Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Loveshaw Little David CF50T

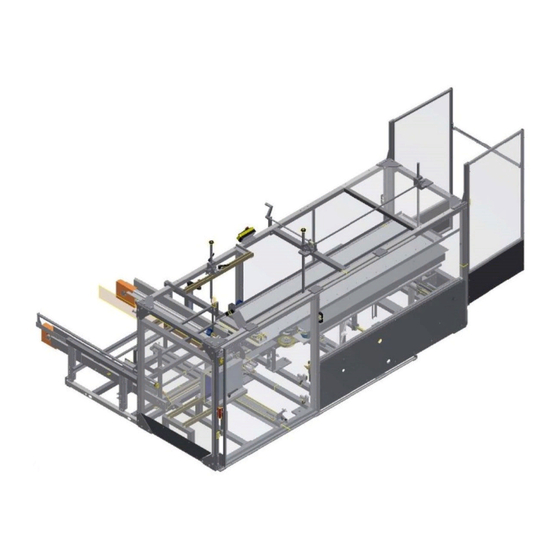

- Page 1 Little David™ Case Erector CF50T / XL Case Erector Version: D Operator’ s Manual...

- Page 2 Contact Information Copyright Loveshaw Loveshaw 2206 Easton Turnpike, PO. Box 83 South Canaan, PA 18459 Tel: 1-800-962-2633 • 570-937-4921 Fax: 570-937-4016 www.loveshaw.com Loveshaw Europe Unit 9 Brunel Gate West Portway Industrial Estate Andover, Hampshire SP10 3SL ENGLAND Tel: 264-357511...

- Page 3 TABLE OF CONTENTS SECTION #1 GENERAL SAFETY PRECAUTIONS SECTION #2 MACHINE SPECIFICATIONS SECTION #3 INSTALLATION PROCEDURES SECTION #4 SEQUENCE OF OPERATION SECTION #5 SET-UP AND SIZE CHANGE-OVER SECTION #6 START UP PROCEDURE SECTION #7 SHUT DOWN PROCEDURE SECTION #8 MAINTENANCE SCHEDULE SECTION #9 HOW TO ORDER PARTS SECTION #10...

- Page 4 GENERAL SAFETY PRECAUTIONS BEFORE INSTALLING, OPERATING, OR SERVICING THIS EQUIPMENT, READ THE FOLLOWING PRECAUTIONS CAREFULLY: THIS MACHINE IS EQUIPPED WITH MOVING PARTS. DO NOT PLACE HANDS IN THE MACHINE WHEN PARTS ARE MOVING. ALWAYS USE A ROLLER-TYPE EXIT CONVEYOR, AND ALWAYS REMOVE BOXES AFTER THEY CLEAR THE EXIT END OF THE MACHINE.

- Page 5 MACHINE SPECIFICATIONS MACHINE MODEL: CF50T/XL STANDARD DISCHARGE HEIGHT: 23" AMERICAN ELECTRICAL REQUIREMENTS: PRIMARY VOLTAGE: 110 VOLTS, 1 PHASE, 60 HERTZ CONTROL VOLTAGE: 110 VOLTS, 1 PHASE, 60 HERTZ EUROPEAN ELECTRICAL REQUIREMENTS: PRIMARY VOLTAGE: 220 VOLTS, 1 PHASE, 50 HERTZ CONTROL VOLTAGE: 220 VOLTS, 1 PHASE, 50 HERTZ CASE CAPACITY: LENGTH:...

- Page 6 INSTALLATION PROCEDURE 1. EXERCISE CARE WHEN HANDLING THIS MACHINE. A SUDDEN JOLT OR JAR MAY CAUSE SERIOUS DAMAGE. 2. DO NOT REMOVE THE SHIPPING SKID UNTIL MACHINE HAS BEEN MOVED TO A POINT OF INSTALLATION. THE SKID IS DESIGNED FOR EASY AND SAFE HANDLING OF YOUR MACHINE.

