Table of Contents

Advertisement

Cat. No. 01021161

Rev. H 01/10/11

DCO # 012139

Installation,

Operation, and

Service Instructions

with Parts Lists

CULLIGAN

®

Smart Controller (GBE)

For Commercial and Industrial Softener

and Filter Applications

Models from 2011

Firmware Version 2.1.3

Printed in USA

©2011 Culligan International Com pa ny

Advertisement

Table of Contents

Summary of Contents for Culligan Smart Controller (GBE)

- Page 1 Rev. H 01/10/11 DCO # 012139 Installation, Operation, and Service Instructions with Parts Lists CULLIGAN ® Smart Controller (GBE) For Commercial and Industrial Softener and Filter Applications Models from 2011 Firmware Version 2.1.3 Printed in USA ©2011 Culligan International Com pa ny...

- Page 2 Products manufactured and marketed by Culligan International Company (Culligan) and its affiliates are protected by patents issued or pending in the United States and other countries. Culligan reserves the right to change the specifications referred to in this literature at any time without prior notice. Culligan, Aqua-Sensor, Tripl-Hull, and SoftMinder are trademarks of Culligan International Company or its affiliates.

-

Page 3: Table Of Contents

Appendix B Data Port Output........92 Customizing Set Up ............22 Appendix C Flow Device K-Factor Data ......97 Softener and Filter Program Log ........29 Culligan® Softener and Filter Program Log ....98 Installing Accessories ............30 Index ................99 Cat. No. 01021161... - Page 4 Document Change History Chapter Description Reason 012139 Programming Updated menu selections and structure FWR 2.1.3 ii ii Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

-

Page 5: Introduction

Introduction Read this Manual First Before you operate the Culligan Smart Controller (GBE), read this manual to become familiar with the device and its capabilities. About this Manual This manual: • Familiarizes the operator with the equipment • Explains installation and setup procedures •... -

Page 6: Smart Controller Features

Smart Controller Features The primary function of the Culligan Smart Controller (GBE) is to initiate and control the regeneration process via methods that are most convenient and cost effective for the customer while offering many operational features and benefits. The controller is designed to operate a wide range of existing and new softener and filtration valves. - Page 7 Flow Meter/Sensor Input Supports various types of Hall effect flow sensors using a pro- grammable K factor to initiate a regeneration sequence. Aqua-Sensor Input Supports the patented digital Culligan Aqua-Sensor technology ® ® used to efficiently initiate and control a regeneration sequence.

-

Page 8: Basic Principles

The regeneration process for your commercial water softener is controlled automatically either on a predetermined time, volume, or external signal basis through the use of the Culligan GBE controller with optional flow sensor. See the Installa- tion chapter for further information. The regeneration process can also be initiated manually by the operator as required. -

Page 9: Operation

Differential Pressure (Filters Only) When combined with an optional differential pressure device, the Culligan Smart Controller has the ability to initiate a backwashing sequence when the pressure differential across the media bed reaches a preset amount (usually 8–10 psi). -

Page 10: Installation

WARNING! One transformer is required for each controller in the system. Do not attempt to operate multiple controllers without a dedicated transformer for each or your system will experi- ence operational difficulties. 6 6 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters... - Page 11 Wiring Procedures and Diagrams Preparation Loosen the screws or latches securing the controller access cover (see Figures 3 or 4) on each controller provided. Figure 4. Figure 3. Figure 5. Cat. No. 01021161 Installation...

- Page 12 Accessories Input Connection for Remote Accessories 24 Volt Power Input Connection Brine Reclaim Solenoid (optional) Brine Refill Valve Figure 7. Figure 6. Blocking Solenoid for Alternating Operation 8 8 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 13 Smart Controller Overview To access the inside of the Smart Controller, refer to the instructions below. CAUTION! Failure to complete the following steps might result in damage to the keypad or circuit board! Loosen the front cover screw. Hinge the front cover upwards. (See Figure 8). Do not remove the front cover yet.

