Summary of Contents for KNF RC600

- Page 1 Rotary evaporator RC600 Operating instructions Before operating the rotary evaporator and the accessories, please read the operating instructions on the web site (www.knf.com/downloads) and pay attention to the safety precau- tions!

- Page 2 KNF Neuberger AG Stockenstrasse 6 8362 Balterswil, Switzerland Tel +41 (0)71 973 993 0 Fax +41 (0)71 973 993 1 www.knf.com...

-

Page 3: Table Of Contents

Operating Instructions RC600 EN Contents Contents Page General information ................4 Information about the instructions Warnings Symbols Disclaimer of liability Manufacturer's address Year of manufacture Other applicable documents Copyright Warranty conditions Use ......................8 Intended use Improper use Safety ....................10 Technical data ................... -

Page 4: General Information

General information Operating Instructions RC600 EN 1 General information 1.1 Information about the instructions Contents The operating instructions contain important information on how to use the rotary evaporator In order to ensure safe working and proper functioning it is essential to observe all the specified safety precautions. -

Page 5: Warnings

Operating Instructions RC600 EN General information 1.2 Warnings Warnings in the operating instructions are identified with the dan- ger symbol, keywords and colours. These provide an indication of the extent of the danger. DANGER Indicates a dangerous situation which will lead directly to death or serious injury if it is not avoided. -

Page 6: Symbols

General information Operating Instructions RC600 EN 1.3 Symbols The following symbols appear in the operating instructions, on labels on the device, and on its packaging: WARNING Risk of injuries and property damage caused by illegible labels The labelling on the device may become illegible with time. -

Page 7: Disclaimer Of Liability

Operating Instructions RC600 EN General information 1.4 Disclaimer of liability In preparing the contents of these operating instructions, ac- count has been taken of applicable regulations and the state of the art. The manufacturer can accept no liability for any damage or malfunctions caused by failure to follow the operating instruc- tions. -

Page 8: Use

Operating Instructions RC600 EN 2 Use 2.1 Intended use The RC 600 rotary evaporator is designed for use in chemical, pharmaceutical and biological laboratories. It is intended solely to separate solutions (distillation, drying, recovery, extraction, etc.). Make sure that the installation location is dry and the rotary evaporator is protected against water in the form of rain, spray, splashes and drips. -

Page 9: Improper Use

Operating Instructions RC600 EN 2.2 Improper use The rotary evaporator may not be used in potentially explosive atmospheres. The rotary evaporator may not be used in a corrosive environ- ment. The heating bath of the rotary evaporator may not be used to warm food. -

Page 10: Safety

Consider any external sources of energy, such as sources of radiation, that could additionally heat the medium. In case of doubt, consult KNF customer service. Proper handling of the initial and resulting substances / heating and cooling media must be ensured. - Page 11 Housing parts with live parts may be opened by trained per- sonnel only. Use only genuine parts from KNF for servicing work. Glass breakage Take special care with glass parts. Carry out a visual inspection on glass parts before each use.

-

Page 12: Technical Data

Technical data Operating Instructions RC600 EN 4 Technical data 4.1 Rotary evaporator Materials for parts in contact with the medium Glass parts Borosilicate glass Vapour tube seal PTFE compound Refilling valve's fitting* Fitting seal Silicon Plug seals PTFE-coated Coolant line materials... - Page 13 Operating Instructions RC600 EN Technical data Evaporation flask parameters Evaporation flask size 50 - 3000 ml Speed [rpm] 25 - 280 Vertical travel [mm] Lifting speed [mm/s] approx. 38 Angle of inclination [°] 12 - 45 General Total weight [kg]...

-

Page 14: Equipment Delivered With Rc 600

Technical data Operating Instructions RC600 EN 4.2 Equipment delivered with RC 600 Rotary evaporator Glass set, comprising: Vapour tube Chilled condenser Collecting flask, 1000 ml Bracket for collection flask Evaporation flask, 1000 ml Heating bath Set of hose fittings 1x Hose fitting ID8 (vacuum) -