- Page 7 SEQUENCE OF OPERATION INITIAL CONDITIONS: A. MAIN AIR VALVE TURNED ON. B. POWER CORD CONNECTED. C. EMERGENCY STOP BUTTON IS PULLED OUT. D. SELECTOR SWITCH IS SET TO “AUTO”. E. HOPPER HAS BLANKS PROPERLY LOADED. GENERAL SEQUENCE: PRESS THE "START" PUSH-BUTTON (PB1). MOTOR CONTACTOR (K1) IS ENERGIZED AND THE MOTOR STARTS.

- Page 8 AT THE EXTENDED POSITION OF THE CASE PUSHER, PROXIMITY SWITCH 4 IS ACTIVATED, ENERGIZING THE INTERNAL RELAY 1003. THIS RELAY THEN DE- ENERGIZES THE CASE PUSHER VALVE (SOL4, OUTPUT 5), SENDING THE CASE PUSHER TO THE HOME POSITION. AS OUTPUT 5 IS DE-ENERGIZED, TIMER 6 STARTS TIMING. WHEN TIMER 6 TIMES OUT, THE MINOR FLAP FOLDER (SOL 6, OUTPUT 3) IS DE-ACTIVATED.

- Page 9 CONTROL DESCRIPTION DEVICE DESCRIPTION PART NUMBER GS1, GS2, GS3 SAFETY GATE SWITCHES A195SG-TM1 PROXIMITY SWITCH ACTIVATES WHEN PROX1 302575 TROLLEY IS HOME PROXIMITY SWITCH ACTIVATES WHEN PROX2 N597 TROLLEY IS PICKING BOX PROXIMITY SWITCH ACTIVATES WHEN CASE PROX3 N597 PUSHER IS RETRACTED PROXIMITY SWITCH ACTIVATES WHEN CASE PROX4 N597...

- Page 10 SET UP and SIZE CHANGE OVER NOTES: TURN POWER OFF BEFORE MAKING ANY ADJUSTMENTS TO THIS MACHINE. REFER TO ASSEMBLY DRAWINGS FOR ITEM I. D. HOPPER WIDTH ADJUSTMENT: SET POINT: WIDTH OF BLANK + 1/8” TO ADJUST HOPPER WIDTH, FIRST LOOSEN THE LOCKING CLAMP (ITEM # 19), THEN, TURN ADJUSTING RATCHET (ITEM # 20) UNTIL THE BLANK FITS LOOSELY (1/8”...

- Page 11 TOP FINGER: SET THE HORIZONTAL POSITION OF THE FINGER SO THAT IT LIES IN THE CENTER OF THE SLOT. LOOSEN THE RATCHET HANDLE (ITEM # 23) AND SLIDE THE ASSEMBLY BY HAND THEN RE-TIGHTEN THE RATCHET HANDLE. SET THE VERTICAL POSITION OF THE FINGER SO THAT APPROXIMATELY 1/4”...

- Page 12 BLANK. THE CUPS SHOULD BE OFFSET FROM THE EDGES BY ABOUT 1/4”. WHENEVER POSSIBLE USE ALL FOUR CUPS TO RUN THE BOXES. TWO CUPS MAY BE USED IF THE MAJOR PANEL IS TOO SMALL. FOR TALL BOXES (OVER 10”) THE VACUUM POST EXTENSION MAY BE USED.

- Page 13 LIGHT PRESSURE ON IT, NOT BINDING. ALIGN THE SCALE TO THE TOP OF THE BRACKET AT A MEASUREMENT EQUAL TO THE HEIGHT OF THE BOX PLUS 1/2 THE WIDTH (IN INCHES). OTHER SET-UP CONSIDERATIONS: WHEN HANDLING SMALL CASES, ONLY TWO VACUUM CUPS WILL BE REQUIRED. REMOVE ONE OF THE VACUUM CUP BARS ALONG WITH THE VACUUM CUPS.

