2-L5 L2-L5 2/2-1 4/2-1 L2-L5 8/2-1 L3-L5 SH 6 Length L L2-L5 L2-L5 4/2-1 L2-L5 SH 6 Length L L2-L5 L2-L5 4/2-1 L2-L5 8/2-1 L3-L5 *1 Gear side 09.07...

-

Page 29: Commissioning

4 Commissioning 4.1 Commissioning The wire rope hoist has been subjected to a final inspection by the manufacturer in accordance with the EC Machinery Directive. Commissioning must be carried out by a qualified person, see page 2. The "Safety instructions" on page 4...6 must also be observed. The following checks must be carried out: •... -

Page 30: Operation

Operation 5.1 Duties of crane operator When working with wire rope hoists, the following points must be observed: • Every day before starting work, check brakes and limit switches and inspect the system for any visible defects. • Stop working with the crane if there are any defects which might prejudice its safety in operation. -

Page 31: Operating Control Pendant

Operation 5.2 Operating from control pendant Standard design 2-step Emergency stop Lifting/lowering: 1st step: slow 2nd step: fast Cross travel: right/left 1st step: slow 2nd step: fast Long travel: right/left 1st step: slow 2nd step: fast Safety note If the rocker switch is no longer depressed by the operator, it returns to the 0 posi- tion, the hoist motion is automatically stopped (dead man’s control). -

Page 32: Inspection And Maintenance

6 Inspection and maintenance This section deals with operational reliability, availability, and maintaining the value of your wire rope hoist. Although this wire rope hoist is practically maintenance-free, the components subject to wear (e.g. wire rope, brake) and components important for ensuring explosion protection must be inspected regularly. -

Page 33: Maintenance Intervals

6 Inspection and maintenance 6.1.2 Once a year • Emergency limit switch (2) if there is an operational limit switch, see page 35 • Check suspension of control pendant (cable and steel wire must be correctly attached) • Load hook (5), cracks, cold deformation, wear •... -

Page 34: Rsm Hoist Motor Brake

6 Inspection and maintenance 6.3 Hoist motor brake (RSM) Carry out work on the hoist brake only when the hoist is unloaded and the bottom hook block has been set down. Switch off and padlock main isolator. 6.3.1 Checking brake •... -

Page 35: Hoist Limit Switch Versions

6 Inspection and maintenance 6.5 Hoist limit switch N.B.: (versions) The hoist limit switch version installed must be determined on the basis of the sticker in the limit switch (see stickers). 6.5.1 Standard crane - version I (Fig. 1/2) See chapter 6.6 for description of system Fig. -

Page 36: Hoist Limit Switch On Standard Crane - Version I

6 Inspection and maintenance 6.6 Hoist limit switch ( 6.6.1 Description of system standard crane The wire rope hoist is equipped as standard with an emergency limit switch for ↑ disconnecting in top and bottom hook position. (Switching points A and A↓). - Page 37 6 Inspection and maintenance 6.6.5 Setting limit switch The cover of the limit switch must be removed to set the contacts. This exposes live contact connections. There is thus a danger of contact with live parts! The limit switch can be adjusted at the setscrews (S1)-(S2) or (S1)-(S4): Turning to the left: switching point is moved "downwards", Turning to the right: switching point is moved "upwards".

- Page 38 6 Inspection and maintenance 6.6.5 Setting limit switch (continued) Switching point A↓ (S1) "Emergency limit switch bottom hook position" (Minimum clearance between rope guide (S) and clamping claws (K) for rope anchorage = 20 mm, see sketch) Set bottom hook position so that the bottom hook block does not touch the ground (would cause slack rope).

-

Page 39: Hoist Limit Switch On Standard Crane - Version Ii

6 Inspection and maintenance 6.7 Hoist limit switch 6.7.1 Description of system (standard crane) The wire rope hoist is equipped as standard with an emergency limit switch for ↑ disconnecting in top and bottom hook position. (Switching points A and A↓). The hoist is also equipped with an operational and emergency limit switch for ↑... - Page 40 6 Inspection and maintenance 6.7.5 Setting limit switch The cover of the limit switch must be removed to set the contacts. This exposes live contact connections. There is thus a danger of contact with live parts! The limit switch can be adjusted at the setscrews (S1)-(S2) or (S1)-(S4): Turning to the left: switching point is moved "downwards", Turning to the right: switching point is moved "upwards".

- Page 41 6 Inspection and maintenance 6.7.6 Servicing limit switch Maintenance work is restricted to checking the cut-off points. No maintenance or inspection is necessary for the gear limit switch itself. Any dust deposits that may be visible when the housing is opened must on no account be removed with compressed air as this would force the dust into the contacts and impair the switching function.

