Summary of Contents for Basler BE1-CDS240

- Page 1 INSTRUCTION MANUAL CURRENT DIFFERENTIAL SYSTEM BE1-CDS240 Publication: 9365200990 Revision: F 12/08...

- Page 3 INTRODUCTION This instruction manual provides information about the operation and installation of the BE1-CDS240 Current Differential System. To accomplish this, the following information is provided: General information, specifications, and a Quick Start guide. Functional description and setting parameters for the input/output functions, protection and control functions, metering functions, and reporting and alarm functions.

- Page 4 December 2008 CONFIDENTIAL INFORMATION of Basler Electric, Highland Illinois, USA. It is loaned for confidential use, subject to return on request, and with the mutual understanding that it will not be used in any manner detrimental to the interest of Basler Electric.

-

Page 5: Revision History

REVISION HISTORY The following information provides a historical summary of the changes made to the BE1-CDS240 hardware, firmware, and software. The corresponding revisions made to this instruction manual (9365200990) are also summarized. Revisions are listed in reverse chronological order. BESTCOMS Software... - Page 6 Updated Table 6-3, Logic Variable Status Report Format, with new logic bits for 59XPU and 59XT. C, 03/04 Enhanced the 24 feature. Added virtual restraint. Minor text edits. B, 10/03 Initial release BE1-CDS240 Introduction 9365200990 Rev F...

-

Page 7: Table Of Contents

SECTION 14 BESTCOMS SOFTWARE ....................14-1 APPENDIX A TIME OVERCURRENT CHARACTERISTIC CURVES ........... A-1 APPENDIX B OVEREXCITATION (24) INVERSE TIME CURVES ............B-1 APPENDIX C TERMINAL COMMUNICATION..................C-1 APPENDIX D SETTINGS CALCULATIONS ..................D-1 9365200990 Rev F BE1-CDS240 Introduction... - Page 8 This page intentionally left blank. BE1-CDS240 Introduction 9365200990 Rev F...

-

Page 9: Section 1 General Information

BESTlogic............................1-24 GENERAL SPECIFICATIONS......................1-24 AC Current Inputs..........................1-24 Analog to Digital Converter ......................1-25 Power Supply ........................... 1-25 Output Contacts ..........................1-25 Control Inputs ........................... 1-25 IRIG ..............................1-26 Contact Inputs ..........................1-26 9365200990 Rev F BE1-CDS240 General Information... - Page 10 Figure 1-8. Style Number Identification Chart ..................1-17 Figure 1-9. Typical 87 Response Characteristic Curves ................. 1-19 Tables Table 1-1. Control Input Burden ......................1-26 Equations Equation 1-1. Time to Trip ........................1-22 Equation 1-2. Time to Reset........................1-22 BE1-CDS240 General Information 9365200990 Rev F...

- Page 11 BESTCOMS to perform the most common protection and control requirements or create a custom scheme using BESTlogic. The BE1-CDS240 is available in a fully draw-out MX case with configurations for horizontal 19" rack mounting, horizontal panel mounting and vertical panel mounting. BE1-CDS240 features include: ...

-

Page 12: I/O Functions

(based software application that enhances communication between the PC user and the BE1-CDS240 relay. This software is provided free with every BE1-CDS240 relay. Another software application tool is BESTWAVE. BESTWAVE is a utility program to view standard COMTRADE (Common Format for Transient Data Exchange) files like those recorded by Basler Electric multifunction relays. -

Page 13: Protection And Control Functions

One (1) zero sequence overvoltage element (59X) provides protection for ground faults on ungrounded systems using calculated 3VO. Frequency Protection Six (6) over/underfrequency protection elements are provided: 81, 181, 281, 381, 481, and 581. 9365200990 Rev F BE1-CDS240 General Information... -

Page 14: Metering Functions

Ampere demand registers are provided for monitoring A, B, C, N, and Q. These registers are assignable to any of the current input circuits. The demand interval and demand calculation method is separately settable for phase, neutral and negative-sequence measurements. BE1-CDS240 General Information 9365200990 Rev F... - Page 15 Active alarms can be read and reset from the optional HMI or from the communications ports. Seventy (70) alarm conditions are available to be monitored including user definable logic conditions using BESTlogic. 9365200990 Rev F BE1-CDS240 General Information...

-

Page 16: Communication Ports

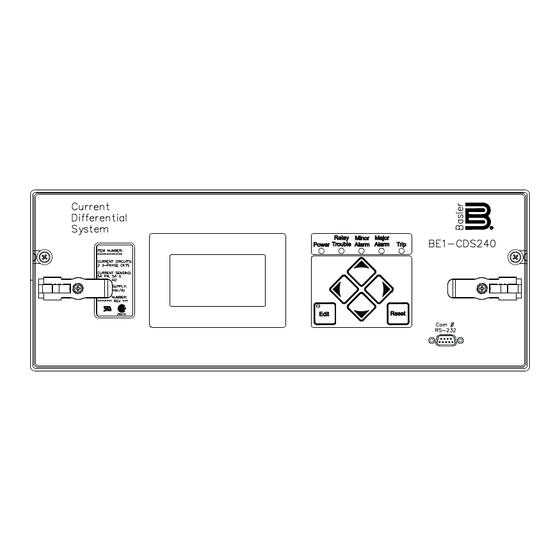

Human-Machine Interface Each BE1-CDS240 comes with a front panel display with LED (light emitting diode) indicators for power, relay trouble alarm, minor alarm, major alarm, and trip. Each BE1-CDS240 also comes with the software application program BESTCOMS for the CDS240. This program is a user ... -

Page 17: Installation

Installation The BE1-CDS240 is available in two, fully draw-out, case styles; MX vertical can be mounted as an M1, M2, FT31, or an FT32. MX horizontal units can be panel mounted or 19" rack mounted. ... -

Page 18: Differential Protection Application Considerations

In addition, digital technology provides a transient monitor function that enables the BE1-CDS240 relay to detect the onset of CT saturation to ride through the condition to further enhance security from misoperation caused by poorly performing CTs. -

Page 19: Problem 2: Measured Current Magnitude Mismatch

This is illustrated in Figure 1-3. BE1-CDS240 Solution The BE1-CDS240 relay applies a tap adjustment factor to the measured currents to cancel the effect of dissimilar CT ratio and voltage bases by converting the currents to per unit quantities on a common base. -

Page 20: Problem 4: Phase Angle Shift

It can be seen that the primary currents flowing into the zone of protection when tap is adjusted for magnitude mismatch still do not sum to zero as shown in Figure 1-4, Illustrations B and C. 1-10 BE1-CDS240 General Information 9365200990 Rev F... - Page 21 180 out of phase with each other. They will always sum to zero (after tap adjust for magnitude mismatch) under all conditions of balance or unbalance except when there is a fault inside the zone of protection. 9365200990 Rev F BE1-CDS240 General Information 1-11...

- Page 22 CT performance calculation. The BE1-CDS240 relays support the traditional solution so that they may be used in retrofit/modernization projects. However, in a numerical relay, it is possible to connect all of the CTs in wye as shown in Figure 1-6 so that the drawbacks mentioned above are not a consideration.

-

Page 23: Figure 1-6. Three-Phase Connections, Delta-Wye Configuration, Internal Phase Compensation

NOTE The BE1-CDS240 relay uses transformer internal connection information to determine the correct phase compensation to use. It is not possible to reliably determine the phase compensation settings based simply upon phase angle shift information because the phase shift from high to low side is dependent upon the phase-sequence of the power system phasors. -

Page 24: Figure 1-7. Traditional Zero-Sequence Trap For Application With Ground Banks

CT delta just as they circulate in the delta of the power transformer on the delta side. The BE1-CDS240 selects the proper phase shift compensation settings to not only provide the correct phase shift but also to block zero-sequence currents as appropriate. -

Page 25: Problem 6: Transformer Energization Inrush And Overexcitation

This application is greatly simplified with the BE1-CDS240. The user can connect all CTs in wye and specify that the delta transformer winding has a ground source. The BE1-CDS240 will apply delta compensation to the wye winding to obtain phase shift and zero-sequence compensation for that current input. -

Page 26: Model And Style Number Description

Finally, the can compensate to maintain accuracy at off-nominal frequency. The BE1-CDS240 uses frequency tracking to adjust the sampling interval to maintain full accuracy across a wide frequency range so that it is both secure and dependable in all applications. For example, tripping of important transformers during a disturbance that causes the system to go unstable can have a catastrophic affect on an already over stressed power system. -

Page 27: Figure 1-8. Style Number Identification Chart

10 to 75 hertz Accuracy: ±0.01 hertz, ±1 least significant digit at 25C Sensing Input 3 Wire Sensing: Phase A - B 4 Wire Sensing: Phase A - Neutral Minimum Frequency Tracking Voltage: 10 V rms 9365200990 Rev F BE1-CDS240 General Information 1-17... -

Page 28: Calculated Values And Accuracy

8 to 24 hours depending on conditions Backup Battery (optional): Greater than 5 years Battery Type: Lithium, 3.6 Vdc, 0.95 Ah (Basler Electric P/N: 9318700012 or Applied Power P/N: BM551902) 87 Differential Functions Restrained Differential (87RPU, 87RT) Pickup Accuracy 5 Ampere CT: ±4% or ±75 mA, whichever is greater... -

Page 29: Figure 1-9. Typical 87 Response Characteristic Curves

Increment: 3.50 3.00 2.50 Unrestrained 2.00 Restrained 1.50 1.00 0.50 0.00 0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10. Multiple of Pickup Figure 1-9. Typical 87 Response Characteristic Curves 9365200990 Rev F BE1-CDS240 General Information 1-19... -

Page 30: Nd Neutral Differential Function

0.1 s from 1.0 to 9.99 s 1 s from 10 to 60 s Timing Accuracy #50TP, #50TN: ±0.5% or ±¼ cycle, whichever is greater, plus trip time for instantaneous response (0.0 setting) 1-20 BE1-CDS240 General Information 9365200990 Rev F... -

