Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Eaton FS-4205A

- Page 1 Installation Guide Eaton PTO Information Guide TRIG2600 EN-US August 2017...

-

Page 2: Important Notice

Always use genuine Eaton replacement parts. Every effort has been made to ensure the accuracy of all information in this guide. However, Eaton makes no expressed or implied warranty or representation based on the enclosed information. -

Page 3: Table Of Contents

UltraShift AW3 Auto Neutral Feature ... . 34 to Eaton Transmission Harnesses ....73 UltraShift® PLUS and FA - PTO Inputs ... -

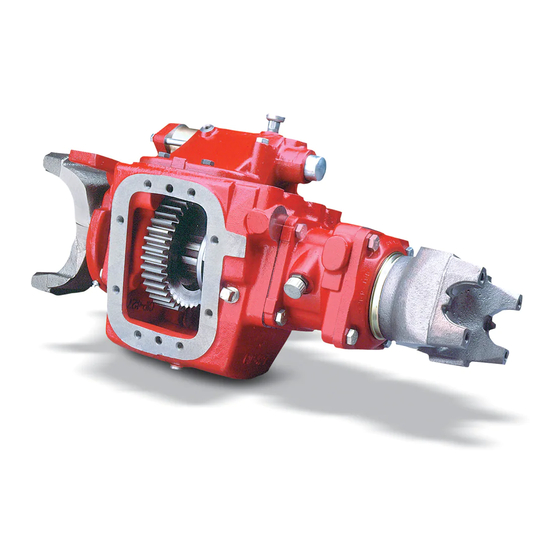

Page 4: Selecting The Right Pto

General Information Selecting the Right PTO There are a wide range of PTOs (Power Take-Off Units) available today, each ranging in design and features. This section will help the user understand every step that is required in understand what PTO will fit the customer's requirements. -

Page 5: Split Shaft (Chelsea)

General Information Split Shaft (Chelsea) • Used on medium-duty trucks that have applications requiring the torque capacity of an 8-Bolt PTO. • Provides 100% of input speed. • Mount in any orientation with the PTO shaft going to the front or rear of the truck. Designed for Class 3, 4, 5, and 6 trucks with automatic transmissions and no PTO opening or trucks ... -

Page 6: Split Shaft (Muncie)

General Information Split Shaft (Muncie) • Through torque to 21,600 lb-ft. • Output torque to 936 lb-ft. • 1410 or 1500 Series companion flange outputs. • 1500, 1600, 1700, 1800 Series main shaft flanges. • SAE “B”, “B-B”,”C”, “C-C” and “D” hydraulic mounts. •... -

Page 7: Geared Pto Adapters

PTO Adapters Geared PTO Adapters Chelsea 626 Series • Mounts a 6-Bolt PTO to a 6-Bolt transmission opening. • Moves the PTO straight out from the transmission. • Uses the same input gears as the 442 and 489 Series. • Uses the same mounting hardware and spacers used to mount a 442 Series to a specific application. - Page 8 PTO Adapters 630 Series • Mounts a 6-Bolt PTO to a 6-Bolt transmission opening. • Moves the PTO down at a 30° angle, helping to eliminate interference problems. • Uses the same input gears as the 442 and 489 Series. •...

-

Page 9: Muncie

PTO Adapters Muncie Single Gear Adapters • Moves the 6-Bolt PTO flange outward away from the transmission. Angular Adapters • Various angles available. • 55° adapter available for relocating high capacity inertia brake on heavy-duty Fuller® UltraShift transmis- sions. 8-Bolt to 6-Bolt Adapter •... -

Page 10: Angular Offset Gear Adapter

PTO Adapters Angular Offset Gear Adapter • Offered in multiple gearing configurations. • All adapters offered with a 10° offset. -

Page 11: Pto Configurations By Model - Manual

Info. shaft Spline Counter- Info. Engine Torque Limit for Info. Speed shaft PTO PTO use (lb-ft) Right FS-4205A 28 Teeth 6.1P & Left Right FS-4205B 28 Teeth 6.1P & Left R=33 Teeth Right L=44, FS-5205A 7.0P, L=19 Teeth 26 Teeth &... -

