Summary of Contents for Efka dc 1500

-

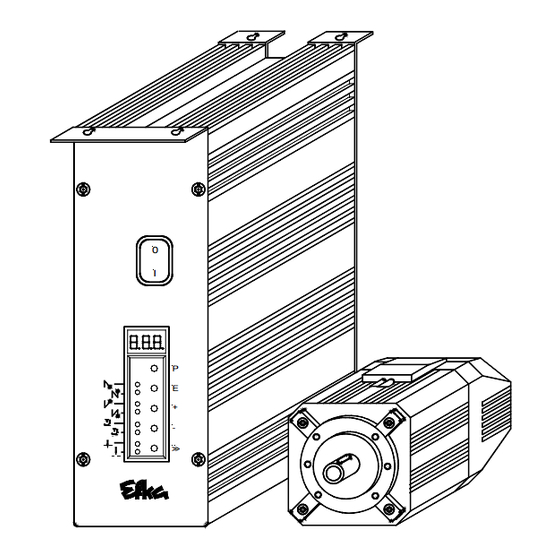

Page 1: Signal Output Position

CONTROL FP220A5911 > > K L2334a INSTRUCTION MANUAL No. 402295 English FRANKL & KIRCHNER EFKA OF AMERICA INC. EFKA ELECTRONIC MOTORS GMBH & CO KG SINGAPORE PTE. LTD. -

Page 2: Table Of Contents

EFKA FP220A5911 CONTENTS Page 1 Important Safety Instructions 2 Range of Applications Use in Accordance with Regulations 3 Scope of Supply Special Accessories 4 Use of the C200 Compiler 5 Connection of Stepping Motor Controls to the FP220A Control SM210A Control Settings for Operating the FP220A Control... - Page 3 EFKA FP220A5911 CONTENTS Page 10 Setting the Basic Functions 10.1 Direction of Motor Rotation 10.2 Transmission Ratio 10.3 Selection of Functional Sequences (Thread Trimming Operations) 10.4 Functions of the Keys Inputs in1...i10 10.5 Positioning Speed 10.6 Maximum Speed Compatible with the Sewing Machine 10.7 Maximum Speed...

- Page 4 EFKA FP220A5911 CONTENTS Page 11.14 Speed Depending on High Lift 11.14.1 Operating Mode of Speed Limitation Depending on High Lift 11.14.2 Setting the Speed Limitation Depending on High Lift with the V820 Control Panel 11.14.3 Setting the Speed Limitation Depending on High Lift with the V810 Control Panel 11.14.4...

- Page 5 EFKA FP220A5911 CONTENTS Page 12 Signal Test 12.1 Signal Test Using the Incorporated Control Panel or the V810/V820 13 Error Displays 14 Operating Elements of the V810 Control Panel 15 Operating Elements of the V820 Control Panel...

-

Page 6: Important Safety Instructions

1 Important Safety Instructions Work on high voltage circuit areas is forbidden, except as When using an EFKA drive and accompanying devices (e g stated in the respective regulations, e.g. DIN VDE 0105 for sewing machines), basic safety precautions should part 1. -

Page 7: Range Of Applications

EFKA FP220A5911 2 Range of Applications The drive is suitable for lockstitch, chainstitch and overlock machines of various manufacturers. Furthermore, stepping motor operation is possible with the SM210A control. See connection scheme in the List of Parameters. With the help of adapter cords (adapter cords see Special Accessories), the drive can be used with the following... -

Page 8: Use In Accordance With Regulations

EFKA FP220A5911 2.1 Use in Accordance with Regulations The drive is not an independently operating machine, but is designed to be incorporated into other machinery. It must not be put into service until the machinery into which it is to be incorporated has been declared in conformity with the provisions of the EC Directive (Appendix II, paragraph B of the Directive 89/392/EEC and supplement 91/368/EEC). -

Page 9: Special Accessories

EFKA FP220A5911 3.1 Special Accessories Control panel Variocontrol V810 - part no. 5970153 Control panel Variocontrol V820 - part no. 5970154 Reflection light barrier module LSM002 - part no. 6100031 Hall sensor module HSM001 - part no. 6100032 Pulse encoder IPG001 - part no. -