Page 31: Time Overcurrent Functions

Volts/Hz (24) Pickup Range: 0.5 to 6 V/Hz Accuracy: ±2% Integrating Time Delay Time Dial: 0.0 to 9.9 V/Hz Reset Dial: 0.0 to 9.9 V/Hz Accuracy: 5% or 4 cycles, whichever is greater 9365200990 Rev F BE1-CDS240 General Information 1-21... -

Page 32: Equation 1-1. Time To Trip

0.050 to 600 s Increment: 1 ms from 0 to 999 ms 0.1 s from 1.0 to 9.9 s 1 s from 10 to 600 s Accuracy: ±0.5% or ±1 cycle, whichever is greater 1-22 BE1-CDS240 General Information 9365200990 Rev F... -

Page 33: Phase Overvoltage Function (59P/159P)

±2% or 0.05 A 1 A CT: 0.05 to 2 A Accuracy: ±2% or 0.01 A SEF: 0.01 A to 0.050 A Accuracy: ±2.5% or 0.0025 A Delay Timer: 50 to 999 ms 9365200990 Rev F BE1-CDS240 General Information 1-23... -

Page 34: General Purpose Timers (62, 162, 262, 362)

½ For other current levels, use the formula I = (K/t) where t = time in seconds and K = 160,000. Begins to Clip (saturate): 150 A Burden: <10 m at 5 Aac 1-24 BE1-CDS240 General Information 9365200990 Rev F... -

Page 35: Analog To Digital Converter

Voltage ranges depend on Jumper configuration. See Section 3, Input and Output Functions, Contact Sensing Inputs. Input Burden: Burden per contact for sensing depends on the power supply model and the input voltage. Table 1-1 provides appropriate burden specifications. 9365200990 Rev F BE1-CDS240 General Information 1-25... -

Page 36: Surge Withstand Capability

2,000 Vac at 50/60 Hz in accordance with IEEE C37.90 and IEC 255-5. (Includes communication ports.) Surge Withstand Capability Oscillatory Qualified to IEEE C37.90.1-2001, Standard Surge Withstand Capability (SWC) Tests for Protective Relays and Relay Systems. 1-26 BE1-CDS240 General Information 9365200990 Rev F... -

Page 37: Radio Frequency Interference (Rfi)

12 lb (5.4 kg) maximum Shipping Weight: Approximately 16.5 lb (7.5 kg) Case Configurations M Horizontal: Panel or 19" rack-mount, draw-out M Vertical: M1, M2/FT31, FT32 size, draw-out L Vertical: L2/FT42 size, draw-out 9365200990 Rev F BE1-CDS240 General Information 1-27... - Page 38 This page intentionally left blank. 1-28 BE1-CDS240 General Information 9365200990 Rev F...

-

Page 39: Section 2 Quick Start

Element Logic Settings ........................2-3 Output Logic Settings........................2-3 USER INTERFACES..........................2-3 Front Panel HMI..........................2-3 ASCII Command Communications ....................2-4 BESTCOMS for BE1-CDS240, Graphical User Interface..............2-5 GETTING STARTED..........................2-6 Connections ............................2-6 Entering Test Settings........................2-6 Checking the State of Inputs......................2-7 Testing .............................. - Page 40 This page intentionally left blank. BE1-CDS240 Quick Start 9365200990 Rev F...

-

Page 41: Section 2 Quick Start

This section provides an overview of the BE1-CDS240 Current Differential System. You should be familiar with the concepts behind the user interfaces and BESTlogic before you begin reading about the detailed BE1-CDS240 functions. Sections 3 through 6 in this manual describe in detail each function of the BE1- CDS240. -

Page 42: Characteristics Of Protection And Control Elements

In the 16 character preprogrammed logic name, the last 4 characters refer to revision A, dash (-), and BE (Basler Electric). When customizing a programmed logic scheme, it is recommended that the user include the revision level of their scheme and change the BE to a 2-digit code representative of the user's company name. -

Page 43: Element Logic Settings

LCD. A complete description of the HMI is included in Section 10, Human- Machine Interface. The BE1-CDS240 HMI is menu driven and organized into a menu tree structure with six branches. A complete menu tree description with displays is also provided in Section 10, Human-Machine Interface. A list of the menu branches and a brief description for scrolling through the menu is in the following paragraphs. -

Page 44: Ascii Command Communications

Figure 2-2. 51 HMI Screen ASCII Command Communications The BE1-CDS240 relay has three independent communications ports for serial communications. Basler Terminal in BESTCOMS can be connected to any of the three ports so that the user may send commands to the relay. Alternatively, a computer terminal or PC running a terminal emulation program ... -

Page 45: Bestcoms For Be1-Cds240, Graphical User Interface

See Section 11, ASCII Command Interface, for a more detailed discussion of how to use ASCII text files for setting the relay. BESTCOMS for BE1-CDS240, Graphical User Interface Basler Electric's graphical user interface (GUI) software, BESTCOMS, is an alternative method for quickly developing setting files in a friendly, Windows based environment. -

Page 46: Getting Started

The GUI also allows for downloading industry standard COMTRADE files for analysis of stored oscillography data. Detailed analysis of the oscillography files may be accomplished using Basler Electric's BESTWAVE software. For more information on Basler Electric's Windows based BESTCOMS (GUI) software, refer to Section 14, BESTCOMS Software. -

Page 47: Checking The State Of Inputs

From this position, press the Right scrolling pushbutton until you have reached the screen titled, \STATUS BE1-CDS240 REPORT STATUS. From this position, press the Down scrolling pushbutton one time (\STAT\TARGETS) and press the Right scrolling pushbutton three times. At this time, you should see the OPERATIONAL STATUS Screen, \STAT\OPER_STAT. - Page 48 What voltage level is used to develop current flow through the contact sensing inputs? Voltage level is dependent on the power supply option (BE1-CDS240 style) and the position of the contact-sensing jumper. See Section 12, Installation, for additional information. How can the BE1-CDS240 be configured into a simple transformer differential relay? Two preprogrammed schemes perform this function.

- Page 49 HMI and front RS-232 are considered the same port. Access needs to be gained only when a write to the BE1-CDS240 is required (control or setting change or report reset). Data can be read and reports can be obtained without gaining access. After gaining access though one of the ports, the session can be ended with the Exit command.

- Page 50 18.) Can the IRIG signal be daisy-chained to multiple BE1-CDS240 units? Yes, multiple BE1-CDS240 units can use the same IRIG input signal by daisy-chaining the BE1-CDS240 inputs. The burden data is non-linear, approximately 4 kilo-ohms at 3.5 Vdc and 3 kilo-ohms at 20 Vdc.

-

Page 51: Section 3 Input And Output Functions

Figure 3-8. Inputs and Outputs Screen, Inputs 1-6 Tab ................3-16 Figure 3-9. Output Logic, General Purpose Output Contacts ..............3-18 Figure 3-10. Output Logic, Fail-Safe Alarm Output Contact ..............3-18 Figure 3-11. Inputs and Outputs Screen, Outputs 1-14, A Tab............... 3-19 9365200990 Rev F BE1-CDS240 Input and Output Functions... - Page 52 Table 3-6. Internal Compensation Chart ....................3-14 Table 3-7. Contact Sensing Turn-On Voltage ..................3-15 Table 3-8. Digital Input Conditioning Function Settings ................3-17 Table 3-9. Output Hold Function Settings ....................3-19 BE1-CDS240 Input and Output Functions 9365200990 Rev F...

-

Page 53: Section 3 • Input And Output Functions

CT ratio.) The virtual circuits are user configurable to sum either two or three of the analog inputs. For each virtual circuit, the BE1-CDS240 calculates the summation and provides a sum for A, B, C phase currents, negative-sequence current, and neutral current. The virtual currents can be used throughout the... -

Page 54: Voltage Measurement

A-phase current circuit one. When the applied signal is greater than 10 volts, or 0.5 amps (0.1 amps for 1 A CTs) the BE1-CDS240 measures the frequency. The measured frequency on the voltage input is used by the 81 function and applies to all measurements and calculations; the current input is used in the sampling rate determination. -

Page 55: Power Measurement

Equation 3-9 WATTs Equation 3-10 VARs where based sensing type For AB, BC, or CA VT connection with ACB phase-sequence: Equation 3-11 WATTs 9365200990 Rev F BE1-CDS240 Input and Output Functions... -

Page 56: Measurement Functions Setup

Virtual Circuit Setup 0 - 13 GND is valid for CT 4 input only when configuring the BE1-CDS240 for a 2 independent ground input. Power System / VT Setup To enter Power System or VT settings, select General Operation from the Screens pull-down menu. Then select the Power System / VT Setup tab. - Page 57 Dependency of other relay system elements on 1 pu Inom is far less critical and using the CT secondary rating will have little functional impact. VTP Setup, VT Ratio. The BE1-CDS240 requires setting information about the VT ratio, the VT connections, the operating modes for the 27/59 and 51/27R functions, the current circuit that is used to compute power, and power flow polarity.

-

Page 58: Ct Setup

CT ratio. The BE1-CDS240 automatically takes this factor into account so it is not necessary for the user to manually compensate when entering the CT ratio. -

Page 59: Transformer Setup

SG-CKT command. For each circuit, you can set Connection, Insert Zero Sequence Trap, Differential Circuit, and Circuit Polarity. You can also set Transformer Phase Relationships, Individual circuits to be used for restraint, and Virtual Circuits. 9365200990 Rev F BE1-CDS240 Input and Output Functions... - Page 60 CT configurations. Mathematically, the compensation factors provide the following: Note: A 1/(square root of 3) factor is missing from the compensation equations. See Table 3-6 for the net compensation equations. BE1-CDS240 Input and Output Functions 9365200990 Rev F...

- Page 61 CT configurations. The BE1-CDS240 can also compensate for phase “mismatch”. That is, if A phase of the incoming system is connected to the transformer primary H1 and A phase of the secondary system is connected to X2, the phases can be matched at the relay with this feature.

