Subscribe to Our Youtube Channel

Summary of Contents for vanEE 6LC

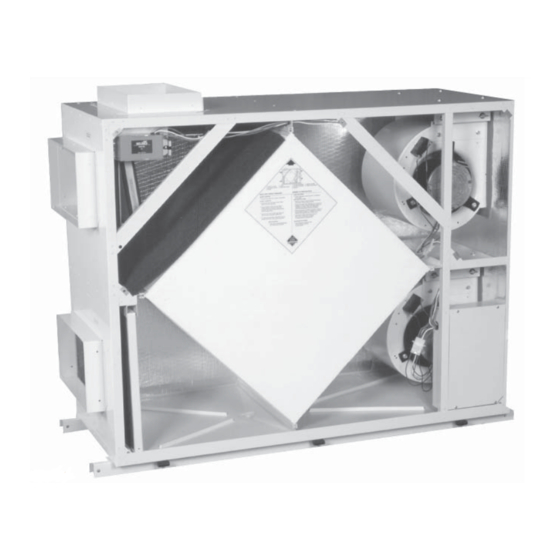

- Page 1 Light Commercial Heat Recovery Ventilators and Energy Recovery Ventilators Installation, Operation and Service Instructions VB0002 VB0003 6LC, V6LC 7000 VB0001 12LC, V12LC 207428 rev. 12...

-

Page 2: Table Of Contents

Appendix E - Terminal Control Diagrams ..........18-19 Appendix F - Control Box Assembly 6LC, V6LC, 12LC and V12LC ......19 Appendix G - Make-up Heat Requirements . -

Page 3: Installation

Appendix C. NOTE: All ports on the 6LC, V6LC, 12LC and V12LC units have 1” (25 mm) flanges to facilitate the installation of the ductwork. Please note These units have minimum clearance requirements when that the “Fresh Air from Outdoors”... -

Page 4: Exterior Hoods

• Power connected, occupied timer/sensor connection open 8.65 6.63 13.4 (unoccupied mode) - Both fans are off, defrost damper closes fresh air from outdoors. For 6LC, V6LC, 12LC and V12LC units 12.5 9.13 only, if equipped with recirculation module, the internal defrost damper opens recirculation opening. -

Page 5: Defrost

The unit functions are controlled by integrated controls in the unit WARNING which may include Exhaust Only Defrost or Recirculation Defrost (via the recirculation module - 6LC, V6LC, 12LC and V12LC units Disconnect power before maintaining unit. only). In cold temperatures, defrost cycles will remove frost from the heat recovery core to maintain good operation. -

Page 6: Annual Maintenance

6LC, V6LC/12LC, V12LC units ONLY: (CAUTION: 120 VAC) Check for 120 volt output across the WHITE/BLACK wires. If 120 volts SERVICE CONNECTOR can be measured at the motor, replace the motor. -

Page 7: Service Parts

Core Defrost Actuator 6LC, V6LC-12LC, V12LC Relay SPDT 120 VAC, 1 HP, Core Defrost Actuator 12LC, V12LC, Powder 500025914 63341 30 A @ 120 VAC, 6LC, V6LC, 12LC, V12LC Coated Relay DPST 120 VAC, 1 HP, 63327 Core Damper 6LC, V6LC... -

Page 8: 6Lc, V6Lc-12Lc, V12Lc Recirculation Defrost

63352 6LC, V6LC, 12LC, V12LC 6LC, V6LC, 12LC, V12LC (Recir. Defrost Option) 202798 Door Assembly 6LC, V6LC, 12LC, V12LC Fuse 0.25 A, 250 V Time Delay 1.25" MDL 6LC, 066176 V6LC-12LC, V12LC (Recirc. Defrost Option) Door Assembly 12LC, V12LC 63343... -

Page 9: Service Parts

202790 1804103P Door Ass’y 7000 (Powder Coated option) 7000 027123 Anti-vibration Bushing 7000 (unitary) 1808130 PCB Electronic 6LC, V6LC, 12LC, V12LC, 7000 Hanger Strap 18" Kit 6LC, V6LC, 12LC, 202382 Thermistor 6LC, V6LC, 12LC, V12LC, 7000 63344 V12LC, 7000 63117 Transformer 7000 * Not Shown. -

Page 10: Appendix A - Mounting Diagrams

Appendix A MOUNTING DIAGRAMS 6LC, V6LC, 12LC AND V12LC UNITS NOTE: Diagrams show standard unit configuration. Reinforced For units with the reversed door option, the Rubber Strap door will be located here. Recirculation Module 3/8" (10mm) (Factory Installed) Threaded Rod... -

Page 11: Appendix B - Unit Dimensions

Appendix B UNIT DIMENSIONS B-1: 6LC AND V6LC (WITHOUT RECIRCULATION MODULE) - Page 12 Appendix B (cont’d) UNIT DIMENSIONS B-2: 6LC AND V6LC WITH RECIRCULATION MODULE (FACTORY INSTALLED)

- Page 13 Appendix B (cont’d) UNIT DIMENSIONS B-3: 12LC AND V12LC (WITHOUT RECIRCULATION MODULE)

- Page 14 Appendix B (cont’d) UNIT DIMENSIONS B-4: 12LC AND V12LC WITH RECIRCULATION MODULE (FACTORY INSTALLED)

- Page 15 Appendix B (cont’d) UNIT DIMENSIONS B-5: 7000...

