Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Troubleshooting

Summary of Contents for Terex AL8000HT

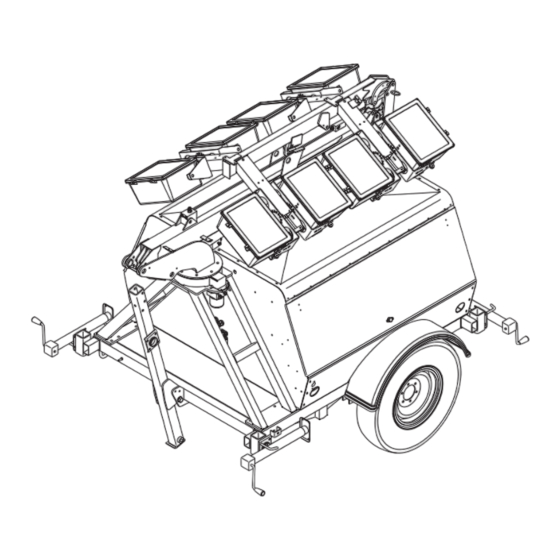

- Page 1 Service Manual AL8000HT First Edition Rev A Part No. 116478 September 2008...

-

Page 2: Introduction

Terex dealer service center. Technical Publications Terex has endeavored to deliver the highest degree of accuracy possible. However, continuous improvement of our products is a Terex policy. Therefore, product specifications are subject to change without notice. -

Page 3: How To Read Your Serial Number

September 2008 How to Read Your Serial Number Serial Number Legend Part No. 116478 AL8000HT Light Tower... - Page 4 September 2008 Safety Rules Danger Failure to obey the instructions and safety rules in this manual and the Terex AL8000HT Operator's Manual on your machine will result in death or serious injury. Many of the hazards identified in the operator’s manual are also safety hazards when maintenance and repair procedures are performed.

- Page 5 Be sure to wear protective eye wear and other protective clothing if the situation warrants it. Be aware of potential crushing hazards such as moving parts, free swinging or unsecured components when lifting or placing loads. Always wear approved steel-toed shoes. Part No. 116478 AL8000HT Light Tower...

-

Page 6: Table Of Contents

Pre-delivery Preparation Report ................3 - 3 Maintenance Inspection Report ................3 - 5 Checklist A Procedures Inspect the Manuals and Decals ..............3 - 7 Perform Pre-operation Inspection ..............3 - 8 Perform Function Tests ................3 - 8 AL8000HT Light Tower Part No. 116478... - Page 7 Perform Engine Maintenance - Kubota Models ........... 3 - 22 Check the Tower Rotation Bearing Bolts ............ 3 - 22 Replace the Hydraulic Return Filter ............3 - 23 Perform Engine Maintenance - Isuzu Models ..........3 - 24 Part No. 116478 AL8000HT Light Tower...

- Page 8 Kubota D1105-E/V1505-E Engine Timing Adjustment ..................4 - 13 Glow Plugs ....................4 - 13 Coolant Temperature and Oil Pressure Switches ........4 - 13 Isuzu 4LE1 Engine Timing Adjustment ..................4 - 14 viii AL8000HT Light Tower Part No. 116478...

- Page 9 AC Electrical Schematic - Autostart Models with 6 Lights ........6 - 12 AC Electrical Schematic - Autostart Models with 8 Lights ........6 - 13 Receptacle Wiring Diagrams ................6 - 14 Hydraulic Schematic .................... 6 - 15 Part No. 116478 AL8000HT Light Tower...

