Table of Contents

Advertisement

Pack Contents

•

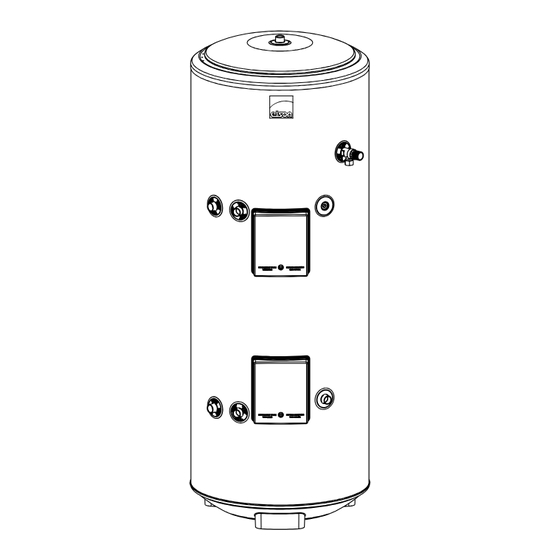

Zircon Solar unvented water heater incorporating immersion heater(s) & thermal controls

•

Factory fitted temperature/pressure relief valve (set at 90°C / 1 Mpa (10bar))

•

Cold water combination valve assembly

•

Expansion vessel & mounting bracket

•

Tundish

•

2 Port motorised valve

•

Compression nuts & olives

•

Immersion heater spanner

•

Installation & servicing instructions

•

Guarantee card

Please read & understand all these instructions before commencing installation.

Please leave this manual with the customer for future reference.

Zircon Installation Manual

Unvented Solar Indirect Water Heaters

Installation & Servicing Instructions

IMPORTANT

1

Advertisement

Table of Contents

Summary of Contents for Elson Zircon 190 S Ind

- Page 1 Zircon Installation Manual Unvented Solar Indirect Water Heaters Installation & Servicing Instructions Pack Contents • Zircon Solar unvented water heater incorporating immersion heater(s) & thermal controls • Factory fitted temperature/pressure relief valve (set at 90°C / 1 Mpa (10bar)) • Cold water combination valve assembly •...

-

Page 2: Table Of Contents

Contents Introduction The cylinder is a purpose designed unvented water heater. The unit has a stainless steel inner vessel, which ensures an excellent standard of corrosion Introduction..............2 resistance. The outer casing is a combination of resilient thermoplastic mouldings and plastic coated General Requirements...........3 corrosion proofed steel sheet. -

Page 3: General Requirements

Table 01: Unit weights General Requirements Nominal Weight of Weight Model IMPORTANT: Type Capacity unit full of unit Reference This appliance can be used by children aged (litres) (Kg) (Kg) from 8 years and above and persons with 190 S Ind reduced physical sensory or mental capabilities 210 S Ind Solar... - Page 4 Limitations Checklist The cylinder should not be used in association with • Unvented cylinder any of the following: • Cold control pack • Solid fuel boilers or any other boiler in which the Tundish energy input is not under effective thermostatic Combination valve control, unless additional and appropriate safety Expansion vessel...

-

Page 5: Installation General

Secondary Circulation Installation General If secondary circulation is required it is recommended that it be connected to the cylinder as shown (see Pipe Fittings Fig. 03 below) The secondary return pipe should All pipe fittings are made via 22mm compression fittings be in 15mm pipe and incorporate a check valve to directly to the unit. - Page 6 Fig. 04 General Dimensions HOT OUTLET T&P VALVE AUXILIARY FLOW AUXILIARY RETURN SECONDARY RETURN AUXILLARY CONTROL SOLAR CONTROL SOLAR FLOW COLD INLET SOLAR RETURN Table 02: Dimensions and Performance Type Model Dimensions (mm) Solar Auxiliary Coil Rating (kW) Heat-up Hot Water Reference Volume Volume...

-

Page 7: Installation Discharge

Tundish Installation Discharge 3.54 The tundish should be vertical, located in the same space as the unvented hot water storage system and be fitted as close as possible to, and lower than, the Discharge Pipework valve, with no more than 600mm of pipe between the It is a requirement of Building Regulation G3 that valve outlet and the tundish (see Fig. - Page 8 3.60 The discharge pipe should not be connected to Worked Example of Discharge Pipe Sizing a soil discharge stack unless it can be demonstrated that the soil discharge stack is capable of safely Fig. 05: shows a G1/2 temperature relief valve with a withstanding temperatures of the water discharged, discharge pipe (D2) having 4 No.

- Page 9 Table 03: Sizing of copper discharge pipe (D2) for common temperature relief valve outlet sizes NOTE: The table below is based on copper tube. Plastic pipes may be of different bore and resistance. Sizes and maximum lengths of plastic should be calculated using data prepared for the type of pipe being used. MINIMUM SIZE OF MINIMUM SIZE OF RESISTANCE CREATED BY...