Page 10: Use Of The C200 Compiler

EFKA FP220A5911 4 Use of the C200 Compiler The Efka C200 Compiler is a software tool for the programming of functions on the FP220A control, with which the user can program a variety of additional user-defined functions. The compiler provides the following basic functions: predetermined functions which are integrated by means of a system file approx. -

Page 11: Connection Of Stepping Motor Controls To The Fp220A Control

EFKA FP220A5911 5 Connection of Stepping Motor Controls to the FP220A Control FP220A SM210A SM210A B 41 m ot m ot B 80 B 776 B 776 B776 B776 EB . . . B 18 B 776 B 1 9... -

Page 12: Control Operation Without Control Panel

EFKA FP220A5911 6 Control Operation without Control Panel 6.1 Access Authorization upon Command Input In order to prevent unintentional changes of preset functions the command input is distributed at various levels. The following persons have access: - the supplier to the highest and all subordinate levels by means of a code... -

Page 13: Programming The Code Number

EFKA FP220A5911 6.2 Programming the Code Number Note The parameter numbers in the illustrations below serve as examples and may not be available in all program versions. In this case, the display shows the next higher parameter number. See List of Parameters. -

Page 14: Parameter Selection

EFKA FP220A5911 6.3 Parameter Selection 6.3.1 Direct Selection After code number input at the Press the >> key Press the + or – key to select programming level (1st digit blinks) the 1st digit 4/ K L2319 Press the >> key Press the + or –... -

Page 15: Changing Parameter Values

EFKA FP220A5911 6.3.2 Changing Parameter Values Display after parameter value selection Change the parameter value by pressing the + or - key 7/ K L2322 Option 1 Press the E key. The next Press the P key. Exit programming. parameter number is displayed. -

Page 16: Parameter Selection With The +/- Keys

EFKA FP220A5911 6.3.3 Parameter Selection with the +/- Keys After code number input at the Select the next parameter by pressing the + key programming level 10 / K L232 5 Select the previous parameter by After pressing the E key, the... -

Page 17: Changing All Parameter Values At The Operator Level

EFKA FP220A5911 6.4 Changing All Parameter Values at the Operator Level All parameter values at the operator level can be changed without code number input (see List of Parameters). ! Press the P key " The first parameter number will be displayed ! Press the E key "... -

Page 18: Program Identification On The Control

EFKA FP220A5911 6.7 Program Identification on the Control Function without control panel Parameter Program number, modification index and identification number display After having selected parameter 179, the following information is displayed in succession: Select parameter 179. Press the E key. -

Page 19: Control Operation With Control Panel

EFKA FP220A5911 7 Control Operation with Control Panel 7.1 Operation of the V810 Control Panel 7.1.1 Code Number Input on the V810 Control Panel Technician Level Code Number => 1907 and Supplier Level Code Number => 3112 Example: Technician level CODE number selection on the V810 control panel TURN POWER OFF C –... -

Page 20: Parameter Input At The Technician/Supplier Level On The V810 Control Panel

EFKA FP220A5911 " New parameter value is displayed ! " F – 0 1 3 Next parameter is displayed ! " Exit programming ! F P 2 2 0 A These values are saved when you start sewing. They remain in effect even after turning the machine off! Using parameter 401 is another possibility for immediate storage without having to start sewing. -

Page 21: Parameter Input At The Operator Level On The V820 Control Panel

EFKA FP220A5911 If CODE number is incorrect, " repeat input ! C–0000 InFo F1 If CODE number is correct, " the first PARAMETER number at the F–100 selected level is displayed. 7.2.2 Parameter Input at the Operator Level on the V820 Control Panel Example: CODE number has not been input ! "... -

Page 22: Program Identification

EFKA FP220A5911 7.3 Program Identification Function with control panel Parameter Program number, modification index and identification number display Display example parameter 179 on the V810 control panel: Select parameter 179! " Press the E key Sr5 [°] is displayed "... -

Page 23: Keys For Background Information (Hit) With V820

EFKA FP220A5911 7.5 Keys for Background Information (HIT) with V820 (key assignment see figure on the last page) Note The following functions are possible only with the V820 control panel! For fast operator information, the values of functions switched on by means of the 1, 2, 3, 4 and 9 keys are displayed on the control panel for approx. -

