Table of Contents

Advertisement

Quick Links

SERVICE MANUAL

2

2005

MA154

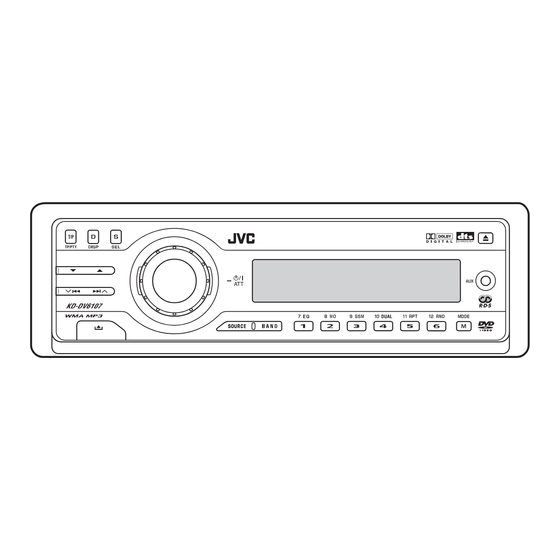

KD-DV6101,KD-DV6107

Steering wheel remote controller

FM frequency range

1

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2

SPECIFIC SERVICE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3

DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

4

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

5

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

DVD/CD RECEIVER

KD-DV6101

FM 87.5 MHz to 108.0 MHz FM1/FM2 87.5 MHz to 108.0 MHz

TABLE OF CONTENTS

COPYRIGHT © 2005 Victor Company of Japan, Limited

KD-DV6101

E ------------- Southern Europe

EU ------------------------- Turkey

KD-DV6107

EE -------- Russian Federation

KD-DV6107

FM3 65.00 MHz to 74.00MHz

KD-DV6101

Area suffix

KD-DV6107

Area suffix

No.MA154

2005/2

Advertisement

Table of Contents

Summary of Contents for JVC KD-DV6101

-

Page 1: Table Of Contents

SERVICE MANUAL DVD/CD RECEIVER MA154 2005 KD-DV6101,KD-DV6107 KD-DV6101 KD-DV6101 Area suffix E ------------- Southern Europe EU ------------------------- Turkey KD-DV6107 Area suffix KD-DV6107 EE -------- Russian Federation KD-DV6101 KD-DV6107 Steering wheel remote controller FM frequency range FM 87.5 MHz to 108.0 MHz FM1/FM2 87.5 MHz to 108.0 MHz FM3 65.00 MHz to 74.00MHz... - Page 2 SPECIFICATION AUDIO AMPLIFIER SECTION Maximum Power Output Front 50 W per channel Rear 50 W per channel 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more Continuous Power Output (RMS) Front than 0.8% total harmonic distortion. 19 W per channel into 4 Ω, 40 Hz to 20 000 Hz at no more Rear than 0.8% total harmonic distortion.

-

Page 3: Precautions

SECTION 1 PRECAUTIONS Safety Precautions Burrs formed during molding may be left over on some parts of the chassis. Therefore, pay attention to such burrs in the case of preforming repair of this system. Please use enough caution not to see the beam directly or touch it in case of an adjustment or operation check. - Page 4 Preventing static electricity Electrostatic discharge (ESD), which occurs when static electricity stored in the body, fabric, etc. is discharged, can destroy the laser diode in the traverse unit (optical pickup). Take care to prevent this when performing repairs. 1.2.1 Grounding to prevent damage by static electricity Static electricity in the work area can destroy the optical pickup (laser diode) in devices such as CD players.

- Page 5 Important for laser products 5.CAUTION : If safety switches malfunction, the laser is able 1.CLASS 1 LASER PRODUCT to function. 2.DANGER : Invisible laser radiation when open and inter 6.CAUTION : Use of controls, adjustments or performance of lock failed or defeated. Avoid direct exposure to beam. procedures other than those specified here in may result in 3.CAUTION : There are no serviceable parts inside the hazardous radiation exposure.