-

Page 14: Smart Controller Circuit Board Layout

(from transformer) Blocking Valve External regeneration Programmable Connection (optional) signal connection (optional) Outputs Motor or external alarm (optional) Connection Figure 11. Smart Controller circuit board layout, rear view. 10 10 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters... - Page 15 Smart Controller Circuit Board Outputs The circuit board supports four outputs: • Motor control (DC Motor) • Blocking valve (Use Aux Out 4) • Two programmable auxiliary outputs (Aux Out 2 and Aux Out 3) for commercial four-cycle and five-cycle valves. •...

- Page 16 Repeat the process for the other 24 V power supply wire attaching the second wire to the opposite terminal on the transformer and next to the other wire connected to the 24V pins on the Smart Controller board. Figure 13. Transformer and Smart Controller circuit board. 12 12 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 17 Brine Refill Valve Wiring NOTE This only applies to Culligan CSM Softeners. Install the Solenoid Coil and Connector Locate the solenoid coil and connector cord. Assemble it to the brine refill valve as shown in Figure 14. Install the Cord Grip Remove the hole plug from the left side of the Smart Controller enclosure.

-

Page 18: Smart Controller Programming

You will be able to get the reserve capacity during programming. Determining Batch Set Point To determine the batch set point for programming the Culligan Smart Controller, use the following formula: Total Capacity – Reserve Capacity... -

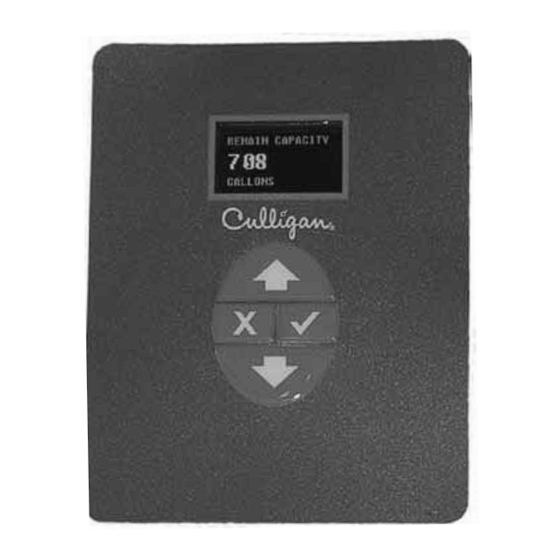

Page 19: Navigating The Menus And Keypad

Navigating the Menus and Keypad UP button CHECK MARK or CANCEL (X) button OK button DOWN button UP ARROW button: scrolls up the menu DOWN ARROW button: scrolls down the menu CHECK MARK button: selects the highlight- ed option, opens a new screen, or accepts a Controller changed setting CANCEL or EXIT... - Page 20 JAN-01-10 12:01P NOTE Unplugging the Culligan water softener will not affect any of the control settings (the control must be plugged in for at least 15 minutes). Once programmed, the settings will be stored indefinitely. 16 16 Cat.

- Page 21 Smart Controller Programming The programming for the Smart Controller is based on a menu structure. There are six top-level menus with additional op- tions in submenus. The top-level menus are: INFORMATION MANUAL MODE SET DATE/TIME ACCESSORIES ADV. SETUP DIAGNOSTICS Here is a brief explanation of what you will find under each menu. Menu/Submenu Description Information...

- Page 22 (for smart brine sensor) • local telemetry data phone number (for modem) • your dealer account number (used with modem for setting up telemetry) 18 18 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

-

Page 23: First Time Set Up

NOTE If this unit will be installed with a modem, this electronic ID number Dec 7 2010 MUST be reported to Culligan on the Web site www.myculligan.com. The screen displays the first date setting for the Smart Controller. MONTH Press to change the month setting from the default value. - Page 24 FILL TIME Fill Time The screen displays the fill time setting, based on the salt dos- 1–170 (softener) age. Press to keep the calculated setting. MINUTES 20 20 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 25 Completed First-Time Setup Initializing When the setup is complete, the circuit board microprocessor automatically calcu- JAN-01-10 12:01P lates softener capacity. The screen displays the initializing status and the current date and time, and then transitions to the home screen. SOFTENING The screen displays the current state (alternate display is the next programmed re- JAN-01-10 12:01P generation) and the date/time set for the unit.

