Summary of Contents for DAJ XR150A

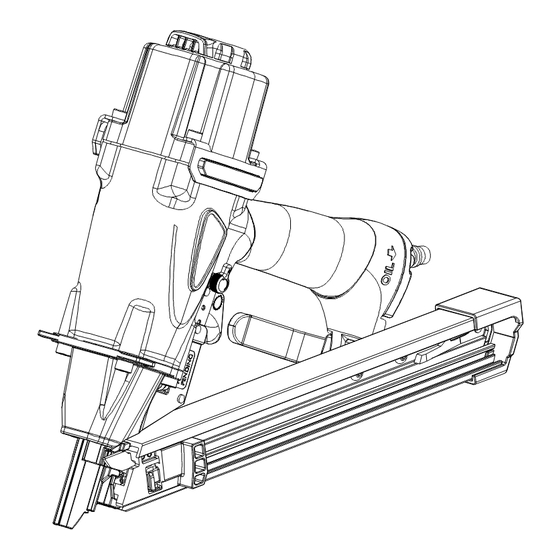

- Page 1 USERS MANUAL XR150A/XR250/XR250S Metal Connector Nailer WARNING Failure to follow warning could result in DEATH OR SERIOUS INJURY. M0301 03/12 V2...

-

Page 2: Table Of Contents

CONTENTS: IMPORTANT INFORMATION EXPLANATION OF THE NAILING ACTION GENERAL SAFETY RULES WORK AREA PERSONAL SAFETY TOOL USE AND CARE SERVICE AIR SOURCE DESCRIPTION AND SPECIFICATION SPECIFICATION FEATURES ASSEMBLY/INSTALLATION OPERATION LUBRICATION ADJUSTING AIR PRESSURE CONNECTING AIR SUPPLY TOOL TESTING NAIL LOADING REMOVING NAILS METHODS OF OPERATION COLD WEATHER OPERATION... -

Page 3: Important Information P1

IMPORTANT INFORMATION The employer must enforce the use of safety glasses by the tool operator and others in work area. ALWAYS WEAR EAR AND HEAD PROTECTION. Always WARNING wear ear protection to protect your ears from loud noise, TO AVOID SERIOUS PERSONAL INJURY, ALL USERS AND Always wear head protection to protect your head from EMPLOYERS/OWNERS MUST READ AND UNDERSTAND flying objects. -

Page 4: Air Source

TOOL SERVICE CONDITION THAT MAY AFFECT THE TOOL'S OPERATION. If damaged, have the tool serviced before using. Many USE ONLY ACCESSORIES THAT ARE IDENTIFIED BY THE accidents are caused by poorly maintained tools. MANUFACTURER FOR THE SPECIFIC TOOL MODEL CHECK SAFETY BEFORE USE. Make sure the safety USE OF UNAUTHORIZED PARTS OR FAILURE TO FOLLOW operates properly. -

Page 5: Specification P3

Normal Operating Pressure: 70-115PSI(0.5-0.8MPa) 0.131-0.162" 0.236" (3.3-4.1mm) 9-10Ga. (6mm) Maintenance: Oiling XR150A Firing Mode: Sequential Fire Fastener Size Range: XR150A: 1-1/2"(38mm) XR250/XR250S: 1-1/2"(38mm) & 2-1/2"(64mm) 8-10Ga. Product Size: XR250 XR250S Length Height Weight Magazine Capacity Model Width 12.80"(325mm) 3.74"(95mm) 12"(305mm) 5.24lbs (2.38kgs) -

Page 6: Features P4

FEATURES If the tool is not used with an in-line lubrication system on the air supply it is necessary to periodically lubricate the 360 adjustable exhaust. tool with air tool lubrication. Anti-dry-firing design. Fire lock prevents accidental firing when the tool is not Under low use, lubricate once a day. -

Page 7: Tool Testing P5

of their maximum pressure rating may operate abnormally Disconnect air hose from tool. Remove all nails from or burst resulting in personal injury. tool. ALL SCREWS MUST BE TIGHTENED. If any screws are WARNING loose, tighten them. To connect the tool to the compressor only use pneumatic THE SAFETY AND TRIGGER MUST MOVE SMOOTHLY. -

Page 8: Removing Nails

REMOVING NAILS: XR250/250S LOAD NAILS CORRECT WARNING FIG. 6 load nails Always disconnect tool from air supply before removing nails from magazine. This avoids the risk of unintentional operation. WARNING Do not disconnect air hose from the tool with finger on the trigger or safety depressed. -

Page 9: Methods Of Operation

FIG. 14 FIG. 16 INCORRECT Placement of nail METHODS OF OPERATION The Sequential Triggering system gets its name from the "sequence" required to drive a fastener. Always handle nails and package carefully. If nails are First, be sure the position and place the tip of the nail dropped, collating bent may be broken, which will cause into the metal connectors preformed hole.(FIG 15) mis-feeding and jamming. -

Page 10: Trigger Lock

TRIGGER LOCK tool will not be in use for an extended period, apply a thin coat of the lubricant to the steel parts to avoid rust. The nailer is equipped with a trigger locker C. Do not store the tool in a cold weather environment. If it is in lock position, tool is restricted to work and be safe. -

Page 11: Trouble Solving P9

TROUBLE SOLVING POSSIBLE CAUSE(S) SYMPTOM CORRECTIVE ACTION Trigger valve housing Replace O-ring O-ring cut or cracked leaks air Trigger leaks air O-ring cut or cracked Replace trigger valve assembly Tighten screws and recheck Loose nose screws Nose leaks air O-ring cut or cracked Replace O-ring Bumper cracked or worn Replace gasket... - Page 12 POSSIBLE CAUSE(S) SYMPTOM CORRECTIVE ACTION Disassemble and clean driver and sleeve Dirt/grime in driver channel Skipping fasteners; Replace bumper, check driver and driver piston Worn bumper intermittent feed O-ring Replace fixed nose Driver channel worn Wrong sized fastener Use only recommended fasteners Fasteners jam in tool Bent/damaged fasteners or collation Discontinue using these fasteners...

Need help?

Do you have a question about the XR150A and is the answer not in the manual?

Questions and answers