Page 12: Heavy-Duty Manual - Rt Series

PTO Configurations Heavy-Duty Manual Transmission - RT Series Model 8-Bolt Gear Info. 6-Bolt Gear Info. Thru- Int. Ext. Aux. Ext. % of Transmission shaft Spline Counter- Spline Engine Torque Limit for Info. shaft PTO Info. Speed PTO use (lb-ft) 33T 6.0P, 33T 6.0P, RT-6609A 20DEG A... -

Page 13: Heavy-Duty Manual - Rt Vocational

PTO Configurations Heavy-Duty Manual Transmission - RT Vocational Model 8-Bolt Gear Info. 6-Bolt Gear Info. Thru- Int. Ext. Aux. Ext. % of Transmission Shaft Spline Counter- Spline Engine Torque Limit for Info. shaft PTO Info. Speed PTO use (lb-ft) 47T 6.0P, 45T 6.0P, RT-8608L 20DEG PA... -

Page 14: Heavy-Duty Manual - Rt Performance

PTO Configurations Heavy-Duty Manual Transmission - RT Performance Model 8-Bolt Gear 6-Bolt Gear Info. Thru- Int. Ext. Aux. Ext. % of Transmission Info. Shaft Spline Counter- Spline Engine Torque Limit for Info. shaft PTO Info. Speed PTO use (lb-ft) 47T 6.0P, 45T 6.0P, RTLO-12913A 20DEG PA... -

Page 15: Heavy-Duty Manual - Fuller Advantage Series

PTO Configurations Heavy-Duty Manual Transmission - Fuller Advantage Series Model 8-Bolt Gear Info. 6-Bolt Gear Info. Thru- Int. Ext. Aux. Ext. % of Transmission Shaft Spline Counter- Spline Engine Torque Limit for Info. shaft PTO Info. Speed PTO use (lb-ft) FA-14810B 47T 6.0P, 45T 6.0P,... -

Page 16: Heavy-Duty Manual - Fr Series

PTO Configurations Heavy-Duty Manual Transmission - FR Series Note: (LL) Lower Left, (UR) Upper Right Model 8-Bolt Gear Info. 6-Bolt Gear Info. Thru- Int. Ext. Aux. Ext. % of Transmission Shaft Spline Counter- Spline Engine Torque Limit for Info. shaft PTO Info. - Page 17 PTO Configurations Model 8-Bolt Gear Info. 6-Bolt Gear Info. Thru- Int. Ext. Aux. Ext. % of Transmis- Shaft Spline Counter- Spline Engine sion Torque Info. shaft PTO Info. Speed Limit for PTO use (lb-ft) 47T 6.0P, 45T 6.0P, 32T 0.5P, FRO-13210C LL &...

-

Page 18: Heavy-Duty Manual - Auxiliary Transmissions

PTO Configurations Heavy-Duty Manual Transmission - Auxiliary Transmissions Model 8-Bolt Gear Info. 6-Bolt Gear Info. Thru- Int. Ext. Aux. Ext. % of Transmission Shaft Spline Counter- Spline Engine Torque Limit for Info. shaft PTO Info. Speed PTO use (lb-ft) 30T 5.0P, 30T 5.0P, AT-1202 20DEG PA... -

Page 19: Pto Configurations By Model - Automated

PTO Configurations PTO Configurations by Model - Automated PTO and Auto Neutral Availability Split Shaft PTO Countershaft PTO** Auto Neutral MD Hybrid Available (Default) Available (Default) UltraShift AW3 Available Available (Default) Available (Default) UltraShift HV Available (Default) AutoShift Available Available (Default) UltraShift DM3 Available (Default) Fuller Advantage... -