Page 24: Further Functions Of The V810/V820 Control Panels

EFKA FP220A5911 " Press the E key! Press the E key several times until the " letter symbol –F– appears ! (ornamental backtack On/Off) " Press the – key! (softstart On/Off) " Press the P key! 4000 FP220A The assignment is completed. -

Page 25: Special Functions Of The V820 Control Panel

EFKA FP220A5911 7.5.3 Special Functions of the V820 Control Panel " Select parameter 200 F-200 " Press the E key. F–200 t1 050 The set value is displayed. " Press the 0 key three times. F-200 t1 000 The minimum value is displayed. -

Page 26: Programming Of Seams (Teach In)

EFKA FP220A5911 7.6 Programming of Seams (TEACH IN) A maximum of 99 patterns with a total of 99 seams can be programmed, i. e. 1 pattern with 99 seams each or 99 patterns with 1 seam each. In between, all combinations are possible. -

Page 27: Programming After Code Number Input

EFKA FP220A5911 7.6.1 Programming after Code Number Input K L2370 ! Input code number by means of the 0...9 keys. K L2371 K L2468 K L23 7 3 K L2374 ! Activate programming of seams TEACH IN by means of the 0 key / Display of pattern number. - Page 28 EFKA FP220A5911 ! Display of seam number K L2379 K L2380 ! Enable all desired functions of the actual seam. as for ex. light barrier, by pressing the 1...9 keys. K L2381 ! After having enabled stitch counting by means of the 2 key, the number of stitches can be varied within 2 seconds.

-

Page 29: Detailed Example

EFKA FP220A5911 7.6.3 Detailed Example A seam 01 with double start backtack, stitch counting forward, position down, sewing foot up, a seam 02 with stitch counting forward, position down and a seam 03 with light barrier, double end backtack, thread trimming, position up, sewing foot up, are to be programmed (without code number input) under the next possible pattern number, e.g. -

Page 30: Inserting A Seam Or Pattern

EFKA FP220A5911 Set functions of seam 03: " Seam number 03 is displayed. Press the E key " The righthand arrow above the 3 key indicates that the light barrier operates covered " Press the 3 key uncovered. The light barrier compensating stitches can be varied as previously shown. -

Page 31: Deleting A Seam Or Pattern

EFKA FP220A5911 7.6.5 Deleting a Seam or Pattern A pattern or seam can be deleted by means of the B “DELETE F2“ key, on condition that the symbol above the pattern or seam number is blinking during programming. Select the pattern or seam number to be deletedc. The symbol above the pattern or seam number must be blinking. - Page 32 EFKA FP220A5911 Parameter 322 = 2 Seam or pattern interruption by thread trimming: The seam can be interrupted by pressing the pedal to pos. –2 and thread trimming, even if the thread trimmer is Off. Then the program switches back to the first seam of the selected pattern.

-

Page 33: Putting Into Service

EFKA FP220A5911 8 Putting into Service Before putting the control into service, the following must be ensured, checked and/or adjusted: The correct installation of the drive, position transmitter and accompanying devices, if necessary The correct selection of the trimming operation by means of parameter 290 If necessary, the correct adjustment of the direction of motor rotation by means of parameter 161 The correct selection of the functions of keys (inputs) by means of parameters 240...249... - Page 34 EFKA FP220A5911 With SIR you can do the most important settings for initial operation with menu prompting. For safety reasons, the menu must be executed point by point. This ensures correct setting of all important parameters. The setting of other parameters is not affected.

-

Page 35: Setting The Basic Functions

EFKA FP220A5911 10 Setting the Basic Functions 10.1 Direction of Motor Rotation Function with or without control panel Parameter Direction of motor rotation (drE) Parameter 161 = 0 Clockwise motor rotation (look at the motor shaft) Parameter 161 = 1... - Page 36 EFKA FP220A5911 Setting the functional sequence using parameter 290 Mode Designation Adapter Outputs Power transistors " " " " ST2/35 ST2/34 ST2/37 ST2/28 ST2/27 ST2/36 ST2/32 ST2/30 Lockstitch; e. g. Functions FA1+2 ML Brother (737-113, 737-913) 1112814 FA1 + Aisin (AD3XX, AD158, 3310; EK1)

- Page 37 EFKA FP220A5911 Explanation of letter symbols of the previous page Outputs: = Sewing foot lifting = Sewing foot lifting without pulsing = Backtacking = Stitch condensing = Thread trimmer = Thread trimmer pos. 1...1A = Thread trimmer pos. 1A...2 FA1+2 = Thread trimmer pos.