- Page 62 Table 3-3. CT Input Circuit Settings 1 for Delta/Wye Circuit Applications BE1-CDS240 Settings Compensation Applied Transformer CT Input Connection Connection Phase Rotation NONE DAB for DAB connections DAC for DAC connections NONE NONE NONE NONE NONE 3-10 BE1-CDS240 Input and Output Functions 9365200990 Rev F...

- Page 63 Table 3-4. CT Input Circuit Settings 2 for Delta/Wye Circuit Applications BE1-CDS240 Settings Compensation Applied Transformer CT Input Connection Connection Phase Rotation NONE NONE NONE NONE 9365200990 Rev F BE1-CDS240 Input and Output Functions 3-11...

- Page 64 Table 3-5. CT Input Circuit Settings 3 for Delta/Wye Circuit Applications BE1-CDS240 Settings Compensation Applied Transformer CT Input Connection Connection Phase Rotation DDAB NONE NONE NONE NONE 3-12 BE1-CDS240 Input and Output Functions 9365200990 Rev F...

- Page 65 Screens 5.1.1.3, 5.2.1.3, 5.3.1.3 and 5.4.1.3, \PROT\SG#\87\TAP in order to enter the new CT settings. See Section 4, Protection and Control, Phase Differential Protection, for more information on the auto-tap calculation function. 9365200990 Rev F BE1-CDS240 Input and Output Functions 3-13...

-

Page 66: Iec Transformer Setup

D-Y-Z + clock method. For instance, a transformer connection will be Dy1 rather than a DAB/Y, though some dual designations will be used for 3-14 BE1-CDS240 Input and Output Functions 9365200990 Rev F... -

Page 67: Contact Sensing Inputs

Vdc nominal sensing voltages. See Table 3-7 for the control voltage ranges. Each BE1-CDS240 is delivered with the contact-sensing jumpers installed for operation in the high end of the control voltage range in “H” or high position. If the contact sensing inputs are to be operated at the lower end of the control voltage range, the jumpers must be changed to the “L”... -

Page 68: Digital Input Conditioning Function

Time. The labels include a label to describe the input, a label to describe the Energized State, and a label to describe the De-Energized State. Labels are used by the BE1-CDS240’s reporting functions. To edit the settings or labels, select Inputs and Outputs from the Screens pull-down menu. Then select the Inputs 1-6 or Inputs 7-12 tab. -

Page 69: Retrieving Input Status Information From The Relay

OUTPUTS BE1-CDS240 relays have ten or fourteen general-purpose output contacts (OUT1 through OUT14) and one fail-safe, normally closed (relay in de-energized state), alarm output contact (OUTA). Each output is isolated and rated for tripping duty. All relays outputs are high speed (one-quarter cycle nominal operating time). -

Page 70: Retrieving Output Status

How to do this is described in Section 7, BESTlogic Programmable Logic, Application Tips. The hold timer can be enabled for each input from the ASCII command input using the SG-HOLD command. Hold timer settings are shown in Table 3-9. 3-18 BE1-CDS240 Input and Output Functions 9365200990 Rev F... -

Page 71: Output Logic Override Control

Pulsing an Output Contact Outputs can be pulsed to provide the push-to-energize function provided in Basler Electric solid-state relays. This is useful in trip testing the protection and control system. When pulsed, the contact changes... -

Page 72: Holding An Output Contact Open Or Closed

OUT=P EXECUTED 3. Disable the trip output (OUT1) by holding it at logic 0. >CS-OUT1=0 OUT1=0 SELECTED >CO-OUT1=0 OUT1=0 EXECUTED 4. Return OUT1 to logic control. >CS-OUT1=L OUT1=L SELECTED >CO-OUT1=0 OUT1=L EXECUTED 3-20 BE1-CDS240 Input and Output Functions 9365200990 Rev F... -

Page 73: Retrieving Output Logic Override Status

(0) or closed (1) state. A P indicates that the contact is being pulsed and will return to logic control automatically. 9365200990 Rev F BE1-CDS240 Input and Output Functions 3-21... - Page 74 This page intentionally left blank. 3-22 BE1-CDS240 Input and Output Functions 9365200990 Rev F...

-

Page 75: Section 4 Protection And Control

BESTlogic Settings for Auxiliary Overvoltage................4-46 Operating Settings for Auxiliary Overvoltage................4-47 Retrieving Auxiliary Overvoltage Status from the Relay............... 4-48 47 - Negative-Sequence Overvoltage Protection................4-48 BESTlogic Settings for Negative-Sequence Overvoltage ............4-49 9365200990 Rev F BE1-CDS240 Protection and Control... - Page 76 Figure 4-19. Percentage Differential Screen, 87ND/187ND Tab ............4-23 Figure 4-20. Instantaneous Overcurrent Logic Block ................4-23 Figure 4-21. BESTlogic Function Element Screen, Phase (50TP) ............4-24 Figure 4-22. Overcurrent Screen, 50T/150T Tab ..................4-26 BE1-CDS240 Protection and Control 9365200990 Rev F...

- Page 77 Table 4-10. BESTlogic Settings for Instantaneous Overcurrent ............. 4-25 Table 4-11. Operating Settings for Instantaneous Overcurrent .............. 4-26 Table 4-12. BESTlogic Settings for Time Overcurrent ................4-28 Table 4-13. Operating Settings for Time Overcurrent ................4-30 9365200990 Rev F BE1-CDS240 Protection and Control...

- Page 78 Equation 4-11. Time OC Characteristics for Trip ..................4-32 Equation 4-12. Time OC Characteristics for Reset ................. 4-32 Equation 4-13. Time to Trip ........................4-37 Equation 4-14. Time to Reset........................4-37 Equation 4-15. Time to Reset........................4-41 BE1-CDS240 Protection and Control 9365200990 Rev F...

-

Page 79: Section 4 Protection And Control

SECTION 4 PROTECTION AND CONTROL GENERAL BE1-CDS240 relays provide many functions that can be used for protection and control of power system equipment in and around the protected zone. Four settings groups are provided for adapting the coordination under various operating conditions with options for controlling which settings are active by automatic or programmable logic criteria. -

Page 80: Bestlogic Settings For Setting Group Control

Setting Group Selection from the Screens pull-down menu. Then select the BESTlogic button in the lower left hand corner of the screen. Alternately, settings may be made using the SL-GROUP ASCII command. Figure 4-2. BESTlogic Function Element Screen, Setting Group Selection BE1-CDS240 Protection and Control 9365200990 Rev F... - Page 81 Figure 4-3 shows an example of how the inputs are read when the setting group control function logic is enabled for Mode 1. Note that a pulse on the D3 input while D0 is also active doesn’t cause a setting group change to SG3 because the AUTO input is active. 9365200990 Rev F BE1-CDS240 Protection and Control...

- Page 82 AUTO input. Note that a pulse on the D1 input while D0 is also active doesn't cause a setting change to SG3 because the AUTO input is active. D2647-21 08-21-98 AUTO Figure 4-4. Input Control Mode 2 BE1-CDS240 Protection and Control 9365200990 Rev F...

-

Page 83: Operating Settings For Setting Group Control

Settings. The Settings menu is used to select the setting group that the elements settings apply to. Using the pull-down menus and buttons, make the application appropriate settings to the Setting Group Selection function. Table 4-3 summarizes the operating settings for Setting Group Control. 9365200990 Rev F BE1-CDS240 Protection and Control... - Page 84 Current varies but stays below 75 percent for 5 minutes and at time = 75, Setting Group 2 becomes active and the setting change output pulses. After 20 minutes, Setting Group 0 becomes active and the setting change output pulses. BE1-CDS240 Protection and Control 9365200990 Rev F...

- Page 85 If the return time delay setting is set to 0 for a setting group, automatic return for that group is disabled and the relay will remain in that setting group until returned manually of by logic override control. 9365200990 Rev F BE1-CDS240 Protection and Control...

-

Page 86: Logic Override Of The Setting Group Control Function

<mode> entry of CS-GROUP command and CO-GROUP command must match or setting group selection will be rejected. If more than 30 seconds elapse after issuing a CS-GROUP command, the CO-GROUP command will be rejected. BE1-CDS240 Protection and Control 9365200990 Rev F... -

Page 87: Retrieving Setting Group Control Status From The Relay

DIFFERENTIAL PROTECTION 87 - Phase Differential Protection BE1-CDS240 relays provide three-phase percentage restrained differential protection with high-speed unrestrained instantaneous differential protection. The differential protection includes harmonic restraint to improve security in transformer applications. The 87 function (see Figure 4-8) has nine outputs 87RPU (restrained pickup), 87RT (restrained trip), 87UT (unrestrained trip), 2NDHAR (second harmonic A, B, C restraint picked up), and 5THHAR (fifth harmonic A, B, C restraint picked up). - Page 88 Inhibit Unrestrained 5th Harmonic setting Status Harmonic Restraint Current Transient Fund I Monitor 87 Unrestrained Trip Unrestrained 2X Unrestrained Element setting D2840-24.vsd 02-08-99 Figure 4-9. 87 Phase Differential Protection Functional Block Diagram 4-10 BE1-CDS240 Protection and Control 9365200990 Rev F...

- Page 89 In many cases, the second harmonic content of the inrush current may show up primarily in only one or two phases, which can cause one or two phases to not be inhibited. The BE1-CDS240 relay allows the second harmonic currents to be shared between the three phases. When second harmonic sharing is...

-

Page 90: Bestlogic Settings For Phase Differential

Table 4-4 summarizes the BESTlogic settings for Phase Differential. Table 4-4. BESTlogic Settings for Phase Differential Function Range/Purpose Default 0 = disabled Mode 1 = enabled Logic expression that disables function when TRUE. 4-12 BE1-CDS240 Protection and Control 9365200990 Rev F... -

Page 91: Tap Compensation Settings For Phase Differential

The input currents can be tap adjusted up to a spread ratio of 10:1. If the ratio between TAP1, and TAP2, 3, or 4 is greater than ten, it will be necessary to adjust the CT ratios to bring the tap factors closer 9365200990 Rev F BE1-CDS240 Protection and Control 4-13... - Page 92 Three-phase versions of the BE1-87T also allow internal phase compensation. The jumper settings for the BE1-87T correspond to the internal compensation for the BE1-CDS240 as follows: 1 = DAC and 2 = DAB. When calculating the tap adjust settings for the BE1-87T, the 3 COMPn factor has to be included regardless of whether phase compensation is done by connecting the CTs in delta or by using internal delta compensation.