-

Page 10: Parts Stocking List

September 2008 Parts Stocking List Required Parts The following parts are required to perform maintenance procedures as outlined in the TEREX AL8000HT Parts and Service Manual. Description Part No. Kubota Models Oil Filter .............. 866050 Air Filter .............. 866127 Fuel Filter ............839200 V-belt .............. -

Page 11: How To Order Parts

September 2008 How To Order Parts Please be prepared with the following information Genie Industries when ordering replacement parts for your TEREX 18340 NE 76th Street product: P.O. Box 97030 Redmond, WA 98073-9730 Machine model number Telephone (877) 367-5606 Machine serial number... -

Page 12: Service Parts Fax Order Form

Ship all available parts and contact customer on disposition of backordered parts Other (please specify) TEREX U Order Number ______________ Origin Code ________________ Comments _________________________ AL8000HT Light Tower Part No. 116478 Date Scheduled ____________ Ship Condition _____________ __________________________________ Order Total ________________... -

Page 13: Machine Specifications

Tire pressure, maximum (cold) 75 psi 5.2 bar Continuous improvement of our products is a For operational specifications, refer to the Terex policy. Product specifications are subject Operator's Manual. to change without notice. Part No. 116478 AL8000HT Light Tower 2 - 1... -

Page 14: Hydraulic Oil Specifications

205°F / 96°C. Note: Terex specifications require additional equipment and special installation instructions for Continuous improvement of our products is a the approved optional fluids. Consult the Terex Terex policy. Product specifications are subject Service Department before use. to change without notice. -

Page 15: Manifold Component Specifications

3 position 4 way solenoid valve, 10V DC 6Ω (schematic items B, C, E and G) Continuous improvement of our products is a Terex policy. Product specifications are subject to change without notice. Part No. 116478 AL8000HT Light Tower 2 - 3... -

Page 16: Kubota D1105-E Engine

Extreme operating temperatures may require the use of alternative engine oils. For oil requirements, refer to the Engine Operator Handbook on your machine. Continuous improvement of our products is a Terex policy. Product specifications are subject to change without notice. 2 - 4 AL8000HT Light Tower... -

Page 17: Kubota V1505-E Engine

(engine shutoff pressure) Oil viscosity requirements Units ship with 10W-30. Extreme operating temperatures may require the use of alternative engine oils. For oil requirements, refer to the Engine Operator Handbook on your machine. Part No. 116478 AL8000HT Light Tower 2 - 5... -

Page 18: Isuzu 4Le1 Engine

Extreme operating temperatures may require the use of alternative engine oils. For oil requirements, refer to the Engine Operating Instructions on your machine. Continuous improvement of our products is a Terex policy. Product specifications are subject to change without notice. 2 - 6 AL8000HT Light Tower... - Page 19 Generator rpm @ full load 60 Hz 1800 rpm Temperature, ambient maximum 104°F 40°C Power 20 kW Continuous improvement of our products is a Terex policy. Product specifications are subject to change without notice. Part No. 116478 AL8000HT Light Tower 2 - 7...

-

Page 20: Hydraulic Hose And Fitting Torque Specifications

85 ft-lbs / 115 Nm 210 ft-lbs / 284.7 Nm 110 ft-lbs / 150 Nm 260 ft-lbs / 352.5 Nm 140 ft-lbs / 190 Nm 315 ft-lbs / 427.1 Nm 180 ft-lbs / 245 Nm 2 - 8 AL8000HT Light Tower Part No. 116478... - Page 21 50.5 39.9 54.1 53.2 72.2 46.7 63.3 62.3 84.4 18.9 25.6 25.1 34.1 48.6 64.9 69.7 94.5 92.2 30.1 40.8 54.3 77.4 46.9 63.6 62.5 84.8 64.5 87.5 86.2 1055 1233 Part No. 116478 AL8000HT Light Tower 2 - 9...

-

Page 22: Genset Torque Specifications

September 2008 GENSET TORQUE SPECIFICATIONS Generator FT*LB Flex Plate to Flywheel Generator Case to Bellhousing Genset Isolators 2 - 10 AL8000HT Light Tower Part No. 116478... -

Page 23: Observe And Obey

Repair any machine damage or malfunction injury. before operating the machine. Indicates a potentially hazardous Use only Terex approved replacement parts. situation which, if not avoided, Machines that have been out of service for a may result in property damage. -

Page 24: Pre-Delivery Preparation Report

Make copies of the Maintenance Inspection Report to use for each inspection. Maintain completed forms for a minimum of 4 years or in compliance with employer, jobsite and governmental regulations and requirements. 3 - 2 AL8000HT Light Tower Part No. 116478... - Page 25 Inspector signature Inspector title Inspector company TEREX Rock Hill P.O. BOX 3147 Rock Hill, SC 29732 USA Toll Free (800) 433-3026 in U.S.A. and Canada Copyright © 2006 by TEREX Corporation. TEREX® is a registered trademark of TEREX Corporation. Rev B...

