Table of Contents

Advertisement

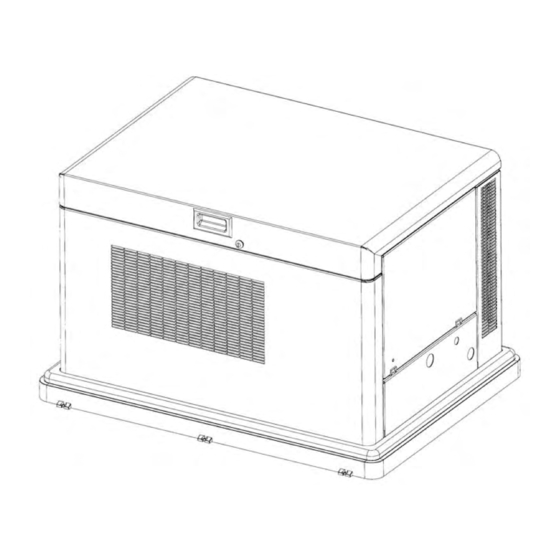

Stationary Standby Electric Generator - 11,200 WATTS - MODEL PM401211

Stationary Standby Electric Generator - 9,7 00 WATTS - MODEL PM400911

IMPORTANT SAFETY INSTRUCTIONS – Please make certain that persons who are to install, operate and maintain

this equipment thoroughly read and understand these instructions prior to operation. SAVE THESE INSTRUCTIONS

— This manual contains important instructions that should be followed during installation and maintenance of the

Generator and battery.

WARNING:

Read and understand all safety precautions in this manual and other

manuals included with this product before installing, operating and maintaining this

equipment. Failure to comply with instructions in this manual could result in personal

injury, property damage, and/or voiding of your warranty. Coleman Powermate WILL

NOT be liable for any damage because of failure to follow these instructions.

Record the model and serial numbers of your generator below:

© Coleman Powermate, Inc. 10-06

OWNERS MANUAL

MODELS: PM401211

AND PM400911

200-2341 - Revision C

Model Number

____________________

Serial Number

____________________

Date Purchased

____________________

Advertisement

Table of Contents

Summary of Contents for Powermate PM401211

- Page 1 Stationary Standby Electric Generator - 11,200 WATTS - MODEL PM401211 Stationary Standby Electric Generator - 9,7 00 WATTS - MODEL PM400911 IMPORTANT SAFETY INSTRUCTIONS – Please make certain that persons who are to install, operate and maintain this equipment thoroughly read and understand these instructions prior to operation. SAVE THESE INSTRUCTIONS —...

-

Page 2: Table Of Contents

Table of Contents ..............2 General Safety Instructions . - Page 3 The following information relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the following symbols. Please read the manual and pay attention to these sections. Also read and follow all safety labels on the engine/generator set. If labels are damaged or unreadable, contact product service for replacements.

- Page 4 WARNING: The National Electrical Code (NEC) requires the frame and external electrically conductive parts of the generator to be connected to an approved earth ground. Keep a fire extinguisher near the generator at all times. Extinguishers rated "ABC" by the National Fire Protection Association are appropriate for use on the standby electric system.

-

Page 5: Installation Planning

The stationary standby electric generator is manufactured for our customers to supply reliable backup power. The generator is a compact unit, designed to supply the power for your needs when utility power fails. The standby generator runs on Liquid Propane Vapor or Natural Gas allowing flexibility for getting the power you need. - Page 6 Proper location of the generator set is important to insure safe and reliable operation and can aid in the installation of the generator. When selecting a site for the generator, first ensure that the pad is outdoors in a well ventilated area to allow for proper cooling and proper removal of deadly exhaust fumes created during operation.

- Page 7 When connecting the generator to a building electrical distribution system, use of a transfer switch is recommended to isolate the normal utility source from the generator supply. By preventing backfeed of the generator power into the utility lines during a utility power outage, the switch provides a level of safety for electrical line workers.

- Page 8 Once installation planning is complete and all necessary local permits are granted, installation of the generator may begin. Within the following section general recommendations are given for installing the generator. However, installations are affected by local site conditions, regional construction practices, material availability, local or regional codes and/or other variables.

- Page 9 200-2341...

-

Page 10: Main Line Output Power

Once the generator is anchored in its final position, it is ready for electrical connections. The generator is supplied with two terminal blocks for connection of three distinct electrical circuits; main line output power, GFCI power input and remote start signal. Main line output power is the electrical output of the generator, GFCI input powers the battery charger and optional block heater devices and the remote start signal is the... -

Page 11: Generator Start Signal

A ground fault circuit interrupting (GFCI) receptacle is provided with the generator to power the battery charger for reliable starting. It is also intended to power an optional block heater if that option is desired. Connection of this circuit to a power supply that is only present when normal utility power is supplied is recommended. - Page 12 200-2341...

- Page 13 FUEL CONSUMPTION TABLE LP Vapor LP Vapor (ft 3/hr) (Gal/hr) PM401211 PM409011 All values reflect consumption at 100% rated output. Per the National Gas Code (NFPA 54 - ANSI 2223.1), a manual shutoff valve in the fuel supply line to the generator is recommended.