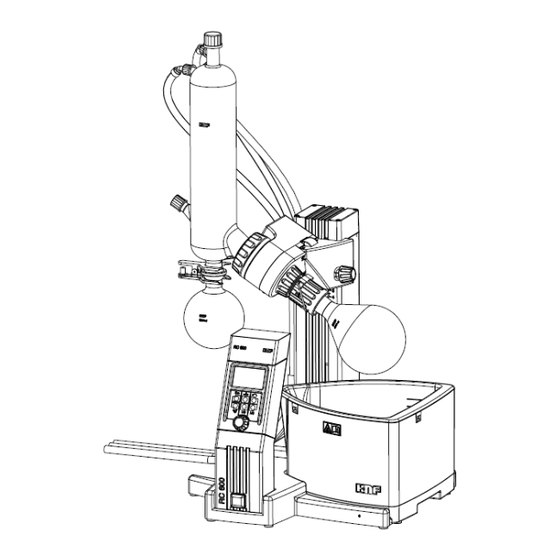

Page 15: Components And Functions

Operating Instructions RC600 EN Components and functions 5 Components and functions 5.1 Components of the rotary evaporator Power switch Terminal 7 8 9 10 Collection flask (coated) Flask clamp for 3 Refilling connection Chilled condenser Tension nut for chilled condenser... -

Page 16: Rotary Evaporator Functions

Components and functions Operating Instructions RC600 EN The RC 600 rotary evaporator is designed for distillation and evaporation of solutions. The rotary evaporator is operated via the terminal (Fig. 1/2, p. 15). The solution that is to be evaporated is located in the evapora- tion flask (13). -

Page 17: Terminal

The USB Connection (Fig. 1/19) is used for technical service and software update. The current software version is dis- played shortly once the RC600 is turned on. Consult with your KNF provider for the latest software version. Translation of original Operating and Installation Instructions, English, BA_RC600_EN_304763_20170608.docx 17... -

Page 18: Setup And Connection

Setup and connection Operating Instructions RC600 EN 6 Setup and connection Connect the rotary evaporator only under the operating pa- rameters and conditions described in Chapter 4 Technical data (pages 12 + 13). Observe all information about the device's intended use and safety precautions (see Chapter 2 and 3, page 8ff). - Page 19 Operating Instructions RC600 EN Setup and connection Connected Attach to the rotary evaporator only components that are de- signed for the rotary evaporator's pneumatic data and/or cool- components ant-supply parameters (see Chapter 4 Technical data). Installing the heating bath Place the included heating bath (Fig. 1/14, p. 15) onto the base connector.

- Page 20 Setup and connection Operating Instructions RC600 EN - - - - Tighten tension nut —— Use chilled condenser to aid in fully tightening the tension nut Fig. 4: Fully tightening the tension nut Attach coolant hoses (Fig. 5/2 and 3) to the condenser or fill the dry ice condenser with dry ice.

- Page 21 Operating Instructions RC600 EN Setup and connection NOTE When installing the hoses, make sure that they are sufficiently long for the entire stroke distance. Vacuum - black Coolant inlet - blue Coolant outlet - red Fig. 5: Attaching lines for coolant and vacuum The chilled condenser is now fastened to the rotary evaporator.

- Page 22 Setup and connection Operating Instructions RC600 EN Removing the chilled con- Requirements: denser Loosen hoses Remove collection flask (see below) Loosen tension nut (7) until the chilled condenser can be pulled out. NOTE When loosening the tension nut, grasp the chilled condenser with your other hand and use it as a lever (refer to Fig.

- Page 23 Operating Instructions RC600 EN Setup and connection Installing the evaporation flask Install the included evaporation flask (Fig. 1/13, page 15): WARNING Risk of injury from glass splinters, chemical reactions (sol- vent with heating medium), solvent, and hot liquids. The evaporation flask may slide down during installation and become damaged (glass breakage).

- Page 24 Setup and connection Operating Instructions RC600 EN WARNING Personal injury by hazardous materials The content of the evaporation flask may be a hazardous material. Additionally, mixing with the heating medium may produce haz- ardous materials. Observe all safety regulations and disposal requirements for the solvent! 1.

- Page 25 Operating Instructions RC600 EN Setup and connection Adjusting the immersion WARNING depth of the evaporator flask Risk of injury from glass splinters, chemical reactions (sol- vent with heating medium), solvent, and hot liquids. Evaporation flask and flask nut may collide with the wall or base of the heating bath during lowering and become damaged (glass breakage).

- Page 26 Setup and connection Operating Instructions RC600 EN Installing protective cover NOTE (accessory) If the rotary evaporator is not operated under a fume hood (heat- ing temperature no more than 90°C), then installation of the protective cover on the heating bath is mandatory for protection...

- Page 27 Operating Instructions RC600 EN Setup and connection Fig. 7: Protective cover closed The walls of the protective cover are transparent, permitting observation of events inside the evaporator flask. It also has a flap (Fig. 8/1) that permits rapid access to the evaporator flask.