-

Page 26: Customizing Set Up

4)REGENTRIGGER VALVE TYPE 4-CYCLE The screen displays the valve type setting specified during the first-time setup. This setting cannot be changed. Press to view the next setting. 22 22 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters... - Page 27 Other System Setup Values Use the same procedure to change the values of other Smart Controller settings. Press the DOWN ARROW button to scroll through the settings, unless otherwise instructed. After changing the setting, press the CHECK MARK button to ac- cept the displayed screen value.

- Page 28 For softeners and filters. For multi-tank systems, this is nor- Regen REGEN MODE mally set to IMMEDIATE. If immediate is selected, be sure to DELAYED Mode* Immediate change the Reserve Capacity setting. 24 24 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 29 Setting Screen Display Range Changing the Setting 3 Plus By default if a power loss is for more than three hours, the unit Power Up POWER UP REGEN Hours will regenerate when it regains power. Setting this value to No 3 PLUS HOURS Regen disables this function, preventing a regeneration after a power...

- Page 30 The screen displays the advanced setup menu. The menu includes SYSTEM SET- 2)REGEN SETUP UP, REGEN SETUP, CYCLE TIMES, and REGENTRIGGER. >3)CYCLE TIMES Press to select 4)REGENTRIGGER. 4)REGENTRIGGER 26 26 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 31 Regeneration Triggers Settings Use the same procedure to change the values of other regeneration trigger settings. Press to scroll through the set- tings, unless otherwise instructed. After changing the setting, press to accept the displayed screen value. The Smart Controller will display the next system setting from the menu. NOTE All system setup settings are displayed when setting up a water softener.

- Page 32 Stand-by and/or has been the whole time. 2)MANUAL MODE 3)SET DATE/TIME The regeneration trigger setup is complete. The screen displays the advanced 4)ACCESSORIES setup menu. Press to display the home screen. >5)ADV. SETUP 28 28 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

-

Page 33: Softener And Filter Program Log

Use this log to record the program settings for any Smart Controller (GBE) controlled softener or filter. Circle or enter the observed value. Make additional copies to keep on file near the installation and with your local Culligan dealer. Program Date: ___________ Installer: _____________________________... -

Page 34: Installing Accessories

2" Autrol Turbine Meter (optional) Seametrics Paddle Wheel Signet (optional) All Clack Meters 2535 & 2536 (optional) (optional) SINGLE OR PROGRESSIVE Figure 17. Flow measuring devices. 30 30 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters... -

Page 35: Cat. No.

Programming the External Flow Meter Most metered commercial units require an external flow meter device. this requires an entry in the programming for the meter chosen. The entry is the pulses per gallon, or K Factor. Refer to the table in Appendix C for meter K Factors. SOFTENING JAN-01-10 12:01P From the HOME screen, press... - Page 36 Verify wiring from terminals to circuit board are correct before applying power to con- trol. 24 VAC power must not be applied to the 2.5 VAC terminals of the circuit board or the circuit board will be damaged. 32 32 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 37 POWER SUPPLY ONE transformer is required for each Control METAL TABS Connect to white connector on main Power to circuit board 24V power cord Power to circuit board 2.5VAC only required for Aqua-Sensor installations 2.5V 24VAC on TRANSFORMER Figure 18. 2.5 VAC Aqua-Sensor power connection (CSM and Hi-Flo 50).

- Page 38 Press to toggle between on and off. ® Press when the correct Aqua-Sensor debugging mode is displayed. ® SOFTENING JAN-01-10 12:01P Press to display the home screen. 34 34 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 39 Installing the Smart Brine Tank (SBT Probe) in to the Brine Tank CAUTION! Do not use the SBT probe if you are using Brine Reclaim. NOTE For a multi-tank system using one brine tank, connect the probe to the Master controller. NOTE IMPORTANT! In order for proper probe functioning, you must physically install the probe into the brine tank and fill the brine tank with a minimum of 16”...