-

Page 93: Operating Settings For Phase Differential

Times Tap. The definitions for the remaining variables in Equation 4-3 are the same as those for Equation 4-1. TAPn 1000 COMPn TAPn CTRn Ipri TAPn TAPn CTRn COMPn Equation 4-2. Tab Adjustment Equation Equation 4-3. Calculate Primary Amps 9365200990 Rev F BE1-CDS240 Protection and Control 4-15... -

Page 94: Retrieving Phase Differential Status From The Relay

To avoid this condition, the BE1-CDS240 provides a Virtual Restraint Element that derives its restraint from the vector sum of two or more high or low side breaker CT inputs (see Section 3, Input and Output Functions, for details on the virtual circuit measurement function and settings). - Page 95 The latter however, could make 87R prone to false operation when full load or external fault current flows through the transformer. Virtual restraint provides a practical way to solve this problem without adding an additional CT. 9365200990 Rev F BE1-CDS240 Protection and Control 4-17...

-

Page 96: 87Nd - Neutral Differential Protection

Using the same example as above, first configure Virtual Circuit 5 for the vector sum of CT Circuits 1 and 2. Next, enable virtual restraint to use Virtual Circuit 5 as one of its restraining inputs. When virtual restraint is enabled to use Virtual Circuit 5, the BE1-CDS240 automatically excludes Circuits 1 and 2 from the restraint calculations. - Page 97 The Operating Current function determines the magnitude of the differential current as the phasor sum of the compensated currents. 9365200990 Rev F BE1-CDS240 Protection and Control 4-19...

-

Page 98: Bestlogic Settings For Neutral Differential

Then select the 87ND/187ND tab. Select the appropriate BESTlogic button for 87ND or 187ND. Alternately, these settings can be made using the SL-87ND and SL-187ND ASCII commands. Figure 4-18. BESTlogic Function Element Screen, Neutral (87ND) 4-20 BE1-CDS240 Protection and Control 9365200990 Rev F... -

Page 99: Auto-Tap Compensation Settings For Neutral Differential

Differential from the Screens pull-down menu. Then select the 87ND/187ND tab. Alternately, settings may be made using S<g>-87ND and S<g>-187ND ASCII commands or through the optional HMI Screens 5.#.2.1, \PROT\SG#\87ND\87ND, 5.#.2.2, \PROT\SG#\187ND\187ND. The operating settings for Neutral Differential are provided in Table 4-9. 9365200990 Rev F BE1-CDS240 Protection and Control 4-21... - Page 100 The 87ND neutral differential operational settings may be entered with BESTCOMS (Figure 4-19), or from the optional front panel HMI from Screens 5.#.2.1, \PROT\SG#\87ND7\87ND, or from the ASCII command interface using the S<g>-87ND command. 4-22 BE1-CDS240 Protection and Control 9365200990 Rev F...

-

Page 101: Retrieving Neutral Differential Status From The Relay

See Section 3, Inputs and Outputs, for details on the virtual current circuits. The instantaneous overcurrent protective functions in the BE1-CDS240 relay are labeled 50T because each has a settable time delay. If the time delay is set to zero, they operate as instantaneous overcurrent relays. -

Page 102: Bestlogic Settings For Instantaneous Overcurrent

Then, select the BESTlogic variable, or series of variables to be connected to the input. Select Save when finished to return to the BESTlogic Function Element screen. For more details on the 4-24 BE1-CDS240 Protection and Control 9365200990 Rev F... -

Page 103: Operating Settings For Instantaneous Overcurrent

50T elements. To open the screen, select Overcurrent from the Screens pull-down menu. Then select the 50T/150T, 250T/350T, etc. tab. Alternately, settings may be made using S<g>-x50T ASCII command or through the optional HMI Screens 5.#.3.1 - 5.#.3.4, \PROT\SG#\x50T\. 9365200990 Rev F BE1-CDS240 Protection and Control 4-25... - Page 104 0.01 cycles from the ASCII command interface. Time delays entered in cycles are converted to milliseconds or seconds. Increment precision after conversion is limited to that appropriate for each of those units of measure. 4-26 BE1-CDS240 Protection and Control 9365200990 Rev F...

-

Page 105: Retrieving Instantaneous Overcurrent Status From The Relay

TRUE and the fault recording function trip logic expression is TRUE. See Section 6, Reporting and Alarm Functions, Fault Reporting, for more details on the target reporting function. 9365200990 Rev F BE1-CDS240 Protection and Control 4-27... -

Page 106: Bestlogic Settings For Time Overcurrent

Circuit 3, 4 = CT Input Circuit 4, 5 = CT Input Circuit 5, 6 = CT Input Circuit. Mode G = Independent Ground Input (#51N functions only) Logic expression that disables function when TRUE. 4-28 BE1-CDS240 Protection and Control 9365200990 Rev F... -

Page 107: Operating Settings For Time Overcurrent

Beside the Logic pull-down menu is a pull-down menu labeled Settings. The Settings menu is used to select the setting group that the element's settings apply to. Table 4-13 summarizes the operating settings for Time Overcurrent. 9365200990 Rev F BE1-CDS240 Protection and Control 4-29... -

Page 108: Retrieving Time Overcurrent Status From The Relay

When set for Control mode of operation, the phase overcurrent element is disabled until the measured voltage drops below the threshold. Thus, as long as the voltage on the appropriate phase is above the 4-30 BE1-CDS240 Protection and Control 9365200990 Rev F... - Page 109 100%. NOTE For single-phase sensing, the unmonitored phase is not restrained or controlled. These phases are marked in the table by N/A (not applicable). 9365200990 Rev F BE1-CDS240 Protection and Control 4-31...

-

Page 110: Operating Settings For Voltage Restraint/Control For Time Overcurrent

Affects the effective range of the time dial. to selected curve Coefficient specific Affects a constant term in the timing equation. Has greatest effect to selected curve on curve shape at high multiples of tap. 4-32 BE1-CDS240 Protection and Control 9365200990 Rev F... -

Page 111: Setting Programmable Curves

46 curve by the process described in Appendix A, Time Overcurrent Characteristic Curves. The K factor is the time the generator can withstand 1 per unit I where 1 pu is the relay setting for nominal current. 9365200990 Rev F BE1-CDS240 Protection and Control 4-33... -

Page 112: Negative-Sequence Overcurrent Protection

When these two factors (3/2 and 1/3) are combined, the 3 factors cancel which leaves the one-half factor. Figure 4-28. Phase-to-Phase Fault Magnitude Figure 4-29. Sequence Components for an A-B Fault 4-34 BE1-CDS240 Protection and Control 9365200990 Rev F... -

Page 113: Coordination Settings For Negative-Sequence Overcurrent

1/3 per unit of the magnitude of the phase-to-ground fault for which you wish to have backup protection. VOLTAGE PROTECTION BE1-CDS240 voltage protection includes elements for overexcitation, phase undervoltage, phase overvoltage, negative-sequence overvoltage, and over/underfrequency. 24 - Volts per Hertz Overexcitation Protection Overexcitation occurs when a generator or transformer magnetic core becomes saturated. -

Page 114: Theory Of Operation For Volts Per Hertz Overexcitation

The maximum time delay is determined by Equation 4-13 with (V/Hz measured / V/Hz nominal) set equal to 1.001. The overall inverse time delay range is limited to 1,000 seconds maximum and 0.2 seconds minimum. 4-36 BE1-CDS240 Protection and Control 9365200990 Rev F... -

Page 115: Bestlogic Settings For Volts Per Hertz Overexcitation

To open the BESTlogic Function Element screen for Overexcitation (24), select Voltage Protection from the Screens pull-down menu and select the 24 tab. Then, select the BESTlogic button. Alternately, settings may be made using SL-24 ASCII command. Figure 4-31. BESTlogic Function Element Screen, 24 9365200990 Rev F BE1-CDS240 Protection and Control 4-37... -

Page 116: Operating Settings For Volts Per Hertz Overexcitation

Protection from the Screens pull-down menu and select the 24 Tab. Alternately, settings can be made using the S<g>-24 and S<g>-24D commands or at the optional front panel HMI using Screen 5.#.5.1, \PROT\SG#\24\24. Figure 4-32. Voltage Protection Screen, 24 Tab 4-38 BE1-CDS240 Protection and Control 9365200990 Rev F... -

Page 117: Programmable Alarm For Volts Per Hertz Overexcitation

Figures 4-33 and 4-34 show examples of a transformer and generator limit curve along with the optimum composite protection characteristic. NOTE Actual damage curves must be obtained from the equipment manufacturer for particular equipment to be protected. 9365200990 Rev F BE1-CDS240 Protection and Control 4-39... - Page 118 Assuming a Vnom of 69.3 volts phase-neutral, 1 pu volts/hertz = (69.3 * 3) / 60 = 2.00. Using IEEE/C37.102, "Guide for AC Generator Protection" as a guide for setting overexcitation protection, the following example demonstrates how to set the BE1-CDS240 to provide a composite V/Hz characteristic for protection of a generator and a step-up transformer: •...

- Page 119 30% instead of 0%, therefore tripping in 70% or the original trip time or 35 seconds. Figure 4-36 illustrates the inverse time delay and reset time. Figure 4-36. Inverse Time Delay and Reset Time 9365200990 Rev F BE1-CDS240 Protection and Control 4-41...

-

Page 120: Retrieving Volts Per Hertz Overexcitation Status From The Relay

At the top center of the BESTlogic Function Element screen is a pull-down menu labeled Logic. This menu allows viewing of the BESTlogic settings for each preprogrammed logic scheme. A custom logic 4-42 BE1-CDS240 Protection and Control 9365200990 Rev F... - Page 121 Undervoltage or overvoltage on all three phases causes pickup. Logic expression that disables function when TRUE. Example 1. Make the following BESTlogic settings to the 27P element. Refer to Figure 4-38. Mode: At least 1of 3 phases BLK: 9365200990 Rev F BE1-CDS240 Protection and Control 4-43...