- Page 26 Section 3 • Scheduled Maintenance Procedures September 2008 This page intentionally left blank. 3 - 4 AL8000HT Light Tower Part No. 116478...

-

Page 27: Maintenance Inspection Report

After repair, place a check in the “R” box. Legend Y = yes, acceptable N = no, remove from service R = repaired Part No. 116478 AL8000HT Light Tower 3 - 5... - Page 28 After repair, place a check in the “R” box. Legend Y = yes, acceptable N = no, remove from service R = repaired 3 - 6 AL8000HT Light Tower Part No. 116478...

-

Page 29: Checklist A Procedures

In addition, maintaining all of the safety and container after use. instructional decals in good condition is mandatory Note: Contact your authorized Terex distributor if for safe machine operation. Decals alert operators replacement manuals or decals are needed. and personnel to the many possible hazards associated with using this machine. -

Page 30: Perform Pre-Operation Inspection

CHECKLIST A PROCEDURES REV A Perform Pre-operation Perform Function Tests Inspection Note: Terex specifications require that this procedure be performed every 8 hours or daily, Note: Terex specifications require that this whichever comes first. procedure be performed every 8 hours or daily, whichever comes first. -

Page 31: Perform Engine Maintenance - Isuzu Models

Leroy Somer LSA 37 Installation and Maintenance Manual Terex part number 116118 Marathon Installation, Operation and Maintenance Manual Terex part number 116188 Newage Installation, Service and Maintenance Manual Terex part number 830001 Part No. 116478 AL8000HT Light Tower 3 - 9... -

Page 32: Perform Axle Maintenance

Lug Nut Torque Required maintenance procedures and additional axle information is available in the Axis Axle Operator Maintenance Manual included with your machine. Axis Axle Operator Maintenance Manual Terex part number 116117 3 - 10 AL8000HT Light Tower Part No. 116478... -

Page 33: Perform Engine Maintenance

Fulton Coupler User Manual (Kubota part number 16683-89169). Terex part number 150139 Isuzu 4LE1 Diesel Engine Instruction Manual Terex part number 116133 Kubota D-1105 and V-1505 Operator's Manual Terex part number 893020 Part No. 116478 AL8000HT Light Tower 3 - 11... -

Page 34: Grease The Turntable Rotationbearing And Rotate Gear

Bearing and Rotate Gear thoroughly greased. 10 Install the pinion gear guard and securely tighten the retaining fasteners. Do not overtighten. Note: Terex specifications require that this Grease Specification procedure be performed every 100 hours of operation. Perform this procedure more often if Chevron Ultra-duty grease, EP NLGI 2 (lithium based) dusty conditions exist. -

Page 35: Perform Engine Maintenance - Kubota Models

Kubota D-1105 and V-1505 Operator's Manual (Kubota part number 16683-89169). (Kubota part number 16683-89169). Kubota D-1105 and V-1505 Operator's Manual Kubota D-1105 and V-1505 Operator's Manual Terex part number 893020 Terex part number 893020 Part No. 116478 AL8000HT Light Tower 3 - 13... -

Page 36: Checklist B Procedures

Checklist B Procedures REV A Inspect the Battery Inspect the Electrical Wiring Note: Terex requires that this procedure be Note: Terex requires that this procedure be performed every 250 hours or quarterly, whichever performed every 250 hours or quarterly, whichever comes first. -

Page 37: Inspect The Tires And Wheels (Including Lug Nut Torque)

CHECKLIST B PROCEDURES Inspect the Tires and Wheels Perform Hydraulic Oil Analysis (including lug nut torque) Note: Terex requires that this procedure be performed every 250 hours or quarterly, whichever Note: Terex requires that this procedure be comes first. performed every 250 hours or quarterly, whichever comes first. -

