Table of Contents

Advertisement

Quick Links

C TRANSMISSION/TRANSAXLE

RE4F04B

TROUBLE DIAGNOSIS - INDEX ........................... . .... 8

Alphabetical & P No. Index for DTC .................... . .... 8

PRECAUTIONS ..................................................... . .. 10

of A/T and Engine ............................................... . .. 10

Precautions ......................................................... . .. 10

Service Notice or Precautions ............................. . .. 12

PREPARATION ...................................................... . .. 14

Special Service Tools .......................................... . .. 14

Commercial Service Tools ................................... . .. 17

A/T FLUID .............................................................. . .. 18

Changing A/T Fluid ............................................. . .. 18

Checking A/T Fluid .............................................. . .. 18

A/T Fluid Cooler Cleaning ................................... . .. 19

OVERALL SYSTEM .............................................. . .. 23

A/T Electrical Parts Location ............................... . .. 23

Circuit Diagram ................................................... . .. 24

Cross-sectional View ........................................... . .. 25

Hydraulic Control Circuit ..................................... . .. 26

Shift Mechanism .................................................. . .. 27

Control System .................................................... . .. 36

Control Mechanism ............................................. . .. 38

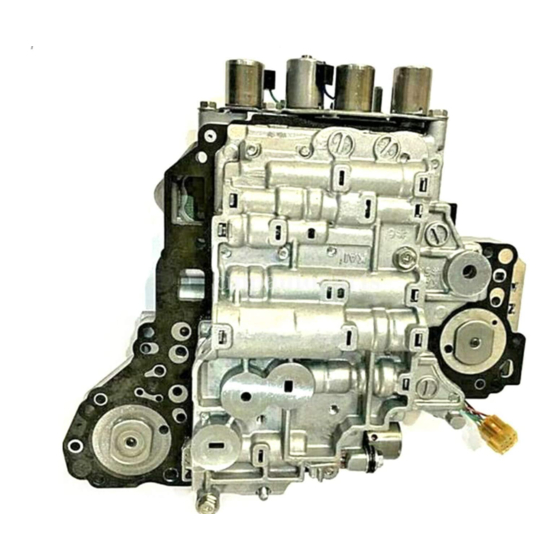

Control Valve ....................................................... . .. 42

TION ....................................................................... . .. 44

Introduction ......................................................... . .. 44

OBD-II Function for A/T System .......................... . .. 44

One or Two Trip Detection Logic of OBD-II ......... . .. 44

OBD-II Diagnostic Trouble Code (DTC) .............. . .. 44

Malfunction Indicator Lamp (MIL) ........................ . .. 48

CONSULT-II Function (TCM) .............................. . .. 48

Diagnostic Procedure Without CONSULT-II ........ . .. 59

TROUBLE DIAGNOSIS - INTRODUCTION .......... . .. 64

Introduction ......................................................... . .. 64

Work Flow ........................................................... . .. 68

Revision: November 2006

AUTOMATIC TRANSAXLE

CONTENTS

TROUBLE DIAGNOSIS - BASIC INSPECTION .... . .. 71

A/T Fluid Check ................................................... . .. 71

A/T Fluid Cooler Cleaning ................................... . .. 71

Stall Test .............................................................. . .. 74