- Page 10 Fig. 06: Typical SOLAR Installation - Schematic Secondary Return Tapping Expansion Balanced cold Cold water (if required) To hot outlets vessel water connection combination T&P relief (if required) valve valve Boost element/ Auxillary Isolating valve control housing (not supplied) Auxillary Mains water Primary return supply...

-

Page 11: Installation Solar

Installation - Solar The solar controller and solar primary circulation pump must be wired via the over-temperature cut-out Connection To Solar Primary Circuit mounted in the lower solar controls housing. This will The lower (solar) coil of the SOLAR cylinder must be ensure that the heat input to the solar coil is interrupted connected to a fully pumped solar primary circuit. -

Page 12: Installation Auxiliary Heating Coil

Boiler Selection Installation - The boiler should have a control thermostat and non Auxiliary Heating Coil self-resetting thermal cut-out and be compatible with unvented storage water heaters. Safety Where use of a boiler without a thermal cut-out is DISCONNECT FROM THE MAINS ELECTRICAL unavoidable a “low head”... - Page 13 Fig. 09: Schematic Wiring Diagram - Basic 2 x 2 port valve system ( ‘S’ plan ) Cylinder terminal block 1 2 3 Zone valve (DHW) Zone valve (HTG) Room stat (supplied) Br Bl 1 3 2 Br Bl (Supply) 3 4 5 6 7 8 9 10 Junction box 1 2 3 4 5 6 7 8 9 10...

-

Page 14: Commissioning

Switch on the boiler, ensure the programmer is set to Commisioning Domestic Hot Water and allow the cylinder to heat up to a normal working temperature (60°C recommended). If necessary the temperature can be adjusted by inserting Filling The Unit With Water a flat bladed screwdriver in the adjustment knob (located Ensure that all fittings and immersion heaters are on front of the thermostat mounting bracket - (see Fig.11... -

Page 15: Maintenance

Over time the immersion heater gasket may become Maintenance stuck to the mating surface. To break the seal insert a round bladed screwdriver into one of the pockets on the immersion heater and gently lever up and down. Maintenance Requirements Unvented hot water systems have a continuing Carefully remove any scale from the surface of the maintenance requirement in order to ensure safe... -

Page 16: User Instructions

Temperature Controls - Solar User instructions Temperature control of the solar primary coil is by means of solar differential temperature controller. This will usually have been set during commissioning to give Warnings a storage temperature of approximately 60°C. Refer to IF WATER DISCHARGES FROM THE TEMPERATURE/ user instructions supplied with the controller for details PRESSURE RELIEF VALVE ON CYLINDER SHUT... -

Page 17: Fault Finding & Servicing

Spare Parts Fault Finding & Servicing A full range of spare parts are available for the cylinder range (Table 05 Page 18). Refer to the Important technical data label on the unit to identify the model • After servicing, complete the relevant Service installed and ensure the correct part is ordered. -

Page 18: Spares

Spares Fig. 12: Solar Cylinder Spares Diagram Table 05: Spares Item Description Part Number Number Immersion heater 95 606 961 Immersion heater gasket 70 351 65 Immersion heater backnut 95 607 869 Immersion heater key 95 607 861 spanner Tundish 95 605 838 Cold water combination 70 344 68... -

Page 19: Heat Loss

Heat Loss Environmental Table 06: Standing heat losses (based on an ambient air Products are manufactured from many recyclable materials. At the end of their useful life they should be temperature of 20°C and a stored water temperature of disposed of at a Local Authority Recycling Centre in order 65°C) to realise the full environmental benefits. -

Page 20: Commissioning Check List

MAINS PRESSURE HOT WATER STORAGE SYSTEM COMMISSIONING CHECKLIST This Commissioning Checklist is to be completed in full by the competent person who commissioned the storage system as a means of demonstrating compliance with the appropriate Building Regulations and then handed to the customer to keep for future reference. Failure to install and commission this equipment to the manufacturer’s instructions may invalidate the warranty but does not affect statutory rights. -

Page 21: Service Record

SERVICE RECORD It is recommended that your hot water system is serviced regularly and that the appropriate Service Record is completed. Service Provider Before completing the appropriate Service Record below, please ensure you have carried out the service as described in the manufacturer’s instructions. SERVICE 01 SERVICE 02 Date:... - Page 22 NOTES...

- Page 23 NOTES...

-

Page 24: Warranty

The Policy Statement guarantee is transferable. This guarantee does not affect your The policy of ELSON is one of statutory rights. continuous product development and, as such, we reserve the right to change specifications without notice.

Need help?

Do you have a question about the Zircon 190 S Ind and is the answer not in the manual?

Questions and answers