Nordson EPC-30 Instruction Sheet

Current-to-pressure (i/p)

transducer epc-30 series

Hide thumbs

Also See for EPC-30:

- Instruction sheet (6 pages) ,

- Instruction sheet (4 pages) ,

- Instruction sheet (4 pages)

Advertisement

Series EPC-30 Current-to-Pressure (I/P)

Transducer

Introduction

Specifications

Item

Air supply input pressure

Air supply output pressure

Input impedance

Input signal

NOTE A: The transducer was calibrated using a 6.6−6.9 bar (95−100 psi) air supply.

B: With a 6.6−6.9 bar (95−100 psi) air supply, the output should be 0−0.3 bar (0−5 psi) with a 4 mA signal or

6.0−6.4 bar (87−93 psi) with a 20 mA signal.

E 2010 Nordson Corporation

WARNING! Allow only personnel with appropriate training and experience

to operate or service the equipment. The use of untrained or inexperienced

personnel to operate or service the equipment can result in injury, including

death, to themselves and others, and damage to the equipment.

This instruction sheet contains the procedure for installing the

current-to-pressure (I/P) transducer (kit P/N 772033).

If the Eclipset EPC-30 pattern control is equipped with an optional

input/output (I/O) board, the I/P transducer can be installed to provide

run-up control for the system. Refer to the Eclipse EPC-30 pattern control

manual for setting the run-up control.

The following table lists specifications for the I/P transducer.

Specification

8.6 − 10.3 bar (125 − 150 psi)

0.2 − 8.3 bar (1 − 120 psi)

260 ohms (nominal)

4 − 20 mA VDC

Instruction Sheet

P/N 331276B

Note

A

A

B

Part 331276B

02

02

Advertisement

Table of Contents

Summary of Contents for Nordson EPC-30

- Page 1 If the Eclipset EPC-30 pattern control is equipped with an optional input/output (I/O) board, the I/P transducer can be installed to provide run-up control for the system. Refer to the Eclipse EPC-30 pattern control manual for setting the run-up control.

-

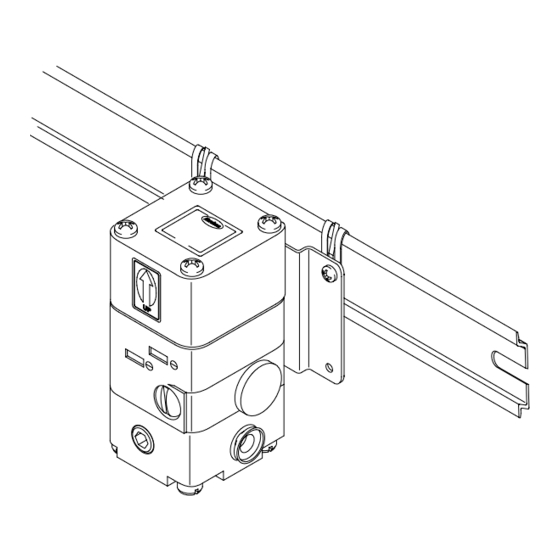

Page 2: I/P Transducer Installation

Series EPC-30 Current-to-Pressure (I/P) Transducer I/P Transducer Installation Use this procedure to install the I/P transducer. CAUTION! Mount the transducer with the UP arrow pointing directly up. Mounting the transducer in any other position will change the current-to-pressure ratio. 1. Use one of the following methods to mount the transducer-and-bracket assembly within 30 feet of the hot melt unit’s pump. - Page 3 5. Set the hot melt unit’s air pressure regulator at the maximum setting (turn the regulator fully clockwise). 6. Route the transducer cable to the Eclipse EPC-30 pattern control. Refer to the Eclipse EPC-30 pattern control manual for instructions on: A.

-

Page 4: Troubleshooting

Series EPC-30 Current-to-Pressure (I/P) Transducer Troubleshooting The following troubleshooting guide allows for a quick check in the field to help reduce down time. For additional troubleshooting information, refer to the manuals provided with the other equipment used in the hot melt system. - Page 5 Series EPC-30 Current-to-Pressure (I/P) Transducer Figure 3 Pneumatic components of the transducer 1. Orifice assembly 5. Spring 9. Body assembly 2. Zero and span protector assembly 6. Spacer 10. In port 3. Strain relief 7. Control diaphragm assembly 11. Gauge port 4.

-

Page 6: Electronic Section

Series EPC-30 Current-to-Pressure (I/P) Transducer Troubleshooting the Pneumatic Section NOTE: If the diaphragm fails, the transducer will leak internally. Problem Possible Cause Corrective Action Supply air on and the signal is set Make sure that the air supply is to 4 mA... - Page 7 Series EPC-30 Current-to-Pressure (I/P) Transducer Figure 4 Electrical components of the transducer 1. Bonnet 4. Circuit board assembly 7. Strain relief 2. Magnet 5. Orifice assembly 8. Gauge port 3. Coil/spring assembly 6. Zero and span protector 9. Housing assembly assembly 10.

-

Page 8: Basic Calibration

Series EPC-30 Current-to-Pressure (I/P) Transducer Troubleshooting the Electronic Section Use a multi-meter with both continuity and resistance to troubleshoot the transducer’s electronic section. Follow the sequence below: 1. Connect the test leads to the black and white leads on the transducer and check for continuity. -

Page 9: Field Troubleshooting

Series EPC-30 Current-to-Pressure (I/P) Transducer SPAN Adjustment The SPAN adjustment potentiometer is located on the front of the transducer. It is used to set the maximum pressure output. The minimum and maximum pressure outputs must be checked each time an adjustment is made. - Page 10 B: The cable and strain relief bushing are preassembled on the transducer. 5742121A Figure 5 Transducer service kit parts Issued 08/10 Original copyright date 1999. Nordson and the Nordson logo are registered trademarks of Nordson Corporation. Part 331276B E 2010 Nordson Corporation...

Need help?

Do you have a question about the EPC-30 and is the answer not in the manual?

Questions and answers