-

Page 122: Operating Settings For Phase Undervoltage/Overvoltage

Time setting that represents the element's time delay defaults to milliseconds. It is also selectable for seconds, minutes, and cycles. Operating settings for Phase Undervoltage/Overvoltage are summarized in Table 4-23. 4-44 BE1-CDS240 Protection and Control 9365200990 Rev F... -

Page 123: Retrieving Phase Undervoltage/Overvoltage Status From The Relay

When this expression is TRUE, the element is disabled by forcing the outputs to logic 0 and resetting the timer. This feature functions in a similar way to the torque control contact of an electromechanical relay. 9365200990 Rev F BE1-CDS240 Protection and Control 4-45... -

Page 124: Bestlogic Settings For Auxiliary Overvoltage

Save when finished to return to the BESTlogic Function Element screen. For more details on the BESTlogic Expression Builder, see Section 7, BESTlogic Programmable Logic. Select Done when the settings have been completely edited. 4-46 BE1-CDS240 Protection and Control 9365200990 Rev F... -

Page 125: Operating Settings For Auxiliary Overvoltage

Beside the Logic pull-down menu is a pull-down menu labeled Settings. The settings menu is used to select the setting group that the elements settings apply to. Figure 4-42. Voltage Protection Screen, 59X Tab 9365200990 Rev F BE1-CDS240 Protection and Control 4-47... -

Page 126: Retrieving Auxiliary Overvoltage Status From The Relay

The 47 element is enabled or disabled by the Mode input. Two modes are available. Selecting Mode 0 disables protection. Mode 1 enables the 47 element. More information about logic mode selections is provided in the BESTlogic Settings for Negative-Sequence Overvoltage paragraphs. 4-48 BE1-CDS240 Protection and Control 9365200990 Rev F... -

Page 127: Bestlogic Settings For Negative-Sequence Overvoltage

Select Save when finished to return to the BESTlogic Function Element screen. For more details on the BESTlogic Expression Builder, see Section 7, BESTlogic Programmable Logic. Select Done when the settings have been completely edited. 9365200990 Rev F BE1-CDS240 Protection and Control 4-49... -

Page 128: Operating Settings For Negative-Sequence Overvoltage

(Per U Volts), and percent volts (% Volts) can also be selected as the pickup setting unit of measure. The unit of measure for the Time setting that represents the element's time delay defaults to milliseconds. It is also selectable for seconds, minutes, and cycles. 4-50 BE1-CDS240 Protection and Control 9365200990 Rev F... -

Page 129: Retrieving Negative-Sequence Overvoltage Status From The Relay

Power system frequency is measured on the optional auxiliary voltage input as well. When the applied voltage is greater than 10 volts, the BE1-CDS240 measures the frequency. Frequency element designations are 81, 181, 281, 381, 481, and 581. Each of the six elements has identical inputs, outputs, and setting provisions. -

Page 130: Bestlogic Settings For Over/Underfrequency

BESTlogic settings for each preprogrammed logic scheme. A custom logic scheme must be created and selected in the Logic pull-down menu at the top of the screen before BESTlogic settings can be changed. See Section 7, BESTlogic Programmable Logic. Enable the 4-52 BE1-CDS240 Protection and Control 9365200990 Rev F... -

Page 131: Operating Settings For Over/Underfrequency

INH/81/181/281/381/481/581 tab. Alternately, settings may be made using the S<g>- <x>81 ASCII command or the optional HMI interface using Screens 5.#.10.1 and 5.#.10.2, \PROT\SG#\81\SETTINGS. Figure 4-48. Voltage Protection Screen, INH/81/181/281/381/481/581 Tab 9365200990 Rev F BE1-CDS240 Protection and Control 4-53... -

Page 132: Retrieving Over/Underfrequency Status From The Relay

The status of each logic variable can be determined through the ASCII command interface using the RG- STAT (report general-status) command. See Section 6, Reporting and Alarm Functions, General Status Reporting, for more information. The status can also be determined using BESTCOMS Metering screen. 4-54 BE1-CDS240 Protection and Control 9365200990 Rev F... -

Page 133: Breaker Failure Protection

BREAKER FAILURE PROTECTION 50BF - Breaker Failure Protection BE1-CDS240 relays provide four independent breaker failure protection functions. Each current circuit has an associated breaker failure function. For example, Current Circuit 1 is internally connected to 50BF; Current Circuit 2 is internally connected to 150 BF and so on. This section discuses 50BF but applies to all BF functions. -

Page 134: Bestlogic Settings For Breaker Failure

Save when finished to return to the BESTlogic Function Element Screen. For more details on the BESTlogic Expression Builder, see Section 7, BESTlogic Programmable Logic. Select Done when the settings have been completely edited. Table 4-30 summarizes the BESTlogic settings for Breaker Failure. 4-56 BE1-CDS240 Protection and Control 9365200990 Rev F... -

Page 135: Operating Settings For Breaker Failure

The default unit of measure for the Pickup setting is secondary amps. The unit of measure for the Time setting that represents the element's time delay defaults to milliseconds. It is also selectable for seconds, minutes, and cycles. Table 4-31 summarizes the operating settings for Breaker Failure. 9365200990 Rev F BE1-CDS240 Protection and Control 4-57... -

Page 136: Retrieving Breaker Failure Status From The Relay

LOGIC TIMERS 62 - General Purpose Logic Timers BE1-CDS240 relays provide four gene ral-purpose logic timers, which are extremely versatile. Each can be set for one of five modes of operation to emulate virtually any type of timer. Each function block has one output (62, 162, 262, or 362) that is asserted when the timing criteria has been met according to the BESTlogic mode setting. -

Page 137: Mode 1, Pu/Do (Pickup/Dropout Timer)

FALSE for the duration of DROPOUT time delay setting T2. If the INITIATE input expression toggles to TRUE before time T2, the output stays TRUE and the T2 timer is reset. D2843-08 10-23-03 Figure 4-53. Mode 1, PU/DO (Pickup/Dropout Timer) 9365200990 Rev F BE1-CDS240 Protection and Control 4-59... -

Page 138: Mode 2, One-Shot Nonretriggerable Timer

ON time of T1 and an OFF time of T2. When the BLOCK input is held TRUE, the oscillator stops and the output is held OFF. Figure 4-56. Mode 4, Oscillator 4-60 BE1-CDS240 Protection and Control 9365200990 Rev F... -

Page 139: Mode 5, Integrating Timer

TRUE. The timer will time for DELAY time T1 and then the output will latch TRUE. Additional INITIATE input expression changes of state are ignored. Time (T2) is ignored. Refer to Figure 4-58. D2863-07 10-23-03 Figure 4-58. Mode 6, Latch 9365200990 Rev F BE1-CDS240 Protection and Control 4-61... -

Page 140: Bestlogic Settings For General Purpose Logic Timers

Logic Mode 5 = Integrating 2 = One Shot Non-Retrig 6 = Latch 3 = One Shot Retrig INITIATE Logic expression that initiates timing sequence. BLOCK Logic expression that disables function when TRUE. 4-62 BE1-CDS240 Protection and Control 9365200990 Rev F... -

Page 141: Operating Settings For General Purpose Logic Timers

0.1 for 0.1 to 9.9 sec. T1 Time, 0.1 to 9999 sec. Seconds 1.0 for 10 to 9999 sec. T2 Time 0 to 599,940 (60 Hz) Cycles 0 to 499,950 (50Hz) 9365200990 Rev F BE1-CDS240 Protection and Control 4-63... -

Page 142: Retrieving General Purpose Logic Timers Status From The Relay

60FL - Fuse Loss Detection BE1-CDS240 relays have one 60FL element that can be used to detect fuse loss or loss of potential in a three-phase system. The 60FL element is illustrated in Figure 4-61. When the element logic becomes TRUE, the 60FL logic output becomes TRUE. -

Page 143: Fuse Loss Detection Blocking Settings

60FL element. Select Reporting and Alarms from the Screens pull-down menu and select the VT Monitor tab. Alternately, settings may be made using the SP-60FL ASCII command. See Section 11, ASCII Command Interface, Command Summary, Protection Setting Commands, for more information. 9365200990 Rev F BE1-CDS240 Protection and Control 4-65... - Page 144 Similarly, zero-sequence voltage polarization can only be performed if 3P4W sensing is selected. The following qualifiers are applied to the voltage polarized ground direction element based on the user selected input quantity: 4-66 BE1-CDS240 Protection and Control 9365200990 Rev F...

-

Page 145: Retrieving Fuse Loss Detection Status From The Relay

Reporting, for more information. The status can also be determined using BESTCOMS Metering screen. VIRTUAL SWITCHES 43 - Virtual Selector Switches The BE1-CDS240 Current Differe ntial System has eight virtual selector switches that can provide manual control, locally and remotely, without using physical switches and/or interposing relays. Each virtual switch can be set for one of three modes of operation to emulate virtually any type of binary (two position) switch. -

Page 146: Bestlogic Settings For Virtual Selector Switches

Default 0 = Disabled 2 = On/Off Mode 1 = On/Off/Pulse 3 = Off/Momentary On Example 1. Make the following BESTlogic settings to the Virtual Switch function. See Figure 4-65. Mode: On/Off 4-68 BE1-CDS240 Protection and Control 9365200990 Rev F... -

Page 147: Select Before Operate Control Of Virtual Selector Switches

An example of an operate command not matching the select command. >CO-243=1 ERROR:NO SELECT (Note: Must ent er “CS-243=1” first to select.) Figure 4-66. Virtual Switches Screen, 43 – 143 – 243 – 343 Tab 9365200990 Rev F BE1-CDS240 Protection and Control 4-69... -

Page 148: Retrieving Virtual Selector Switches Status From The Relay

A virtual switch can be used instead of a physical switch to reduce costs with the added benefit that the virtual switch can be operated both locally from the HMI and remotely from a substation computer or modem connection to an operator's console. The BE1-CDS240 relays provide four Virtual Breaker Control Switches (101, 1101, 2101, and 3101). -

Page 149: Select Before Operate Control Of Virtual Breaker Control Switches

CO-x101 control command will be accepted. The control selected and the operation sele cted must match exactly or the operate command will be blocke d. If the operate command is blocke d and error message is output. 9365200990 Rev F BE1-CDS240 Protection and Control 4-71... -

Page 150: Retrieving Virtual Breaker Control Switch Status From The Relay

HMI Screens 2.2.1 through 2.2.4 provide switch control and displays the status of the virtual control switches (after-trip or after-close). As the previous Example 1 demonstrated, the state of each virtual selector switch can be determined using the CO-2101 command in a read-only mode. 4-72 BE1-CDS240 Protection and Control 9365200990 Rev F... -

Page 151: Section 5 Metering

Figure 5-3. Metering - Alarms, Targets, Output Status, Input Status ............5-3 Figure 5-4. Metering - Logic Bits Views..................... 5-3 Tables Table 5-1. Auto Ranging Scales for Metered Values ................5-1 Table 5-2. ASCII Command and HMI Metering Cross-Reference ............5-4 9365200990 Rev F BE1-CDS240 Metering... - Page 152 This page intentionally left blank. BE1-CDS240 Metering 9365200990 Rev F...

