Table of Contents

Advertisement

Quick Links

Download this manual

See also:

User Manual

Advertisement

Table of Contents

Summary of Contents for Keofitt W9

- Page 1 W9™ SAMPLING VALVE anUal S O M E P E O P L E W O U L D N ’ T G A M B L E W I T H T H E I R S A M P L E www.sks-online.com...

- Page 2 www.sks-online.com www.sks-webshop.com...

- Page 3 INTRODUCTION: MANUFACTURER Keofitt a/s, Lumbyvej 11H 5000 Odense C Denmark TYPE: W9 SAMPLING VALVE PATENTS: U.S. PAT. 5,246,204 • E.P. 0468957 YEAR OF INTRODUCTION: 1998 YEAR OF REVISED DESIGN: 2003 www.sks-online.com www.sks-webshop.com...

- Page 4 www.sks-online.com www.sks-webshop.com...

-

Page 5: Table Of Contents

Block diagram for welding to pipe and tank ......................15 Keofitt valve type P (pipe): ..............................15 Keofitt valve type T (tank): ..............................15 Keofitt valve type P (pipe connection vertical) Inline: .....................15 Block diagram for installation with Clamp,Varivent® and Thread ................. 16 Keofitt valve type Clamp connection: ..........................16 Keofitt valve type Varivent®: .............................16... - Page 6 www.sks-online.com www.sks-webshop.com...

-

Page 7: Presentation

The W9 valve is 3-A and EHEDG Type El authorised. 3-A Sanitary Standard is an American standard which is normative for a component’s ease of cleaning and sterilisation. The standard ensures optimum conditions for food products which may come into contact with the component in question. -

Page 8: Everyday Use Of The Valve

• Use saturated steam without condensation at max. 2 bar(g). At higher pressures the membrane can be damaged/split. In most cases the coaxial design ensures absolute cleanliness without the use of CIP or similar. If CIP is used, please refer to enclosed data sheet. If in doubt, contact Keofitt. IMPORTANT! •... -

Page 9: Technical Data

TECHNICAL DATA Material Valve body: AISI 316L (1.4404) Valve head: AISI 316L (1.4404) Membrane: Silicone (grey) EPDM (black) PTFE (white) Certificate Valve body: ® Membrane silicone acc. to FDA & BGA Membrane EPDM acc. to FDA & BGA Membrane PTFE acc. -

Page 10: Valve Bodies W9

VALVE BODIES W9 Hose piece Mini tri-clamp M16x1,5 Tank welding (type T) - process connection 850001 850006 850015 Key measurements (Please refer to bottom page 11!) Pipe welding (type P) - process connection 850011 850010 850016 Key measurements (Please refer to bottom page 11!) - Page 11 Hose piece Mini tri-clamp M16x1,5 Varivent® Ø50 - process connection OD Ø56 mm 850008 Key measurements (Please refer to bottom page 11!) Varivent® Ø68 - process connection OD Ø68 mm 850009 Key measurements (Please refer to bottom page 11!) Thread - Socket - process connection OD M28x1,5 850031 Key measurements (Please refer to bottom page 11!)

-

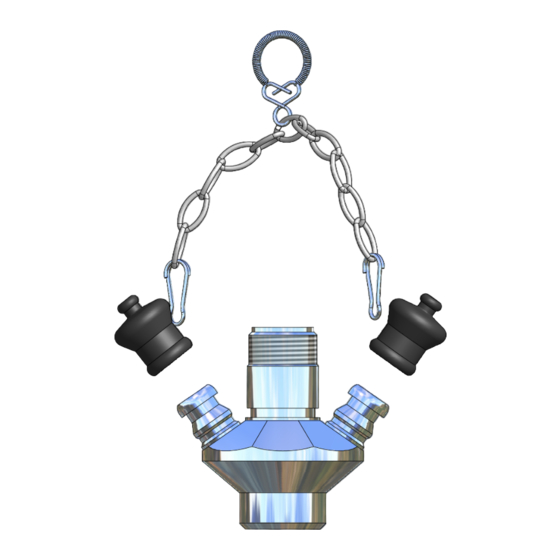

Page 12: Valve Heads For W9

VALVE HEADS FOR W9 Available with: Valve head item no. 600041 Type H, manually 600041E operated 855541 600042 Type K, manually 600042E operated key version 855542 600043 Type Q, manually 600043E operated with lever ... -

Page 13: Parts And Accessories For W9

PARTS AND ACCESSORIES FOR W9 Item Material Ident no. Remark Membrane EPDM black EPDM 600052 Membrane silicone grey Silicone 600051 Membrane EPDM black EPDM 600252 with Micro Port Membrane silicone grey Silicone 600251 with Micro Port Membrane teflon Teflon 850055... -