-

Page 6: Specific Service Instructions

SECTION 2 SPECIFIC SERVICE INSTRUCTIONS This service manual does not describe SPECIFIC SERVICE INSTRUCTIONS. 1-6 (No.MA154) -

Page 7: Disassembly

SECTION 3 DISASSEMBLY Main body section 3.1.1 Removing the front panel assembly (See Fig.1) Push the detach button in the lower left part of the front panel as- sembly and remove the front panel assembly. Front panel assembly Detach button Fig.1 3.1.2 Removing the bottom cover (See Fig.2) - Page 8 3.1.3 Removing the front chassis assembly (See Figs.3 and 4) • Remove the front panel assembly and bottom cover. (1) From the front side of the main body, remove the two Front chassis assembly screws A attaching the front chassis assembly. (See Fig.3.) (2) From the both sides of the main body, remove the two screws B attaching the front chassis assembly.

- Page 9 H attaching the rear bracket. Wire holder Rear bracket Reference: Slot Screw E" is used for KD-DV6101 only. (2) Remove the LINE IN, SUBWOOFER and AUDIO OUT ca- bles from the rear bracket in the direction of the arrow. AUDIO OUT cable Reference: •...

- Page 10 3.1.8 Removing the main sub board (See Figs.9 to 11) • Remove the front panel assembly, bottom cover, front chassis assembly, side heat sink, main board and DVD mechanism as- DVD mechanism assembly sembly. (1) From the top side of the DVD mechanism assembly, re- move the two screws L attaching the dust cover.

- Page 11 3.1.9 Removing the switch board (See Figs. 12 to 14) • Remove the front panel assembly. (1) From the back side of the front panel assembly, remove the Rear cover five screws P attaching the rear cover. (See Fig.12.) (2) Release the ten joints i attaching the rear cover to the front panel assembly.

- Page 12 DVD mechanism assembly 3.2.1 Removing the mechanism control board (See Fig.1) Caution: Before disconnecting the flexible wire extending from the DVD Lug wire Flexible wire pickup, solder the short-circuit point on the flexible wire using Feed motor a grounding soldering iron. If you do not follow this instruction, Double tape the DVD pickup may be damaged.

- Page 13 3.2.2 Removing the top cover (See Fig.2) (1) Remove the two screws D attaching the top cover on the back of the body. (2) Remove the top cover upward. Reference: When reassembling, set part b of the top cover under the bending part c of the chassis frame.

- Page 14 3.2.4 Removing the clamper unit (See Fig.5 to 7) • Remove the top cover and the mechanism section. (1) Remove the clamper2 spring on the bottom of the mecha- Clamper2 spring nism section. (See Figs.5.and 6.) (2) Release the part d of the clamper spring from the bending part of the chassis base assembly.

- Page 15 Clamper unit Clamper spring Fig.8 Clamper unit Notch Fig.9 (No.MA154)1-15...

- Page 16 3.2.6 Removing the front unit (See Fig.10 to 12) • Remove the top cover and the mechanism section. (1) Disconnect the flexible wire from connector CN202 on the mechanism control board at the bottom of the body. (See Front unit Fig.10.) (2) Remove the screw G attaching the front unit on the top of the body.

- Page 17 3.2.7 Removing the loading arm assembly (See Fig.13 , 14) • Remove the top cover, the mechanism section and the front unit. (1) From the top of the body, move the loading arm assembly from the front side upward, and release the bosses from the right and left joints k and m of the chassis base assem- bly.

- Page 18 3.2.8 Removing the rod (L)(R)/roller assembly (See Fig.15 and 16) • Remove the top cover, the mechanism section, the front unit and the loading arm assembly. Collar Collar (1) Release the rod (L) and (R) from the joints q at the bottom of the loading arm assembly (See Fig.15.) (2) Remove the roller assembly from the loading arm assem- bly.

- Page 19 3.2.9 Removing the DVD pickup assembly (See Fig.17 to 19) • Remove the mechanism control board. (1) From the bottom of the body, turn the feed gear in the di- Feed gear rection of the arrow to move the DVD pickup outwards. (See Fig.17.) (2) Remove the screw J attaching the thrust spring.

- Page 20 3.2.10 Removing the spindle motor (See Fig.20) • Remove the mechanism control board. Remove the two screws L attaching the spindle motor on the Spindle motor bottom of the body. Caution: Perform adjustment when reattaching the spindle motor. Fig.20 3.2.11 Removing the feed motor assembly (See Fig.21 and 22) •...