-

Page 153: Section 5 Metering

Section 3, Input and Output Functions, Power System Inputs, Power Measurement. Energy measurement is covered in Section 6, Reporting and Alarm Functions. Auto Ranging The BE1-CDS240 automatically scales metered values. Table 5-1 illustrates the ranges for each value metered. Table 5-1. Auto Ranging Scales for Metered Values... - Page 154 Figure 5-1. Metering - Circuits 1 - 6 Other metering views can be selected from the View pull-down menu. These alternate views are shown in Figures 5-2 through 5-4. Figure 5-2. Metering - Watts/Vars/VA, Phase-Phase, Sequence, Phase-Neutral, Ground 1, Frequency BE1-CDS240 Metering 9365200990 Rev F...

- Page 155 Figure 5-3. Metering - Alarms, Targets, Output Status, Input Status Figure 5-4. Metering - Logic Bits Views 9365200990 Rev F BE1-CDS240 Metering...

- Page 156 M5-IA, M6-IA M1-IB, M2-IB, Current, Circuits 1-6, B-phase M3-IB, M4-IB, \METER\CRNT\CT_1-6\I_MEAS M5-IB, M6-IB M1-IC, M2-IC, Current, Circuits 1-6, C-phase M3-IC, M4-IC, \METER\CRNT\CT_1-6\I_MEAS M5-IC, M6-IC M1-IN, M2-IN, Current, Circuits 1-6, Neutral M3-IN, M4-IN, \METER\CRNT\CT_1-6\I_CALC M5-IN, M6-IN BE1-CDS240 Metering 9365200990 Rev F...

- Page 157 \METER\DIFF\COMP\IN Voltage The BE1-CDS240 meters A-phase voltage, B-phase voltage, C-phase voltage, voltage across phases A and B, phases B and C, and phases A and C. Positive-sequence voltage, negative-sequence voltage, and three-phase zero-sequence (residual) voltage are also metered. The VTP connection determines what is measured.

-

Page 158: Current

+1,500 kilovars. True Power True power is metered over a range of –7,500 kilowatts to +7,500 kilowatts on five-ampere nominal systems. One-ampere nominal systems meter true power over a range of –1,500 watts to +1,500 watts. BE1-CDS240 Metering 9365200990 Rev F... -

Page 159: Section 6 Reporting And Alarm Functions

Figure 6-2. Reporting and Alarms Screen, Clock Display Mode Tab............6-2 Figure 6-3. Reporting and Alarms Screen, I Demand Tab ................ 6-8 Figure 6-4. Reporting and Alarms Screen, V & P Demand Tab.............. 6-10 Figure 6-5. Differential Alarm Characteristics..................6-14 9365200990 Rev F BE1-CDS240 Reporting and Alarm Functions... - Page 160 Table 6-19. Oscillographic Records Settings ..................6-35 Table 6-20. Relay Trouble Alarms......................6-39 Table 6-21. Programmable Alarms......................6-39 Table 6-22. Programmable Alarm Settings ..................... 6-42 Equations Equation 6-1. Energy Data Equation ......................6-7 BE1-CDS240 Reporting and Alarm Functions 9365200990 Rev F...

-

Page 161: Introduction

It is important to attach (label) meaningful names to the relays and the relay reports. To provide this feature, BE1-CDS240 relays have four relay identification fields: Relay ID, Station ID, User Label 1, and User Label 2. These fields are used in the header information lines of the Fault Reports, the Oscillographic Records, and the Sequence of Events Recorder (SER) Reports. -

Page 162: Clock

CLOCK The BE1-CDS240 provides a real-time clock with capacitor backup that is capable of operating the clock for up to eight hours after power is removed from the relay. The clock is used by the demand reporting function, the fault reporting function, the oscillograph recording function, and the sequence of events recorder function to time-stamp events. -

Page 163: Alternate Dst (Daylight Saving Time) Settings

SG-UTC=M,R,B M (Offset from UTC in Minutes) = -720 to 840 R (Reference Time) = 0 (Local) or 1 (UTC) B (Bias: amount of minutes to adjust DST) = 0 to 300 9365200990 Rev F BE1-CDS240 Reporting and Alarm Functions... -

Page 164: General Status Reporting

Refer to Section 11, ASCII Command Interface, for a list of all ASCII commands. GENERAL STATUS REPORTING BE1-CDS240 relays have extensive capabilities for reporting relay status. This is important for determining the health and status of the system for diagnostics and troubleshooting. Throughout this manual, reference is made to the RG-STAT (report general, status) report and the appropriate HMI screens for determining the status of various functions. -

Page 165: Other Report General Commands

If the command RG is entered by itself, the relay reports the time, date, target information, and other reports as shown in the following example. The RG-VER command has multiple line outputs and is not read with the RG command. 9365200990 Rev F BE1-CDS240 Reporting and Alarm Functions... - Page 166 Table 6-3. Logic Variable Status Report Format BE1-CDS240 Reporting and Alarm Functions 9365200990 Rev F...

-

Page 167: Energy Data

In addition, the demand reporting function keeps an additional set of registers for Yesterday's Peak. Each day at midnight, the demand reporting function 9365200990 Rev F BE1-CDS240 Reporting and Alarm Functions... -

Page 168: Setting The Demand Reporting Function

Demand Circuits pull-down menu. Using the pull-down menus and buttons, make the application appropriate current demand settings. Demand reporting settings are summarized in Table 6-4. Figure 6-3. Reporting and Alarms Screen, I Demand Tab BE1-CDS240 Reporting and Alarm Functions 9365200990 Rev F... -

Page 169: Retrieving Demand Reporting Information

DWATT ASCII command or with BESTCOMS (Figure 6-4). The SA-DVAR ASCII command is used to set the Var Positive and Negative demand thresholds, which can also be set using BESTCOMS (Figure 6-4). Alternately, HMI Screen \SETUP\DMD\ALARMS, can be used to set all demand alarms. 9365200990 Rev F BE1-CDS240 Reporting and Alarm Functions... -

Page 170: Optional Load Profile Recording Function

Optional Load Profile Recording Function Load profile recording is an optional selection when the BE1-CDS240 is ordered. The Load Profile, 4000 Point Data Array option (2 or 3 as the third character from the right in the style chart) uses a 4,000-point data array for data storage. -

Page 171: Differential Current Monitoring Function

Primary current (MEASURED I PRI) is calculated simply as the secondary current multiplied by the CT turns ratio. Secondary current (MEASURED I SEC) is the current actually measured by the relay. Angle compensated current (ANGLE COMPENSATED I) is the 9365200990 Rev F BE1-CDS240 Reporting and Alarm Functions 6-11... - Page 172 200.8 @ 180 200.8 @ 60 200.8 @ 300 CT CKT3 125.5 @ 151 125.5 @ 31 125.5 @ 271 CT CKT4 54.5 @ 180 54.5 @ 60 54.4 @ 300 6-12 BE1-CDS240 Reporting and Alarm Functions 9365200990 Rev F...

-

Page 173: Setting Differential Current Monitoring Alarms

Function Range Increment Unit of Measure Default Differential Alarm Level 50 – 100 Percent (%) Retrieving Differential Current Monitoring Information To retrieve the differential check record, use the ASCII command RA-DIFF. 9365200990 Rev F BE1-CDS240 Reporting and Alarm Functions 6-13... - Page 174 D2850-15 05-27-99 RESTRAINT CURRENT (IN MULTIPLES OF TAP) Figure 6-5. Differential Alarm Characteristics Figure 6-6. Percentage Differential Screen, Diff Alarm Tab 6-14 BE1-CDS240 Reporting and Alarm Functions 9365200990 Rev F...

-

Page 175: Transformer Monitoring Functions

Screen 6.6.1, \SETUP\XFRMR\DUTY. This function selects the transformer CT to be monitored that also affects the transformer alarm function (SA-TX). Table 6-8 lists the settings for the transformer duty monitoring function. 9365200990 Rev F BE1-CDS240 Reporting and Alarm Functions 6-15... -

Page 176: Transformer Alarms

(through-fault counter or through-fault duty). That is, you may program an alarm threshold (limit) to monitor each function. Alternately, you may program three different alarm thresholds to monitor one of the monitored functions. The transformer alarms may be programmed using BESTCOMS 6-16 BE1-CDS240 Reporting and Alarm Functions 9365200990 Rev F... -

Page 177: Vt Monitor Functions

To open the screen shown in Figure 6-8, select Reporting and Alarms, from the Screens pull-down menu. Then select the VT Monitor tab. Alternately, settings may be made using the SP-60FL ASCII command. 9365200990 Rev F BE1-CDS240 Reporting and Alarm Functions 6-17... -

Page 178: Breaker Monitoring

Figure 6-8. Reporting and Alarms Screen, VT Monitor Tab BREAKER MONITORING Depending on the system scheme, one BE1-CDS240 relay can provide overcurrent protection for more than one circuit breaker. However, breaker-monitoring functions provide extensive monitoring and alarms for only a single circuit breaker. This extensive monitoring helps to manage equipment inspection and maintenance expenses. -

Page 179: Breaker Duty Monitoring

When the breaker opens, the N power of the current interrupted in each pole of the circuit breaker is accumulated by the breaker duty monitor. Breaker opening is defined by the breaker status monitoring 9365200990 Rev F BE1-CDS240 Reporting and Alarm Functions 6-19... - Page 180 OR logic term (e.g., IN1 or VO7) which blocks the breaker monitoring logic when TRUE (1). BLKBKR is set to zero to disable blocking. When breaker monitoring is blocked (logic expression equals 1), breaker duty is not accumulated. 6-20 BE1-CDS240 Reporting and Alarm Functions 9365200990 Rev F...

