Table of Contents

Advertisement

Your new tool has been engineered and manufactured to WEN's highest standards for dependability,

ease of operation, and operator safety. When properly cared for, this product will supply you years

of rugged, trouble-free performance. Pay close attention to the rules for safe operation, warnings,

and cautions. If you use your tool properly and for intended purpose, you will enjoy years of safe,

reliable service.

30-TON GAS

LOG SPLITTER

IMPORTANT:

NEED HELP? CONTACT US!

Have product questions? Need technical support?

Please feel free to contact us at:

800-232-1195

techsupport@wenproducts.com

WENPRODUCTS.COM

Model # 56230

bit.ly/WENvideo

(M-F 8AM-5PM CST)

Advertisement

Table of Contents

Summary of Contents for Wen 56230

-

Page 1: Log Splitter

IMPORTANT: Your new tool has been engineered and manufactured to WEN’s highest standards for dependability, ease of operation, and operator safety. When properly cared for, this product will supply you years of rugged, trouble-free performance. Pay close attention to the rules for safe operation, warnings, and cautions. -

Page 2: Table Of Contents

TABLE OF CONTENTS Log Splitter Identification Service Record Introduction Safety Information General Safety Procedures Important Safety Instructions Log Splitter Components Assembly Log Splitter Preparation Starting the Log Splitter Stopping the Log Splitter Subsequent Starting of the Log Splitter Using the Log Splitter Maintenance &... -

Page 3: Introduction

Every effort has been made to ensure the accuracy of the information in this manual. WEN® reserves the right to change this product and specifications at any time without prior notice. Please keep this manual available to all users during the entire life of the log splitter. -

Page 4: General Safety Procedures

GENERAL SAFETY PROCEDURES For any questions regarding the hazard and safety notices listed in this manual or on the product, please call (800) 232-1195 M-F 8-5 CST before using the log splitter. DANGER: CARBON MONOXIDE Using a engine indoors CAN KILL YOU IN MINUTES. Engine exhaust contains carbon monoxide (CO). This is a poison gas you cannot see or smell. -

Page 5: Important Safety Instructions

GENERAL SAFETY PROCEDURES WARNING: The engine produces heat when running. Temperatures near exhaust can exceed 150 Do not touch hot surfaces. Allow engine to cool down after use before touching any areas of the log splitter that become hot during use (such as the engine). CAUTION: Misuse of this log splitter can damage it or shorten its life. - Page 6 IMPORTANT SAFETY INSTRUCTIONS 10. Only uses square log ends: logs that are not cut square can slide out while splitting and become a safety hazard or cause excessive force to log splitter components. Use a chain saw to cut logs square on each end before attempting to split them.

-

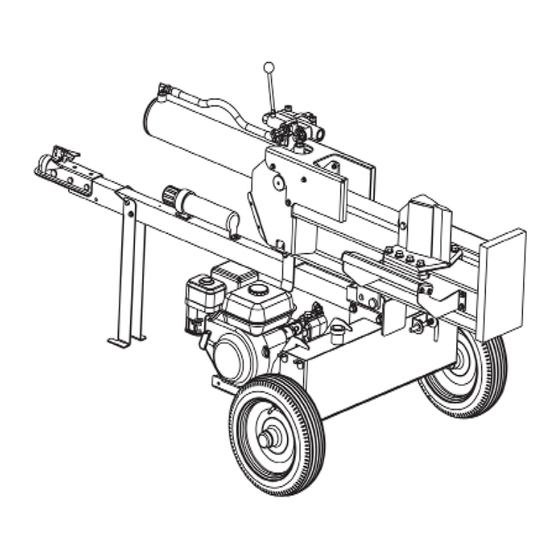

Page 7: Log Splitter Components

Safety Chain Support Leg Horizontal Lock Pump Return Line Filter Tire Engine Engine ON/OFF Switch Hydraulic Dipstick Hydraulic Tank Vertical Lock Closely inspect all log splitter components If you have missing or damaged components, please contact WEN Customer Service at 1-800-232-1195. -

Page 8: Assembly

ASSEMBLY STEP 1 - ATTACHING THE TIRES TO THE 2 3 4 HYDRAULIC TANK (FIGURE 1) 1. Slide a bearing (1A) and the tire onto axle with the 1A - Bearing valve stem (valve for inflation) facing out (Figure 1A) 1B - Bearing (bearings 1A and 1B may already be mounted on the 2 - Washer... - Page 9 ASSEMBLY STEP 2 - ATTACHING THE TOW BAR TO THE HYDRAULIC TANK (FIGURE 2) 1. Lock the support leg (4) in its downward position be- fore starting. 2. Slide the tow bar (1) into the pivot mount (3). Fasten 1. Tow Bar it in place using the included bolts (2) and nuts (5) as 2.