-

Page 28: Connections

Setup and connection Operating Instructions RC600 EN 6.2 Connections Connect the suction side of the vacuum pump to the vacu- um connection (Fig. 5/1, page 21). NOTE Use a vacuum hose for this purpose. NOTE Safely divert gas emissions (from the pump) so no gases escape into the ambient air. -

Page 29: Operation

Operating Instructions RC600 EN Operation 7 Operation 7.1 Initial start-up Before switching on the rotary evaporator, check the following points: Prerequisites for start-up All hoses attached properly Specifications of the power supply correspond with the data on the rotary evaporator’s type plate... - Page 30 Operation Operating Instructions RC600 EN Filling heating bath WARNING Risk of burns from hot media. Hot vapours may be produced when filling the heating bath. Ensure that the heating bath temperature is always lower than the boiling temperature of the medium.

- Page 31 Operating Instructions RC600 EN Operation Fill heating bath with heating medium. WARNING Risk of burns from hot surfaces. If the heating bath is not sufficiently filled, the base of the bath in particular may overheat. Ensure that the heating bath contains sufficient heating medium at all times and that it does not run dry through evaporation during operation.

-

Page 32: Shutdown

Operation Operating Instructions RC600 EN 7.2 Shutdown Stop the current process. Ventilate rotary evaporator WARNING Risk of personal injury from poisoning or explosion and damage to the rotary evaporator. Ventilation of the rotary evaporator may result in poisonous or explosive mixtures. -

Page 33: Operating The Rotary Evaporator

Operating Instructions RC600 EN Operating the rotary evaporator 8 Operating the rotary evaporator 8.1 Terminal 8.1.1 General functions and displays Rotary knob for: Entering setpoints: Heating tempera- ture Rotation Fine adjustment of immersion depth Button to lower lift Button to raise lift... - Page 34 Operating the rotary evaporator Operating Instructions RC600 EN Displays Heating bath status display Heating bath setpoint Selection icon for heating bath Actual value of heating bath Unit of temperature Icon for digital end point Set digital end point Selection icon / status...

- Page 35 Operating Instructions RC600 EN Operating the rotary evaporator 8.1.2 Operation Base settings When the rotary evaporator is switched on, a start screen is displayed for 2-5 seconds with the logo and version number of the firmware. a) Activate/deactivate electronic monitoring of the protective...

- Page 36 Operating the rotary evaporator Operating Instructions RC600 EN Entering setpoints The following setpoints may be selected through the mem- brane keyboard: Setpoint Input field * Function range 1 - 4 (+ Rotary knob) Immersion depth 0…12.9 2 + Rotary knob Speed [rpm] 25…280...

-

Page 37: Change The Evaporation Flask

Operating Instructions RC600 EN Operating the rotary evaporator Exchange flask function WARNING Risk of injury from glass splinters, chemical reactions (sol- vent with heating medium), solvent, and hot liquids. When using the "Exchange flask" button, any changes to the size or shape of the evaporation flask may cause the flask to collide with the heating bath tank or other parts. -

Page 38: Servicing

Servicing Operating Instructions RC600 EN 9 Servicing If you have any questions about servicing, call your KNF tech- nical adviser (see last page for contact telephone number). 9.1 Servicing schedule Component Servicing interval Rotary evaporator Inspect regularly for external damage or... - Page 39 Operating Instructions RC600 EN Servicing Evaporation flask 1. Remove evaporation flask (see Ch. 6.1). 2. Dispose of contents in evaporation flask according to local regulations. 3. Rinse evaporation flask with suitable cleaning agent. 4. Re-install evaporation flask (see Ch. 6.1).

-

Page 40: Changing Vapour Tube

Servicing Operating Instructions RC600 EN 9.3 Changing vapour tube Requirements Rotary evaporator disconnected from mains power and de-energised Heating bath empty Evaporation flask removed (see Ch. 6.1). Rotary evaporator free of hazardous materials Rotary evaporator must be ventilated Protective cover removed (if present) - Page 41 Operating Instructions RC600 EN Servicing NOTE Finding the engagement point may also be easier when the con- denser is removed (see Ch. 6.1). 5. Lightly tighten the vapour tube's tension nut (3). NOTE While doing this, press and hold the block for the rotation drive (4).