Page 20: Medium-Duty Automated

PTO Configurations Medium-Duty Automated Model 8-Bolt Gear 6-Bolt Gear Info. Thru- Int. Ext. Aux. Ext. % of Transmission Info. Shaft Spline Counter- Spline Engine Torque Limit for Info. Info. Speed shaft PTO PTO use (lb-ft) Left or 48T 7.00P, 26DEG 26T 45DEG F-5405B-DM3 R.H. -

Page 21: Medium-Duty Dual Clutch - Procision

PTO Configurations Medium-Duty Dual Clutch - Procision Model 8-Bolt Gear Info. 6-Bolt Gear Info. Thru- Int. Ext. Aux. Ext. Spline % of Transmission Shaft Spline Counter- Info. Engine Torque Limit for Info. shaft PTO Speed PTO use (lb-ft) Left or 45T 6.0P, EDCO-6F107A Right... -

Page 22: Medium-Duty Hybrid

PTO Configurations Medium-Duty Hybrid Model 8-Bolt Gear 6-Bolt Gear Info. Thru- Int. Ext. Aux. Ext. % of Transmission Info. Shaft Spline Countershaft Spline Engine Torque Limit for Info. Info. Speed PTO use (lb-ft) Left or 48T 7.00P, 26DEG 26T 45DEG EH-6E706B-BP Right R.H. -

Page 23: Heavy-Duty Automated - Autoshift / Ultrashift / Ultrashift Plus 10-Speeds

PTO Configurations Heavy-Duty Automated - AutoShift / UltraShift / UltraShift PLUS 10-Speeds Model 8-Bolt Gear 6-Bolt Gear Info. Thru- Int. Ext. Aux. Ext. % of Transmission Info. Shaft Spline Counter- Spline Engine Torque Limit for Info. shaft PTO Info. Speed PTO use (lb-ft) 47T 6.0P, 45T 6.0P,... - Page 24 PTO Configurations Model 8-Bolt Gear 6-Bolt Gear Info. Thru- Int. Ext. Aux. Ext. % of Transmission Info. Shaft Spline Counter- Spline Engine Torque Limit for Info. shaft Info. Speed PTO use (lb-ft) 47T 6.0P, 45T 6.0P, Lower 32T 0.5P, RTO-14910C-AS3 20DEG PA 20DEG PA Left...

-

Page 25: Heavy-Duty Automated - Fuller Advantage Series

PTO Configurations Heavy-Duty Automated - Fuller Advantage Series Model 8-Bolt Gear 6-Bolt Gear Info. Thru- Int. Ext. Aux. Ext. % of Transmission Info. Shaft Spline Counter- Spline Engine Torque Limit for Info. shaft PTO Info. Speed PTO use (lb-ft) 47T 6.0P, 45T 6.0P, Lower 32T 0.5P,... - Page 26 PTO Configurations Model 8-Bolt Gear 6-Bolt Gear Info. Thru- Int. Ext. Aux. Ext. % of Transmission Info. Shaft Spline Counter- Spline Engine Torque Limit for Info. shaft PTO Info. Speed PTO use (lb-ft) 47T 6.0P, 45T 6.0P, Lower 32T 0.5P, FAOM-14810S-EC3 20DEG PA 20DEG PA...

-

Page 27: Heavy-Duty Automated - Ultrashift Plus - Vcs And Vms

PTO Configurations Heavy-Duty Automated - UltraShift PLUS - VCS and VMS Model 8-Bolt Gear Info. 6-Bolt Gear Info. Thru- Int. Ext. Aux. Ext. % of Transmission Shaft Spline Counter- Spline Engine Torque Limit for Info. shaft PTO Info. Speed PTO use (lb-ft) 47T 6.0P, 45T 6.0P, Lower... -

Page 28: Heavy-Duty Automated - Autoshift / Ultrashift / Ultrashift Plus 13/16/18-Speed