- Page 14 START UP PROCEDURE THIS MACHINE IS TO BE USED, AS DESCRIBED, BY PROPERLY TRAINED PERSONNEL. WARNING: NEVER..START THE MACHINE UNTIL ALL PERSONNEL ARE CLEAR. NEVER..LUBRICATE OR REPAIR THE MACHINE WHILE IT IS RUNNING. NEVER..PUT YOUR HANDS IN THE MACHINE WHILE IT IS RUNNING. NEVER..ALLOW ANY PART OF YOUR BODY TO COME IN CONTACT WITH MOVING PARTS OF THE MACHINE WHILE IT IS RUNNING.

- Page 15 SHUT DOWN PROCEDURE EMERGENCY SHUT DOWN. TO SHUT THE MACHINE DOWN IN AN EMERGENCY, PRESS THE E-STOP BUTTON OR OPEN A SAFETY GATE. NOTE: YOU WILL HAVE TO CLEAR ANY CASES THAT WERE BEING FORMED BY THE MACHINE BEFORE YOU CAN RESTART THE MACHINE. NORMAL SHUT DOWN.

- Page 16 MAINTENANCE SCHEDULE TURN MACHINE OFF BEFORE PERFORMING ANY MAINTENANCE. ELECTRICAL CHECK MONTHLY: CHECK OVER-CURRENT RELAY SETTINGS. TIME (ΔT) MUST BE SET TO 0. CURRENT (ΔI) SET JUST ABOVE THRESHOLD OF RED LIGHT COMING ON. INSPECT FOR LOOSE WIRES THROUGHOUT THE MACHINE AND INSIDE THE PANEL BOX.

- Page 17 MECHANICAL CHECK WEEKLY: INSPECT THE BOTTOM FLAP FOLDER ASSEMBLIES. CHECK FOR BEARING WEAR. LUBRICATE PIVOT BUSHINGS WITH A GREASE GUN AND A MULTI-PURPOSE LITHUIM GREASE. CHECK THE CLEVIS FOR WEAR AND LUBRICATE WITH A TEFLON BASED SPRAY SUCH AS DUPONT TEFLON LUBRICANT WITH MOLY. CHECK AIR CYLINDER MOUNTINGS FOR TIGHTNESS.

- Page 18 PLEASE HAVE YOUR MACHINE MODEL AND SERIAL NUMBER WHEN CALLING FOR PARTS OR SERVICE. THEY CAN BE FOUND ON THE LABEL LOCATED ON THE OUTSIDE OF THE ELECTRICAL PANEL BOX. WHEN CALLING LOVESHAW FOR PARTS: GIVE THE MACHINE MODEL AND SERIAL NUMBER. GIVE THE ASSEMBLY PART NUMBER AND DESCRIPTION.

- Page 19 302575 PROXIMITY SWITCH A195SG-TM1 SWITCH, SAFETY GATE A195SG-TM1 KEY SWITCH KEY, SAFETY GATE N401-242/R SEAL KIT, 40 mm CYLINDER N401-241/R SEAL KIT, 50 mm CYLINDER (*) THESE COMPONENTS ARE FOR 2” MACHINE, (**) THESE COMPONENTS ARE FOR 3” MACHINE. www.loveshaw.com...

- Page 20 TROUBLE SHOOTING IF THE MACHINE WILL NOT START CYCLING OR STOPS IN MID-CYCLE. IT IS LIKELY A SENSOR OR SWITCH IS NOT IN THE CORRECT STATE. REFER TO THE “SEQUENCE OF OPERATION” SECTION AND CHECK EACH COMPONENT. CHECK THE SAFETY GATES TO ENSURE THAT THEY ARE CLOSED. CHECK THAT PROXIMITY SWITCHES AND PHOTOCELLS ARE BEING TRIPPED.

- Page 21 PROBLEM SOLUTION 3. VACUUM TROLLEY WILL NOT MOVE A. SOLENOID VALVE MAY BE DEFECTIVE. PUSH BACK FROM BLANK PICK UP POSITION MANUAL OVERRIDE TO SEE IF VALVE FUNCTIONS. (CYLINDER IN EXTENDED POSITION). IF SO, CHECK SOLENOID FOR CONTINUITY. REPLACE IF DEFECTIVE. B.