Page 38: Perform Engine Maintenance - Isuzu Models

Leroy Somer LSA 37 Installation and Maintenance Manual Terex part number 116118 Marathon Installation, Operation and Maintenance Manual Terex part number 116188 Newage Installation, Service and Maintenance Manual Terex part number 830001 3 - 16 AL8000HT Light Tower Part No. 116478... -

Page 39: Perform Hitch Maintenance

Required maintenance procedures and additional axle information is available in the Axis Axle Operator Maintenance Manual included with your machine. Axis Axle Operator Maintenance Manual Terex part number 116117 Part No. 116478 AL8000HT Light Tower 3 - 17... - Page 40 Section 3 • Scheduled Maintenance Procedures September 2008 REV A This page intentionally left blank. 3 - 18 AL8000HT Light Tower Part No. 116478...

-

Page 41: Checklist C Procedures

Perform Engine Maintenance Retract Cables and Pulleys Note: Engine specifications require that this procedure be performed every 500 hours or Note: Terex requires that this procedure be semi-annually, whichever comes first. performed every 500 hours or semi-annually, Required maintenance procedures and additional whichever comes first. -

Page 42: Perform Axle Maintenance

Required maintenance procedures and additional Terex part number 116133 axle information is available in the Axis Axle Operator Maintenance Manual included with your machine. Axis Axle Operator Maintenance Manual Terex part number 116117 3 - 20 AL8000HT Light Tower Part No. 116478... -

Page 43: Perform Engine Maintenance - Kubota Models

Required maintenance procedures and additional engine information is available in the Kubota D-1105 and V-1505 Operator's Manual (Kubota part number 16683-89169). Kubota D-1105 and V-1505 Operator's Manual Terex part number 893020 Part No. 116478 AL8000HT Light Tower 3 - 21... -

Page 44: Checklist D Procedures

Perform Engine Maintenance - Check the Tower Rotation Kubota Models Bearing Bolts Note: Engine specifications require that this Note: Terex requires that this procedure be procedure be performed annually. performed every 1000 hours or annually, whichever comes first. Required maintenance procedures and additional... -

Page 45: Replace The Hydraulic Return Filter

Refer to Section 2, Filter Specifications . Tongue Note: Terex requires that this procedure be performed every 1000 hours or annually, whichever comes first. Replacement of the hydraulic return filter is essential for good machine performance and service life. -

Page 46: Perform Engine Maintenance - Isuzu Models

Isuzu 4LE1 Diesel Engine Instruction Manual (Isuzu part number IDE-6033). (Isuzu part number IDE-6033). Isuzu 4LE1 Diesel Engine Instruction Manual Terex part number 116133 Isuzu 4LE1 Diesel Engine Instruction Manual Terex part number 116133 3 - 24 AL8000HT Light Tower Part No. 116478... -

Page 47: Perform Generator Maintenance

Leroy Somer LSA 37 Installation and Maintenance Manual Terex part number 116118 Marathon Installation, Operation and Maintenance Manual Terex part number 116188 Newage Installation, Service and Maintenance Manual Terex part number 830001 Part No. 116478 AL8000HT Light Tower 3 - 25... -

Page 48: Perform Tongue Jack And Outrigger Jack Maintenance

Cequent Tongue Jack Use Manual Terex part number 150140 axle information is available in the Axis Axle Operator Maintenance Manual included with your machine. Axis Axle Operator Maintenance Manual Terex part number 116117 3 - 26 AL8000HT Light Tower Part No. 116478... -

Page 49: Test Or Replace The Hydraulic Oil

Loosen hydraulic connections very slowly to allow Note: Terex requires that this procedure be the oil pressure to dissipate performed every 2000 hours or every two years, gradually. Do not allow oil to squirt whichever comes first. -

Page 50: Perform Engine Maintenance - Kubota Models

19 Make sure unit is in a clear area during steps 17 and 18 as air in the cylinders can cause sudden movements of the tower. 3 - 28 AL8000HT Light Tower Part No. 116478... -