- Page 40 Use this setting to select the salt geometry (the shape of the Rock/Solar Salt SALT GEOMETRY softening salts). Press and then to change the Pellet/cube Geometry Special setting. Block/Brick SOFTENING JAN-01-10 12:01P Press to display the home screen. 36 36 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 41 Brine Reclaim For brine reclaim, AUX OUT 2 and AUX OUT 3 must be set to open and close the valves to direct the brine. There are four things to set for each aux output. See page 48 for a complete description of auxiliary output settings. Refer to the Brine Reclaim Installation Manual (01018946) for information required to determine appropriate auxiliary settings.

- Page 42 NOTE For testing purposes, use the Aux2 and Aux3 control options available on the Diagnostics and Aux Out Test settings. 38 38 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 43 Multi-Tank Systems Communication Cable—Multiple Units Multiple units require a communication cable between each unit. Refer to the table below for the cable type, part number and quantity required. Cables are attached to the RS485 terminal of the circuit board. Table 1. Communication cable requirements System Configuration Cable Part Qty of Cables...

- Page 44 RS 485 Comm Port on third GBE Circuit Board. PARALLEL CABLE 01016327 Figure 27. Parallel cable for Smart Controller. 40 40 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 45 Duplex Alternating with Meter (Optional) For triplex, quad, and other alternating connections, you must use a meter on each unit and connect the same way as progressive flow. See Figure 28. Communication Cable 01016342 Unit 1 Unit 2 Flow meter Figure 28.

- Page 46 Set the second unit to SLAVE 1. Set the third unit to SLAVE 2. A multi-tank system may have up to five slaves connected to a master. 42 42 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 47 Setting Screen Display Range Changing the Setting This setting establishes a flow rate which, when attained, will PROG FLOW TRIP Prog Flow 0–999 cause another unit to come online until the total flow rate is Trip less than the established trip point for 30 seconds. Should the flow demand exceed the trip point by a rate equal to or greater than two times the trip point, another unit shall be brought on-line (when Progress Flow or Unbal Prog Flow is selected).

- Page 48 The additional settings needed on the slave units will be for accessories such as Aqua-Sensor and Smart Brine Tank Probe. Service phone number, wireless remote, and modem settings are not transferred because in a multi-tank system they are installed on the Master only. 44 44 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 49 Blocking Solenoid Valve For Multi-tank Alternating Operation NOTE Proceed to page 47 if your system is a single tank configuration. The solenoid valve is only required for multiple unit alternating or progressive flow systems. The purpose of the solenoid valve is to assist the controller in providing automatic alternation of multiple tank systems. Each Brunermatic multiport valve in the system will require its own solenoid valve.

- Page 50 Solenoid Valve Energized Solenoid Valve Not Energized When Tank When Tank "Online" in Regen or Standby Figure 32. S O L Figure 33. Smart Controller board with solenoid connection. 46 46 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 51 Auxiliary Board The auxiliary board (Figure 34) comes installed in all commercial softeners and filters. It can control up to four 24 VAC outputs for energizing a relay coil only (max current 2.1 Amps output). The Auxiliary Outputs (see Figure 35) are output triacs that can be programmed to provide power to a normally open (normally no power to auxiliary output until power required) or a normally closed contact (user choice).

- Page 52 AUX 2 VALV POS Brine/SRinse. The screen displays the AUX OUT 2 setting. Backwash, Valve Brine/SRinse Brine/ For repeat cycle auxiliary output type, keep the setting at Position SRinse SERVICE. 48 48 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 53 Setting Screen Display Range Changing the Setting AUX OUT 2 Press and then to change the capacity, in Aux Out 2 0–4342 gallons, of the selected auxiliary output. Gals AUX2 OUT DELAY Press to leave the AUX 2 OUT DELAY setting at zero. Set Aux2 Out the AUX3 OUT delay to the same value as the AUX2 OUT (the 0–25...

- Page 54 The screen displays the Auxil- Secs iary Output menu. SOFTENING JAN-01-10 12:01P Press to save the settings and return to the home screen. 50 50 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 55 Auxiliary Input (Optional) One auxiliary input is provided for optional signal devices such as remote push buttons, differential pressure switches, hardness monitors, turbid meters, etc. for the purpose of receiving a regeneration signal. The Aux Input can also be con- figured as an external alarm trigger.