-

Page 16: Appendix C - Balancing Dampers Position

Appendix C BALANCING DAMPERS POSITION 6LC, V6LC, 12LC AND V12LC Gravity Backdraft Damper (for recirculation defrost option only) Reverse Door Option Min.12" (305 mm) Exhaust Air to Outdoors Min. 8" (203 mm) (Optional) Canvas Vibration Isolator Fresh Air From Outdoors... -

Page 17: Appendix D - Drain Connections

Appendix D DRAIN CONNECTIONS 6LC, V6LC, 12LC AND V12LC Plastic drain fitting Min. 3” Min. 3” [76 mm] [76 mm] 3/4” NPT coupler To drain Min. 4” Min. 1” [102 mm] [25 mm] Min. 4” Min. 1” [102 mm] [25 mm]... -

Page 18: Appendix E - Terminal Control Diagrams

1. Slide Switch Wall Control with fan switch and dehumidistat two terminals adjacent to the exhaust fan outlet (or adjacent to the control (for 6LC, V6LC, 12LC and V12LC units) supply fan outlet on the 7000 unit). All field installed wiring must be 2. -

Page 19: Appendix F - Control Box Assembly 6Lc, V6Lc, 12Lc And V12Lc

(ex. thermostat) to prevent outputs. interconnection of Class 2 interconnection of Class 2 outputs. outputs. VE0314A VE0005A Appendix F CONTROL BOX ASSEMBLY 6LC, V6LC, 12LC AND V12LC Remote control access plate Remote wiring terminal block Control box Unit cabinet Control cover plate VE0001A... -

Page 20: Appendix G - Make-Up Heat Requirements

Appendix G MAKE-UP HEAT REQUIREMENTS 6LC, V6LC AND 7000 12LC AND V12LC... -

Page 21: Appendix H - Wiring Diagrams

Appendix H WIRING DIAGRAMS 6LC, V6LC,12LC & V12LC - Exhaust Defrost - Normal Low Speed CONTROL from 1012 BOARD 1000 1020 MAIN 120 VAC UCB1021 EXT. CAP1001 POWER PJ1001A 5 μF PJ1001 CR1026 PJ1001B BK/Y BK/Y 1001 1021 from 1013... -

Page 22: Wiring Diagrams

Appendix H (cont’d) WIRING DIAGRAMS 6LC, V6LC, 12LC & V12LC - Recirculation Defrost - Normal Low Speed PJ1027 BK/Y CONTROL from 1012 MAIN BOARD CAP1001 1000 to 2029 1020 120 VAC POWER EXT. UCB1021 5 μF SUPPLY ON PJ1001 CR1026... - Page 23 Appendix H (cont’d) WIRING DIAGRAMS 6LC, V6LC, 12LC & V12LC - Recirculation Defrost - Normal Low Speed ( cont’d UNIT CONTROL BOX ADDER CONTROL BOX NOTE: Written numbers on CR2028 relay may differ from the ones shown, but the relay orientation must be the same as illustrated.

- Page 24 Appendix H (cont’d) WIRING DIAGRAMS 7000 - Recirculation Defrost CONTROL from 1001 1000 CAP1001 1020 BOARD SPLITTER BLOCK 120 VAC UCB1021 5 μF TB1001 PJ1001 W/BL 1001 1021 BN/W to 1020, 2023 USE COPPER from 1024 to 1008 from 2008 CONDUCTORS 120 VAC LOW SPEED...

- Page 25 Appendix H (cont’d) WIRING DIAGRAMS 7000 - Recirculation Defrost ( cont’d CONTROL BOX BOM TAGS QTY. DESCRIPTION CR1029 DPDT 120 VAC 1/2 ELAY CR1030 15 A @ 120 VAC 0.5 A USE HOLDER FU2023 FLUSH MOUNT UCB1021 PC B OARD XF2024 RANSFORMER R2004...

-

Page 26: Appendix I - Troubleshooting

Appendix I TROUBLESHOOTING SYMPTOMS POSSIBLE CAUSES SOLUTIONS Inside air is too dry Over ventilation - speed setting too high Adjust speed setting Dehumidistat setting is too low Set dehumidistat control in a higher position (if applicable) Persistent condensation on windows, walls, Improper adjustment of dehumidistat Adjust dehumidistat control knob to a lower ceilings, etc.

Need help?

Do you have a question about the 6LC and is the answer not in the manual?

Questions and answers