Page 51: Perform Engine Maintenance - Kubota Models

Leroy Somer LSA 37 Installation and Maintenance Manual Terex part number 116118 Marathon Installation, Operation and Maintenance Manual Terex part number 116188 Newage Installation, Service and Maintenance Manual Terex part number 830001 Part No. 116478 AL8000HT Light Tower 3 - 29... -

Page 52: Perform Generator Maintenance

Leroy Somer LSA 37 Installation and Maintenance Manual Terex part number 116118 Marathon Installation, Operation and Maintenance Manual Terex part number 116188 Newage Installation, Service and Maintenance Manual Terex part number 830001 3 - 30 AL8000HT Light Tower Part No. 116478... - Page 53 Be sure that all necessary tools and parts are injury. available and ready for use. Indicates a potentially hazardous Use only Terex approved replacement parts. situation which, if not avoided, may cause minor or moderate Read each procedure completely and adhere to injury.

-

Page 54: Lighting

10 to 20 minutes. Note: Be sure to wrap a clean cloth around a lamp when installing a lamp into a lamp socket. 4 - 2 AL8000HT Light Tower Part No. 116478... - Page 55 Refer to the following chart. Open Circuit Voltage 375V AC to 465V AC Specification Note: If there is no reading on the meter. Repair or replace the capacitor, ballast or wiring. Part No. 116478 AL8000HT Light Tower 4 - 3...

-

Page 56: Light Bar Components

Note: During removal, the overhead crane strap will need to be carefully adjusted for proper balancing. 4 - 4 AL8000HT Light Tower Part No. 116478... -

Page 57: Light Bar Lift Cylinder

3 Remove the pin retaining fasteners from both the rod end and barrel-end pivot pins. 4 Place a rod through the pins and twist to remove. Remove the cylinder from the machine. Part No. 116478 AL8000HT Light Tower 4 - 5... -

Page 58: Tower Components

3 tower tube number 2 tower tube number 1 tower lift cylinder tower rotation riser 4 - 6 AL8000HT Light Tower Part No. 116478... -

Page 59: Plastic Cable Track

2 Repeat step 1 for each link. 3 To remove a single link, open the lower clip and then use a screw driver to pry the link to the side. Part No. 116478 AL8000HT Light Tower 4 - 7... - Page 60 Crushing hazard. The tower assembly could become unbalanced and fall when removed from the machine if not properly supported and secured to the forklift. 4 - 8 AL8000HT Light Tower Part No. 116478...

- Page 61 Remove the clevis pins. Do not remove the pulley clevis pin. Note: Always use a new cotter pin when installing a clevis pin. Part No. 116478 AL8000HT Light Tower 4 - 9...

-

Page 62: Tower Lift Cylinder

Guide the cylinder out the pivot end of the tower and carefully remove the cylinder from the machine. Component damage hazard. Cables and hoses can be damaged if the cylinder is dragged across them. 4 - 10 AL8000HT Light Tower Part No. 116478... -

Page 63: Tower Extension Cylinder

Do not allow oil to squirt or spray. 2 Attach a lifting strap from an overhead crane to the tower extension cylinder. Part No. 116478 AL8000HT Light Tower 4 - 11... -

Page 64: Tower Rotation Motor

Note: When installing a rotation motor, the gear Check for tight spots and binding. Readjust if backlash will need to be adjusted. See How to necessary. Adjust the Tower Rotation Gear Backlash. 4 - 12 AL8000HT Light Tower Part No. 116478... -

Page 65: Kubota D1105-E/V1505-E Engine

2 Connect the leads from an ohmmeter between each glow plug terminal and ground. Result: The resistance should be approximately 1Ω. Result: The resistance is 0Ω or greater than 1Ω. The glow plug is faulty. Part No. 116478 AL8000HT Light Tower 4 - 13... -

Page 66: Glow Plugs

2 Connect the leads from an ohmmeter between each glow plug terminal and ground. Result: The resistance should be approximately 1Ω. Result: The resistance is 0Ω or greater than 1Ω. The glow plug is faulty. 4 - 14 AL8000HT Light Tower Part No. 116478... -

Page 67: Generator

4 With an ohmmeter set to its highest resistance scale, connect the ohmmeter leads to the capacitor terminals and observe the reading on the meter. Then, reverse the connections and observe the reading on the meter. Part No. 116478 AL8000HT Light Tower 4 - 15... - Page 68 2 Raise the tower to a vertical position. Do not engine components may cause extend the tower or raise the light bar. Turn the severe burns. Use caution when machine off. working around a hot engine. 4 - 16 AL8000HT Light Tower Part No. 116478...

