Table of Contents

Advertisement

DC

Safety and operating instructions

Transverse Drum Cutters

Valid from serial number

DC 200

DC 400

DC 600

DC 1000

DC 1200

DC 2000

DC 2100

DC 2900

© Construction Tools GmbH | 3390 5192 01 | 2016-12-01

Original instructions

200, 400, 600, 1000, 1200, 2000, 2100, 2900

DEQ161115

DEQ140244

DEQ140245

DEQ140246

DEQ161163

DEQ132047

DEQ140172

DEQ161168

Advertisement

Table of Contents

Summary of Contents for Atlas Copco DC 200

- Page 1 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Transverse Drum Cutters Valid from serial number DC 200 DEQ161115 DC 400 DEQ140244 DC 600 DEQ140245 DC 1000 DEQ140246 DC 1200 DEQ161163 DC 2000 DEQ132047 DC 2100 DEQ140172...

-

Page 3: Table Of Contents

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Contents Contents Introduction ..............................7 About these Safety and Operating Instructions ..................7 Safety instructions ............................8 Signal words ............................. 8 Qualification .............................. 9 Intended use .............................. 9 Use other than intended ........................... 9 Protective equipment .......................... - Page 4 Contents DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Preparations before starting ........................32 Commissioning ............................33 Checks during commissioning ......................33 Switching the transverse drum cutter on and off ................33 Functional test ............................33 Correct operation ............................ 34 Prohibited operation ..........................

- Page 5 DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Contents Sending in the hydraulic attachment for repairs ................. 61 Storage ................................62 Transverse drum cutter .......................... 62 Short storage ............................62 Long storage ............................62 Cutter drums ............................62 Round attack picks ..........................62 Disposal ................................

-

Page 7: Introduction

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Introduction About these Safety and Operating Instructions Thank you for choosing an Atlas Copco product! We have been working according to a customer- The aim of these Instructions is to familiarise you oriented approach since 1873. -

Page 8: Safety Instructions

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety instructions Signal words The signal words Danger, Warning, Caution, and This is the safety alert symbol. It is used to alert you to Notice are used as follows in these Safety and potential personal injury hazards. -

Page 9: Qualification

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Qualification Intended use Transporting the hydraulic attachment is only Only attach the transverse drum cutter to a permitted if carried out by people who: hydraulic carrier of a suitable load-bearing capacity. -

Page 10: Protective Equipment

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Protective equipment Transport, precautions Personal protective equipment must comply with WARNING Risk of death due to suspended the applicable health and safety regulations. loads Always wear the following personal protective When lifting loads these can swing out and fall. -

Page 11: Hydraulic Installation, Precautions

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Hydraulic installation, Media/consumables, precautions precautions WARNING Hydraulic pressure too high WARNING Hot hydraulic oil under high pressure If the hydraulic pressure is too high, the parts of... -

Page 12: Explosion And Fire, Precautions

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Explosion and fire, Electrical shock, precautions precautions DANGER Electrical shock Any contact of the hydraulic attachment with DANGER Explosion and fire electric circuits or other sources of electricity will Explosions cause serious injury or death. -

Page 13: Emissions, Precautions

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Emissions, precautions Handling machines, precautions WARNING Noise hazard Operating the hydraulic attachment creates a loud WARNING Injuries due to incorrect noise. Long term high sound pressure level can operation affect your hearing. -

Page 14: Repair, Precautions

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Repair, precautions Changes to the hydraulic attachment, precautions Maintenance work must be conducted exclusively by authorised and trained maintenance personnel. WARNING Changes to the hydraulic Maintenance works not allowed by Atlas... -

Page 15: Environmental Pollution, Precautions

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Environmental pollution, precautions NOTICE Environmental pollution due to hydraulic Hydraulic oil is permanently environmentally harmful. Escaped hydraulic oil will lead to groundwater and soil contamination. Organisms may die. -