- Page 10 ASSEMBLY STEP 4 - ASSEMBLING THE LOG Figure 4 CRADLES (FIGURE 4) Attach the two log cradles (2) to beam using four bolts (3) and four locknuts (1). Figure 4A 1. Nuts (4) 2. Log Cradles (2) 3. Bolts (4) Figure 4B Figure 4C Figure 5...

- Page 11 ASSEMBLY Figure 5B 1. Pivot Mount 2. Beam Pivot Pin 3. Cotter Pin 4. Beam Assembly 5. Beam Pivot Bracket Figure 5A Figure 6A Figure 6 Figure 6C Figure 6B...

- Page 12 ASSEMBLY STEP 7 - CONNECTING THE HOSES WARNING: Be extremely careful when connecting the hoses. Connecting the hose to the wrong port could quickly ruin your log splitter and also runs the risk of inflicting an unwanted injury. Double check that the hoses are running to the correct inlets and outlets before starting the log splitter. 1.

-

Page 13: Log Splitter Preparation

LOG SPLITTER PREPARATION USING THE LOG SPLITTER FOR THE FIRST TIME The following section describes steps necessary to prepare the log splitter for use. If after reading this section, you are unsure about how to perform any of the steps please call (800) 232-1195 M-F 8-5 CST for customer service. - Page 14 LOG SPLITTER PREPARATION Step 2 - ADD GASOLINE WARNING: The engine may emit highly flammable and explosive gasoline vapors, which can cause severe burns or even death if ignited. A nearby open flame can lead to explosion even if not directly in contact with gasoline. Use fresh (within 30 days from purchase) lead-free gasoline with a minimum of 87 octane rating.

-

Page 15: Starting The Log Splitter

LOG SPLITTER PREPARATION HOW TO ADD HYDRAULIC FLUID Hydraulic Dipstick 1. Remove hydraulic dipstick. 2. Fill hydraulic tank with 10 wt AW32, ASLE H-150, or ISO 32 oil. Use a funnel if need. 3. Remove hydraulic dipstick and check the level. Note: Do not screw in dipstick when checking levels. - Page 16 STARTING THE LOG SPLITTER STARTING THE ENGINE To start the engine, perform the following steps: 1. Check the oil, fuel and hydraulic fluid levels. 2. Push the Fuel Valve to “ON” position, moving the fuel valve over to the right as shown. 3.

-

Page 17: Stopping The Log Splitter

STOPPING THE LOG SPLITTER TO TURN OFF THE LOG SPLITTER WARNING: Allow the engine to cool for several minutes before touching areas that become hot during use. CAUTION: Allowing gasoline to sit in the fuel tank for long periods of time can make it difficult to start the engine in the future. - Page 18 SUBSEQUENT STARTING OF THE LOG SPLITTER WARNING: This engine may emit highly flammable and explosive gasoline vapors, which can cause severe burns or even death if ignited. A nearby open flame can lead to explosion even if not directly in contact with fuel.

-

Page 19: Using The Log Splitter

USING THE LOG SPLITTER WARNING: It is important to select an appropriate work site and properly set up the log splitter in order to minimize the risk of slips and falls, equipment rolling or tipping over, carbon monoxide poison- ing, and accidental fires. SELECT LOCATION Make sure to find a dry level surface with good footing for operation. - Page 20 USING THE LOG SPLITTER SET TO VERTICAL LOCK Pull out horizontal lock latch rod, grasp and lift beam until it rotates into vertical position. Vertical Lock WARNING: Crush hazard. The beam is heavy – do not let it just drop. It could crush fingers or cause dam- age to the splitter.

- Page 21 USING THE LOG SPLITTER EXTENDING AND RETURNING THE WEDGE CAUTION: Remove both hands from log before activating Split Control Lever. Use only your hand to operate the Split Control Lever. Never use any other body part, or a rope, cable, or other remote device to actuate the control.