- Page 22 PROBLEM SOLUTION 5. MINOR FLAP FOLDERS WILL NOT A. SOLENOID VALVE MAY BE DEFECTIVE. PUSH EXTEND. MANUAL OVERRIDE TO SEE IF VALVE FUNCTIONS. IF SO, CHECK SOLENOID FOR CONTINUITY. REPLACE IF DEFECTIVE. B. SPOOL IN VALVE MAY BE STUCK. DISASSEMBLE VALVE, CLEAN THOROUGHLY, REPLACE DEFECTIVE PARTS.

- Page 23 PROBLEM SOLUTION 8. CASE IS NOT SQUARE AT DISCHARGE. A. PUSHER LUGS OUT OF ALIGNMENT. TO CORRECT: STOP THE MACHINE SO THAT THE LUGS ARE IN THE AREA OVER THE TAPE CARTRIDGE. REMOVE THE CARTRIDGE. DISCONNECT THE ELECTRICAL SUPPLY. REMOVE OPERATOR SIDE CHAIN DRIVE COVER. LOCATE THE DRIVE SPROCKET AT THE DISCHARGE END OF THE SYSTEM.

- Page 24 THE WARRANTY PERIOD SHALL COMMENCE AS OF THE DATE OF DELIVERY TO THE PURCHASER. THE OBLIGATION OF LOVESHAW UNDER THIS WARRANTY IS STRICTLY LIMITED TO THE COST OF REPAIRING OR REPLACING, AS LOVESHAW MAY ELECT, ANY PART OR PARTS THAT PROVE IN LOVESHAW’S JUDGMENT TO HAVE BEEN DEFECTIVE IN MATERIAL OR WORKMANSHIP AT THE TIME THE GOODS WERE SHIPPED FROM LOVESHAW’S PLANT.

- Page 25 ILLUSTRATED MACHINE ASSEMBLIES FRAME ASSEMBLY MAIN DRIVE ASSEMBLY DRIVE CHAIN ASSEMBLY HOPPER FRAME ASSEMBLY HOPPER DRIVE ASSEMBLY BOTTOM FINGER ASSEMBLY HOPPER GATE ASSEMBLY TOP FINGER ASSEMBLY VACUUM TROLLEY ASSEMBLY VACUUM BAR ASSEMBLY VACUUM CUP ASSEMBLY FRONT FLAP FOLDER ASSEMBLY REAR FLAP FOLDER ASSEMBLY TOP SLED ASSEMBLY PLOW BAR ASSEMBLY SAFETY GUARD ASSEMBLY...

- Page 26 DWG NO .FRACF50XL SCALE METRIC = .3mm FINISH LOVESHAW-ITW AND IS TO BE TREATED BY YOU AS CONFIDENTIAL PRPRIETARY INFORMATION. THIS DRAWING OR SUBJECT MATTER THEROF SHALL NOT BE .XXX = .1mm MATERIAL CHECKED REPRODUCED OTHER THAN FOR YOUR OWN USE OR TO BE DISCLOSED TO OTHER...

- Page 27 .MDACF50B SCALE NONE METRIC = .3mm FINISH LOVESHAW-ITW AND IS TO BE TREATED BY YOU AS CONFIDENTIAL PRPRIETARY INFORMATION. THIS DRAWING OR SUBJECT MATTER THEROF SHALL NOT BE .XXX = .1mm MATERIAL CHECKED REPRODUCED OTHER THAN FOR YOUR OWN USE OR TO BE DISCLOSED TO OTHER...

- Page 28 THIS DRAWING AND SUBJECT MATTER THEREON IS THE EXCLUSIVE PROPERTY OF DWG NO SCALE = .3mm METRIC FINISH LOVESHAW-ITW AND IS TO BE TREATED BY YOU AS CONFIDENTIAL PRPRIETARY .XXX = .1mm INFORMATION. THIS DRAWING OR SUBJECT MATTER THEROF SHALL NOT BE CHECKED MATERIAL...