- Page 38 EFKA FP220A5911 Mode 6 Chainstitch Machines with Tape Cutter or Fast Scissors Signal M1 after stop in position 2 after delay (kd1) during ON period (kt1) Signal M2 after stop in position 2 after delay (kd2) during ON period (kt2)

- Page 39 EFKA FP220A5911 Mode 15 Backlatch Machines (Pegasus SSC100) Chain blowing (M1) during stitch count (c4) at the start of the seam and during ON period (kt1) at the seam end after tape cutting Chain suction (M2) during stitch count (c3) at the start of the seam and during ON period (kt1) at the...

-

Page 40: Functions Of The Keys Inputs In1

EFKA FP220A5911 Mode 24 Chainstitch Machine (Pegasus MHG-100) Thread trimmer (M1) after stop in position 2 after delay (kd2) during ON period (kt2) Thread trimmer (M2) after stop in position 2 after delay (kd1) during ON period (kt1) Thread wiper (M3) after stop in position 2 after delay (kd3) during ON period (kt3) Sewing foot lifting (see chapter "Sewing Foot Lifting") -

Page 41: Positions

EFKA FP220A5911 10.8 Positions Function with or without control panel Parameter Selection according to position sensor (PGm) Number of angular degrees from the sensor position to position 2 (PGr) Transmission ratio between motor shaft and machine shaft (trr) After setting parameter 270 at “1, 2, 3 or 4“ an angular degree must be selected by means of parameter 271, which determines the stop in position 2 or 1 after the sensor position. - Page 42 EFKA FP220A5911 Connection of a sensor e. g. light barrier or proximity switch to socket B18/7. The following settings are possible using parameter 270: Parameter 270 = 1 - Setting the sensor to position 2. - Position 1 is set according to the angular degree setting by means of parameter 271.

-

Page 43: Setting The Reference Position (Parameter 270 = 0)

EFKA FP220A5911 10.8.1 Setting the Reference Position (Parameter 270 = 0) The angular positions necessary on the machine e.g. “needle down position“ or “thread lever up position“ are stored in the control. A reference position is needed in order to establish a relationship between position transmitter information and actual mechanical position. -

Page 44: Setting The Positions On The V810 Control Panel (Parameter 270 = 0)

EFKA FP220A5911 10.8.3 Setting the Positions on the V810 Control Panel (Parameter 270 = 0) If parameter 270 = 0, the positions integrated in the motor are activated and can be set as follows: " Select parameter 171 F –... -

Page 45: Display Of The Signal And Stop Positions

EFKA FP220A5911 Display of the 1st parameter value " » of position 1 (B key) P1E 140 If necessary, change parameter value " P1E XXX by pressing the +/- or 0...9 keys or by turning the handwheel. Parameter value of position 2 "... -

Page 46: Positioning Shift

EFKA FP220A5911 V820 control panel display Arrow above symbol "position 1" on the 7 key on corresponds to position 1 Arrow above symbol "position 1" on the 7 key turns off corresponds to position 1A Arrow above symbol "position 2" on the 7 key on corresponds to position 2 Arrow above symbol "position 2"... -

Page 47: Inputs For Proximity Switches

EFKA FP220A5911 10.14 Inputs for Proximity Switches Function with or without control panel Parameter Switch proximity switches for inputs in2, in7, in8, in9 (nAm) If parameter 295 is sete at “1“, a load resistor is connected in parallel to inputs in2, in7, in8, in9, which allows to operate 2 wire proximity switches. -

Page 48: Functions With Or Without Control Panel

EFKA FP220A5911 11 Functions with or without Control Panel 11.1 Softstart Function with or without control panel Parameter Softstart On/Off (SSt) Functions: after power on at the beginning of a new seam speed pedal controlled and limited to (n6) lower speed of a parallel function prevailing (e. g. start backtack, stitch counting) - Page 49 EFKA FP220A5911 Function with or without control panel Parameter Automatic sewing foot with pedal forward at the seam end if light barrier or (AFL) stitch counting is On Switch-on delay with pedal in position –1 (half heelback) (t2) Start delay after switching off the sewing foot lift signal...

