Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Aertesi BREZZA DOUBLE Series

- Page 1 Technical Manual New Water Cassette Series BREZZA DOUBLE...

- Page 2 AERTESI srl Cassetta BREZZA DOUBLE Tecnical manual Pag.2 AER.MT.I.BREDOPPIA.000.02.15...

-

Page 3: Table Of Contents

INDEX 1-INTRODUCTION………………………………………………………………………………………………………………………4 2- WORKING CONDITION LIMITS……………………………………………………………………………………….……….4 3- COANDA EFFECT…………………………………………………………………………………………………………………….4 4- KEY READING CODES………………………………………………………………………………………………………………5 5-TECHNICAL DETAILS………………………………………………………………………………………………………………..6 6-TECHNICAL DATA (AC motors)…………………………………………………………………………………………………8 6.1-Cassette with 3 rows coil ....................... 8 7-TECHNICAL DATA(EC motors)………………………………………………………………………………………………….9 7.1-Cassette with 3 rows coil ....................... 9 8- COIL TECNICAL DATA(AC motors)………………………………………..……………………………………………….10 8.1- Cassette with 1 or 2 rows coil ..................... -

Page 4: 1-Introduction

1-INTRODUCTION The new Water Cassette Series units BREZZA are designed for air conditioning in residential and commercial plants. The installation is indoor and not exposed to ice or extreme temperatures, dust-free environment and not explosive materials. The manufacturer is not responsible in case of incorrect use. The series BREZZA is proposed with traditional AC motors with three speeds and which EC motors with low consumption. -

Page 5: 4- Key Reading Codes

In case where the ceiling is higher than 3m, accordingly there is the need to channel down the air flow, Aertesi provides an accessory panel with adjustable flaps. So you can set manually, for each of the four turns, the orientation of the flow: horizontal (with Coanda effect), or in vertical position. -

Page 6: 5-Technical Details

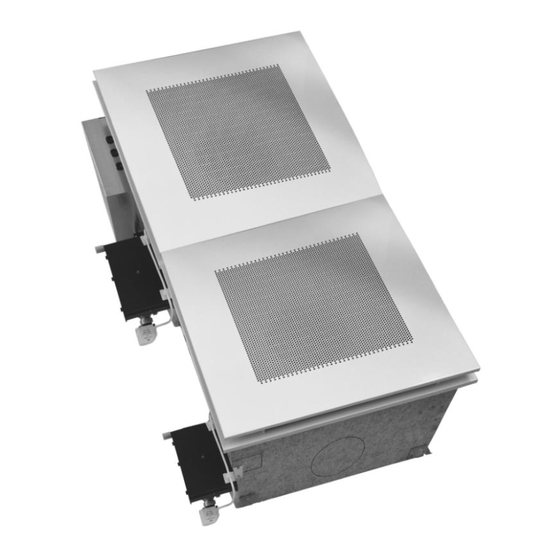

5-TECHNICAL DETAILS STRUCTURE: made on galvanized steel sheet, thickness 1.00mm. The robust design prevents the vibration and it includes mounting brackets to the ceiling. FRONTAL PANEL: painted plate thickness 0.8mm. The conformation of the baffles ensures a Coanda Effect to the air flow output. As an accessory, you can have the adjustable deflectors to have the Coanda effect or vertical airflow (or intermediate positions). - Page 7 INSULATION: cassette body insulated with cross-linked polyethylene foam 10 mm thick, class B-BL-s2d0 s1d0 according to EN13501-1. Front panel insulated with polyethylene thickness 3mm. ELECTRICAL BOARD: made of galvanized steel plate and positioned on the same side of water connections. CONDENSATE DRAIN PUMP: centrifugal type, equipped with a double level float (on-off pump and alarm) and check valve (to avoid the return of odors from the plughole and reduce the noise power).

-

Page 8: 6-Technical Data (Ac Motors)

6-TECHNICAL DATA (AC motors) 6.1-Cassette with 3 rows coil 2 TUBI 4 TUBI Speed(E) Airflow mc/h 1140 1260 1470 1140 1260 1470 COOLING – Air 27°C b.s. , 19°C b.u. – Input water temperature 7°C , output water temperature 12°C Total capacity(E) 4,11... -

Page 9: 7-Technical Data(Ec Motors)

7-TECHNICAL DATA(EC motors) 7.1-Cassette with 3 rows coil 2 PIPES 4 PIPES Speed(E) Airflow mc/h 1120 1050 1520 1120 1050 1520 COOLING – Air 27°C d.b. , 19°C w.b.. – inlet water temperature 7°C , output water temperature 12°C 3,11 5,28 7,35 4,17... -

Page 10: 8- Coil Tecnical Data(Ac Motors)