-

Page 14: Fuel Hookup

After electrical connections are complete, the next installation step is to connect a fuel supply to the unit. The fuel inlet fitting supplied with the generator is male ½" NPT and is located adjacent to a fuel access hole in the lower engine end panel as illustrated in Fig E. -

Page 15: Propane Vapor (Lpg)

Propane Vapor (LPG) In cases where liquefied propane vapor is selected as the fuel of choice, insure fuel delivery in the gaseous state, with a minimum energy content of 2500 BTU/ft 3 , at inlet pressures between 7" and 11" of water column (4 - 6 oz). - Page 16 To insure reliable starting in most weather conditions, it is important to properly match a battery to the requirements of the generator. The generator uses a 12 Volt, direct current, negative ground control system powered by an automotive style lead acid battery. Successful engine starting is dependent upon the cranking speed of the engine, which in turn is affected by the cranking capacity of the battery.

- Page 17 To install the battery, begin by placing the battery (A) into the battery rack as shown in Fig G. Orientation of the battery terminals is according to installer preference as the supplied battery cables are of adequate length to reach terminals regardless of battery direction. Secure the battery to the rack using the J-bolts (B), nuts (C) and battery strap (D) packed in the literature bag packed with the unit, as illustrated by Fig G.

- Page 18 After completing all installation procedures, read and understand the operating instructions for the generator controller. Know how the control panel operates, what to expect when activating control panel switches and how to shut the generator off in the event of an emergency. Before starting the generator for the first time, check off all items on the following list, then follow the given procedure to verify correct operation of the generator.

- Page 19 Oil Filter Air Filter (paper element) Spark plugs Spark plug gap Valve Clearance Intake Exhaust * Average @ 7 m 200-2341 PM401211 11.2 kW 9.5 kW 46.7 A 39.6 A 240 V 60 Hz Single 50 Amp -20°F to 104°F (-29°C to 40°C)

-

Page 20: Alternator

(100% load) Propane Vapor Natural Gas Min Energy Content Propane Vapor Natural Gas † Measured @ 30% instantaneous voltage dip PM401211 2 pole, brushless 3600 RPM Self regulated 12 sKVA † 0.30 – 0.50 W 1.4 – 1.6 W 5.9 – 6.0 W... -

Page 21: Electrical

Before installing, operating or maintaining the generator, take a few moments to become familiar with the features of the generator as illustrated. 1. CONTROL PANEL Controls the operation of the generator and communicates system status. 2. MAIN LINE CIRCUIT BREAKER Protects generator and connected loads from electrical faults. - Page 22 A standby generator is an engine driven air cooled system to convert the energy contained in either liquid propane vapor or natural gas to electrical power. When coupled with an automatic transfer switch to monitor for failure of utility power, the unattended system can start, stop and transfer between sources to insure a nearly seamless supply of power.

- Page 23 Two methods are available to start the generator. The automatic, or AUTO mode is for use with an automatic transfer switch. With the control panel mode switch set to this position, the generator waits for an external signal to start. This signal is supplied by the transfer switch when utility power is of unacceptable quality.

- Page 24 Status indicator lights relay conditions of generator function for user or service technician convenience. Illumination of these indicator lights communicate conditions that require generator service but are not severe enough to cause damage if the generator is allowed to operate. Contact a qualified service technician immediately for service if any of the listed lights are lit, even if the generator appears to function normally.

-

Page 25: Generator Operation

To ensure reliable generator operation, it is critical to periodically inspect all components. The following chart is provided as a guide for service check intervals. When the generator is operated under excessively hot, or dusty conditions, shorten service intervals according to the severity of the conditions encountered. - Page 26 W W A A R R N N I I N N G G • Before performing any maintenance, make sure the Mode switch is in the OFF position, the circuit breaker is in the OFF position and the positive (red) battery cable is disconnected. •...

- Page 27 Selection of the correct grade and type of engine oil greatly affects the performance of the generator, especially when starting. Before selecting replacement oil for an oil change, consider the anticipated operating conditions the generator may be exposed to. Choose the appropriate weight of oil for anticipated temperatures from Chart C.

- Page 28 The generator engine is equipped with a dry element air filter to block particles in the combustion air from getting into the engine and causing excessive engine wear. Over time this dirt builds-up on the filter, restricting the amount of combustion air available to the engine, in turn leading to a loss of generator power output.

- Page 29 5. Insure the the battery charger is powered and functioning properly. A correctly operating battery charger displays lights on the face of the charger to relay the state of the charger. To locate the battery charger (A) and check the lights (B) (see note below) refer to Fig F.

- Page 30 Engine spark plugs are an important part of the engine ignition system. Worn or incorrectly adjusted spark plugs can negatively affect engine starting and operation. Therefore, it is important to inspect and regap, or replace the engine spark plugs as indicated in the service interval table.

- Page 31 In some areas of the United States, a USDA Forest Service approved exhaust spark arrestor is legally required. This optional accessory is added to the generator during initial installation. To identify whether the generator is equipped with a spark arrestor, inspect the exhaust tailpipe opening for a screen.