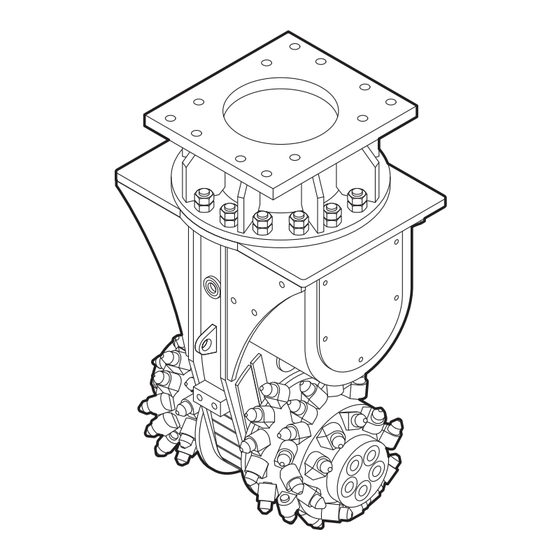

Page 16: Overview

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Overview Modules Cutter drums Equipment description The illustration gives an overview of the main parts and components of the hydraulic attachment. Actual details may differ. The transverse drum cutter is equipped with one left and one right cutter drum. - Page 17 DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Transport lug Gear housing The gear housing contains a spur gear driven by a hydraulic motor. The gear's drive shafts turn the cutter drums. The hydraulic motor transfers the The transport lug (E) serves as an anchor point for drive moment through the gear to the cutter drums.

-

Page 18: Signs / Labels

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Pick boxes Signs / labels WARNING Missing warnings The name plate and the labels on the hydraulic attachment contain important information about the hydraulic attachment and for personal safety. A... -

Page 19: Labels

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Labels Working area and hazardous area A. Working area for operating personnel A. Danger zone B. Hazardous area when working with the Danger zone transverse drum cutter... -

Page 20: Removing The Packaging

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Removing the packaging ◆ Remove all the packaging material. ◆ Dispose of it in accordance with the applicable provisions. ◆ Check that the delivery is complete. ◆... -

Page 21: Standard Round Attack Picks

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Standard round attack picks Ø Ø Ø Type Ø S Ø H Ø T Locking system Shaft diameter Shaft length Head diameter Head length Tip diameter DC 200 11.4 mm (0.45 in.) 26.0 mm (1.02 in.) 24.0 mm (0.94 in.) 28.0 mm (1.10 in.) 11.5 mm (0.45 in.) Knock on retainer... -

Page 22: Transport

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Transport WARNING Hoist tipping over / hydraulic attachment falling The hydraulic attachment is heavy. The hoist/lifting equipment and/or hydraulic attachment tipping over or falling may cause serious injury and material damage. -

Page 23: Transport Using A Forklift Truck

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Transport using a forklift Transport using a truck truck Always transport the transverse drum cutter whilst secured to the assembly stand. Always transport the transverse drum cutter whilst secured to the assembly stand. -

Page 24: Installation

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Installation Non-mineral hydraulic oil NOTICE Mixed hydraulic oil WARNING Hot hydraulic oil squirting out Never mix mineral and non-mineral hydraulic oils! Even small traces of mineral oil mixed in with non- The hydraulic system is under high pressure. -

Page 25: Preconditions For Adapter Plate

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions The pressure in the leakage oil line is of 3 bar Have the web plates welded to the adapter • ► maximum during operation. plate base plate by a qualified welding specialist. -

Page 26: Attaching The Hydraulic Attachment To The Carrier

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Attaching the hydraulic attachment to the carrier Mechanical mounting aspects You need an assistant to attach the hydraulic attachment to the carrier. ◆ Agree on hand signals with your assistant, to... -

Page 27: First Installation

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions First installation WARNING Risk of death due to defective first installation Faults during the first installation or commissioning can lead to life-threatening situations and may cause considerable damage to property. -

Page 28: Making The Hydraulic Connections

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Always check the leakage oil line pressure ► NOTICE Damage to hydraulic parts when mounting the transverse drum cutter to a carrier. Polluted hydraulic lines and connections may enable sand, fragments of material and dirt to ◆... -