-

Page 42: Hoist Limit Switch On Radio-Controlled Crane - Version Iii

6 Inspection and maintenance 6.8 Hoist limit switch 6.8.1 Description of emergency hoist limit switch system (radio-controlled crane) The wire rope hoist is equipped as standard with an emergency limit switch for ↑ disconnecting in top and bottom hook position. (Switching points A and A↓). - Page 43 6 Inspection and maintenance 6.8.5 Description of optional operational hoist limit switch system An additional operational limit switch for disconnecting in top and bottom hook position during normal operation can be fitted as an option. In this case 2 cut-off ↑...

- Page 44 6 Inspection and maintenance 6.8.8 Setting hoist limit switch The cover of the limit switch must be removed to set the contacts. This exposes live contact connections. There is thus a danger of contact with live parts! The limit switch can be adjusted at the setscrews (S1)-(S3) or (S1)-(S4): Turning to the left: switching point is moved "downwards", Turning to the right: switching point is moved "upwards".

- Page 45 6 Inspection and maintenance 6.8.8 Setting hoist limit switch (continued) Combined operational and emergency hoist limit switch: ↑ 1. A (S1) ↑ 2. B (S3) ↓ 3. A (S2) ↓ 4. B (S4) ↑ Switching point A (S1) "Emergency limit switch top hook position" •...

- Page 46 6 Inspection and maintenance 6.9 Overload cut-off 6.9.1 Description of system The SLE21 / Multicontroller SMC21 load monitor with its electronic sensor is set in the factory. Corrections are only permitted in special cases, see page 57. The factory settings are shown under the front cover of the SLE 21 load monitor (sketch).

-

Page 47: Crane Test

6 Inspection and maintenance 6.10Crane test SLE21 / SMC21 1. Carefully remove front cover of SLE21 / SMC21. 2. The cut-off point is increased by pressing button (S5) permitting the test load of 125% to be lifted. Button (S5) pressed. Cut-off threshhold is raised. -

Page 48: Rope Drive

6 Inspection and maintenance 6.11 Rope drive 6.11.1 Rope and rope attachment - general information After commissioning a new wire rope hoist, or after replacing the rope, the rope of multi-fall hoists may twist. This can be seen from the bottom hook block turning, particularly when unloaded. Twisting in the rope prejudices safety and service life. - Page 49 6 Inspection and maintenance 6.1.2 Replacement of wire rope due to broken wires Twist-free wire rope Rope diameter [mm] Number of external strands Rope make-up * 18X7+SE d1315z d1315z d1315z d1315z d1318 Broken wires visible 1Bm, 1Am (FEM 9.661) 2m - 4m over a length of [mm] Broken wires visible 1Bm, 1Am (FEM 9.661)

- Page 50 37, 40,44, "Setting hoist limit switch". • If the new rope twists after some time in operation, untwist the rope immediately. See page 25, "Reeving rope" and "Removing rope". Type SH 3 SH 4 SH 5 SH 6 10.08...

- Page 51 6 Inspection and maintenance 6.11.5 Fitting rope guide • Grease thread and rope guide groove thoroughly. • Place the half-ring (1) with the short window section onto the rope drum next to the last rope winding so that the rope exits from the region of the window (x). •...

- Page 52 6 Inspection and maintenance 6.11.6 Inspection and maintenance of rope sheave • Check rope sheaves for wear. We recommend having them checked by personnel trained by us. They should also be checked for easy running, indicating that the ball bearings are in good condition. Wear on rope sheave Notes on limits for wear Rope sheaves...

-

Page 53: Trolley/Crab

6 Inspection and maintenance 6.12 Trolley/crab Wheels, wheel drive and runway • Visual inspection of wheels for wear. See tables for limits for wear. • Visual inspection of runway girder for wear. Visual inspection of wheel flanges for wear. Nominal value Limit for wear Fig. -

Page 54: Remaining Service Life

If 90% of the theoretical full load lifetime has expired, a general overhaul (GO) must be scheduled and carried out at the earliest possible date. 6.13.2 STAHL SMC21 Multicontroller (optional) The operating time of the hoist and the full load operating hours are recorded in the SMC21. -

Page 55: Fault-Finding

7 Fault-finding 7.1 What is to be done if? 7.1.1 Wire rope hoist does not start, motor hums • Not all power phases are present. 1. Check fuses, 2. Check supply cable, 3. Check control pendant and switchgear. 7.1.2 Wire rope hoist does not start after a long stoppage, or starts with difficulty, motor hums •... - Page 56 7 Fault-finding 7.1 What is to be done if? 7.1.8 Load is not lifted (continued) • SLE21 load monitor / SMC21 Multicontroller has been actuated or is faulty. 1. Check setting, see page 46. 2. Actions for SLE21 / SMC21 LED I...III "on"...