- Page 69 8 Remove the tower rest pad weldment fasteners. Remove the rest pad from the cabinet. 9 Support the cabinet top with a suitable lifting device. Part No. 116478 AL8000HT Light Tower 4 - 17...

- Page 70 15 Use a lifting jack or similar device to support the high voltage electrical rear of the engine. Do not apply any lifting components. pressure. 13 Tag and disconnect the wires at the top of the generator. Remove the cover. 4 - 18 AL8000HT Light Tower Part No. 116478...

-

Page 71: Chassis Components

1 Move the engine start switch to timed start. 2 On the timer, move the mode switch (upper left switch) to and the set switch (upper right AUTO switch) to Part No. 116478 AL8000HT Light Tower 4 - 19... -

Page 72: Light Ballast

Note: If the ballast capacitor to be tested is located · Incorrect capacitor voltage rating. under another ballast box, the top ballast box will need to be removed first. · Capacitor becomes loose in ballast box. 4 - 20 AL8000HT Light Tower Part No. 116478... -

Page 73: Fuel Tank

2 for the other fuel tank. 3 Tag, disconnect and plug the fuel hoses from the fuel tank. Clean up any fuel that may have spilled. Part No. 116478 AL8000HT Light Tower 4 - 21... - Page 74 Note: Clean the fuel tank and inspect for cracks and other damage before installing it onto the machine. 4 - 22 AL8000HT Light Tower Part No. 116478...

-

Page 75: Function Manifold Components

0.2 gpm / 0.76 L/min ......D ... Light bar up/down circuit ......20 ft-lbs / 27 Nm Orifice plug, 0.025 inch / 0.64 mm ......F ... Tower rotate circuit Part No. 116478 AL8000HT Light Tower 4 - 23... -

Page 76: Valve Adjustments - Function Manifold

Install the hose to the tee fitting. 3 Activate and hold the tower rotate toggle switch in either direction. 4 Observe the pressure reading on the pressure gauge. Refer to Section 2, Specifications. 4 - 24 AL8000HT Light Tower Part No. 116478... -

Page 77: Troubleshooting And Repair Procedures Shall Be

Remove all rings, watches and other jewelry. Burn hazard. Contact with hot engine components may cause severe burns. Use caution when working around a hot engine. Part No. 116478 AL8000HT Light Tower 5 - 1... -

Page 78: Troubleshooting Guide

5 - 2 AL8000HT Light Tower Part No. 116478... - Page 79 Voltage should be within 10% of rating when operating at normal load. Increase supply voltage or remove external load. Part No. 116478 AL8000HT Light Tower 5 - 3...

- Page 80 "cycle". Usually after 3 tries to start at 30 to 60 second intervals, lamp will stabilize and operate normal 5 - 4 AL8000HT Light Tower Part No. 116478...

-

Page 81: Light Fixture Troubleshooting

D. Before disconnecting ballast, turn off circuit breaker and wait 30 seconds for capacitor to discharge. E. If all the lights are out and all the ballasts are receiving power, suspect burned out power cable. Part No. 116478 AL8000HT Light Tower 5 - 5... - Page 82 September 2008 Section 5 • Troubleshooting REV A This page intentionally left blank. 5 - 6 AL8000HT Light Tower Part No. 116478...

- Page 83 Be sure that all necessary tools and test equipment are available and ready for use. Malfunction Identify Troubleshoot symptoms discovered problem still exists Return to Inspect Perform service and test repair problem solved Part No. 116478 AL8000HT Light Tower 6 - 1...

