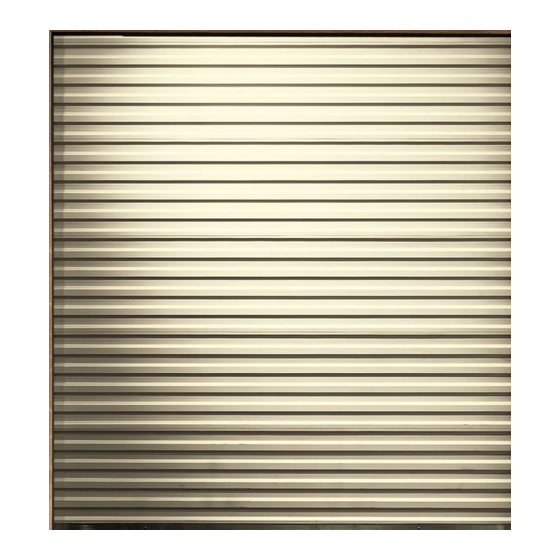

Summary of Contents for Overhead door 780 CD Series

-

Page 1: Installation Instructions

INSTALLATION INSTRUCTIONS Series 780 CD, 790 CW CAUTION USE PROPER LIFTING EQUIPMENT AND CORRECT LIFTING PROCEDURES TO AVOID INJURY. 220153-0001 8/14/03 © Overhead Door Corporation... -

Page 2: Safety Information

HIGH SPRING TENSION tools and instructions. READ THIS MANUAL CAREFULLY AND OBSERVE ALL WARNINGS WHEN INSTALLING, OPERATING OR MAINTAINING YOUR OVERHEAD DOOR. IMPORTANT Read these instructions completely before CHECK for shipping damage. attempting to install this door. -

Page 3: Installation

Operation Door Type 10“ 6“ 6“ 12“ 10“ FOR REFERENCE DRIVE END Push Up 10“ 10“ 4“ 4“ 8“ 10“ 10“ 4“ 6“ 10“ Reduced Chain Drive 10“ 4“ 10“ 8“ 12“ 10“ 10“ 4“ 4“ 8“ Operator 10“ 4“ 10“... - Page 4 Self Clinching Nut Installation 780 Installation No Windlocks 790 Installation With Windlocks Figure 2a-4:1 Hoist See Page 9 For Bill Of Materials...

- Page 5 Figure 2b-8:1 Hoist See Page 9 For Bill Of Materials...

- Page 6 4. Curtain assembly counterbalance springs will have to Table 2 - Guide Fasteners be wound during the installment procedure. It is Fastener Spacing Jamb Doors Width essential that the curtain bottom bar be positioned correctly when placing curtain assembly on headplates. 1/4“...

- Page 7 TO ADJUST SPRING TENSION: a. Raise curtain to fully OPEN position. b. Loosen set screw on chain hoist, if present. Figure 5 c. Adjust spring tension (Figure 8) according to the following procedure: aa. Apply torque to door shaft using a pipe wrench. bb.

- Page 8 See Page 9 For Bill Of Materials...

- Page 9 STANDARD DOOR HARDWARE ITEM PART NUMBER PART DESCRIPTION 202023-0002 BRACKET, HEADPLATE 220154-0002 STOP, BOTTOM BAR, RH 220154-0001 STOP, BOTTOM BAR, LH 202157-0001 SADDLE CLAMP, SHAFT Table 3 306973-0002 SLIDEBOLT, 1"w X 11-1/4" L 080302-2832 WSHR, FLAT, PLD, 3/8 X 1 OD 080105-0628 BOLT, HH, NC, 3/8 X 3 1/2"...

- Page 10 ADDITIONAL MOUNTING BRACKETS ITEM PART NUMBER PART DESCRIPTION 204215-0002 JAMB EXTENSION - IDLE END 204214-0002 JAMB EXTENSION - DRIVE END 205981-0005 MOUNTING BRKT., .188 THK, LH 205981-0006 MOUNTING BRKT., .188 THK, RH...

-

Page 11: Troubleshooting

TROUBLE SHOOTING SYMPTOM POSSIBLE CAUSE 1. Door is easy to close, but hard to open... - Insufficient spring tension. 2. Door is easy to open, but hard to close... - Excessive spring tension. 3. Door is hard to operate... - Mounting brackets are not level. - Curtain assembly is not parallel to opening. - Page 12 TROUBLE SHOOTING OPTIONAL HEADER SEAL 1. With door closed, mark attachment point for header seal on curtain (Figure 10). 2. Raise curtain until attachment point is accessible. 3. Hold header seal along attachment point and drill holes for rivets on 12“ centers using a number 29 drill. 4.

- Page 13 HEADER MOUNTED RUBBER SEAL HEADER MOUNTED BRUSH SEAL...

Need help?

Do you have a question about the 780 CD Series and is the answer not in the manual?

Questions and answers