PTO Configurations Heavy-Duty Automated - AutoShift / UltraShift / UltraShift PLUS 13/16/18-Speed Model 8-Bolt Gear 6-Bolt Gear Info. Thru- Int. Ext. Aux. Ext. % of Transmission Info. shaft Spline Counter- Spline Engine Torque Limit Info. shaft PTO Info. Speed for PTO use (lb-ft) 47T 6.0P, 45T 6.0P,... - Page 29 PTO Configurations Model 8-Bolt Gear 6-Bolt Gear Info. Thru- Int. Ext. Aux. Ext. % of Transmission Info. shaft Spline Counter- Spline Engine Torque Limit Info. shaft PTO Info. Speed for PTO use (lb-ft) 47T 6.0P, 45T 6.0P, FO-18E318B-MXP 20DEG PA 20DEG PA 47T 6.0P, 45T 6.0P,...

-

Page 30: Heavy-Duty Automated - Endurant

PTO Configurations Heavy-Duty Automated - Endurant Model 8-Bolt Gear Info. % of Engine Transmission Power Limit Speed for PTO Use (HP) EEO-14F112C EEO-15F112C 42T 3.156 MODULE, 137 Opposite of EEO-16F112C 20DEG PA, 28.9747 95 HP @ 950 RPM min. Engine DEG H.A. -

Page 31: Cable Configuration

Cable Configuration Cable Configuration The cable for the Deutsch connector shall be: • 16 GXL max 18 TXL min for Communication and Control wires • 12 GXL for Power Supply wires • 12 GXL or 14 SXL for V-Ignition wires The cable for the 3-Way Metri-Pack connector should be: •... -

Page 32: Contact Lubrication

(R-72506 profile) *(R-69246 round) Convo- 13 mm [.500]; 125° C or higher temperature luted Tubing; Size 13 mm [.500]; 125° C or rating higher temperature rating ® Note: (*) Eaton recommended component. Recommended Bend Radius (6 X Hardness Diameter):... -

Page 33: Contact Lubrication Application

Contact Lubrication Recommendation Note: Eaton recommends the use of (NyoGel 760G) on all electrical contacts. The preferred method of application is to use a metered dispensing mechanism that places the material on the socket of the connector. It is also preferred that the mate- rial be placed immediately prior to connector mating to reduce the probability of contamination. -

Page 34: Medium- And Heavy-Duty Gen 2 - Pto Inputs And Configurations

PTO Interface Medium- and Heavy-Duty Gen 2 - PTO Inputs and Configurations Countershaft and Split Shaft PTOs Electrical Interface Requirements ® All countershaft-driven Power Take-Offs mounted on Fuller UltraShift ASW transmissions must provide an electrical interface with the transmission. The PTO-mounted switch is used to activate the PTO operating mode of the transmission. This feature uses pin F1 of the 18-way transmission connector. -

Page 35: Ultrashift Asw Auto Neutral Feature

PTO Interface UltraShift ASW Auto Neutral Feature Electrical Interface Requirements ® All devices mounted on the vehicle that require Auto Neutral function from the Fuller UltraShift ASW transmission must provide an electrical interface with the transmission. A switch must be used to activate the Neutral mode of the transmission. This feature uses pin A1 and B1 of the 30-way push button connector. -

Page 36: Medium- And Heavy-Duty Gen 3 - Pto Inputs And Configurations

The ground connection must be isolated from local power device ground returns. Frame rail ground is not recommended. This specific mode indicator light feature is for the Eaton push button only. The split shaft PTO is not available on the UltraShift with a DM3 clutch. -

Page 37: Ultrashift Aw3 Auto Neutral Feature

UltraShift AW3 Auto Neutral Feature All devices mounted on the vehicle that require Auto Neutral function from the Eaton UltraShift AW3 transmission must provide an electrical interface with the transmission. A switch must be used to activate the Neutral mode of the transmission. This ... -

Page 38: Ultrashift ® Plus And Fa - Pto Inputs And Configurations

Countershaft, Thru-Shaft®, and Split Shaft PTOs In any case a PTO is used, regardless of PTO style, Eaton requires the OEM provide a “PTO active” input to the transmission ECU. The vehicle interface harness shall be pre-populated at the ECU 38-way connector with wiring and a connector needed to connect the PTO. -