- Page 56 GBE will enter an alarm condition when it receives a signal. The screen displays the error message AUX INPUT ALARM. SOFTENING JAN-01-10 12:01P Press to save the settings and return to the home screen. 52 52 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 57 Installing the Modem (Optional) NOTE The modem can be installed into either the back of the main controller or the back of the remote con- trol board. The functionality of the modem is the same in either installation. NOTE Use of the modem kit requires a one-year subscription to either a Level 1 or Level 2 Telecom package. Self-service registration is available at www.myculligan.com.

- Page 58 Press and then to change the Modem Loca- IN MAIN CONTROL Control or Location tion setting. Change this setting only if a modem is installed. In Remote 54 54 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 59 These lo- cal access numbers, for nearly every area code around the globe, can be found from the My Culligan website at http:// www.myculligan.com/technical/tech_ref-gbe-boards.asp. The unit can also be programmed with the default toll-free access number.

- Page 60 (as opposed to installed in the remote control) then this testing process will also check to see if there is an updated version of firmware available on the Culligan servers. After conducting a phone line test, it is important to verify that the new time and date settings on the controller are correct.

- Page 61 Installing the Wireless Remote Select a location for the wireless remote monitor (Figure 40). The location must be near an electrical outlet. If a modem is used in the remote, then the location should also be near a standard RJ-11 type telephone wall jack. 5 3/8”...

- Page 62 915 Mhz Frequency or 915 change the RF frequency for North America installations. SOFTENING JAN-01-10 12:01P Press to save the settings and return to the home screen. 58 58 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 63 Wireless Remote Setup This setup is completed using the wireless remote device. SOFTENING JAN-01-10 12:01P From the HOME screen, press to view the main menu. 1)INFORMATION 2)MANUAL MODE The screen displays the main menu. Press to select 3)SET DATE/TIME 4)ACCESSORIES. >4)ACCESSORIES 3)AUX IN From the Accessories menu, press...

- Page 64 RSSI=5 will test the signal strength again and repeat until you press again. SOFTENING JAN-01-10 12:01P Press to save the settings and return to the home screen. 60 60 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 65 Chlorinator/Relay Board/Aux5 Setup The GBE board offers support for the Culligan Chlorinator/Relay board (PN 01021961). See Figure 43. To use the chlorinator/relay board, install it onto the back of the GBE board. See Figure 42. ALARM BOARD PLUG IN HERE...

- Page 66 Terminals 1 and 2 are connected, leaving the lamp circuit open (lamp off) ERROR CONDITION: Terminals 1 and 3 are connected, completing the lamp circuit (lamp on) Figure 44. Example of customer wiring to the GBE Alarm Signal Output 62 62 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 67 Smart Controller Alarm Signal Output The Smart Controller Alarm Signal Output is provided thru three screw terminals located on the Plug-in Circuit board. These terminals provide a pair of dry contacts rated at 10 A at 240 VAC. One dry contact is open and one is closed at all times as defined in the table below.

- Page 68 12 hour warnings Never Between 8 AM–8 PM 24 hour warnings Never Always SOFTENING JAN-01-10 12:01P Press to save the settings and return to the home screen. 64 64 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 69 If the Modem is not installed it is possible, in addition to displaying the error message, to display a message that reads “Call Culligan at: XXXXXXXXXX” where the telephone number XXXXXXXXXX can be programmed by the dealership (typically programmed to be the telephone number of the dealership).

- Page 70 Once the auxiliary filter has been replaced, the auxiliary filter alarm must be reset by returning to the same menu: Main Menu / Accessories. SOFTENING JAN-01-10 12:01P Press to save the settings and return to the home screen. 66 66 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 71 Set Date/Time If the unit loses time for some reason, you can use this setting to reset the correct date and time. Please note that if you have a modem installed and connected to the phone line, the unit will check for the correct time each time it calls in. SOFTENING JAN-01-10 12:01P From the HOME screen, press...