- Page 181 Breaker interruption duty T ransformer (W hen SG-TRIGGER (PU) is TRUE) fault duty Setting group (W hen SG-TRIGGER (PU) is TRUE) D2843-42 change blocked 09-29-03 Figure 6-10. Protective Fault Analysis 9365200990 Rev F BE1-CDS240 Reporting and Alarm Functions 6-21...

- Page 182 Breaker Duty Monitoring function for Circuits 1 - 4. To open the screen, select Reporting and Alarms from the Screens pull-down menu. Then select the Bkr Duty tab. Alternately, settings may be made using the SB-DUTY ASCII command. 6-22 BE1-CDS240 Reporting and Alarm Functions 9365200990 Rev F...

- Page 183 BESTlogic Expression Builder, See Section 7, BESTlogic Programmable Logic. Select Done when the settings have been completely edited. Figure 6-12. BESTlogic Function Element Screen, Circuit 1 Breaker Duty Monitoring, Block 9365200990 Rev F BE1-CDS240 Reporting and Alarm Functions 6-23...

-

Page 184: Breaker Alarms

BESTCOMS. Figure 6-13 illustrates the BESTCOMS screen used to select settings for the Breaker Alarms function. Alternately, settings may be made using the SA-BKR ASCII command or the HMI using Screen 6.5.2, \SETUP\BKR\ALARM. 6-24 BE1-CDS240 Reporting and Alarm Functions 9365200990 Rev F... -

Page 185: Trip Circuit Monitor

If this current flow presents a problem for the application, the monitor circuits can be physically disconnected by Connectors P5, P6, P7, and P8. Figure 6-14 shows the trip Figure 6-14. Trip Circuit Monitor Logic circuit monitor logic. 9365200990 Rev F BE1-CDS240 Reporting and Alarm Functions 6-25... - Page 186 This may cause false tripping of the other devices and prevent the BE1-CDS240 trip circuit monitor from reliably detecting an open circuit. If this situation exists, the trip coil monitor can be removed from the circuit.

-

Page 187: Fault Reporting

Fault Reporting Expressions and Settings The fault reporting function records and reports information about faults that have been detected by the relay. The BE1-CDS240 provides many fault reporting features. These features include Fault Summary Reports, Sequence of Events Recorder Reports, Oscillographic Records, and Targets. -

Page 188: Targets

TRUE (refer to Figure 6-11 and Table 6-10, call-out B). Target information can be viewed and reset at the HMI and through the communication ports. 6-28 BE1-CDS240 Reporting and Alarm Functions 9365200990 Rev F... - Page 189 Alternately, targets can be enabled using the SG-TARG ASCII command. Using the SG-TARG command, you can select which protective elements trigger a target and what type of logic condition will reset the targets. 9365200990 Rev F BE1-CDS240 Reporting and Alarm Functions 6-29...

- Page 190 Figure 6-19. Target Reset Logic target reports are still available from the HMI menu branch 4, Reports. Password access is not required to reset targets at the HMI. Figure 6-19 illustrates the target reset logic. 6-30 BE1-CDS240 Reporting and Alarm Functions 9365200990 Rev F...

-

Page 191: Fault Summary Reports

Reports must be gained to reset the targets using the ASCII command interface. Fault Summary Reports The BE1-CDS240 records information about faults and creates fault summary reports. A maximum of 16 fault summary reports are stored in the relay. The two most recent reports are stored in nonvolatile memory. - Page 192 The following example illustrates a typical fault summary report. Call-outs shown in the report are references to the gend of Table 6-11. 6-32 BE1-CDS240 Reporting and Alarm Functions 9365200990 Rev F...

- Page 193 Breaker Failure: A fault was detected as defined by the pickup expression and the breaker failure trip became TRUE before the fault was cleared. RF=TRIG: A fault report was recorded by the ASCII command interface. 9365200990 Rev F BE1-CDS240 Reporting and Alarm Functions 6-33...

- Page 194 RF-NEW. If additional detail is desired, Sequence of Events Recorder data and Oscillographic data can be obtained for the faults also. This is discussed in greater detail later in this section. 6-34 BE1-CDS240 Reporting and Alarm Functions 9365200990 Rev F...

-

Page 195: Oscillographic Records

OSC (settings general, oscillography) ASCII command. See Table 6- 19 for possible settings. Table 6-19. Oscillographic Records Settings Range 6, 8, 10, 12, 15, 16, 20, 24, 32 Default Figure 6-22. Oscillographic Records 9365200990 Rev F BE1-CDS240 Reporting and Alarm Functions 6-35... - Page 196 Software for IBM compatible computers is available from Basler Electric to convert binary files to ASCII format. The download protocol may be either XMODEM or XMODEM CRC format. For ease of reference the name of the downloaded file should be the same as the command.

-

Page 197: Sequence Of Events Recorder

SER Directory Report A directory report lists the number of events currently in memory and the time span that the events cover. Directory reports are accessed using the RS (report SER) command. 9365200990 Rev F BE1-CDS240 Reporting and Alarm Functions 6-37... -

Page 198: Alarms Function

If your application requires a normally closed contact that opens to indicate a relay trouble condition, use BESTlogic to program the output logic. One of the output relays with normally open contacts (OUT1 6-38 BE1-CDS240 Reporting and Alarm Functions 9365200990 Rev F... -

Page 199: Major, Minor, And Logic Programmable Alarms

Trip circuit continuity and voltage monitor 3 (OUT9). CKT MON 4 OPEN ALARM Trip circuit continuity and voltage monitor 4 (OUT10). BKR 1 FAIL ALARM Breaker Failure Initiate > Control Time (50BF). 9365200990 Rev F BE1-CDS240 Reporting and Alarm Functions 6-39... - Page 200 LOGIC = NONE ALARM Active Logic=NONE. No logic selected. PHASE DEMAND 1 ALARM Circuit 1 Phase Current Demand threshold exceeded. PHASE DEMAND 2 ALARM Circuit 2 Phase Current Demand threshold exceeded. 6-40 BE1-CDS240 Reporting and Alarm Functions 9365200990 Rev F...

- Page 201 Alternately, settings for Major, Minor, and Logic alarms can be made using the SA-MAJ, SA-MIN, or SA- LGC ASCII commands. Refer to Section 11, ASCII Command Interface, Command Summary, Alarm Setting Commands, for complete command descriptions. 9365200990 Rev F BE1-CDS240 Reporting and Alarm Functions 6-41...

- Page 202 DIAG/ALARM line of the General Status Report. Refer to the General Status Reporting subsection for more information about obtaining relay status with the RG-STAT command. Figure 6-27 shows the alarm reset logic. 6-42 BE1-CDS240 Reporting and Alarm Functions 9365200990 Rev F...

-

Page 203: Links Between Programmable Alarms And Bestlogic

Pressing the front panel Reset key when HMI Screen 1.2, \STAT\ALARMS is active. By connecting the alarms reset logic in BESTCOMS. Alternately, this can be done using the SA- RESET ASCII command. 9365200990 Rev F BE1-CDS240 Reporting and Alarm Functions 6-43... -

Page 204: Hardware And Software Version Reporting

To view the version of the relay once the download is complete, select General Operation from the Screens pull-down menu. Then select the Identification tab (Figure 6-30). The General Info tab (Figure 6- 31) displays all of the style information about the relay. 6-44 BE1-CDS240 Reporting and Alarm Functions 9365200990 Rev F... - Page 205 Figure 6-30. General Operation Screen, Identification Tab Figure 6-31. General Operation Screen, General Info Tab 9365200990 Rev F BE1-CDS240 Reporting and Alarm Functions 6-45...

-

Page 206: Settings Compare

If there are any differences in the two files, a dialog box will pop up notifying you that Differences Are Found. The BESTCOMS Settings Compare dialog box pops up (Figure 6-33) where you can select to Show All or Show Diffs. Figure 6-33. BESTCOMS Settings Compare Dialog Box 6-46 BE1-CDS240 Reporting and Alarm Functions 9365200990 Rev F... -

Page 207: Section 7 Bestlogic Programmable Logic

Figure 7-7. BESTlogic Expression Builder Screen.................. 7-10 Figure 7-8. BESTlogic Screen, Logic Select Tab ..................7-11 Tables Table 7-1. Logic Variable Names and Descriptions .................. 7-7 Table 7-2. Programmable Variable Name Setting................... 7-13 9365200990 Rev F BE1-CDS240 BESTlogic Programmable Logic... - Page 208 This page intentionally left blank. BE1-CDS240 BESTlogic Programmable Logic 9365200990 Rev F...

-

Page 209: Introduction

LOGIC INTRODUCTION Multifunction relays such as the BE1-CDS240 Current Differential System are similar in nature to a panel of single-function protective relays. Both must be wired together with ancillary devices to operate as a complete protection and control system. In the single-function static and electromechanical environment, elementary diagrams and wiring diagrams provide direction for wiring protective elements, switches, meters, and indicator lights into a unique protection and control system. - Page 210 Figure 7-1. BESTlogic Function Blocks - page 1 of 5 BE1-CDS240 BESTlogic Programmable Logic 9365200990 Rev F...