Page 29: Mechanical Mounting Aspects

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Contact the Atlas Copco Customer Center/Dealer WARNING Injury by impacts in your area before removing the check valve. A sudden movement of the carrier may cause your ◆... -

Page 30: Removing The Hydraulic Attachment From The Carrier

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 ◆ Extend the bucket cylinder (E) until the bore in Removing the hydraulic the linkage (F) links up with the bore in the attachment from the carrier adapter plate (B). -

Page 31: Operation

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Operation If you have to carry out activities where you ► have to touch the parts, wait for them to cool down first. DANGER Risk of death due to a failure to... -

Page 32: Preparations Before Starting

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Preparations before starting rock with a high SiO 2 content, when using • spray water and when cutting under water hard rock such as granite, basalt •... -

Page 33: Commissioning

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Commissioning Never switch on or off the transverse drum ► cutter when working at full capacity. ◆ Switch the hydraulic attachment on and off, as Note: Observe the carrier's safety and operating described in the carrier‘s operating instructions. -

Page 34: Correct Operation

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Correct operation web. The vibrations during cutting work can lead to serious damage to the housing. Make sure that the material between the ► ◆ Bring the transverse drum cutter into a raised cutter drums is removed and does not form position. -

Page 35: Prohibited Operation

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Prohibited operation Moving the carrier ◆ Never relocate the carrier sideways by placing the hydraulic attachment on the ground to lift ◆ Do not activate the transverse drum cutter with the carrier. -

Page 36: Impacting/Chopping

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Impacting/chopping Turning the transverse drum ◆ Do not use the hydraulic attachment to impact cutter or chop to destroy material. This would seriously damage the hydraulic When carrying out certain works (e.g. tunnel attachment. - Page 37 DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions the wear of the individual components of the transverse drum cutter increase. ◆ Turn the transverse drum cutter to the desired position. WARNING Hands and fingers being cut...

-

Page 38: Maintenance

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Maintenance WARNING Risk of injury due to inadequate safeguards whilst working on the machine The maintenance work described in the following Inadequate safeguarding of the carrier during... -

Page 39: Maintenance Works Not Allowed By Atlas Copco

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Maintenance works not WARNING Risk of injury due to incorrectly allowed by Atlas Copco executed maintenance work Incorrect maintenance can result in severe injuries and may cause considerable damage to property. -

Page 40: Maintenance Schedule

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Maintenance schedule daily, before and after operation Cutter drums: Check if all round attack picks exist. Check the round attack picks for wear and play in the pick box. -

Page 41: Depressurising The Hydraulic System

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Depressurising the hydraulic Cleaning system Clean the transverse drum cutter daily after use. Even when you have switched off the carrier, a NOTICE Environmental damage due to hydraulic considerable residual pressure can still be present in the hydraulic system. -

Page 42: Checking The Hydraulic Attachment And Adapter Plate For Cracks

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 ◆ Check all bolted connections regularly for tight WARNING Risk of injury due to oil pressure fit (see Chapter Bolted connections / tightening in the gear torques). -

Page 43: Fill Up Gear Oil

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions ◆ Clean the transverse drum cutter (see chapter Cleaning). ◆ Carefully loosen the oil filler screw (A) using an Allen key and allow any pressure in the gear to drop. -

Page 44: Check The Round Attack Picks

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Check the round attack picks Replace round attack picks Check the round attack picks daily, before and ◆ You must replace the round attack picks: after operation. -

Page 45: Replace Round Attack Pick With Knock On Retainer

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Replace round attack pick with knock on retainer The following special equipment is required to replace the round attack picks: • Mounting tool for knock on retainer Dismantling tool for knock on retainer •... -

Page 46: Replace Round Attack Pick With Retaining Sleeve

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Replace round attack pick with retaining 3. Give the impact surface (F) of the puller (E) a forceful blow with a hammer. sleeve The round attack pick will loosen from the pick The following special equipment is required to box. -

Page 47: Replace Round Attack Picks With Quick Snap Retainer

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Replace round attack picks with quick snap retainer The following special equipment is required to replace the round attack picks: • Puller tool for pick with quick snap retainer The special equipment is included in the scope of delivery. -