-

Page 42: Changing Seal

Servicing Operating Instructions RC600 EN 9.4 Changing seal Remove chilled condenser (see Ch. 6.1). Remove vapour tube (see Ch. 9.3). Remove old seal (see Fig. 13). Re-install vapour tube (see Ch. 9.3). Slide the new seal (see Ch. 12.1 "Spare parts") onto the vapour tube. -

Page 43: Changing Fuses

Operating Instructions RC600 EN Servicing 9.5 Changing fuses Requirements Rotary evaporator disconnected from mains power and de-energised Heating bath empty Rotary evaporator free of hazardous materials CAUTION Danger of burns from hot parts Glass parts and the heating bath may be hot even after the rotary evaporator has been shut off. -

Page 44: Troubleshooting

Troubleshooting Operating Instructions RC600 EN 10 Troubleshooting DANGER Risk of electric shock, danger of death Separate the rotary evaporator from the power supply before working on the rotary evaporator. Make sure that the pump is de-energised. Rotary evaporator generally: see Tab. - Page 45 Operating Instructions RC600 EN Troubleshooting The rotary drive does not Flask drive blocked by Remove foreign parts. reach the selected speed foreign parts. or does not move. The wrong speed setpoint Correct the setpoint has been selected. (see Ch. 8.1.2, page 35).

- Page 46 Determine cause of error and remove NOTE If you are unable to determine the cause of the error, call your Fig. 16: Resetting the heating KNF technical adviser (see last page for telephone number). bath's circuit breaker Reset circuit breaker NOTE Use a pointed object such as a pencil or a pointed tool to press the button on the underside of the heating bath (see arrow in Fig.

- Page 47 Tab. 6: Error message Fault persists If you are still unable to diagnose the problem, please send the rotary evaporator to KNF customer service (see address on last page). 1. Clean rotary evaporator, heating bath, and any parts that come into contact with the medium (see Chapter 9.2, page 38ff).

-

Page 48: Solvent Library

Solvent library Operating Instructions RC600 EN 11 Solvent library Solvent Formula Molar Evaporation Boiling point at Density Vakuum benö- mass enthalpy [J/g] 1013mbar [°C] [g/cm tigt für Siede- [g/mol] punkt von 40°C Aceton 58.1 0.790 Acetonitril 41.1 0.786 n-pentanol 88.1 0.814... - Page 49 Operating Instructions RC600 EN Solvent library Solvent Formula Molar Evaporation Boiling point at Density Vakuum benö- mass enthalpy [J/g] 1013mbar [°C] [g/cm tigt für Siede- [g/mol] punkt von 40°C trichlormethan Tetrachlor- 165.8 1.623 ethen THF (tetrahy- 72.1 0.889 drofuran) Tuelene 92.2...

-

Page 50: Spare Parts And Accessories

Spare parts and accessories Operating Instructions RC600 EN 12 Spare parts and accessories 12.1 Spare parts Spare part Order No. Seal 113046 Mains cable D 026363 Mains cable CH 027523 Mains cable UK 129326 Mains cable USA/JP 127875 ® Norprene... -

Page 51: Glass Product

Operating Instructions RC600 EN Spare parts and accessories 12.3 Glass product Glass product Order No. Collection flask (coated) 100 ml 300557 250 ml 300558 500 ml 128158 1000 ml 113939 2000 ml 113938 Evaporation flask NS29/32 50 ml 113079 100 ml... -

Page 52: Returns

Declaration of No Objection and Decontamination. For optimal processing of a return, a copy of this declaration should be sent in advance via e-mail, regular mail, or fax to KNF Customer Service (refer to final page for address). In order to avoid... -

Page 53: Declaration Of No Objection And Decontamination

Operating Instructions RC600 EN Declaration 14 Declaration of No Objection and Decon- tamination Translation of original Operating and Installation Instructions, English, BA_RC600_EN_304763_20170608.docx... - Page 55 KNF worldwide Netherlands United Kingdom Sweden, Denmark, Finland, Norway KNF Verder B.V. KNF Neuberger U.K. Ltd. KNF Neuberger AB Utrechtseweg 4a Avenue 2 Mejerivägen 4, NL-3451 GG Vleuten Station Lane P.O. Box 44060 Tel. 0031 (0)30 677 92 40 Industrial Estate...

- Page 56 Declaration of No Objection and Decontamination KNF Flodos BA_RC600_EN_304763_20170608.docx Translation of original Operating and Installation Instructions...

Need help?

Do you have a question about the RC600 and is the answer not in the manual?

Questions and answers