Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Rohde TC 504

- Page 1 TC 504...

-

Page 2: Table Of Contents

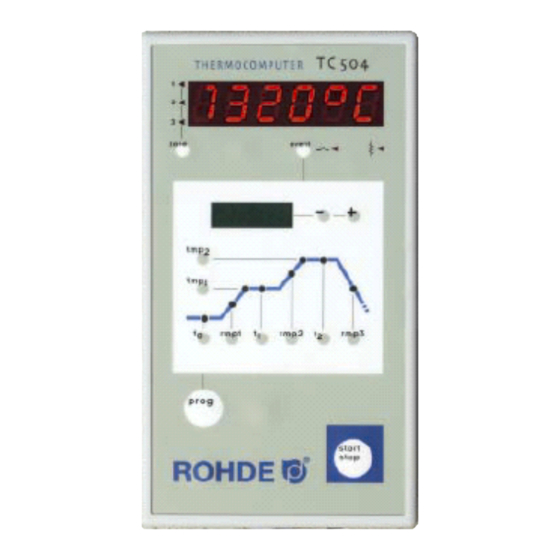

Appendix E: Calling up equipment.......... Appendix F: Electrical connection.......... General Information You have opted for a TC 504 controller, the professional model of the highly advanced bentrup TC 500 series. This controller series applies world-wide leading state-of-the-art technology for this controller type. The controller is very easy to operate from the outside. -

Page 3: Operating Elements

Quick instructions Starting the programme: Changing the programme: 1.-2. Power on. Red display of actual temperature. The power switch is located at See left. the bottom of the controller housing. Call up a programme by pressing the button one or several times. The Call up adjustable firing curve values. - Page 4 The microprocessor of your TC 504 controller allows you to control your kiln with high precision and reproducible results. The firing curve of the TC 504 is illustrated in the following diagram. In consists of various segments: Delay time / delay of programme start The controller waits for the preset period of time until it starts the actual firing process.

-

Page 5: Firing Curve

Calling up a Programme The TC 504 has the capacity of storing 10 firing curves (programmes). The manufacturer has preset the programmes with standard firing curves, which can be modified. The preset programmes contain the following values: rmp3 Prog.nr. Description t0(min) rmp.1(°C/h) - Page 6 By means of the firing curve you can monitor how the TC 504 executes the firing segments one by one. The programme is finished, when the kiln has reached 150° C during the cooling process. At that moment the display (3) will show “End”...

-

Page 7: Input And Control Of Firing Curve

Input and control of a firing curve You can view and adjust the preset values of the firing curve at any time, i.e. even while the programme is running. You only have to stop the programme if you want to change the values. In order to control e.g. -

Page 8: Display Of Kiln Temperature

You can retrieve the kiln temperature values one by one by pressing the “zone” (2) key. The TC 504 also supports multi-zone kilns. The symbols to the left of the red display indicate which zone belongs to which kiln value. The sequence of the displayed process values can be determined in the configuration. - Page 9 Current day and time The TC 504 can be equipped with a real-time clock 14.45 with weekday function for an automatic programme start (optional, can be upgraded). If the TC 504 is equipped with this function the weekday and time are displayed in this place for control purposes.

-

Page 10: Locking The Controller

The TC 504 can be locked against unauthorized access by a key lock. Press the “O” of ROHDE for at least 3 seconds. If the keys are locked you can see a dot in the red display on the left side next to the temperature display. -

Page 11: Forward Switching In Skip Ramps

SKIP ramps the final temperature has been reached. For multi- zone kilns the TC 504 will wait at every zone. In order to prevent the kiln from locking itself due to heat shifts between the zones a complex algorithm automatically decides when a segment has to be terminated. -

Page 12: Appendix A: Event Display Of Tc 504

Event display of will be treated accordingly. Important events will be displayed immediately on the red display according TC 504 to the codes (see example to the left, code A4). The events are stored internally (see Appendix B). The event codes are categorized into operating and controller problems (code A…), power failure... - Page 13 Event A4 Temperature increase too low despite heating on full load This error message always indicates a problem at the kiln. Possible causes: • Mains supply fuse / phase, heating element defect • Heating elements too old (at high temperatures) •...

- Page 14 Event B3 Firing has been interrupted after power failure After the power has retured after power failure the firing process has been aborted as e.g. the kiln temperature has dropped too far in the meantime. Further information about the event might be displayed by adding a decimal number (e.g.

-

Page 15: Appendix B: Data And Event Memory

Appendix B Your TC 504 controller is equipped with a memory for data and events. All data produced during the entire Data and events firing process are recorded. This is a unique feature in controllers of this kind. You will no longer have to... -

Page 16: Calling Up Stored Data

Alternatively you can also leave the data display by pressing the “O“ in ROHDE(10) key followed by “tmp1“ (5). Please note: The controller stores a value every 60 seconds. A very short switch impulse might not be visible in the data memory if it has happened in between two recordings. -

Page 17: Calling Up Stored Events

Calling up stored In order to call up the event memory press the “O” key followed by the tmp2 key. events You may do this at any time, even if a programme is in operation. The red display will show the letter “E” (for “Event”) and a consecutive number. -

Page 18: Appendix C Configuration

Appendix C Some of the settings of the TC 504 depend on the kiln or the application. Usually the required settings have been Configuration made by your kiln manufacturer. If you are technically minded you may make changes yourself if required. The controller will store changes permanently. -

Page 19: Explanation Of Parameters

Explanation of parameters (in brackets: parameter numbers) Kiln performance (1) The kiln performance value is only used for calculating the energy consumption. For multi- zone kilns you have to input the overall performance. The controller assumes an even distribution of heating performance for the calculation. Thermocouple Code (3) Type of the temperature sensor. - Page 20 Funktion of 1./2./3. additional control outlet (13) ff. The TC 504 is available with up to 4 control outlets. For single-zone kilns you can opt for up to 3 control outlets for special functions. The respective functions have to be configurated.

-

Page 21: Calling Up Configuration

Calling up the configuration Please press the zone key and keep it pressed for approx. 3 seconds. The TC 504 will switch into configuration mode and shows the first parameter of the list (see previous page). The red display shows the parameter number, the green display shows the current value. -

Page 22: Appendix D: Data Interface (Optional)

Appendix D Data interface The TC 504 can be equipped with a RS232C data interface (for connection to a PC serial port) or a RS422/485 interface for industrial use. The electric signals are separated by galvanization. With the data interface you have full access to all process values, programmes, configuration parameters and operation commands. -

Page 23: Appendix F: Electrical Connection

Please compare the type of the thermocouple with the type specification that is stated on the back of the controller. Otherwise you might cause damage to the kiln and the kiln content! We reserve the right to make changes contributing to technical improvement. Instruction Manual TC 504 V1.20 (C) 2004 HELMUT ROHDE GMBH DEUTSCHLAND Ceramics: 06/2004...

Need help?

Do you have a question about the TC 504 and is the answer not in the manual?

Questions and answers