8- OPTIONAL COIL TECNICAL DATA(AC motors) 8.1- Cassette with 1 or 2 rows coil 2 PIPES 4 PIPES Speed mc/h 1140 1260 1470 1140 1260 1470 Airflow COOLING – Air 27°C d.b. , 19°C w.b.. – inlet water temperature 7°C , output water temperature 12°C 3,37 4,53 5,94... -

Page 11: 9-Technical Data Optional Coils (Ec Motor)

9-TECHNICAL DATA OPTIONAL COILS (EC motor) 9.1- Cassette with1 or 2 rows coil 2 PIPES 4 PIPES Speed Airflow mc/h 1120 1050 1520 1120 1050 1520 COOLING – Air 27°C d.b. , 19°C w.b.. – inlet water temperature 7°C , output water temperature 12°C 2,46 4,38 5,85... -

Page 12: 10-Dimensional & Weight

10-DIMENSIONAL & DRAWINGS Batteria principale IN 1/2" Batteria principale OUT 1/2" Batteria ausiliaria IN 1/2" Batteria ausiliaria OUT 1/2" Scarico condensa d.12 132/162 133/163 134/164 135/165 Unit gross Weight Internal volume main coil litri Internal volume auxiliary coil litri... -

Page 13: 11-Accessories

11-ACCESSORIES Accessories available are: HYDRAULIC ACCESSORIES A/K/C V22 2-way valve ON-OFF 230V V42 2-way valve ON-OFF for 4 pipe V23 3-way valve ON-OFF 230V V43 3-way valve ON-OFF 230V for 4 pipe V22M V22M Valve 2-way modulating 0-10V V42M V42M Valve 2-way modulating 0-10V for 4 pipe V23M V23M valve 3 way modulating 0-10V V43M... - Page 14 Valves can be supplied to the unit assembled or in kit (disassembled parts). All codes kits include two valves, one for each battery in double cassette. The drain pan is supplied as standard with the cassette, without extra-price (ADPB) The cassette have two double 1200x600 kit valves, one for the right battery and one for the left battery. Both kits valves are connected in parallel, the aim is a kit consisting of hoses and TEE brass (see paragraph on accessory Flex2 - Flex4).

-

Page 15: Hose Connecting Valves (Flex2 And Flex4)

VALVES FOR MAIN COILS 132-133-134-135-162- 163-164-165 VALVES FOR AUXILIARY COILS 134-135-164-165 GENERAL FEATURES Size connections 1/2" 3/4" Kv (valvola 2 vie) Kv (valvola 3 vie, via diritta) Kv (valvola 3 vie, by-pass) Max differential pressure 2,0bar 1,0bar Nominal pressure 16bar Nominal pressure 4-110°C ON-OFF ACTUATOR... -

Page 16: Condensate Drain Pump Auxiliary (Pscc-Bi)

11.3- Condensate drain pump Auxiliary (PSCC-BI) The supplementary condensate drain pump is supplied assembled outside of the box, at the side of the drainage pipe. Then must provide for the possibility of inspection also on this side. Maximum water flow 20 l/h Maximum discharge height 10m (4l/h) - Page 17 ELECTRICAL CONNECTIONS FOR 3 SPEEDSCONTROL : you must close the jumpers J3 and J4; jumpers J1, J2, J5, J6 are reserved to factory settings and should not be changed. Model 7x-13x opened closed closed closed closed closed 9x-16x closed opened closed closed closed...

- Page 18 ELECTRICAL CONNECTIONS FOR CONTROL SIGNAL 0-10V: you must open the jumpers J3 and J4; jumpers J1, J2, J5, J6 are reserved to factory settings and should not be changed. Model 7x-13x closed closed opened opened opened opened 9x-16x closed closed opened opened closed...

-

Page 19: Flange For Air Delivery Duct (Flma)

11.5- Flange for air delivery duct (FLMA) You can connect up to 3 throws ducted through D.160 collars. The available prevalence is a function of the number of collars connected and the air flow rate. Collars positions are represented in the figure below. 11.6- Flange for external air intake (FLAE-FLAE2) It is possible to connect an external air intake via a D.100 collar. -

Page 20: 12-Electrical Wiring Diagrams

12-Electrical wiring diagrams 12.1- Wiring diagram cassette with AC motor... -

Page 22: Wiring Diagram Cassette With Ec Motor

12.2-Wiring diagram cassette with EC motor... - Page 23 0-10V signal for motor control NOTES: ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ ________________________________________________ Aertesi srl. It reserves the right to introduce at any time whatever modifications deemed necessary for improving the product with possible modification of the relevant technical data...

- Page 24 Aertesisrl Unipersonale viale della tecnica, 6a 35026 Conselve (PD) ITALY t. +39.049.9501109 f. +39.049.9500823 www.aertesi.com info@aertesi.com...

Need help?

Do you have a question about the BREZZA DOUBLE Series and is the answer not in the manual?

Questions and answers