Page 48: Replace Round Attack Picks With Retaining Ring

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Replace round attack picks with retaining ring The following special equipment is required to replace the round attack picks: • Long nose pliers, curved 1. Remove both retaining rings (L) from the pick shaft one after another using long nose pliers (M). -

Page 49: Replace Cutter Drums

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Replace cutter drums The following maintenance activities are carried out in the workshop. ◆ You must replace the cutter drums: if the bearing surfaces of the pick boxes are •... -

Page 50: Assemble Cutter Drums

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 4. Insert the clamping sleeves with the opening (slit) (H) opposite to the turning direction (see arrow) of the cutter drum. Assemble cutter drums Note: In order to ensure safe and optimum cutting behaviour always mount the cutter drums in a symmetrical situation in relation to the pick boxes. - Page 51 DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions 9. Tighten the fixing screws with the requisite tightening torque in a diagonal sequence. Type Tightening torque for the fixing screws DC 200 30 Nm (22 ft lbs)

-

Page 52: Assemble And Disassemble Rotatable Upper Part

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Assemble and disassemble rotatable upper part The following maintenance activities are carried out in the workshop. WARNING Risk of accidents due to use of old parts Using old parts (old hydraulic hoses, screws or clips) can lead to accidents, which may in turn result in severe injuries. -

Page 53: Checking Hydraulic Lines

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions WARNING Hands and fingers being cut Type Size Tightening torque off or hurt DC 200 M 12 84 Nm (62 ft lbs) Bores and surfaces can act like a pair of... -

Page 54: Replace Hydraulic Hoses

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 ◆ ◆ Secure the carrier such that it cannot move Clean the immediate environment around the unexpectedly. hydraulic hose connections requiring replacement. ◆ Change the oil filter cartridge after the first 50 ◆... -

Page 55: Bolt Connections/ Tightening Torques

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Bolt connections/ Tightening torques The bolt connections of transverse drum cutters are subjected to very high loads. ◆ Tighten any loose connections without exceeding the recommended tightening torques. - Page 56 Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 The bolt connections of transverse drum cutters are subjected to very high loads. ◆ Tighten any loose connections without exceeding the recommended tightening torques. DC 1200 DC 2000...

-

Page 57: Troubleshooting

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Troubleshooting Ensure that all covers and safety devices • are installed and that these function correctly. The following chapter describes the possible causes of faults and the procedures to repair them. -

Page 58: Cutter Drums Do Not Turn / Are Blocked

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Cutter drums do not turn / are blocked Cause Remedy Cutting material trapped between cutter Shut down machine, depressurise and safeguard against Carrier driver drum and gear a restart. -

Page 59: Unusual Oscillation Of The Cutter Drums

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Unusual oscillation of the cutter drums Cause Remedy Round attack picks worn, damaged or Replace round attack picks. Carrier driver uneven head lengths Round attack picks do not turn... -

Page 60: Overpressure Cover For The Hydraulic Motor Deformed, Oil Leak On Sealing Surface, Oil Leak At The Pressure Limiting Valve

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Overpressure cover for the hydraulic motor deformed, oil leak on sealing surface, oil leak at the pressure limiting valve Cause Remedy Pressure in the leakage oil line too high. -

Page 61: Repair

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Repair ◆ For technical support contact the Atlas Copco Customer Center/Dealer in your area. Sending in the hydraulic attachment for repairs NOTICE Mixed hydraulic oil Never mix mineral and non-mineral hydraulic oils! -

Page 62: Storage

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Storage Fill hydraulic motor with hydraulic oil. Rinse hydraulic motor with preservation agent. ◆ Always store the transverse drum cutter: Fill hydraulic motor with preservation agent. secured on the assembly stand •... -

Page 63: Disposal

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Disposal Hydraulic hoses ◆ Drain the hydraulic oil from the hydraulic hoses WARNING Risk of injury due to improper and collect it. disassembly ◆ Dispose of the hydraulic hoses in accordance... -