-

Page 84: Electrical Symbols Legend

N.O.H.C N.C.H.O Oil pressure switch Limit switch normally closed Circuit breaker with amperage Power relay Main circuit breaker Fuel or RPM solenoid N.O. Control relay contact normally open Light switch Coil 6 - 2 AL8000HT Light Tower Part No. 116478... -

Page 85: Hydraulic Symbols Legend

Priority fixed displacement with pressure setting flow regulator valve 3000 psi (206.8 bar) Pump prime mover (engine or motor) Cross-relief valve Counterbalance valve with pressure and pilot ratio Double acting cylinder Part No. 116478 AL8000HT Light Tower 6 - 3... -

Page 86: Electrical Schematic - Machine Functions

TOWER RETRACT VALVE COIL BLK/WH RETRACT TOWER EXTEND TOWER EXTEND VALVE COIL TOWER DOWN VALVE COIL RED/BLK DOWN TOWER TOWER UP VALVE COIL STOWED LIMIT SWITCH PUMP MOTOR CONTACTOR LIFT PUMP MOTOR 6 - 4 AL8000HT Light Tower Part No. 116478... - Page 87 September 2008 Section 6 • Schematics DC Electrical Schematic - Control Box and Engine REV A Isuzu Models Part No. 116478 AL8000HT Light Tower 6 - 5...

-

Page 88: Dc Electrical Schematic - Control Box And Engine Kubota Models

Section 6 • Schematics September 2008 DC Electrical Schematic - Control Box and Engine Kubota Models REV A 6 - 6 AL8000HT Light Tower Part No. 116478... - Page 89 September 2008 Section 6 • Schematics DC Electrical Schematic - Control Box and Engine REV A with Autostart Option Part No. 116478 AL8000HT Light Tower 6 - 7...

-

Page 90: Ac Electrical Schematic - Standard Models With 4 Lights

Section 6 • Schematics September 2008 AC Electrical Schematic - Standard Models with 4 Lights REV A 6 - 8 AL8000HT Light Tower Part No. 116478... -

Page 91: Ac Electrical Schematic - Standard Models With 6 Lights

September 2008 Section 6 • Schematics AC Electrical Schematic - Standard Models with 6 Lights REV A Part No. 116478 AL8000HT Light Tower 6 - 9... -

Page 92: Ac Electrical Schematic - Standard Models With 8 Lights

Section 6 • Schematics September 2008 AC Electrical Schematic - Standard Models with 8 Lights REV A 6 - 10 AL8000HT Light Tower Part No. 116478... -

Page 93: Ac Electrical Schematic - Autostart Models With 4 Lights

September 2008 Section 6 • Schematics AC Electrical Schematic - Autostart Models with 4 Lights REV A Part No. 116478 AL8000HT Light Tower 6 - 11... -

Page 94: Ac Electrical Schematic - Autostart Models With 6 Lights

Section 6 • Schematics September 2008 AC Electrical Schematic - Autostart Models with 6 Lights REV A 6 - 12 AL8000HT Light Tower Part No. 116478... -

Page 95: Ac Electrical Schematic - Autostart Models With 8 Lights

September 2008 Section 6 • Schematics AC Electrical Schematic - Autostart Models with 8 Lights REV A Part No. 116478 AL8000HT Light Tower 6 - 13... -

Page 96: Receptacle Wiring Diagrams

Section 6 • Schematics September 2008 Receptacle Wiring Diagrams REV A Standard Receptacle Package Extra GFCI Receptacle Package Enhanced Receptacle Package 6 - 14 AL8000HT Light Tower Part No. 116478... -

Page 97: Hydraulic Schematic

September 2008 Section 6 • Schematics Hydraulic Schematic REV A Part No. 116478 AL8000HT Light Tower 6 - 15... - Page 98 Section 6 • Schematics September 2008 REV A This page intentionally left blank. 6 - 16 AL8000HT Light Tower Part No. 116478...

- Page 100 California Proposition 65 Warning The exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects or other reproductive harm. Towing Checklist (Use at each stop) · Boom hold-down latch is securely locked in place Before Towing ·...

Need help?

Do you have a question about the AL8000HT and is the answer not in the manual?

Questions and answers