- Page 29 DWG NO .HFACF50-XL SCALE METRIC = .3mm FINISH LOVESHAW-ITW AND IS TO BE TREATED BY YOU AS CONFIDENTIAL PRPRIETARY INFORMATION. THIS DRAWING OR SUBJECT MATTER THEROF SHALL NOT BE .XXX = .1mm MATERIAL CHECKED REPRODUCED OTHER THAN FOR YOUR OWN USE OR TO BE DISCLOSED TO OTHER...

- Page 30 THIS DRAWING AND SUBJECT MATTER THEREON IS THE EXCLUSIVE PROPERTY OF DWG NO SCALE METRIC = .3mm LOVESHAW-ITW AND IS TO BE TREATED BY YOU AS CONFIDENTIAL PRPRIETARY FINISH INFORMATION. THIS DRAWING OR SUBJECT MATTER THEROF SHALL NOT BE .XXX = .1mm...

- Page 31 .BPACF50-DC-XL SCALE 1/2:1 METRIC = .3mm FINISH LOVESHAW-ITW AND IS TO BE TREATED BY YOU AS CONFIDENTIAL PRPRIETARY INFORMATION. THIS DRAWING OR SUBJECT MATTER THEROF SHALL NOT BE .XXX = .1mm MATERIAL CHECKED REPRODUCED OTHER THAN FOR YOUR OWN USE OR TO BE DISCLOSED TO OTHER...

- Page 32 DWG NO .UFACF50-XL SCALE METRIC = .3mm FINISH LOVESHAW-ITW AND IS TO BE TREATED BY YOU AS CONFIDENTIAL PRPRIETARY INFORMATION. THIS DRAWING OR SUBJECT MATTER THEROF SHALL NOT BE .XXX = .1mm MATERIAL CHECKED REPRODUCED OTHER THAN FOR YOUR OWN USE OR TO BE DISCLOSED TO OTHER...

- Page 33 DWG NO .VTACF50XL SCALE METRIC = .3mm FINISH LOVESHAW-ITW AND IS TO BE TREATED BY YOU AS CONFIDENTIAL PRPRIETARY INFORMATION. THIS DRAWING OR SUBJECT MATTER THEROF SHALL NOT BE .XXX = .1mm MATERIAL CHECKED REPRODUCED OTHER THAN FOR YOUR OWN USE OR TO BE DISCLOSED TO OTHER...

- Page 34 DWG NO .VBACF50-PIN SCALE METRIC = .3mm FINISH LOVESHAW-ITW AND IS TO BE TREATED BY YOU AS CONFIDENTIAL PRPRIETARY INFORMATION. THIS DRAWING OR SUBJECT MATTER THEROF SHALL NOT BE .XXX = .1mm MATERIAL CHECKED REPRODUCED OTHER THAN FOR YOUR OWN USE OR TO BE DISCLOSED TO OTHER...

- Page 35 THIS DRAWING AND SUBJECT MATTER THEREON IS THE EXCLUSIVE PROPERTY OF DWG NO SCALE = .3mm METRIC FINISH LOVESHAW-ITW AND IS TO BE TREATED BY YOU AS CONFIDENTIAL PRPRIETARY .XXX = .1mm INFORMATION. THIS DRAWING OR SUBJECT MATTER THEROF SHALL NOT BE CHECKED MATERIAL...

- Page 36 DWG NO .FFFCF50-PIN SCALE METRIC = .3mm FINISH LOVESHAW-ITW AND IS TO BE TREATED BY YOU AS CONFIDENTIAL PRPRIETARY INFORMATION. THIS DRAWING OR SUBJECT MATTER THEROF SHALL NOT BE .XXX = .1mm MATERIAL CHECKED REPRODUCED OTHER THAN FOR YOUR OWN USE OR TO BE DISCLOSED TO OTHER...

- Page 37 DWG NO .RFFCF50-PIN SCALE METRIC = .3mm FINISH LOVESHAW-ITW AND IS TO BE TREATED BY YOU AS CONFIDENTIAL PRPRIETARY INFORMATION. THIS DRAWING OR SUBJECT MATTER THEROF SHALL NOT BE .XXX = .1mm MATERIAL CHECKED REPRODUCED OTHER THAN FOR YOUR OWN USE OR TO BE DISCLOSED TO OTHER...

