Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Vortex MINI ROK

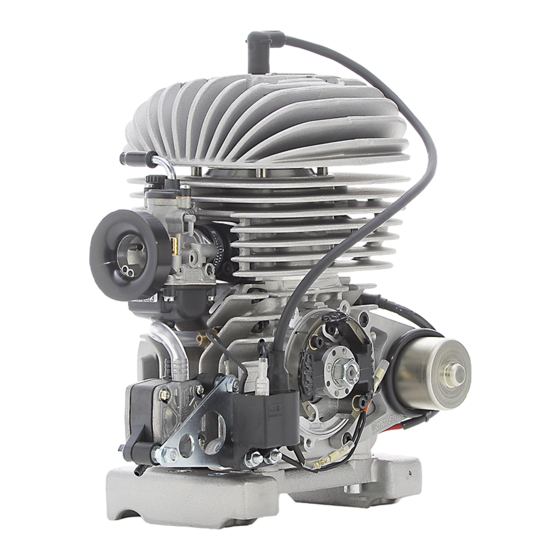

- Page 1 MINI R OK OWNER’S MANUAL ...

- Page 2 INDEX 1. GENERAL I NFORMATION 3 1.1. I ntroduction 3 1.2. S ymbols 3 1.3. S afety I nformation 3 1.4. ...

-

Page 3: I Ntroduction

Vortex u pdate t his m anual c onstantly. A ll t he i nformation i n t his m anual i s b ased o n ... -

Page 4: T Echnical S Pecifications

Vortex M ini R ok E ngine i s p roduced i n o ne v ersion o nly. H owever, r efer t o y our ... -

Page 5: Engine A Ssembling

2. ENGINE A SSEMBLING I n o rder t o p erform t his j ob, y ou w ill n eed t he f ollowing t ools: ... - Page 6 3 Engine W heelbase M easurements i n c ase y ou need t o d rill y our e ngine m ount. 4 1 0mm F ixed W rench Use 2 silent blocks screwing into engine (without loctite), mount metal-chromed bracket on short threads protruding from...

- Page 7 7 Insert “ stop” c able e nd c oming f rom t he ignition i nto t he c oil p lug. Flat S crewdriver Remove ...

- Page 8 11 Flat S crewdriver Ensure t he c arburettor i s c orrectly s eated, t hen tighten t he c arburetor t o t he i nlet m anifold b y using ...

- Page 9 15 8 m m F ixed W rench Tighten t he c arburettor t hrottle c able r egister elbow. 16 Pass t he t hrottle c able t hrough t he s pring a nd into ...

- Page 10 19 Hook t he l ead n ut i n t he s lide b y m oving i t aside o f t he c enter. 20 ...

- Page 11 Optional addition as per KA Homologation for return line to tank with fixed restrictor inserted inside line. *Note: Fuel tank requires professional fitment of a bottom fuel feed fitting to facilitate this option of return line to top of tank.

- Page 12 28 Insert t he "Vortex AU" debris filter i nto t he intake s ilencer. T here i s a s lot i n t he r ubber ...

- Page 13 31 Flat S crewdriver Attach t he a ssembled i ntake s ilencer t o t he adaptor a nd f ix i t b y u sing t he s pecific c lamp provided.

-

Page 14: Engine/Chassis A Ssembly

3. ENGINE/CHASSIS A SSEMBLY 1 5 m m A llen W rench + 1 0 m m F ixed Wrench Place t he s procket i n t he s procket c arrier a nd tighten ... - Page 15 5 1 7 m m F ixed W rench Once c hain t ension i s c orrect, t ighten m ount clamps c ompletely a nd r e-‐check t he c hain tension ...

- Page 16 9 3 mm A llen W rench Insert a c lamp i nto t he t hrottle c able a nd p ass the f ree e nd t hrough t he w elded r ing o n t he throttle ...

- Page 17 13 4 m m A llen W rench + 1 0 m m F ixed Wrench Remove r elay f rom s ocket i n t he w iring l oom. Secure ...

- Page 18 17 Secure t he r elay w ith t he s pecific s pring provided. Be s ure t he s pring i s i n t he r ight p osition a nd pressing. ...

- Page 19 21 11 m m S ocket W rench Before f itting t he e xhaust m anifold r emove t he exhaust g asket a nd t he e xhaust p ort c over. R efit the ...