-

Page 22: Maintenance & Care

MAINTENANCE & CARE Proper routine maintenance of the log splitter will help prolong the life of the machine. Please perform mainte- nance checks and operations according to the schedule outlined in the chart below. If there are any questions about the maintenance procedures listed in this manual, please call (800) 232-1195 M-F 8-5CT. - Page 23 MAINTENANCE & CARE CLEANING THE LOG SPLITTER Never clean the log splitter when it is running! Never clean with a bucket of water or a hose. If the log splitter becomes dirty, clean the exterior with a damp cloth, a soft brush, a vacuum or pressurized air. CHECKING THE OIL Check the oil level of the engine according to the Recommended Maintenance Schedule (page 22).

- Page 24 MAINTENANCE & CARE To refill the crankcase with oil, follow these steps: 1. Make sure the log splitter is on a level surface. 2. Remove the dipstick from the engine. 3. Using a funnel or appropriate dispenser, add the correct amount of oil into the crankcase. The engine is equipped with a low-oil pressure sensor and will not start if the amount of oil is insufficient.

-

Page 25: Spark Plug Maintenance

MAINTENANCE & CARE SPARK PLUG MAINTENANCE The spark plug is important for proper engine operation. A good spark plug should be intact, free of deposits, and properly gapped. Refer to Recommended Maintenance Schedule. To inspect the spark plug: 1. Remove spark plug boot. Be careful not to tear insulation or wire. 2. -

Page 26: Storage & Transport

STORAGE & TRANSPORT Return to horizontal. If in the vertical position, turn off engine and return log splitter to the horizontal posi- tion for greater stability during transportation. Avoid contact with the muffler and the surrounding area, as these parts may be hot. Remove engine debris. -

Page 27: Specifications

Splash lubrication Run time on 50% load 4 hours Noise rating 63 dB at 22 feet Spark plug A5RTC Log Splitter Model 56230 Ram Force 30 Ton Continuous Force 28 Ton Max. Log Length 25” Max. Log Width 14” Diameter. -

Page 28: Engine Exploded View And Parts List

ENGINE EXPLODED VIEW AND PARTS LIST FIG.1 CYLINDER HEAD ASSEMBLY ITEM STOCK # DESCRIPTION Fig01-1 56212-0101 GASKET, CYLINDER HEAD Fig01-2 56212-0102 COVER, CYLINDER HEAD Fig01-3 56212-0103 GASKET, CYLINDER HEAD COVER Fig01-4 56212-0104 TUBE, BREATHER Fig01-5 56212-0105 BOLT Fig01-6 56212-0106 STUD Fig01-7 56212-0107 STUD... - Page 29 ENGINE EXPLODED VIEW AND PARTS LIST FIG.3 CRANKCASE COVER ITEM STOCK # DESCRIPTION Fig03-1 56212-0301 COVER, CRANKCASE Fig03-2 56212-0302 BEARING Fig03-3 56212-0303 SEAL, OIL Fig03-4 56212-0304 GASKET, CRANKCASE Fig03-5 56212-0305 Fig03-6 56212-0306 DIPSTICK ASSEMBLY, OIL Fig03-8 56212-0308 PLUG ASSEMBLY, ENGINE OIL Fig03-9 56212-0309 BOLT...

- Page 30 ENGINE EXPLODED VIEW AND PARTS LIST FIG.5 PISTON & CONNECTING ROD ITEM STOCK # DESCRIPTION Fig05-1 56212-0501 CLIP, PISTON PIN Fig05-2 56212-0502 PISTON Fig05-3 56212-0503 PIN, PISTON Fig05-4 56212-0504 ROD, CONNECTING Fig05-6 56212-0506 RING, THE FIRST Fig05-7 56212-0507 RING, THE SECON Fig05-8 56212-0508 RING SET, OIL...

- Page 31 ENGINE EXPLODED VIEW AND PARTS LIST FIG.7 RECOIL STARTER ITEM STOCK # DESCRIPTION Fig07-1 56212-0701 BOLT Fig07-2 56212-0702 STARTER ASSEMBLY, RECOIL FIG.8 SHROUD ITEM STOCK # DESCRIPTION Fig08-1 56212-0801 SHROUD Fig08-2 56212-0802 SHROUD, CYLINDER BODY Fig08-3 56212-0803 SHIELD,LOWER Fig08-4 56212-0804 PROTECTOR, OIL Fig08-5 56212-0805...

- Page 32 ENGINE EXPLODED VIEW AND PARTS LIST FIG.9 CARBURETOR ITEM STOCK # DESCRIPTION Fig09-1 56212-0901 CARBURETOR ASSEMBLY Fig09-2 56212-0902 GASKET, AIR CLEANER Fig09-3 56212-0903 GASKET, CARBURETOR Fig09-33 56212-0933 PLATE, CARBURETOR INSULATOR Fig09-34 56212-0934 GASKET, CARBURETOR INSULATOR FIG.10 AIR CLEANER ITEM STOCK # DESCRIPTION Fig10-13 56212-1013 CLEANER, AIR...