Page 39: Pto Configurations

“Through-Shaft PTO” operation. If the application requires use of a “Split Shaft PTO”, the transmission ECU configuration software shall be changed to reflect “Split-Shaft PTO”. The Eaton ServiceRanger tool is the recommended interface for changing the configuration setting. -

Page 40: Endurant - Pto Inputs And Configurations

PTO Interface Endurant - PTO Inputs and Configurations The Endurant transmission is designed to provide an enhanced acknowledgment for PTO applications. • PTO operation requires a double pole single throw switch. • Consult PTO manufacturer for power requirements needed for fuses, switches and wires on PTO circuitry. •... -

Page 41: Pto Wiring Diagrams

PTO Interface PTO Wiring Diagrams J 1939 = J1939 PTO Installation with Hardwire Confirm Battery Voltage = Ground = Switched Ground = 1. Request from PTO Switch Solenoid Driver = 2. OEM ECU sends the to OEM ECU Request message via J1939 Air Supply = to the TCM PTO Switch... - Page 42 PTO Interface J 1939 = J1939 PTO Installation Battery Voltage = Ground = Switched Ground = Solenoid Driver = Air Supply = 1. Request from PTO Switch 2. OEM ECU sends the to OEM ECU Request message via J1939 to the TCM PTO Switch 6.

- Page 43 PTO Interface PTO w/Confirm Switched to Chassis GND Inside or on Dashboard VBATT (Fused) B-14 (RTN_2) SW02 SW01 B-15 (PTO REQUEST) SW04 SW03 B-5 (RTN_1) DPST Switches shown in inactive posistion Engage VBATT Relay PTO Lamp/LED Contact Customer Support Engineering for additional options PTO-Power PTO-Confirm PTO 01...

- Page 44 PTO Interface PTO w/Confirm Switched to Power Inside or on Dashboard B-14 (RTN_2) VBATT B-15 (PTO REQUEST) (Fused) SW02 SW01 B-5 (RTN_1) SW04 SW03 DPST Switches shown in inactive posistion Engage Confirm Relay Relay PTO Lamp/LED L(+) L(-) Contact Customer Support Engineering for additional options CHASSIS GROUND CHASSIS GROUND...

-

Page 45: Medium-Duty Hybrid - Pto Inputs And Configuration

PTO Interface Medium-Duty Hybrid - PTO Inputs and Configuration Eaton recommends the OEM provide a connector and wiring coming from the Hybrid Control Module 38-Way (Vehicle Interface) with the PTO wires installed. Note: Connector used must be compatible with 18 TXL. - Page 46 PTO Interface ePTO (HCM Analog Controlled) Description From Pin# Pin# PTO Signal ePTO PTO Power Plus ePTO PTO Power Minus ePTO ePTO (HCM J1939 Controlled) Description From Pin# Pin# J1939 Low (CAN) J1939 Backbone J1939 High (CAN) J1939 Backbone mPTO (HCM Controlled) Description From Pin#...

-

Page 47: Medium-Duty Dual Clutch - Pto Inputs And Configurations

PTO must be enabled within the software for PTO functionality. Contact dealer for more information. • The Eaton Procision Transmission is designed to provide an enhanced acknowledgment for PTO applica- tions. Procision TCM will receive a “PTO Request” from the vehicle to enter into a PTO mode. If the TCM deems that conditions are suitable for PTO operations, the TCM will supply a “PTO Engage”... - Page 48 PTO Interface PTO w/Confirm Switched to Chassis GND Inside or on Dashboard VBATT (Fused) B-14 (RTN_2) SW02 SW01 B-15 (PTO REQUEST) SW04 SW03 B-5 (RTN_1) DPST Switches shown in inactive posistion Engage VBATT Relay PTO Lamp/LED Contact Customer Support Engineering for additional options PTO-Power PTO-Confirm PTO 01...