-

Page 21: Adjustment

SECTION 4 ADJUSTMENT Test instruments required for adjustment Standard measuring conditions (1) Digital oscilloscope (100MHz) Power supply voltage DC14.4V(11 to 16V) (2) Jitter meter Load impedance 4Ω(2 Speakers connection) (3) Digital tester Line Output 20KΩ (4) Electric voltmeter (5) Tracking offset meter Caution: (6) Test Disc : VT501 or VT502 Be sure to attach the heat sink and rear bracket onto the power... - Page 22 After replacing the pickup, set the unit in the service mode to display a jitter value on the LCD. Confirm that the jitter value measured with a jitter meter is within 12% of the jitter value displayed on the LCD. If it is within 12%, then adjustment is not necessary. Please note that a jitter value displayed on the LCD is hex data.

-

Page 23: No.ma154)1

Jitter value conversion table Load the test DVD and set the unit to the service mode. A jitter value converted to the hex value is displayed on the LCD. Refer to the corresponding decimal notation value shown in the following Jitter Conversion Table. The adjustment is OK if the jitter value measured with a jitter meter is within 12% of the jitter value displayed on the LCD. - Page 24 Service mode 4.5.1 Standard input/output conditions Power supply voltage DC14.4V(11 to 16V) Load impedance 4Ω(2 Speakers connection) Line Output 20KΩ 4.5.2 Service mode setting procedure (The DVD does not need to be loaded before starting the following procedure.) [STANDBY/ON ATTENUATOR] button [SEL] button [DISC UP] button [DISC DOWN] button...

- Page 25 4.5.3 Operation procedures Keep this state more than 2 seconds while continuing pressing the [SEL] button, [STANDBY/ON ATTENUATOR] button and [SOURCE] button sequentially. The unit enters the service mode. "INIT ALL" is Initialize all data to the factory setting Press the [SEL] key indicated on the LCD.

- Page 26 "CD ERROR" is Read loading and ejection error history Press the [SEL] key indicated on the LCD. : The error history saved in the system control is read and displayed. TOT-xxxx : Total error count. Total error count (A figure between 0 and 9999 is displayed.

- Page 27 "SYS-TEMP" is Thermistor's temperature data readout Press the [SEL] key indicated on the LCD. : Data in the temperature sensor in the system control is read every 5 seconds and displayed in hex numbers. "CHK MODE" is DVD unit check mode Press the [SEL] key indicated on the LCD.

- Page 28 4.5.4 DVD unit check mode Change LCD indication with a [FF ] button and a [REW ] button. Check item list Example of A/D key DVD unit operation Indication contents LCD indication Start at normal speed NORMPLAY (After start, it is measured JITTER on the Laser current value internal position) Jitter value...

-

Page 29: Troubleshooting

SECTION 5 TROUBLESHOOTING 16 PIN CORD DIAGRAM Black Green Violet GN/BK WH/BK Blue Gray VI/BK GY/BK White Yellow Orange Brown Yellow Green BL/WH OR/WH BL/WH OR/WH 2 RD RD 7 MEMORY 16 YL YL 4 1 BK 3 BL/WH REMOTE 13 BR TEL MUTING 15 OR/WH... - Page 30 Victor Company of Japan, Limited AV & MULTIMEDIA COMPANY CAR ELECTRONICS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan (No.MA154) Printed in Japan...

- Page 31 This file was downloaded and provided FREE OF CHARGE from the ManualDirectory community. You can find many free to download Service Manuals & Schematics at http://www.manualdirectory.co.uk...

- Page 32 SCHEMATIC DIAGRAMS DVD/CD RECEIVER KD-DV6101,KD-DV6107 CD-ROM No.SML200502 KD-DV6101 Area suffix KD-DV6101 E ------------- Southern Europe EU ------------------------- Turkey KD-DV6107 Area suffix EE -------- Russian Federation KD-DV6107 KD-DV6101 KD-DV6107 Steering wheel remote controller FM Frequency range FM: 87.5 MHz to 108.0 MHz FM1/FM2: 87.5 MHz to 108.0 MHz FM3: 65.00 MHz to 74.00 MHz...