- Page 33 ENGINE EXPLODED VIEW AND PARTS LIST FIG.11 MUFFLER ASSY ITEM STOCK # DESCRIPTION Fig11-1 56212-1101 GASKET, EXHAUST OUTLET Fig11-2 56212-1102 Fig11-3 56212-1103 MUFFLER ASSEMBLY FIG.12 FUEL TANK ITEM STOCK # DESCRIPTION Fig12-1 56212-1201 TANK, FUEL Fig12-2 56212-1202 STRAINER,FUEL Fig12-3 56212-1203 COVER, FUEL TANK Fig12-4 56212-1204...

- Page 34 ENGINE EXPLODED VIEW AND PARTS LIST FIG.13 FLYWHEEL & IGNITION COIL ITEM STOCK # DESCRIPTION Fig13-1 56212-1301 NUT, FLYWHEEL Fig13-2 56212-1302 PULLEY,STARTER Fig13-3 56212-1303 IMPELLER Fig13-4 56212-1304 FLYWHEEL ASSEMBLY Fig13-7 56212-1307 BOLT Fig13-9 56212-1309 COIL, IGNITION FIG.14 THROTTLE CONTROL ITEM STOCK # DESCRIPTION Fig14-1...

-

Page 35: Log Splitter Exploded View And Parts List

LOG SPLITTER EXPLODED VIEW AND PARTS LIST BEAM ASSEMBLY ITEM STOCK# DESCRIPTION 56227-0101 CYLINDER ASSEMBLY 56222-0102 HIGH PRESSURE FITTING FOR CYLINDER 56222-0103 HIGH PRESSURE HOSE FOR CYLINDER 56222-0104 VALVE MOUNT FITTING 56222-0105 HIGH PRESSURE FITTING FO CYLINDER 56222-0106 VALVE HANDLE COTTER PIN 56222-0107 VALVE HANDLE PINES 56222-0108 VALVE HANDLE 56222-0109 CONTROL VALVE... - Page 36 LOG SPLITTER EXPLODED VIEW AND PARTS LIST TOW BAR ASSEMBLY ITEM STOCK # DESCRIPTION 56222-0201 TONGUE 56222-0202 BOLT M6X15 56222-0203 MANUAL TUBE 56222-0204 PIN CATCH 56222-0205 NUT M12 56222-0206 BOLT M12X80 56222-0207 BALL COUPLER ASSEMBLY 56222-0208 BOLT M10X90 56222-0209 WASHER M10 56222-0210 NUT NYLOCK M10 56222-0211...

- Page 37 LOG SPLITTER EXPLODED VIEW AND PARTS LIST HYDRAULIC TANK & TIRE ASSEMBLY ITEM STOCK # DESCRIPTION 56222-0301 TANK 56222-0302 VENT CAP ASSEMBLY 56222-0303 FLAT WASHER 56222-0304 TIRE ASSEMBLY 4.8X 8 56222-0305 56222-0306 COTTER PIN 56222-0307 HUB CAP 56222-0308 SUCTION STRAINER 56222-0309 SUCTION FITTING 56222-0310...

- Page 38 LOG SPLITTER EXPLODED VIEW AND PARTS LIST ENGINE & PUMP ASSEMBLY ITEM STOCK# DESCRIPTION 56222-0401 ENGINE 56222-0402 BAR, KEY STOCK FOR ENGINE 56222-0403 JAW COUPLER 3/4-INCH BORE 56222-0404 SET SCREW M6X12 56222-0405 JAW SPIDER COUPLER 56222-0406 PUMP MOUNT 56222-0407 JAW COUPLER, 1/2-INCH BORE 56222-0408 BAR, KEY STOCK FOR PUMP 56227-0409 PUMP 2 STAGE 12 GPM 56222-0410 HIGH PRESSURE FITTING FOR PUMP...

-

Page 39: Warranty Statement

WEN® will repair or replace, at its discretion, any part that is proven to be defective in materials or workman- ship under normal use during the two (2) years warranty period. Warranty repairs or replacements will be made without charge for parts or labor. - Page 40 Thanks for remembering...

Need help?

Do you have a question about the 56230 and is the answer not in the manual?

Questions and answers