- Page 38 DWG NO .TSACF50XL SCALE METRIC = .3mm FINISH LOVESHAW-ITW AND IS TO BE TREATED BY YOU AS CONFIDENTIAL PRPRIETARY INFORMATION. THIS DRAWING OR SUBJECT MATTER THEROF SHALL NOT BE .XXX = .1mm MATERIAL CHECKED REPRODUCED OTHER THAN FOR YOUR OWN USE OR TO BE DISCLOSED TO OTHER...

- Page 39 THIS DRAWING AND SUBJECT MATTER THEREON IS THE EXCLUSIVE PROPERTY OF DWG NO .PBACF50 SCALE = .3mm METRIC LOVESHAW-ITW AND IS TO BE TREATED BY YOU AS CONFIDENTIAL PRPRIETARY FINISH .XXX = .1mm INFORMATION. THIS DRAWING OR SUBJECT MATTER THEROF SHALL NOT BE MATERIAL...

- Page 40 SCALE THIS DRAWING AND SUBJECT MATTER THEREON IS THE EXCLUSIVE PROPERTY OF = .3mm METRIC LOVESHAW AND IS TO BE TREATED BY YOU AS CONFIDENTIAL PRPRIETARY FINISH .XXX = .1mm INFORMATION. THIS DRAWING OR SUBJECT MATTER THEROF SHALL NOT BE...

- Page 41 SCALE THIS DRAWING AND SUBJECT MATTER THEREON IS THE EXCLUSIVE PROPERTY OF = .3mm METRIC LOVESHAW AND IS TO BE TREATED BY YOU AS CONFIDENTIAL PRPRIETARY FINISH .XXX = .1mm INFORMATION. THIS DRAWING OR SUBJECT MATTER THEROF SHALL NOT BE...

- Page 42 THIS DRAWING AND SUBJECT MATTER THEREON IS THE EXCLUSIVE PROPERTY OF DWG NO SCALE METRIC = .3mm FINISH LOVESHAW-ITW AND IS TO BE TREATED BY YOU AS CONFIDENTIAL PRPRIETARY INFORMATION. THIS DRAWING OR SUBJECT MATTER THEROF SHALL NOT BE .XXX = .1mm MATERIAL CHECKED...

- Page 47 LOVESHAW CASE ERECTOR - MODEL CF50 CF50R1.RSS...

- Page 48 CF50 - CASE ERECTOR Program File List Name Number Type Rungs Debug Bytes [SYSTEM] SUBROUTINE LADDER MACH START LADDER SEQUENCER LADDER VACUUM LADDER VAC TROLLY LADDER FLAP FOLD LADDER BOX PUSHER LADDER SEQ. TIMER LADDER HOPPER LADDER LOW TAPE LADDER LOW HOPPER LADDER BOX JAM...

- Page 49 CF50 - CASE ERECTOR LAD 2 - SUBROUTINE --- Total Rungs in File = 13 MACHINE START LOGIC SUBROUTINE 0000 Jump To Subroutine SBR File Number MACHINE CYCLE SEQUENCER LOGIC 0001 Jump To Subroutine SBR File Number VACUUM GENERATOR SUPPLY LOGIC 0002 Jump To Subroutine...

- Page 50 CF50 - CASE ERECTOR LAD 2 - SUBROUTINE --- Total Rungs in File = 13 BLANK HOPPER DRIVE LOGIC 0007 Jump To Subroutine SBR File Number U:10 TAPE DETECTION LOGIC 0008 Jump To Subroutine SBR File Number U:11 HOPPER DETECTION LOGIC 0009 Jump To Subroutine...

- Page 51 CF50 - CASE ERECTOR LAD 3 - MACH START --- Total Rungs in File = 4 WHEN THE OUTPUT IS ENERGIZED THE MAIN AIR DUMP IS OPENED ALLOWING AIR PRESSURE TO BULID. THE TIMER IS USED TO ALLOW THE SLOW START VALVE TO COMPLETELY OPEN BEFORE THE MACHINE STARTS TO ERECT BOXES.