-

Page 50: Start Backtack/Start Stitch Condensing

EFKA FP220A5911 11.3 Start Backtack/Start Stitch Condensing Function without control panel Control Single start backtack LED 1 On S2 key Double start backtack LED 2 On Start backtack Off both LEDs Off Start stitch condensing On; number of stitches with stitch regulator... -

Page 51: Stitch Correction And Speed Release

EFKA FP220A5911 11.3.3 Stitch Correction and Speed Release Function with or without control panel Parameter Stitch correction time (t8) Delay until speed release after start backtack (t1) Speed release after single and double backtack can be influenced by parameter 200. -

Page 52: Speed N4 At The Seam End

EFKA FP220A5911 11.4.1 Speed n4 at the Seam End Function with or without control panel Parameter End backtack/end stitch condensing speed (n4) When programming 3-digit or 4-digit parameter values on the control, the 2-digit or 3-digit values displayed must be multiplied by 10. -

Page 53: Backtack Synchronization

EFKA FP220A5911 11.4.6 Backtack Synchronization Function with or without control panel Parameter Backtack synchronization for start and end backtack On/Off (nSo) Backtack synchronization speed (nrS) If parameter 298 is on, the backtack speed will be switched to backtack synchronization speed one stitch before engaging and disengaging of the backtack solenoid. -

Page 54: Intermediate Backtack

EFKA FP220A5911 The parameters of the end backtack speed and the backtack stitches forward / backward are identical with the standard end backtack. Difference from the standard end backtack: The drive stops for stitch regulator switching The stop time can be set... -

Page 55: Reverse Motor Rotation

EFKA FP220A5911 Value Duty ratio (ED) Effect low holding power 100 % high holding power (full power) 11.10 Reverse Motor Rotation Function with or without control panel Parameter Positioning speed (n1) Number of reversing degrees (ird) Switch-on delay of reverse motor rotation... -

Page 56: Machine Run Blockage (Safety Switch)

EFKA FP220A5911 Parameter 190 = 4: Sequence with pedal in position –2 / no unlocking of the chain if seam end with light barrier, cutting and run-out stitches is set: Press pedal to position –2 Run at positioning speed to position 1... -

Page 57: High Lift For Walking Foot Signal Output M6 / Flip-Flop

EFKA FP220A5911 Machine run blockage in the start backtack / start stitch condensing: The start backtack / start stitch condensing is interrupted by opening and/or closing the switch. Stop in the basic position Needle up is not possible Sewing foot lift is possible... -

Page 58: High Lift Walking Stitches

EFKA FP220A5911 11.13.3 High Lift Walking Stitches Function with or without control panel Parameter Number of high lift walking stitches (chP) Upon pressing the external key “high lift for walking foot” depending on the setting of parameters 240...249, the speed is limited to high lift walking speed. -

Page 59: Setting The Speed Limitation Depending On High Lift With The V820 Control Panel

EFKA FP220A5911 Graduation of the examples below is as follows: Speed 3500 upper speed break point 3200 3110 3020 2930 2840 2740 ----------------------------------------------------------- X 2650 2560 2470 2380 2280 2190 2100 2000 lower speed break point 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 Levels "... -

Page 60: Setting The Speed Limitation Depending On High Lift With The V810 Control Panel

EFKA FP220A5911 11.14.3 Setting the Speed Limitation Depending on High Lift with the V810 Control Panel Call parameter 188. " Press the E key. [ ° ] " Press theF2 key. Actual display. 1 1. 3 2 0 0 "... -

Page 61: Potentiometer Adjustment On Juki Machine Model Lu-2210/Lu2260

EFKA FP220A5911 11.14.4 Potentiometer Adjustment on JUKI Machine Model LU-2210/LU2260 Set potentiometer (A) in the machine head, which is accessible by a bore at the rear, to the left endstop. Turn the handwheel to position 1 for the speed depending on high lift (minimum high lift). -

Page 62: Disabling Of Flip-Flop Functions At The Seam End

EFKA FP220A5911 11.17 Disabling of Flip-Flop Functions at the Seam End Function with or without control panel Parameter Disabling of flip-flop functions at the seam end On/Off (FFm) Determine by means of parameter 183 whether signals M6 and/or M10 shall be switched off at the seam end. If 183 = 0, the signals can be switched off only by means of the appropriate keys. -