- Page 57 7 Fault-finding 7.1.9 Correction of cut-off threshhold for SLE21 with electronic sensor • Corrections to the cut-off threshhold may be carried out by trained personnel only. The load monitor will only accept alterations of -20% to +8% on the factory setting. If these limits are exceeded, I and II flash.

-

Page 58: Technical Data

8 Technical data 8.1 FEM classification Classification of mechanism, rope drive and motor in acc. with FEM for SH Type FEM 9.661 FEM 9.511 FEM 9.683 Type FEM 9.661 FEM 9.511 FEM 9.683 2/2-1 4/2-1 1000 2000 SH 3005-25 SH 3005-40 1250 2500 SH 3006-25... -

Page 59: Hoist

8 Technical data 8.3 Hoist 8.3.1 Pole-changing hoist motors 50Hz Hoists Motor 50 Hz Main fuse gL / gG *3 220...240 V 380...415 V 480...525 V 220... 380... 480... 240 V 415 V 525 V % DC In [A] Ik [A] In [A] Ik [A] In [A]... - Page 60 8 Technical data 8.3.2 Pole-changing hoist motors 60Hz Hoists Motor 60 Hz Main fuse gL / gG *3 380...415 V 440...480 V 550...600 V 380... 440... 550... 415 V 480 V 600 V %DCD In [A] Ik [A] In [A] Ik [A] In [A] Ik [A]...

- Page 61 8 Technical data 8.3.3 Frequency-controlled hoist motors 50Hz 50 Hz cos ϕ FU Hoist motor 380-415 V 480-525 V Mains fuse 380-415 V 480-525 V In [A] I max. FU [A] In [A] I max. FU [A] 4H33 12,8 0,98 4H42 0,98 10,6...

-

Page 62: Cable Cross Sections And Lengths Of Supply Cables

8 Technical data 8.4 Cable cross sections and lengths of supply cable Hoist motor Trolley/crab Rising mains Crane Stationary Crane Trolley/crab type max. 10 m Crane Fixed installation in PVC Festoon cable in free air as Fixed installation in PVC Festoon cable in free air as Festoon cable in free air as Fixed... -

Page 63: Tightening Torques For Screws

Other screw connections and applicable tightening torques Screw connection Screw connection Type Part 1 / Part 2 Grade MA [Nm] Gear casing/panel box SH 3 - SH 4 Gear casing/support plate SH 3 SH 4 SH 5 SH 5 Rope drum/gear drive shaft Rope drum/clamping plate... -

Page 64: Lubricants

8 Technical data 8.6 Lubricants W0572a F0450a SH 30 SH 30 SH 40 SH 40 SH 50 SH 50 SH 60 SH 60 SHR 60 * Oil filling/oil drainage screw Depending on installation position of gear, the filling screw is "at the top" and the drainage screw "at the bottom". -

Page 65: Sound Pressure Level

8 Technical data 8.8 Sound pressure level The sound pressure level was measured at a distance of 1 m from the wire rope hoist. The mean sound pressure level is calculated for one operating cycle (50% with nominal load, 50% without load). Instead of stating an emission value based on a workplace, the values from table 1 and 2 at measuring distance "h"... -

Page 66: Wearing Parts

9 Wearing parts 9.1 Serial number When ordering original spare parts, please always indicate the serial number of the hoist. This is affixed to the inside of the bearing support plate (see sketch). 9.2 Hoist RSM hoist motor brake Hoist Hoist motor motor brake... -

Page 67: General Information

The seminars are individual modules or can form part of a long-term training course; they are held in German or English. Each seminar is concluded with a certificate. You can obtain information on our seminar programme from: STAHL CraneSystems GmbH Daimlerstraße 6 | D-74653 Künzelsau | Tel. +49 7940 128-0 marketing@stahlcranes.com →... - Page 68 Die Adressen von über 100 Vertriebspartnern weltweit finden Sie im Internet auf www.stahlcranes.com unter Kontakt. You will find the addresses of over 100 sales partners on the Internet at www.stahlcranes.com under Contact. STAHL CraneSystems GmbH, Daimlerstr. 6, 74653 Künzelsau, Germany Tel +49 7940 128-0, Fax +49 7940 55665, marketing@stahlcranes.com...

Need help?

Do you have a question about the SH 3 and is the answer not in the manual?

Questions and answers

HELLO, CAN I HAVE THE DIMENSIONS AS DIAMETER AND LENGTH FOR A WIRE ROPE? AS ATTACHED PICTURE DATA

The dimensions of the Stahl SH 3 wire rope vary depending on the type. For twist-free wire rope, diameters listed include 5.5 mm, 7 mm, 9 mm, 12 mm, 14 mm, and 20 mm. For non twist-free wire rope, diameters include 5.5 mm, 7 mm, 9 mm, 12 mm, 12.5 mm, 14 mm, and 20 mm. Length is not specified in the provided context.

This answer is automatically generated