- Page 72 . The display should be blank—if not go back to step 1. After a brief 10-20 second delay, the screen lights up for two seconds and then displays FIRST TIME SETUP. Follow the first time setup process. 68 68 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

-

Page 73: Service And Maintenance

Service and Maintenance Control Valve Information The following information can be displayed at the control valve or remote display. SOFTENING JAN-01-10 12:01P From the HOME screen, press to view the main menu. >1)INFORMATION 2)MANUAL MODE The screen displays the main menu. Press to select 1)INFORMATION. - Page 74 External Filter Alarm. This information is displayed only if the GALLONS Remain- External Filter Alarm is installed. ing* SOFTENING JAN-01-10 12:01P Press to save the settings and return to the home screen. 70 70 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

-

Page 75: Manual Regeneration

Manual Regeneration Follow either procedure to bypass the softener or to initiate a manual regeneration at the control valve or the remote display. NOTE In multi-tank systems, the regeneration request is sent to the master control. It will allow the unit to regenerate at the next available time. -

Page 76: Manual Cycling

(such as from the meter or Aqua-Sensor). The unit will return to service. Press to accept the new regeneration setting. SOFTENING JAN-01-10 12:01P Press to return to the home screen. 72 72 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters... -

Page 77: Error And Alert Codes

Low Salt level Salt level is low; less than 15 days of Contact Culligan dealer for salt deviery or fill brine salt remaining. tank with salt. Low battery Battery needs replacement. - Page 78 Incorrect valve type selected. Change the valve type using the Advanced Setup/ Valve Type menu then return to the home screen. The screen will blank while the unit reinitializes. 74 74 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

-

Page 79: Diagnostic Screens

Diagnostic Screens There are a large number of diagnostic menu screens to aid in setup and troubleshooting of the Smart Controller. Below is an overview of the menus. Advanced Statistics SOFTENING JAN-01-10 12:01P From the HOME screen, press to view the main menu. 3)SET DATE/TIME 4)ACCESSORIES The screen displays the main menu. - Page 80 You can use this value to check if the 0–9999999 Time proper amount of water is being used to fill the tank. Press SECONDS to return to the Advanced Stats menu. 76 76 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 81 Tank Statistics 1)FLOW STATS 2)REGEN STATS The screen displays the advanced statistics. Press to select 3)TANK >3)TANK STATS STATS. The screen displays the tank statistics information for the softener. 4)FW VERSION Setting Screen Display Range Description REMAIN CAPACITY 0–9999999 The screen displays the the remaining capacity of the unit, in gallons.

- Page 82 Regeneration is initi- ated when it reaches 7.5% or more for at least six minutes. This screen is displayed only if the Aqua-Sensor is installed. ® 78 78 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 83 Setting Screen Display Range Description SBT SENSOR Expected Readings on the Sensor/Diagnostic screen when Salometer=OP the SBT probe is installed inside the brine tank. See below for Salt Level=OP Sensor settings. FR1=OP FR2=OP Displays BL (= Blocked) Displays OP (= Open) Salometer Brine at least 1"...

- Page 84 Diagnostics menu. 5:OFF Aux Out Test 4)TEST PROGFLOW 5)MOTOR CONTROL From the Diagnostics menu, press to select 7)AUX OUT 6)AUX OUT STAT TEST. >7)AUX OUT TEST 80 80 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 85 AUX OUT TEST The AUX OUT TEST allows you to turn the Aux Out switches on or off for testing purposes. For example, the screen displays AUX 1 ON then PRESS ENTER. This AUX 3 ON indicates that AUX 1 is currently off and if you press enter ( ) the state changes Press Enter...

-

Page 86: Menu Overview

Menu Overview 82 82 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters... - Page 87 Cat. No. 01021161 Menu Overview...

- Page 88 84 84 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 89 Cat. No. 01021161 Menu Overview...