- Page 52 CF50 - CASE ERECTOR LAD 4 - SEQUENCER --- Total Rungs in File = 9 WHEN THE OUTPUT IS ENERGIZED THE SEQUENCER IS INITIATED TO RUN A MACHINE CYCLE. CASE HOPPER DEMAND INTERNAL DEMAND INTERNAL INTERNAL INTERNAL PHOTO RELAY PHOTO RELAY RELAY RELAY...

- Page 53 CF50 - CASE ERECTOR LAD 4 - SEQUENCER --- Total Rungs in File = 9 THE INSTRUCTION CLEAR THE SEQUENCER AFTER EACH COMPLETE CYCLE OR IF THE MACHINE IS RE-STARTED. MOTOR STARTER AUX. MACHINE CONTACT CYCLE FUNCTION SEQUENCER R6:1 0002 1761-Micro SEQUENCER INTEGER...

- Page 54 CF50 - CASE ERECTOR LAD 4 - SEQUENCER --- Total Rungs in File = 9 WHEN THE OUTPUT IS ENERGIZED THE SEQUENCER WILL MOVE TO THE NEXT STEP. THE SEQUENCER WILL AUTOMATICALLY ADVANCE IF B3:1/4 IS ENERGIZED. IF B3:1/4 IS DE-ENERGIZED THAN THE STEP BUTTON WILL ADVANCE THE SEQUENCER MANUALLY.

- Page 55 CF50 - CASE ERECTOR LAD 4 - SEQUENCER --- Total Rungs in File = 9 INTERNAL MACHINE RELAY SEQUENCER SEQUENCER RE-CYCLE STEP TIME DELAY DONE BIT N7:20 T4:5 0007 0008 Page 9 Thursday, April 02, 2009 - 16:32:52...

- Page 56 CF50 - CASE ERECTOR LAD 5 - VACUUM --- Total Rungs in File = 4 THE MCR ZONE IS ACTIVE WHEN THE TIMER REACHES ITS PRESET VALUE. THE TIMER INSURES THAT THE SLOW START PNEUMATIC VALVE IS FULLY OPEN BEFORE A MACHINE CYCLE CAN START. MACHINE LOGIC START...

- Page 57 CF50 - CASE ERECTOR LAD 6 - VAC TROLLY --- Total Rungs in File = 4 THE MCR ZONE IS ACTIVE WHEN THE TIMER REACHES ITS PRESET VALUE. THE TIMER INSURES THAT THE SLOW START PNEUMATIC VALVE IS FULLY OPEN BEFORE A MACHINE CYCLE CAN START. MACHINE LOGIC START...

- Page 58 CF50 - CASE ERECTOR LAD 7 - FLAP FOLD --- Total Rungs in File = 4 THE MCR ZONE IS ACTIVE WHEN THE TIMER REACHES ITS PRESET VALUE. THE TIMER INSURES THAT THE SLOW START PNEUMATIC VALVE IS FULLY OPEN BEFORE A MACHINE CYCLE CAN START. MACHINE LOGIC START...

- Page 59 CF50 - CASE ERECTOR LAD 8 - BOX PUSHER --- Total Rungs in File = 4 THE MCR ZONE IS ACTIVE WHEN THE TIMER REACHES ITS PRESET VALUE. THE TIMER INSURES THAT THE SLOW START PNEUMATIC VALVE IS FULLY OPEN BEFORE A MACHINE CYCLE CAN START. MACHINE LOGIC START...

- Page 60 CF50 - CASE ERECTOR LAD 9 - SEQ. TIMER --- Total Rungs in File = 7 THE MCR ZONE IS ACTIVE WHEN THE TIMER REACHES ITS PRESET VALUE. THE TIMER INSURES THAT THE SLOW START PNEUMATIC VALVE IS FULLY OPEN BEFORE A MACHINE CYCLE CAN START. MACHINE LOGIC START...

- Page 61 CF50 - CASE ERECTOR LAD 9 - SEQ. TIMER --- Total Rungs in File = 7 0005 0006 Page 15 Thursday, April 02, 2009 - 16:32:52...