Line Pressure Test ............................................... . .. 77

Road Test ............................................................ . .. 78

TION ....................................................................... . .. 93

Symptom Chart .................................................... . .. 93

TCM Terminals and Reference Value .................. . 103

CAN Communication ........................................... . 106

TROUBLE DIAGNOSIS FOR POWER SUPPLY ... . 107

Wiring Diagram - AT - MAIN ........................... . 107

Diagnostic Procedure .......................................... . 108

Description ........................................................... . 110

On Board Diagnosis Logic ................................... . 110

Possible Cause .................................................... . 110

cedure .................................................................. . 110

Wiring Diagram - AT - PNP/SW ...................... . 112

Diagnostic Procedure .......................................... . 113

CIRCUIT ................................................................. . 116

Description ........................................................... . 116

On Board Diagnosis Logic ................................... . 116

Possible Cause .................................................... . 116

cedure .................................................................. . 116

Wiring Diagram - AT - FTS ............................. . 118

Diagnostic Procedure .......................................... . 120

OLUTION SENSOR) .............................................. . 122

Description ........................................................... . 122

On Board Diagnosis Logic ................................... . 122

Possible Cause .................................................... . 122

cedure .................................................................. . 122

Wiring Diagram - AT - VSSA/T ....................... . 124

Diagnostic Procedure .......................................... . 125

AT-1

SECTION

A

B

AT

D

E

F

G

H

I

J

K

L

M

2006 Altima

Advertisement

Table of Contents

Summary of Contents for Jatco RE4F04B

-

Page 1: Table Of Contents

C TRANSMISSION/TRANSAXLE SECTION AUTOMATIC TRANSAXLE CONTENTS RE4F04B TROUBLE DIAGNOSIS - BASIC INSPECTION ..71 A/T Fluid Check ............71 TROUBLE DIAGNOSIS - INDEX ........ 8 A/T Fluid Cooler Cleaning ........71 Alphabetical & P No. Index for DTC ......8 Stall Test .............. - Page 2 DTC P0725 ENGINE SPEED SIGNAL ....127 On Board Diagnosis Logic ........166 Description ............127 Possible Cause ............ . 166 On Board Diagnosis Logic ........127 Diagnostic Trouble Code (DTC) Confirmation Pro- Possible Cause ............ . 127 cedure ..............

-

Page 3: A/T Does Not Shift

Possible Cause ........... . 201 Shift Lock Control Unit Reference Values ... . 262 Diagnostic Trouble Code (DTC) Confirmation Pro- Component Inspection ......... . 263 cedure ..............201 SHIFT CONTROL SYSTEM ........265 Wiring Diagram — AT — VSSMTR ..... . 203 Control Device ............. - Page 4 Reduction Pinion Gear ......... 383 Check Before Engine is Started ......445 Band Servo ............384 Check at Idle ............445 Output Shaft ............384 Cruise Test - Part 1 ..........447 Bearing Retainer ........... 385 Cruise Test - Part 2 ..........

- Page 5 Possible Cause ........... . 493 Possible Cause ............ . 529 DTC Confirmation Procedure ....... 493 DTC Confirmation Procedure ....... 529 Wiring Diagram — AT — TRSC ......494 Wiring Diagram — AT — TCCSIG ......530 Diagnostic Procedure ..........

- Page 6 Diagnostic Procedure .......... . 564 TROUBLE DIAGNOSIS FOR SYMPTOMS ... . 598 Component Inspection ......... . 566 A/T CHECK Indicator Lamp does not come on ..598 DTC P0775 PRESSURE CONTROL SOLENOID Engine Cannot Be Started In “P” or “N” Position .. . 600 VALVE B (SHIFT PRESSURE) ......

- Page 7 ASSEMBLY ............. 678 Time Lag .............. . 704 Assembly (1) ............678 Shift Solenoid Valves ..........704 Adjustment ............685 Solenoid Valves ........... . 704 Assembly (2) ............686 Clutch and Brakes ..........705 SERVICE DATA AND SPECIFICATIONS (SDS) ...

-

Page 8: Trouble Diagnosis - Index

TROUBLE DIAGNOSIS - INDEX [RE4F04B] TROUBLE DIAGNOSIS - INDEX PFP:00000 Alphabetical & P No. Index for DTC ECS0095J NOTE: If DTC U1000 is displayed with other DTC, first perform the trouble diagnosis for DTC U1000. Refer to AT-190, "DTC U1000 CAN COMMUNICATION LINE"... - Page 9 TROUBLE DIAGNOSIS - INDEX [RE4F04B] P NO. INDEX FOR DTC Items Reference page CONSULT-II (CONSULT-II screen terms) GST*1 P0705 PNP SW/CIRC AT-110 P0710 ATF TEMP SEN/CIRC AT-116 P0720 VEH SPD SEN/CIR AT*3 AT-122 P0725 ENGINE SPEED SIG AT-127 P0731 A/T 1ST GR FNCTN...

-

Page 10: Precautions

PRECAUTIONS [RE4F04B] PRECAUTIONS PFP:00001 Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT BELT PRE-TENSIONER” ECS0095K The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of collision. - Page 11 PRECAUTIONS [RE4F04B] When connecting or disconnecting pin connectors into or from TCM, take care not to damage pin terminals (bend or break). Make sure that there are not any bends or breaks on TCM pin terminal, when connecting pin connectors.