Page 14: Mounting Instructions

W9 valve welded onto a 2 mm 3” dairy pipe: 50-60 Amp. It should be noted that Keofitt can supply all P type valves welded onto a pipe section according to customer specifications. Flaring is thus avoided and only a girth weld is required. -

Page 15: Block Diagram For Welding To Pipe And Tank

Keofitt valve type T (tank): Welded to tank Welded to tank inside outside Keofitt valve type P (pipe connection vertical) Inline: Welded to pipe K E O F I T T U S E R M A N U A L P A G E www.sks-online.com... -

Page 16: Block Diagram For Installation With Clamp,Varivent® And Thread

BLOCK DIAGRAM FOR INSTALLATION WITH CLAMP,VARIVENT® AND THREAD Keofitt valve type Clamp connection: Keofitt valve type Varivent®: Keofitt valve type Thread: K E O F I T T U S E R M A N U A L P A G E www.sks-online.com... -

Page 17: Maintenance

MAINTENANCE The rubber membrane should be replaced every two months. PTFE membranes should be replaced every 12 months. In the event of intensive sterilisation and cleaning it may be necessary to replace it more frequently. For valve heads with Micro Port, approx. -

Page 18: Instructions On Replacing Ptfe Membrane

INSTRUCTIONS ON REPLACING PTFE MEMBRANE INSTRUCTIONS ON REPLACING PTFE MEMBRANE 1. Open valve. 2. Remove the valve head from the valve body. 3. Push the membrane upwards until the tool for membrane fi ts under it. 4. Insert tool for membrane, between the membrane and the bushing. 5. -

Page 19: Upgrade From Silicone To Ptfe Membrane

Ident no. Part name Material 600340 Lower stem for PTFE AISI 316L 850055 Membrane for W9 PTFE 600411 Spring H-Q-K 12 bar(g) St.St. K E O F I T T U S E R M A N U A L P A G E www.sks-online.com... -

Page 20: Upgrade From Silicone To Ptfe Membrane

• Do not use a hammer or any other hard material to mount the membrane. This can damage the membrane seal. UPGRADE KIT 854455 CONSISTING OF: Ident no. Part name Material 600345 Stem for W9 AISI 316L 850055 Membrane for W9 PTFE 850820 O-ring ø32... - Page 21 SILICONE MEMBRANE - ITEM NO. 600051 TECHNICAL SPECIFICATION • Type: Silicone • Colour: Grey • Resistance to chemicals acids/bases) Suitable • Food safe Yes (FDA*) • Temp. max. 130-250°C / 266-482°F • Steam pressure max. 2 bar/29 psi • Process pressure 1-6 bar/14-87 psi Keofi tt recommends to change the silicone membrane 4-6 times a year or as needed.

- Page 22 SILICONE MEMBRANE FOR MICRO PORT - ITEM NO. 600251 TECHNICAL SPECIFICATION • Type: Silicone • Colour: Grey • Resistance to chemicals acids/bases) Suitable • Food safe Yes (FDA*) • Temp. max. 130-250°C / 266-482°F • Steam pressure max. 2 bar/29 psi •...

- Page 23 EPDM MEMBRANE - ITEM NO. 600052 TECHNICAL SPECIFICATION • Type: EPDM • Colour: Black • Resistance to chemicals acids/bases) Very good • Food safe Yes (FDA*) • Temp. range 1-130°C / 34-266°F • Steam pressure max. 2 bar/29 psi • Process pressure 1-6 bar/14-87 psi Keofi tt recommends to change the EPDM membrane 4-6 times a year or as needed.

- Page 24 EPDM MEMBRANE FOR MICRO PORT- ITEM NO. 600252 TECHNICAL SPECIFICATION • Type: EPDM • Colour: Black • Resistance to chemicals acids/bases) Very good • Food safe Yes (FDA*) • Temp. max. 130-150°C / 266-302°F • Steam pressure max. 2 bar/29 psi •...

- Page 25 PTFE MEMBRANE - ITEM NO. 850055 TECHNICAL SPECIFICATION • Type: PTFE • Colour: White • Resistance to chemicals acids/bases) Excellent** • Food safe Yes (FDA*) • Temp. range 1-150°C / 34-302°F • Steam pressure max. 2 bar/29 psi • Process pressure 1-6 bar/14-87 psi 17.9 mm Keofi tt recommends to change the PTFE membrane once a year or as needed.

- Page 26 www.sks-online.com www.sks-webshop.com...

- Page 27 www.sks-online.com www.sks-webshop.com...

- Page 28 Keofitt reserves the right to change technical data without notice! For complete set of updated data sheets and manuals for Keofitt products please refer to our web page www.keofitt.dk www.sks-online.com www.sks-webshop.com...

Need help?

Do you have a question about the W9 and is the answer not in the manual?

Questions and answers