-

Page 20: Starting A Nd B Rake-‐In

4. STARTING A ND B RAKE-‐IN Only a p roper b reak-‐in w ill i nsure t he b est p erformance o ut o f y our e ngine i n t he f uture a nd guarantee ... -

Page 21: Servicing Y Our E Ngine

5. SERVICING Y OUR E NGINE Good m aintenance i s e ssential f or s afe, e conomical a nd t rouble-‐free o peration. H ere y ou w ill f ind a ... -

Page 22: Ize A Nd M Easure

5.3. S izes a nd M easures Tolerance C ylinder/piston 0.10 + 0.05mm Timming 3mm Piston S izes W240/MR01A 41,88 W240/MR03A 41,91 W240/MR06A 41,93 ... -

Page 23: Throttle C Able

Changing m ain j et: 1.Take t he i ntake s ilencer o ff t he c arburettor b y unscrewing t he c lamp. I t i s n ot n ecessary t o u nscrew the ... -

Page 24: C Lutch A Nd Tarter G Ear

3.Stop t he c lutch d rum b y u sing t he s pecial t ool d esigned b y Vortex f or t his s pecific t ask. ... - Page 25 3.Stop t he c lutch d rum b y u sing t he s pecial t ool d esigned b y Vortex f or t his s pecific t ask. ...

-

Page 26: P Inion

2.Stop t he c lutch d rum b y u sing t he s pecial t ool d esigned b y Vortex s tandard a ssembling i s Z 11. ... -

Page 27: Cylinder

5.12. C ylinder Every 3 0 h ours c ylinder m ust b e In o rder t o p erform t his j ob, w e h ighly r ecommend t aking honed. ... - Page 28 variations o n t he c ylinder h ead 2.Remove t he c arburettor f rom t he e ngine b y u nscrewing volume. the s pecific c lamp. 3.Unscrew ...

-

Page 29: Connecting R Od

5.14. C onnecting R od Every 6 0 h ours t he r oller c age m ust b e c hanged. D uring t his o peration i s g ood u se t o c heck, a nd ... -

Page 30: Engine E Xploded V Iew A Nd P Art L Ist

6. ENGINE E XPLODED V IEW A ND P ARTS L IST... - Page 31 W610/1MRC04 Cylinder Base Gasket 0.4mm W610/1MRC05 Cylinder Base Gasket 0.5mm W461/1VLC Cylinder stud bolt m8 x 142mm W2050/MR Inlet manifold phbg 18 Mini Rok W825/1MR Carburettor clamp d.23-35mm V.TCE6X16 Socket-head screw m6 x 16mm W820/MR Dellorto carburettor phbg 18b W981400...

- Page 33 MINI ROK ENGINE SPARE PARTS Number Part Number Description Max. No. W050/MRC Complete crankcase 60cc with bearings V.TCE6X40 Socket head screw m6 x 40mm V.TCE6X45 Socket-head screw m6 x 45mm W075/1 Crankcase dowel 10 x 10,5 x 6,5mm W10267 Copper gasket d. 8 x 12 x 1mm...

- Page 35 MINI ROK ENGINE SPARE PARTS Number Part Number Description Max. No. W240/MR01A Complete Piston 41,88mm W240/MRO3A Complete Piston 41,91mm W240/MR06A Complete Piston 41,93mm W240/MR09A Complete Piston 41,95mm W240/MR11A Complete Piston 41,98mm W260/MR95L Piston ring 41,95mm W260/MR00L Piston ring 42,00mm W260/MR05L...

- Page 37 MINI ROK ENGINE SPARE PARTS Number Part Number Description Max. No. W410/MR Coil Mini Rok W531/06 Nut m6 x 1mm W570/12 Flat washer D6 x1 2 x 1,5mm W2052/MR Fuel pump support plate W440 Coil fix. Silent - block W11023...

- Page 39 MINI ROK ENGINE SPARE PARTS Number Part Number Description Max. No. W850/1AF Air Filter Mini Rok AU 134A W850/1AFD AIRFILTER YELLOW DIRT/SPEEDWAY W856/MR Mini rok filter support W850/1MR Airbox WA052/KF Clutch puller WA061 Clutch nut fix key 139A WA053/MR 24mm clutch removal socket...

- Page 40 In vigore dal - Effective from 01-02-2016...

- Page 41 MINI ROK ENGINE SPARE PARTS Number Part Number Description Max. No. 161V W820/MR Dellorto carburettor 162H W53036-78 Tube 90° kit 163I W53031-78 Carby Cap W9597-61 Gas valve spring W14958-21 Needle Retainer W9596211 Circlip W959523 Needle W23 W947540-764 Slide 40 x 64...

- Page 43 MINI ROK ENGINE SPARE PARTS Number Part Number Description Max. No. VTCE10X50 Socket head screw 10x50 0039.V28A Engine Mount Bracket (Shorter) 0039.V28 Engine Mount Bracket (Long) 0039.R28 Flat Engine Mount (MR) VTCE8X35 Socket Head screw 8x35 www.vortex-engines.com.au...

- Page 44 ⸀ 愀 甀...

- Page 45 7. CONTACTS Manufacturer Vortex F actory Via E . F ermi 5 27040 – C ampospinoso Italy Tel: + 39 0 385 7 65200 ...

Need help?

Do you have a question about the MINI ROK and is the answer not in the manual?

Questions and answers