-

Page 90: Smart Controller (Gbe) Parts And Accessories

Universal Conversion, works on Hi-Flo 2/2e, 2850, 3150 01018209 Fleck 2" Meter Conversion Kit, Mechanical to Electronic, 8 ft. Cable 01023062 Fleck 3" Meter Conversion Kit, Mechanical to Electronic 86 86 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters... -

Page 91: Appendix A Programming Examples

Appendix A Programming Examples Quick Programming—First Time Setup with Delayed Regeneration Hi-Flo 22 Softener (WS-090, 5-Cycle) with Single Meter: salt dosage=30, hardness=15 gpg Cat. No. 01021161 Appendix A Programming Examples... - Page 92 Quick Programming—Duplex Progressive Flow with Aqua-Sensor ® CSM 450-2: salt dosage=90 lbs, hardness=24 gpg NOTE Perform first-time setup and programming for Unit 2 and then for Unit 1. 88 88 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 93 Quick Programming Chart—Duplex Alternating Flow CSM 300-2: salt dosage=150 lbs, hardness=18 gpg NOTE Perform first-time setup and programming for Unit 2 and then for Unit 1. Cat. No. 01021161 Appendix A Programming Examples...

- Page 94 Quick Programming Chart—Triplex with Parallel Flow/Brine Reclaim CSM 750-3: salt dosage=375 lbs, hardness=40 gpg NOTE Perform first-time setup and programming for Unit 3, then Unit 2, and then for Unit 1. 90 90 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 95 Quick Programming Chart—CSM Filter (Single Time Clock Regeneration) NOTE Set up Total Capacity only if the system configuration uses a meter to trigger regeneration. Cat. No. 01021161 Appendix A Programming Examples...

-

Page 96: Appendix B Data Port Output

(W, X, Y and Z) are then combined into a four digit binary word which is converted to a hexadecimal digit. As an example, if there are no errors present, then the value would be 0x0000. 92 92 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters... - Page 97 Single softener section above. Electrical Connections The Culligan Data Cable Connector is terminated with a D-sub9 style female termination. The customer must provide the following pin connections:...

- Page 98 In order to connect the Smart Controller to a com- ® puter you will need a USB-to-GBE cable, Culligan P/N 01021507. You will also need to download a installation file from the myCulligan Web site on the GBE downloads page. The file is called “Setup_Culligan_GBE.EXE”. Once you copy the file to your PC, you can double-click on the file to install the USB drivers and the Data Port Output Viewer to your local hard drive.

- Page 99 Send a Test Message from the Smart Controller SOFTENING JAN-01-10 12:01P From the HOME screen, press to view the main menu. 3)SET DATE/TIME 4)ACCESSORIES The screen displays the main menu. Press to select 5)ADV. STATS 6)DIAGNOSTICS. >6)DIAGNOSTICS 5)MOTOR CONTROL 6)AUX OUT STAT From the diagnostics menu, press to select 8)USE 7)AUX OUT TEST...

- Page 100 Flow Profile R5 = 0 Dosage = 9.0 LBS Flow Profile R6 = 0 DAS = SOFTEST Iron = 0 PPM * Softener only. Figure 45. Mini Report from data port. 96 96 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

- Page 101 C Flow Device K-Factor Data Meter Type Installation Fitting Pipe Size Flow Range K-Factor K-Factor Culligan Shaded = Obsolete Type/Material (GPM) Gallons Liters Part No. Culligan Turbine, PVC, NPT 0.5" 21.1 01021033 Tubine, PVC, NPT 0.75" 21.1 01021259 Turbine, Noryl, NPT 1.5"...

-

Page 102: Culligan® Softener And Filter Program Log

Use this log to record the program settings for any Smart Controller (GBE) controlled softener or filter. Circle or enter the observed value. Make additional copies to keep on file near the installation and with your local Culligan dealer. Program Date: ___________ Installer: _____________________________... -

Page 103: Index

Flow Statistics 75 OLED Display 2, 10 Operation 5 Cable Routing 8 Output 93 GBE Circuit Board Layout 10 Call Culligan 65 GBE Controller Parts 86 Capacity 20, 24 GBE Controller Programming 14, Capacity Remaining 70 73, 75 Parallel 39... - Page 104 Single Water Softener 92 Slew Rates 14 Smart Brine Tank 35 Smart Brine Tank Probe 3 Smart Brine Tank T3 measure- ment 79 Softener 5 1 00 1 00 Cat. No. 01021161 Culligan® Smart Controller (GBE) for Softeners and Filters...

Need help?

Do you have a question about the Smart Controller (GBE) and is the answer not in the manual?

Questions and answers