- Page 49 PTO Interface PTO w/Confirm Switched to Power Inside or on Dashboard B-14 (RTN_2) VBATT B-15 (PTO REQUEST) (Fused) SW02 SW01 B-5 (RTN_1) SW04 SW03 DPST Switches shown in inactive posistion Engage Confirm Relay Relay PTO Lamp/LED L(+) L(-) Contact Customer Support Engineering for additional options CHASSIS GROUND CHASSIS GROUND...

- Page 50 PTO Interface PTO with Confirm Switched to Power From Description Notes TCM - B-14 DPST - SW01 PTO Request DPST - SW02 TCM - B-15 PTO Request TCM - B-5 PTO Engage Relay - PTO Engage PTO Engage Relay - TCM - B-2 PTO Engage Vbatt...

-

Page 51: Auto Neutral And Pto Wiring Diagrams

Wiring Diagrams Auto Neutral and PTO Wiring Diagrams The typical relay used for Auto Neutral and PTO wiring is listed below. • Bosch: 0332-209-151 (+12 volt), 0332-204-203 (+ 24 volt) or equivalent • HELLA: 4RD 960 388-22 (+12 volt) (Recommended) •... -

Page 52: Dual Relay Pto Application (Double Switch)

Wiring Diagrams Dual Relay PTO Application (Double Switch) The dual relay option provides one input for transmission PTO operation and another input for the vehicle. Note: Vehicle can be wired for normally open or normally closed (87 or 87a). Protected Power Battery or VIGN Indicator Lamp 18 (PTO Switch +) -

Page 53: Automated Pto Operating Instructions

PTO Operation Medium-Duty and Heavy-Duty Automated PTO Operating Instructions AutoShift Countershaft and Split Shaft PTO Operation Stationary PTO Operation The transmission countershaft PTO is used in this application. To engage the PTO for stationary operation perform the following steps: Select “N” on the Shift Control.PTO Operation Apply the parking brake. -

Page 54: Ultrashift® Countershaft Pto Operation

PTO Operation ® UltraShift Countershaft PTO Operation ® transmissions are not approved for PTO applications that would require the engine to operate at less than ® Fuller UltraShift 1000 RPM for heavy-duty transmissions and 1200 RPM for medium-duty transmissions. Stationary PTO Operation The transmission countershaft PTO is used in this application. -

Page 55: Ultrashift ® Plus And Fa Countershaft And Split Shaft Pto Operation

PTO Operation ® UltraShift PLUS and FA Countershaft and Split Shaft PTO Operation Stationary PTO Operation The transmission countershaft PTO is used in this application. To engage the PTO for stationary operation perform the following steps: Apply the parking brake. Depress the service brake. -

Page 56: Eaton Hybrid Countershaft Pto Operation

PTO Operation Eaton Hybrid Countershaft PTO Operation Stationary Mechanical PTO Operation The transmission countershaft PTO is used in this application. To engage the PTO for stationary operation perform the following steps: Apply the parking brake. Depress the service brake. Select “D” on the Shift Control (this stops countershaft rotation for PTO engagement). - Page 57 PTO Operation Note: The electric motor powering the ePTO is activated by a hydraulic demand signal generated by the hydraulic system. It will start and stop with hydraulic usage. ePTO Shutdown Procedure: Shutdown and return PTO driven equipment to storage position. Push “ePTO”...

-

Page 58: Endurant Countershaft Pto Operation

PTO Operation Endurant Countershaft PTO Operation Stationary PTO Operation The transmission countershaft PTO is used in this application. To engage the PTO for stationary operation perform the following steps: Apply the parking brake. Depress the service brake. PTO engagement must be made from neutral Select “N”... -

Page 59: High Capacity Inertia Brake Relocation - Ultrashift Transmissions

HCIB can be moved to the 6-Bolt PTO opening if desired. Depending on the application, the HCIB can either be directly mounted to the 6-Bolt PTO opening using Eaton Kit numbers K-3683 for Generation II transmissions, K-3739 for ... -