-

Page 12: Service Notice Or Precautions

PRECAUTIONS [RE4F04B] Service Notice or Precautions ECS0095N FAIL-SAFE The TCM has an electronic Fail-Safe (limp home mode). This allows the vehicle to be driven even if a major electrical input/output device circuit is damaged. Under Fail-Safe, the vehicle always runs in third gear, even with a shift lever position of 1, 2 or D. The cus- tomer may complain of sluggish or poor acceleration. - Page 13 PRECAUTIONS [RE4F04B] *: For details of OBD-II, refer to EC-53, "ON BOARD DIAGNOSTIC (OBD) SYSTEM" Certain systems and components, especially those related to OBD, may use a new style slide- locking type harness connector. For description and how to disconnect, refer to GI-24, "How to Check Terminal"...

-

Page 14: Preparation

PREPARATION [RE4F04B] PREPARATION PFP:00002 Special Service Tools ECS0095P The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here. Tool number Description (Kent-Moore No.) Tool name KV381054S0 Removing differential side oil seals (J-34286) Removing differential side bearing outer... - Page 15 PREPARATION [RE4F04B] Tool number Description (Kent-Moore No.) Tool name KV32101000 Removing and installing manual shaft re- (J-25689-A) taining pin Pin punch Removing and installing pinion mate shaft lock pin a: 4 mm (0.16 in) dia. NT410 KV31102400 Removing and installing clutch return...

- Page 16 PREPARATION [RE4F04B] Tool number Description (Kent-Moore No.) Tool name (J-34290) Selecting differential side bearing adjusting Shim selecting tool set shim NT080 ST3306S001 Removing differential side bearing inner race (J-22888-D) a: 38 mm (1.50 in) dia. Differential side bearing puller set b: 28.5 mm (1.122 in) dia.

-

Page 17: Commercial Service Tools

PREPARATION [RE4F04B] Commercial Service Tools ECS0095Q Tool name Description Puller Removing idler gear bearing inner race Removing and installing band servo piston snap ring NT077 Puller Removing reduction gear bearing inner race a: 60 mm (2.36 in) dia. b: 35 mm (1.38 in) dia. -

Page 18: A/T Fluid

A/T FLUID [RE4F04B] A/T FLUID PFP:KLE40 Changing A/T Fluid ECS00EMQ Run the engine to warm up the transaxle until the fluid is at full operating temperature “HOT”. Temperature range COLD : 30° – 50° C (86° – 122° F) : 50° – 80° C (122° – 176° F) Stop the engine. -

Page 19: A/T Fluid Cooler Cleaning

A/T FLUID [RE4F04B] Check the fluid level with the engine idling. CAUTION: Firmly secure the A/T fluid level gauge into the A/T fluid charging pipe using the attached stopper, this will provide an accurate reading on the gauge. WLIA0008E Remove the A/T fluid level gauge and wipe it clean with a lint-free paper. - Page 20 A/T FLUID [RE4F04B] Identify the inlet and outlet fluid cooler hoses. Disconnect the fluid cooler inlet and outlet rubber hoses from the steel cooler tubes or bypass valve. NOTE: Replace the cooler hoses if rubber material from the hose remains on the tube fitting.

- Page 21 A/T FLUID [RE4F04B] Insert the extension adapter hose of a can of Transmission Cooler Cleaner (Nissan P/N 999MP-AM006) into the cooler out- let hose. CAUTION: Wear safety glasses and rubber gloves when spraying the Transmission Cooler Cleaner. Spray cooler cleaner only with adequate ventilation.

- Page 22 A/T FLUID [RE4F04B] If one or more pieces of debris are found that are over 1mm (0.040 in) in size and/or peeled clutch facing material is found in the coffee filter, the fluid cooler is not serviceable. The A/T fluid cooler/radiator must be replaced and the inspection procedure is ended.