-

Page 33: Safety Precaution

Safety precaution Burrs formed during molding may be left over on some parts of the chassis. Therefore, pay attention to such burrs in the case of preforming repair of this system. Please use enough caution not to see the beam directly or touch it in case of an adjustment or operation check. -

Page 34: Block Diagram

CHANGER HEADPHONE HEADPHONE AUXINL EPROM AUDIO OUT AUXINR E.VOLUME SW1 to SW3 SI/SO SW1 to SW3 HPDATA LRMUTE IC801 HPCK SW4,TRVSW UCS,SCS JVC BUS HPSTB SCLK SW1,SW4 MOTOR IC961 U2SDT,S2UDT BUSSO SW4,SW5 CPURST IC962 BUSSCK LEVEL BUSINT I/O,SI/SO CONV. EPDAI LCD &... -

Page 35: Standard Schematic Diagrams

Standard schematic diagrams C428 Main amplifier section (For KD-DV6101) 4.7/25 KTD1304-X DVDR KTD1304-X R436 DVDL KTD1304-X C438 4.7/25 KTD1304-X 6.8K C433 C435 C434 R437 R434 R431 HPDATA C437 R438 CN141 150P 220/10 100P CN191 HPCK QGA2006C1-04 4.7/25 4.7K Q432 QGA2501C3-03Z... - Page 36 LCD & Key switch section (For KD-DV6101) IC602 RPM7338-V4 R670 DIMOUT DIM_CON REMOCON LCD1 ENC1 QLD0349-001 ENC2 LCDCE TO CN701 LCDDA (SHEET 1) LCDCL KEY2 KEY1 KEY0 AUX.R IC601 AUX.GND PT6523LQ-L AUX.L R606 R605 R604 R603 R602 R601 KEY2 3.9K 2.7K...

- Page 37 Main amplifier section (For KD-DV6107) C428 4.7/25 KTD1304-X DVDR KTD1304-X R436 DVDL KTD1304-X C438 KTD1304-X 4.7/25 6.8K C433 R437 C435 C434 R434 R431 HPDATA C437 R438 CN191 150P 220/10 CN141 100P QGA2006C1-04 QGA2501C3-03Z HPCK 4.7K 4.7/25 Q432 HPSTB R433 R193 L431 Q431 NQR0007-002X...

- Page 38 LCD & Key switch section (For KD-DV6107) IC602 RPM7338-V4 R670 DIMOUT DIM_CON REMOCON LCD1 ENC1 QLD0349-001 ENC2 LCDCE TO CN701 LCDDA LCDCL (SHEET 3) KEY2 KEY1 KEY0 AUX.R IC601 AUX.GND PT6523LQ-L AUX.L R606 R605 R604 R603 R602 R601 KEY2 3.9K 2.7K 1.8K 1.2K...

- Page 39 DVD section (Common) R300 D3.3V K399 NQR0502-001X P3.3V IC303 R301 IC399 K4S281632F-UC75 K301 C399 IC398 0.1/16 SG32M90TFIR3 NQR0502-001X MDQ0 MDQ15 0.1/16 EXADT15 EXADR16 MDQ1 C392 MDQ14 EXADT14 R399 MDQ2 MDQ13 EXADT13 C393 P3.3V EXADT12 EXDAT15 MDQ3 0.1/16 MDQ12 D1.2V EXADT11 EXDAT7 MDQ4 MDQ11...

- Page 40 Printed circuit boards Main board Forward side Reverse side R905 R906 IC301 C316 Q901 IC901 Q912 IC901 C311 IC301 Q301 R961 C910 C360 C340 C907 Q302 CN961 D305 D301 C916 C917 C901 R894 C702 C891 C911 C701 R893 B402 D709 C892 C349 C359...

- Page 41 Switch board Mechanism control board Forward side R435 C431 R438 Forward side C433 B204 C432 K445 IC411 C533 D619 LCD1 IC602 IC401 S611 C532 R531 C452 C453 S612 D605 R610 S613 D604 C454 S614 R535 K451 K301 D606 D607 R612 C451 J601 R355...

- Page 42 Mechanism control board Reverse side C404 R403 C403 C405 B201 R404 R402 B202 K443 R421 B203 R521 C402 C522 TP455 R401 K442 TP433 R365 R366 C368 TP416 TP446 TP417 C369 TP448 C603 K601 R602 TP322 TP324 K434 TP321 C395 CN402 TP316 C602 TP318...

- Page 43 Victor Company of Japan, Limited AV & MULTIMEDIA COMPANY CAR ELECTRONICS CATEGORY 10-1,1chome,Ohwatari-machi,Maebashi-city,371-8543,Japan Printed in Japan (No.MA154SCH)

Need help?

Do you have a question about the KD-DV6101 and is the answer not in the manual?

Questions and answers