Page 60: Inertia Brake Right-Hand Mounting Installation Instructions - Medium-Duty

Inertia Brake Inertia Brake Right-Hand Mounting Installation Instructions - Medium-Duty This kit provides hardware and instructions for moving a Medium-Duty inertia brake from the left side to the right side of the transmission. This kit is only for use with transmissions already fitted with inertia brakes that can be mounted in either location. This is easily determined by the existence of 2 speed sensor adapter ports on the inertia brake casting. - Page 61 Inertia Brake Remove Left Side Inertia Brake Disconnect harness at 2 connector locations and remove ty-raps from inertia brake. Note: Take care not to damage harness. Protect connector ends from dirt contamination. Disconnect oil hose from inertia brake and transmission case. Remove (6) mounting bolts from the inertia brake.

- Page 62 Inertia Brake Install PTO Cover on Left Side Install PTO cover and gasket on the left side of the transmission. Note: Make sure cover and transmission opening is clean and dry. Apply thread adhesive to bolt threads. Torque bolts to 10-20 lb-ft. (14-27 Nm) in a cross pattern. Speed Sensor Adapter hex socket...

- Page 63 Inertia Brake 10. Remove the inertia brake electrical connector by removing the two cap screws and gently pulling the connector free from the inertia brake. (Internal wires must remain attached.) 11. Rotate the connector 180 degrees, so the connector is facing the speed sensor. (The connector will be pointing up when the inertia brake is installed.

- Page 64 Inertia Brake Note: The inertia brake is mounted so that the speed sensor is pointed upwards and the 5 allen head bolts and oil hose fitting are facing the front of the transmission. These 5 bolts should face the front of the transmission Inertia Brake should be mounted in this orientation on the right side.

- Page 65 Inertia Brake 4.Install harness strap bracket to the shift bar housing. Remove the shift bar housing bolt and place bracket as shown. Torque shift bar housing bolt to 35-40 lb-ft (47-54 Nm). Jumper Harness Harness Strap Bracket Install Jumper Harness A jumper harness is supplied to connect between the transmission harness and the inertia brake connectors.

- Page 66 Inertia Brake Note: Use only Eaton lubricant part number 5564527 (Nye Lubricants NYOGEL 760G) - For MSDS safety sheet or other informa- tion see www.nyelubricants.com Make sure all connectors (2 on the right side, 2 on the left side) are fully mated and latches are locked.

- Page 67 Inertia Brake Recheck for leaks. Final Check Make sure all bolts are properly tightened. Make sure the oil supply line and fittings are properly tightened. Make sure transmission is properly filled with lubricant. Make sure harness is connected and properly secured. Look for leaks and repair as necessary.

-

Page 68: Generation 2 - Inertia Brake Relocation Instruc- Tions - Heavy-Duty (8- To 6-Bolt Pto Opening)

Eaton to the user. This drawing and/or technical information is the property of Eaton and is loaned for mutual assistance to be returned when its purpose has been served. THIS DRAWING AND/OR TECHNICAL INFORMATION IS THE PROPERTY OF EATON. -

Page 69: Installation

If the Inertia brake is installed directly mounted to the 6-bolt opening, proper orientation must be followed as shown in the “Final Check” section. A directly mounted Inertia Brake also requires a new lubrication hose, Eaton part number 5588209. -

Page 70: Final Check

Inertia Brake Reconnect the lubricant supply line to the Inertia Brake and tighten to 20-22 lb-ft. (27-30 Nm). For Inertia Brakes directly mounted to the 6-bolt opening - orient the 45 degree elbow facing inboard, and connect the 45 degree elbow fitting end of the 5588209 hose to the Inertia Brake elbow. - Page 71 Inertia Brake Drawing shows inertia brake with angle adaptor. Please see instructions above for installation without angle adaptor. Note orientation of hose connection end of Inertia Brake when mounted to Inertia Brake mounting to 6-bolt a PTO Angle Adapter Angle Adapter as viewed from rear of transmission Mate inertia brake connector and insert push-in harness anchor into...