-

Page 23: Overall System

OVERALL SYSTEM [RE4F04B] OVERALL SYSTEM PFP:00000 A/T Electrical Parts Location ECS0095R WCIA0474E AT-23 Revision: November 2006 2006 Altima... -

Page 24: Circuit Diagram

OVERALL SYSTEM [RE4F04B] Circuit Diagram ECS0095S BCWA0481E AT-24 Revision: November 2006 2006 Altima... -

Page 25: Cross-Sectional View

OVERALL SYSTEM [RE4F04B] Cross-sectional View ECS0095T SCIA3174E Band servo piston Reverse clutch drum Converter housing Oil pump Brake band Reverse clutch High clutch Front planetary gear Low one-way clutch 10. Rear planetary gear 11. Forward clutch 12. Overrun clutch 13. Low & reverse brake 14. -

Page 26: Hydraulic Control Circuit

OVERALL SYSTEM [RE4F04B] Hydraulic Control Circuit ECS0095U LCIA0040E AT-26 Revision: November 2006 2006 Altima... -

Page 27: Shift Mechanism

OVERALL SYSTEM [RE4F04B] Shift Mechanism ECS0095V CONSTRUCTION SAT998I Torque converter Oil pump Input shaft Brake band Reverse clutch High clutch Front sun gear Front pinion gear Front internal gear 10. Front planetary carrier 11. Rear sun gear 12. Rear pinion gear 13. - Page 28 OVERALL SYSTEM [RE4F04B] Band servo For- Low & For- Over- ward High one- verse ward one- Lock- Shift position clutch verse Remarks 3rd re- clutch clutch clutch clutch brake apply lease apply clutch NEUTRAL POSITION Automatic *1 A shift 1 ⇔ 2 ⇔ 3 *1 A ⇔...

- Page 29 OVERALL SYSTEM [RE4F04B] POWER TRANSMISSION P and N Positions SAT991I P position Similar to the N position, the clutches do not operate. The parking pawl engages with the parking gear to mechanically hold the output shaft so that the power train is locked.

- Page 30 OVERALL SYSTEM [RE4F04B] Position WCIA0355E Forward clutch As overrun clutch engages, rear internal gear is locked by the operation of low and reverse brake. Low one-way clutch This is different from that of D , and 3 Forward one-way clutch...

- Page 31 OVERALL SYSTEM [RE4F04B] and 2 Positions WCIA0356E Forward one-way clutch Rear internal gear is locked to rotate counterclockwise because of the functioning of these three clutches. Forward clutch Low one-way clutch Overrun clutch : Overdrive control switch OFF and throttle opening is less than 3/16...

- Page 32 OVERALL SYSTEM [RE4F04B] and 1 Positions WCIA0357E Forward clutch Rear sun gear drives rear planetary carrier and combined front internal gear. Front internal gear now rotates around front sun gear accompanying front planetary carrier. Forward one-way clutch As front planetary carrier transfers the power to rear internal gear through forward clutch and...

- Page 33 OVERALL SYSTEM [RE4F04B] and 3 Positions WCIA0358E High clutch Input power is transmitted to front planetary carrier through high clutch. And front planetary carrier is connected to rear internal gear by operation of forward clutch and forward one-way Forward clutch clutch.

- Page 34 OVERALL SYSTEM [RE4F04B] Position WCIA0360E High clutch Input power is transmitted to front carrier through high clutch. This front carrier turns around the sun gear which is fixed by brake band and makes front Brake band internal gear (output) turn faster.

- Page 35 OVERALL SYSTEM [RE4F04B] R Position WCIA0359E Reverse clutch Front planetary carrier is stationary because of the operation of low and reverse brake. Input power is transmitted to front sun gear through reverse clutch, which drives front inter- Low and reverse brake nal gear in the opposite direction.

-

Page 36: Control System

OVERALL SYSTEM [RE4F04B] Control System ECS0095W OUTLINE The automatic transaxle senses vehicle operating conditions through various sensors. It always controls the optimum shift position and reduces shifting and lock-up shocks. SENSORS ACTUATORS Park/neutral position (PNP) switch Accelerator pedal position (APP) signal... - Page 37 OVERALL SYSTEM [RE4F04B] TCM FUNCTION The function of the TCM is to: Receive input signals sent from various switches and sensors. Determine required line pressure, shifting point, lock-up operation, and engine brake operation. Send required output signals to the respective solenoids.