- Page 32 Proper cooling of the generator is vital to maintain performance and prevent equipment failure. Blocked cabinet openings or other airflow obstructions are potential fire hazards and can cause failures. Periodically inspect generator cabinet openings and the engine oil cooler for blockages. Do not allow leaves, grass, dirt, snow or other objects to build up around the cabinet.

- Page 33 Over time, normal engine operation leads to wear in the engine valve train which decreases generator output. To restore generator output, it is necessary to check and adjust the engine valve lash at regular intervals throughout the life of the engine. However, proper valve lash adjustments require specialized training and tools.

- Page 34 SYMPTOM Engine does not crank Loose battery cables Defective battery Improper battery charger function • Ensure charger is plugged into GFCI Fault in starter signal circuit Blown control circuit fuse Engine cranks without starting Low battery Poor fuel supply Engine starts then Low oil pressure immediately shuts down High engine temperature...

-

Page 35: Shutdown

SYMPTOM Low generator output voltage Low engine speed Excitation capacitor failure Generator diode or varistor failure • Contact a qualified generator dealer for service Overspeed light stays lit Shutdown due to high engine speed Underspeed light stays lit Shutdown due to low engine speed Overcrank light stays lit Failure to start... - Page 36 Item Part No Description Screw, 10-16 x .50” lg Star washer, #10 Rivet Not replaceable Label, hot, stamped steel 115-0262 Cover, muffler (includes items 3, 4, 6 & 7) 094-0069 Insulation 094-0073 Insulation Nut, 5/16-18 0056767 Clamp, saddle (includes (2) item 019-0214 Exhaust manifold muffler, Honda Nut, 1/4-20, Nylon stop...

- Page 37 Item Part No Description Screw, 10-16 x .50” lg Star washer, #10 115-0264 Side panel, left side (includes item 16) S115-0242 Prop arm, lid S115-0240 Lid assembly, complete (see page 38 for separate parts) 115-0265 Panel, back (includes items 11 & . 115-0266 Access panel, top portion (includes items 13, 14 &...

- Page 38 Item Part No Description 0056765 Lock (includes 1A, 1B, 1C & 1D) 146-0023 Order item # 1 Washer Order item #1 Bolt Order item #1 0056761 Handle S115-0251 Lid weldment (order S115-0240 for complete lid assembly) Nut, 10-32 0056766 Lock, hooked pawl 114-0571 Bracket, lid stop 0058221...

- Page 39 Torque to 15 lbs-ft Item Part No Description 0056629 Discharge louvered cover 0056623 Engine adapter 160-0311 Rotor assembly 100-0003 Diode/varistor assembly 059-0348 Rotor bolt 160-0312 Stator assembly 166-0133 Capacitor, 40F, 500V 077-0168 Terminal box cover 098-2827 Warning label 200-2341 ITEM 10 ITEM 11 Item Part No...

- Page 40 Detail A Item Part No Description 094-0091 Insulation 115-0268 Panel, left side (includes item 1) Screw, 10-32 x .50” lg Bolt, 5/16 NC x 1.25” lg Lock washer, 5/16” Washer, 5/16” 160-0309 Generator assembly Bolt, 3/8-16 x .75” lg Bolt, 5/16 NC x 1.50” lg Lock washer, 5/16”...

- Page 41 These are standard parts available at your local hardware . store. Torque to 8.5 lbs-ft Torque to 15 lbs-in Description Regulator assy, GX670 (PM401211) Regulator assy, GX620 (PM400911) Bolt, 1/4-20 x 1.75” lg Oil cooler Bolt, 1/4-20 x .63” lg Bracket, oil cooler Hose, high temp oil, 3/8”...

- Page 42 These are standard parts available at your local hardware store. Torque to 10 lbs-in Torque to 15 lbs-in Description Circuit breaker, 50 Amp, 120/240V (PM401211) Circuit breaker, 45 Amp, 120/240V (PM400911) Circuit breaker mount Control panel label, CP200 Wire harness...

- Page 43 Item Part No Description Nut, 1/4-20 S114-0563 Bracket, battery hold down 026-0480 Battery cable, positive 026-0481 Battery cable, negative Battery, BCI Group 26 or 26R 059-0344 J-bolt, 1/4-20 S115-0229 Battery shelf 0057024 Battery standoff, rubber Bolt, 1/4-20 x .625” lg Screw, 1/4-20 x 1”...

- Page 44 200-2341...

- Page 45 200-2341...

-

Page 46: Maintenance

Your Coleman PowerStation™ emergency back up power system generator has been manufactured to stringent guidelines & standards for years of dependable operation & service. Coleman Powermate warrants this product to the original consumer against defects in material and workmanship for a period of 3-Years or 1500 hours, whichever occurs first, from the date of purchase and is not transferable. - Page 47 Incluso los equipos de calidad como el generador de emergencia Coleman Powermate que ha comprado necesitan ocasionalmente piezas de repuesto para mantenerlos en buenas condiciones a través de los años.

- Page 48 200-2341...

Need help?

Do you have a question about the PM401211 and is the answer not in the manual?

Questions and answers