- Page 211 Figure 7-2. BESTlogic Function Blocks - page 2 of 5 9365200990 Rev F BE1-CDS240 BESTlogic Programmable Logic...

- Page 212 Figure 7-3. BESTlogic Function Blocks - page 3 of 5 BE1-CDS240 BESTlogic Programmable Logic 9365200990 Rev F...

- Page 213 Figure 7-4. BESTlogic Function Blocks - page 4 of 5 9365200990 Rev F BE1-CDS240 BESTlogic Programmable Logic...

- Page 214 Figure 7-5. BESTlogic Function Blocks - page 5 of 5 BE1-CDS240 BESTlogic Programmable Logic 9365200990 Rev F...

- Page 215 150BF Tripped 451NT 451 Neutral Tripped BFRT2 150BF Retrip 451NPU 451 Neutral Picked Up BFT3 250BF Tripped BFRT3 250BF Retrip BFT4 350BF Tripped BFRT4 350BF Retrip Fuse Loss 60FL 60 Loss of Potential Alarm 9365200990 Rev F BE1-CDS240 BESTlogic Programmable Logic...

- Page 216 181 Tripped 181PU 181 Picked Up 281T 281 Tripped 281PU 281 Picked Up 381T 381 Tripped 381PU 381 Picked Up 481T 481 Tripped 481PU 481 Picked Up 581T 581 Tripped 581PU 581 Picked Up BE1-CDS240 BESTlogic Programmable Logic 9365200990 Rev F...

-

Page 217: Function Block Logic Settings

A virtual output exists only as a logical state inside the relay (VO1 through VO15). A hardware output is a physical relay contact that can be used for protection or control. The BE1-CDS240 relay has up to 14 isolated output contacts (I/O Option E) (OUT1 - OUT14) consisting of two Form C output contacts (OUT1,2) and 12 Form A output contacts (OUT 3-14). -

Page 218: Logic Schemes

Unneeded inputs or outputs may be left open to disable a function. Or a function element can be disabled through operating settings. Unused current sensing inputs should be shorted to minimize noise pickup. 7-10 BE1-CDS240 BESTlogic Programmable Logic 9365200990 Rev F... -

Page 219: The Active Logic Scheme

Naming the new logic distinguishes it from the preprogrammed logic scheme. In the 16 character preprogrammed logic name, the last 4 characters refer to revision A, dash (-), and BE (Basler Electric). When customizing a programmed logic scheme, it is recommended that the user include the revision level of their scheme and change the BE to a 2-digit code representative of the user's company name. -

Page 220: Custom Logic Schemes

If there are problems with a customized logic scheme, the RG-STAT command can be used to check the status of all logic variables. More information about the RG-STAT command can be found in Section 6, Reporting and Alarm Functions. 7-12 BE1-CDS240 BESTlogic Programmable Logic 9365200990 Rev F... -

Page 221: User Input And Output Logic Variable Names

Input and output logic variable names are assigned by typing them into the appropriate text box on the related BESTCOMS screen. All of the BE1-CDS240’s inputs, outputs, and 43 switches have labels that can be edited. Table 7-2 shows the range and purpose of each label. Alternately, labels may be edited using the SN-ASCII command. - Page 222 This page intentionally left blank. 7-14 BE1-CDS240 BESTlogic Programmable Logic 9365200990 Rev F...

-

Page 223: Section 8 Application

Block Neutral and Negative Sequence Protection ................8-54 Setting Group Selection ........................8-54 Output Contact Seal-in ........................8-55 Latching a Tripping Contact ......................8-56 Latching a Programmable Logic Alarm or Creating a Pseudo Target ..........8-57 9365200990 Rev F BE1-CDS240 Application... - Page 224 Figure 8-6. Typical Logic Diagram for CDS240-TXCL-B-BE..............8-19 Figure 8-7. Typical Logic Diagram for CDS240-TXBU-B-BE ..............8-25 Figure 8-8. Device Interconnection for Integrated Protection System using BE1-CDS240 for Transformer Protection and BE1-851 or BE1-951 for Bus and Feeder Protection........8-26 Figure 8-9.

- Page 225 Table 8-37. Miscellaneous Logic Expressions ..................8-52 Table 8-38. Output Contact Seal-in Logic ....................8-56 Table 8-39. Logic Settings Associated with Figure 8-19 ................. 8-58 9365200990 Rev F BE1-CDS240 Application...

- Page 226 This page intentionally left blank. BE1-CDS240 Application 9365200990 Rev F...

-

Page 227: Section 8 Application

Transformer with Control Logic, Basic Transformer with Backup Logic, Bus Protection with Backup Logic, and Motor Protection are available on the Basler Web site and included in the logic library of BESTCOMS, Basler Electric's Windows based graphical user interface program. A description of each of those schemes follows the Basic Transformer discussion. -

Page 228: Overview Of Preprogrammed Basic Transformer Protection Logic

Basler Electric products are among the most reliable in the industry, but we believe that it does not make good engineering sense to place all your eggs in one basket. That is why Basler strongly recommends that a second multifunction device be installed to provide independent backup and zone overlapping for each protected zone. -

Page 229: Cds240-Batx-A-Be Logic Scheme (Basic Transformer Protection)

SL-251Q=2,0 SL-VO14=IN7 SL-351P=0,0 SL-VO15=IN8 SL-351N=0,0 SL-OUTA=VOA SL-351Q=0,0 SL-OUT1=VO1 SL-451N=0,0 SL-OUT2=VO1 SL-24=0,0 SL-OUT3=VO1 SL-27P=0,0 SL-OUT4=VO4 SL-127P=0,0 SL-OUT5=VO5 SL-47=0,0 SL-OUT6=VO6 SL-59P=0,0 SL-OUT7=0 SL-59X=0,0 SL-OUT8=0 SL-159P=0,0 SL-OUT9=0 SL-81=0,0 SL-OUT10=0 SL-181=0,0 SL-OUT11=0 SL-281=0,0 SL-OUT12=0 SL-381=0,0 SL-OUT13=0 SL-481=0,0 SL-OUT14=0 SL-581=0,0 9365200990 Rev F BE1-CDS240 Application... - Page 230 Out4 52-1 151P 151N 151Q Out2 Out1 CT Input 1 Out3 CT Input G (Optional) CT Input 2 Out5 251P 251N 251Q 52-2 CT Input 2 D2843-33 02-26-03 Figure 8-1. Typical One-line Diagram for CDS240-BATX-A-BE BE1-CDS240 Application 9365200990 Rev F...

- Page 231 (N only) is connected to a ground CT at the grounded side of a delta-wye transformer. The ground-input (G) is an option on the BE1-CDS240 and must be ordered. Paralleled CTs inside a delta tertiary (3Io) can also feed the 51N. The 87, 51, 151, and 251 protection elements are logic enabled by the settings shown in Table 8-1 to provide a trip through the BE1-CDS240 output contacts.

-

Page 232: Integration Of Protection, Control, And I/O Elements

SER reporting. For example, sudden INPUT_6, IN6 - IN8 pressure trip or transformer hot spot alarm, etc. INPUT_7, CLOSED OPEN Drives VO13 - VO15 that are programmable INPUT_8 alarm points 21 - 23. Label inputs as appropriate. BE1-CDS240 Application 9365200990 Rev F... - Page 233 BESTlogic Expression: VO1=87RT+87UT Time overcurrent trip. May be VO4 TRUE if any time 151TRIP- used to direct trip main overcurrent (51N, 151P, N, or TRIP NORMAL breaker or lockout. Q) trip occurs. BESTlogic Expression: VO4=51NT+151NT+151PT+151QT 9365200990 Rev F BE1-CDS240 Application...

- Page 234 BESTlogic Expression: OUT1=VO1 OUT2 contact closes if restrained or unrestrained OUT2 Phase differential trip. trip occurs. BESTlogic Expression: OUT2=VO1 OUT3 contact closes if restrained or unrestrained OUT3 Phase differential trip. trip occurs. BESTlogic Expression: OUT3=VO1 BE1-CDS240 Application 9365200990 Rev F...

-

Page 235: Cds240-Ba87-B-Be (Basic Differential) Logic Scheme

The following preprogrammed logic schemes can be found in logic library of BESTCOMS for the CDS240 or at the Basler Electric Web site. Two of the logic schemes are intended for use on transformers. One of the schemes is for motor protection with a speed sensing input, one is for bus protection with backup, and one is a basic 87 function designed for multiple applications including transformer, motor, bus, or generator protection. -

Page 236: Cds240-Bsbu-A-Be (Bus Protection With Backup) Logic Scheme

BE1-CDS240 are hard wired to the feeder protection package, providing a high-speed backup, bus interlocked, zone of bus protection. When the BE1-CDS240 detects a feeder relay out of service, the BE1-CDS240 50/51P, N, and Q protection elements and outputs are automatically reconfigured to provide feeder protection. -

Page 237: Cds240-Ba87-B-Be (Basic Differential) Logic Scheme

SL-VO15=IN8 SL-251Q=0,0 SL-OUTA=VOA SL-351P=0,0 SL-OUT1=VO1 SL-351N=0,0 SL-OUT2=VO1 SL-351Q=0,0 SL-OUT3=VO1 SL-451N=0,0 SL-OUT4=VO4 SL-24=0,0 SL-OUT5=0 SL-27P=0,0 SL-OUT6=VO6 SL-127P=0,0 SL-OUT7=0 SL-47=0,0 SL-OUT8=0 SL-59P=0,0 SL-OUT9=0 SL-59X=0,0 SL-OUT10=0 SL-159P=0,0 SL-OUT11=0 SL-81=0,0 SL-OUT12=0 SL-181=0,0 SL-OUT13=0 SL-281=0,0 SL-OUT14=0 SL-381=0,0 SL-481=0,0 SL-581=0,0 9365200990 Rev F BE1-CDS240 Application 8-11... - Page 238 Figure 8-3. Typical One-line Diagram for CDS240-BA87-B-BE 8-12 BE1-CDS240 Application 9365200990 Rev F...

-

Page 239: Protection Elements