- Page 62 CF50 - CASE ERECTOR LAD 10 - HOPPER --- Total Rungs in File = 7 THE MCR ZONE IS ACTIVE WHEN THE TIMER REACHES ITS PRESET VALUE. THE TIMER INSURES THAT THE SLOW START PNEUMATIC VALVE IS FULLY OPEN BEFORE A MACHINE CYCLE CAN START. MACHINE LOGIC START...

- Page 63 CF50 - CASE ERECTOR LAD 10 - HOPPER --- Total Rungs in File = 7 THE TIMER CONTROLS THE ADVANCE TIME OF THE INDEXING HOPPER RATCHET. HOPPER HOPPER FEED FEED "ON" "OFF" TIMER TIME DONE BIT DELAY T4:11 0004 Timer On Delay Timer T4:12 Time Base...

- Page 64 CF50 - CASE ERECTOR LAD 11 - LOW TAPE --- Total Rungs in File = 3 WHEN LOW TAPE IS DETECTED THE OUTPUT IS STROBED. OPTIONAL LOW TAPE INTERNAL ALARM TAPE TOWER LT. PHOTO CELL ON / OFF AMBER PULSE TRAIN 0000 1761-Micro...

- Page 65 CF50 - CASE ERECTOR LAD 12 - LOW HOPPER --- Total Rungs in File = 3 WHEN LOW HOPPER IS DETECTED THE OUTPUT IS STROBED. OPTIONAL INTERNAL MAGAZINE MAGAZINE ALARM BLUE PROX. SW. ON / OFF TOWER LT. PROX 5 PULSE PROX_5 TRAIN...

- Page 66 CF50 - CASE ERECTOR LAD 13 - BOX JAM --- Total Rungs in File = 3 WHEN THE PUTPUT IS ENERGIZED IT SIGNALS THE MACHINE HAS A BOX JAM. OPTIONAL OPTIONAL VACUUM MOTOR CASE CASE JAM TROLLEY STARTER INTERNAL VAC. TROL. SOLENOID AUX.

- Page 67 CF50 - CASE ERECTOR RSLogix 500 Cross Reference Report - Sorted by Address O:0/0 - {SOL_1} MAIN AIR SOLENOID VALVE SOL 1 OTE - File #3 MACH START - 0 O:0/1 - {SOL_5} VACUUM TROLLEY SOLENOID VALVE SOL 5 OTE - File #6 VAC TROLLY - 1 XIC - File #6 VAC TROLLY - 1 File #13 BOX JAM - 0 O:0/2...

- Page 68 CF50 - CASE ERECTOR RSLogix 500 Cross Reference Report - Sorted by Address OTE - File #14 BOX COUNT - 0 XIC - File #14 BOX COUNT - 1 B3:0/14 - INTERNAL RELAY MAN. / AUTO SWITCH LATCH OTL - File #3 MACH START - 1 OTU - File #3 MACH START - 2 XIC - File #4 SEQUENCER - 5 File #5 VACUUM - 1...

- Page 69 CF50 - CASE ERECTOR RSLogix 500 Cross Reference Report - Sorted by Address T4:12/DN - HOPPER FEED "OFF" TIMER DONE BIT XIO - File #10 HOPPER T4:15 - LOW TAPE DETECTED TIME DELAY TON - File #11 LOW TAPE - 1 T4:15/DN - LOW TAPE TIME DELAY DONE BIT XIO - File #6 VAC TROLLY - 1...

- Page 70 CF50 - CASE ERECTOR RSLogix 500 Cross Reference Report - Sorted by Address - MINOR FLAP FOLDER LOGIC JSR - File #2 SUBROUTINE - 4 - BOX CROSS PUSHER LOGIC JSR - File #2 SUBROUTINE - 5 - MACHINE CYCLE SEQUENCER TIMERS JSR - File #2 SUBROUTINE - 6 U:10 - BLANK HOPPER DRIVE LOGIC...

Need help?

Do you have a question about the Little David CF50T and is the answer not in the manual?

Questions and answers

Tape on back side of the box doesn’t go all the way up. So the top isn’t against the box