Page 64: Technical Specifications

3363 1196 33 3363 1155 29 3363 1155 30 3363 1155 31 1 Weight applies to standard carriers only. Any variations must be agreed with Atlas Copco and / or the carrier manufacturer. 2 transverse drum cutter including adapter plate of medium size Please note that the working weight can be considerably higher, depending on the adapter plate. - Page 65 3363 1197 50 3363 1155 33 3363 1155 34 3363 1155 35 1 Weight applies to standard carriers only. Any variations must be agreed with Atlas Copco and / or the carrier manufacturer. 2 transverse drum cutter including adapter plate of medium size Please note that the working weight can be considerably higher, depending on the adapter plate.

-

Page 66: Appendix

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Appendix Hydraulic installation version 1 for hydraulic hammer min. 5 bar 72.5 PSI - Parts not included in the scope of delivery + Parts included in the scope of delivery HP = high pressure, LP = low pressure A. -

Page 67: Hydraulic Installation Version 2 For Hydraulic Shear Systems

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Hydraulic installation version 2 for hydraulic shear systems - Parts not included in the scope of delivery + Parts included in the scope of delivery A. Pressure line (High pressure HP) 350 bar (5075 PSI) max., Q = X l/min (Y gal/min) B. -

Page 68: Hydraulic Settings Dc 200

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Hydraulic settings DC 200 The combination of oil flow rate and operating pressure must not exceed the nominal power of the Drum Cutter. Nominal power [kW] x 600... -

Page 69: Hydraulic Settings Dc 400

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Hydraulic settings DC 400 The combination of oil flow rate and operating pressure must not exceed the nominal power of the Drum Cutter. Nominal power [kW] x 600... -

Page 70: Hydraulic Settings Dc 600

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Hydraulic settings DC 600 The combination of oil flow rate and operating pressure must not exceed the nominal power of the Drum Cutter. Nominal power [kW] x 600... -

Page 71: Hydraulic Settings Dc 1000

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Hydraulic settings DC 1000 The combination of oil flow rate and operating pressure must not exceed the nominal power of the Drum Cutter. Nominal power [kW] x 600... -

Page 72: Hydraulic Settings Dc 1200

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Hydraulic settings DC 1200 The combination of oil flow rate and operating pressure must not exceed the nominal power of the Drum Cutter. Nominal power [kW] x 600... -

Page 73: Hydraulic Settings Dc 2000

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Hydraulic settings DC 2000 The combination of oil flow rate and operating pressure must not exceed the nominal power of the Drum Cutter. Nominal power [kW] x 600... -

Page 74: Hydraulic Settings Dc 2100

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Hydraulic settings DC 2100 The combination of oil flow rate and operating pressure must not exceed the nominal power of the Drum Cutter. Nominal power [kW] x 600... -

Page 75: Hydraulic Settings Dc 2900

DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions Hydraulic settings DC 2900 The combination of oil flow rate and operating pressure must not exceed the nominal power of the Drum Cutter. Nominal power [kW] x 600... -

Page 76: Ec Declaration Of Conformity (Ec Directive 2006/42/Ec)

Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 EC Declaration of Conformity (EC Directive 2006/42/EC) We, Construction Tools GmbH, hereby declare that the machines listed below conform to the provisions of EC Directive 2006/42/EC (Machinery Directive), and the harmonised standards mentioned below. - Page 77 DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 Safety and operating instructions We, Construction Tools GmbH, hereby declare that the machines listed below conform to the provisions of EC Directive 2006/42/EC (Machinery Directive), and the harmonised standards mentioned below.

- Page 78 Safety and operating instructions DC 200, 400, 600, 1000, 1200, 2000, 2100, 2900 We, Construction Tools GmbH, hereby declare that the machines listed below conform to the provisions of EC Directive 2006/42/EC (Machinery Directive), and the harmonised standards mentioned below.

- Page 80 Any unauthorized use or copying of the contents or any part thereof is prohibited. This applies in particular to trademarks, model denominations, part numbers, and drawings. www.atlascopco.com...

Need help?

Do you have a question about the DC 200 and is the answer not in the manual?

Questions and answers