-

Page 72: Generation 3 - Inertia Brake Relocation Instruc- Tions - Heavy-Duty (8 To 6-Bolt Pto Opening)

Eaton to the user. This drawing and/or technical information is the property of Eaton and is loaned for mutual assistance to be returned when its purpose has been served. -

Page 73: Installation

If the Inertia brake is installed directly mounted to the 6-bolt opening, proper orientation must be followed as shown in the illustration in the “Final Check” section. A directly mounted Inertia Brake also requires a new lubrication hose, Eaton part number 5588209. -

Page 74: Final Check

Inertia Brake Apply contact lubrication to jumper harness per instructions in the “How to Apply Contact Lubrication to Eaton Transmission Harnesses” section then connect the jumper harness to the transmission harness. Reroute and reconnect the Transmission Harness to the Inertia Brake. Dress the harness along the transmission case from the inertia brake up to the top of the transmission. - Page 75 Inertia Brake Drawing shows inertia brake with angle adaptor. Please see instructions above for installation without angle adaptor. Note orientation of hose connection end of Inertia Brake when mounted to Inertia Brake mounting to 6-bolt a PTO Angle Adapter Angle Adapter as viewed from rear of transmission...

-

Page 76: How To Apply Contact Lubrication To Eaton Transmission Harnesses

– about the size of a BB. Use care to prevent damage to the terminal. Each package contains enough material for one har- ness installation. Apply to all female terminals on all connectors. Mate connector immediately after applying lubrication. Use only Eaton lubricant part number 5564527 (Nye Lubricants NYOGEL 760G - For MSDS safety or other information see www.nyelubricants.com. -

Page 77: I-Brake Harness Routing Scheme

Inertia Brake I-Brake Harness Routing Scheme 1 Tie Wrap to Bracket 2 Tie Wrap to harness 3 Push-in Anchor Mate inertia brake connector and insert push-in harness anchor into threaded hole as shown. Route the harness up along side of the transmission case as indicated. -

Page 78: Pto Manufacturers - Contact Information

Contact Information PTO Manufacturers - Contact Information Chelsea Products Division 8225 Hacks Cross Road Olive Branch, MS 38654 (662) 895-1011 www.parker.com/chelsea Muncie Power Products, Inc. P.O. Box 548 Muncie, IN 47308-0548 (765)284-7721 www.munciepower.com... -

Page 79: Change Control Log

UltraShift® PLUS - PTO Inputs and Configurations section: Removed - “Note: The active signal will illuminate the “Mode” indicator only on the Eaton® push button console when the transmission direct drive gear is engaged for split shaft PTO operation.”... - Page 80 Change Log Last Revised Date Description of Clarifications and Updates June 2012 Updated front and back covers to new Eaton Standard Format General Types of PTO section: Added - “Countershaft” to the 6-Bolt and 8-Bolt headers Added - Note to the end of the Thru-Shaft section...

- Page 81 Change Log Last Revised Date Description of Clarifications and Updates June 2012 Medium-Duty and Heavy-Duty Automated PTO Operating Instructions section: UltraShift PLUS Countershaft PTO Operation section - Mobile PTO Operation section - Changed - item #4 from “Select the transmission PTO switch” to “Engage PTO” Changed - Item #6 from “Release the service brake to engage the clutch and the PTO”...

- Page 82 Copyright Eaton, 2017 Eaton hereby grant their customers, vendors, or distributors permission to freely copy, reproduce and/or distribute this document in printed format. It may be copied only in its entirety without any changes or modifications. THIS INFORMATION IS NOT INTENDED FOR SALE OR RESALE, AND THIS NOTICE MUST REMAIN ON ALL COPIES.

Need help?

Do you have a question about the FS-4205A and is the answer not in the manual?

Questions and answers

I have a EH8-E306A-CD transmission, i also have a PK1-17-17KBBX pump could you possibly tell me what PTOs I could choose from, I’m having a hard time figuring out where to get information on this hybrid transmission.