Page 63: Thread Trimming Operation

EFKA FP220A5911 11.19 Thread Trimming Operation Function with or without control panel Parameter Thread trimmer On/Off (FA) Thread wiper On/Off (FW) Function with control panel V820 Thread trimmer or thread wiper On/Off 5 key When a V820 control panel is connected, the functions can also be switched on and off by means of the 5 key. -

Page 64: Chainstitch Machine Trimming Signal Times

EFKA FP220A5911 11.19.4 Chainstitch Machine Trimming Signal Times Signal delay times and ON periods can be set with the help of the following parameters. Function with or without control panel Parameter Delay time output M1 (kd1) ON period output M1... -

Page 65: Functions For Pegasus Mhg-100 Machine (Mode 24)

EFKA FP220A5911 11.22 Functions for Pegasus MHG-100 Machine (Mode 24) Function with or without control panel Parameter Delay time from light barrier uncovered to release of light barrier speed n5 (dnL) Stitch counting until signal M9 Off (cb2) The corresponding values are set automatically in mode 24! See table in chapter “ Preset Values Depending on Mode“. -

Page 66: Start And End Counts

EFKA FP220A5911 Parameter 193 = 0 Thread tension release and chain suction after the light barrier compensating stitches. Parameter 193 = 1 Chain suction from light barrier uncovered onwards and thread tension release after the light barrier compensating stitches. Parameter 199 = 0 Thread tension release On at the seam end until pedal in pos. -

Page 67: Function Of Output Signal M11

EFKA FP220A5911 11.25 Function of Output Signal M11 Function with or without control panel Parameter Functions of signal M11 (m11) The following settings are possible using parameter 297: Parameter 297 = 0 Function according to setting of parameter 290 Parameter 297 = 1 Signal M11 is On whenever the light barrier is uncovered. -

Page 68: Functions For Mode 15

EFKA FP220A5911 When using the V810 control panel, parameter 291 will automatically be set to slide-in strip "7" if 290 = 7. When using the V820 control panel, parameter 292 will automatically be set to slide-in strip "5" if 290 = 7. -

Page 69: Functions For Mode 16

EFKA FP220A5911 Function with control panel V820 Chain suction/blowing at the start of the seam and/or at the seam end On/Off 1 key Stitch counting On/Off 2 key Light barrier On/Off 3 key Tape cutter at the start of the seam and/or at the seam end On/Off... -

Page 70: Manual Tape Cutter/Fast Scissors

EFKA FP220A5911 Function with control panel V820 Tape cutter/Fast scissors at the start of the seam On/Off 1 key Tape cutter/Fast scissors at the seam end On/Off 2 key Light barrier On/Off 3 key Chain suction On/Off 4 key Blow fabric onto stack from light barrier uncovered onwards On/Off... -

Page 71: Manual Stacker

EFKA FP220A5911 11.28 Manual Stacker Function with or without control panel Parameter Stacker function with open/closed key (iS1) ON period for manual stacker (ktS) After pressing the key that has been allocated for the purpose, a stacker signal will be issued for a certain period of time (parameter 265) at output M7 (socket ST2/23). -

Page 72: Stitch Counting Speed

EFKA FP220A5911 11.30.2 Stitch Counting Speed Function with or without control panel Parameter Positioning speed (n1) Stitch counting speed (n12) Speed mode for a seam with stitch counting (SGn) Activation of speed n12 when key is open/closed (ktS) Speed control for stitch counting can be selected by means of parameter 141. -

Page 73: Light Barrier

EFKA FP220A5911 11.32 Light Barrier Function with or without control panel Parameter Light barrier On/Off Function with control panel V820 Light barrier covered/uncovered On righthand arrow above key On 3 key Light barrier uncovered/covered On lefthand arrow above key On... -

Page 74: Reflection Light Barrier Ls002

EFKA FP220A5911 11.32.3 Reflection Light Barrier LS002 Sensitivity setting: Set minimum sensitivity depending on the distance between light barrier and reflection area (turn potentiometer as far as possible to the left). Potentiometer directly on the light barrier module Mechanical orientation: Orientation is facilitated by a visible light spot on the reflection area. -

Page 75: Functional Variations Of The Light Barrier Input

EFKA FP220A5911 11.32.7 Functional Variations of the Light Barrier Input Function with or without control panel Parameter Selection of the input function on socket B18/5 If the light barrier function is not used, a switching function can be assigned to the input on socket B18/5 as well as to inputs in1...i10. -

Page 76: Software Debouncing Of All Inputs

EFKA FP220A5911 240 = 21 Handwheel running in the direction of rotation: Upon pressing the key, the drive runs in the opposite direction of rotation according to the setting of parameter 161. 240 = 22 Speed limitation n11 (flip-flop 2): Upon pressing the key in the seam, the speed limitation n11 is enabled, and a signal is issued at the output ST2/29. -

Page 77: Functioning Of Handwheel When Pressing A Key

EFKA FP220A5911 The following functions are possible using parameters 293 and 294: 293/294 = 0 Input function blocked 293/294 = 1 Needle up/down: Upon pressing the key, the drive runs from position 1 to position 2 or from position 2 to position 1. If the drive is not in the stop position, it runs to the preselected basic position. -

Page 78: Signals A1 And A2

EFKA FP220A5911 Parameter 124: Maximum value for speed limitation with external potentiometer Parameter 125: Minimum value for speed limitation with external potentiometer The following functions for speed limitation are possible by means of external potentiometer using parameter 126: Parameter 126 = 0 Function “external potentiometer”... - Page 79 EFKA FP220A5911 P aram eter FA- E P = 0 [m s] [m s] [St] [St] 0256/ B I LD 4 NA = Start of seam LS-D = Light barrier covered at the start of the seam P=0 = Pedal in pos. 0 (neutral)

-

Page 80: Signal "Machine Running

EFKA FP220A5911 The ON periods can be selected separately for signal A1 by means of parameter 305 and for signal A2 by means of parameter 315. The speed mode can be set separately for signal A1 by means of parameter 306 and for signal A2 by means of parameter 316. -

Page 81: Signal Output 512 Impulses Per Rotation

EFKA FP220A5911 11.42 Signal Output 512 Impulses per Rotation Transistor output with open collector Signal whenever a generator slot of the position transmitter is sensed 512 impulses per rotation of the handwheel Independent of sewing, thus also when turning the handwheel manually Suitable e. -

Page 82: Audible Signal

EFKA FP220A5911 Function with or without control panel Parameter Speed stage graduation (nSt) The pedal characteristics (speed change from stage to stage) can be varied. Possible characteristic curves: - linear - progressive - highly progressive 11.44 Audible Signal Function with control panel... - Page 83 EFKA FP220A5911 Note If an input If an input is active with open contact, the corresponding arrow lights up when the contact is open. active with closed contact, the corresponding arrow lights up when the contact is closed. Output Test: Select the desired output by means of the +/- keys Enable the selected output by means of the >>...

-

Page 84: Error Displays

EFKA FP220A5911 13 Error Displays General Information On the control On the V810 On the V820 Signification InF A1 InF A1 Pedal not in neutral position when turning the machine on -StoP- blinking -StoP- blinking + Machine run blockage symbol display... -

Page 85: Operating Elements Of The V810 Control Panel

EFKA FP220A5911 14 Operating Elements of the V810 Control Panel variocontrol 810 K L2185 The V810 control panel is supplied with the no. 1 slide-in strip above the keys. For different functions the strip can be replaced with another one supplied with the control panel. Set parameter 291 in this case. See also V810 / V820 instruction... -

Page 86: Operating Elements Of The V820 Control Panel

EFKA FP220A5911 15 Operating Elements of the V820 Control Panel variocontrol 820 K L2186 The V820 control panel is supplied with the no. 1 slide-in strip above the keys. For different functions the strip can be replaced with another one supplied with the control panel. Set parameter 292 in this case. See also V810 / V820 instruction... - Page 87 – http://www.efka.net OF AMERICA INC. 3715 NORTHCREST ROAD – SUITE 10 – ATLANTA – GEORGIA 30340 PHONE: (770)457-7006 – TELEFAX: (770)458-3899 – email: efkaus@efka.net ELECTRONIC MOTORS SINGAPORE PTE. LTD. 67, AYER RAJAH CRESCENT 05-03 – SINGAPORE 139950 PHONE: 7772459 – TELEFAX: 7771048 – email: efkaems@efka.net...

Need help?

Do you have a question about the dc 1500 and is the answer not in the manual?

Questions and answers