-

Page 38: Control Mechanism

OVERALL SYSTEM [RE4F04B] Control Mechanism ECS0095X LINE PRESSURE CONTROL TCM has various line pressure control characteristics to meet the driving conditions. An ON-OFF duty signal is sent to the line pressure solenoid valve based on TCM characteristics. Hydraulic pressure on the clutch and brake is electronically controlled through the line pressure solenoid valve to accommodate engine torque. - Page 39 OVERALL SYSTEM [RE4F04B] The line pressure is reduced below 60°C (140°F) to prevent shifting shock due to low viscosity of automatic transaxle fluid when temperature is low. SAT006J Line pressure is increased to a maximum irrespective of the throttle opening when fluid temperature drops to −10°C (14°F).

- Page 40 OVERALL SYSTEM [RE4F04B] Relation between shift solenoid valves A and B and gear positions Gear position Shift solenoid valve (O/D) ON (Closed) OFF (Open) OFF (Open) ON (Closed) ON (Closed) ON (Closed) ON (Closed) OFF (Open) OFF (Open) ON (Closed)

- Page 41 OVERALL SYSTEM [RE4F04B] The torque converter clutch piston is designed to slip to adjust the ratio of ON-OFF, thereby reducing lock-up shock. OFF-time INCREASING ↓ Amount of drain DECREASING ↓ Pilot pressure HIGH ↓ Lock-up RELEASING SAT011J Torque Converter Clutch Control Valve Operation...

-

Page 42: Control Valve

OVERALL SYSTEM [RE4F04B] Overrun Clutch Solenoid Valve Control The overrun clutch solenoid valve is operated by an ON-OFF signal transmitted by the TCM to provide overrun clutch control (engine brake control). When this solenoid valve is ON, the pilot pressure drain port closes. - Page 43 OVERALL SYSTEM [RE4F04B] Valve name Function Shift valve B Simultaneously switches two oil circuits using output pressure of shift solenoid valve B in relation to driving conditions (vehicle speed, throttle opening, etc.). Provides automatic downshifting and up-shifting (1st → 2nd → 3rd → 4th gears/4th →...

-

Page 44: On Board Diagnostic System Description

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION [RE4F04B] ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION PFP:00000 Introduction ECS0095Z The A/T system has two self-diagnostic systems. The first is the emission-related on board diagnostic system (OBD-II) performed by the TCM (transaxle control module) in combination with the ECM. The malfunction is indicated by the MIL (malfunction indicator lamp) and is stored as a DTC in the ECM memory but not the TCM memory. - Page 45 ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION [RE4F04B] A sample of CONSULT-II display for DTC and 1st trip DTC is shown in the following page. DTC or 1st trip DTC of a malfunction is dis- played in “SELF DIAGNOSIS” mode for “ENGINE” with CONSULT- II.

- Page 46 ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION [RE4F04B] HOW TO ERASE DTC The diagnostic trouble code can be erased by CONSULT-II, GST or ECM DIAGNOSTIC TEST MODE as described following. If the battery terminal is disconnected, the diagnostic trouble code will be lost within 24 hours.

- Page 47 ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION [RE4F04B] Touch “ERASE”. (The DTC in the ECM will be erased.) WCIA0361E HOW TO ERASE DTC (WITH GST) If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 10 seconds and then turn it ON (engine stopped) again.

-

Page 48: Malfunction Indicator Lamp (Mil)

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION [RE4F04B] Malfunction Indicator Lamp (MIL) ECS00963 The malfunction indicator lamp will light up when the ignition switch is turned ON without the engine running. This is for checking the lamp. If the malfunction indicator lamp does not light up, refer to 31, "WARNING LAMPS"... - Page 49 ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION [RE4F04B] SELF-DIAGNOSTIC PROCEDURE (WITH CONSULT-II) Touch on CONSULT-II, touch "START (NISSAN BASED VHCL)", and touch “ENGINE” for OBD-II detected items or touch “A/T” for TCM self-diagnosis. If A/T is not displayed, check TCM power supply and ground cir- cuit.

- Page 50 ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION [RE4F04B] Detected items TCM self-diagnosis OBD-II (DTC) (Screen terms for CONSULT-II, “SELF Available by malfunc- Available by A/T check DIAGNOSIS” test mode) Malfunction is detected when... tion indicator lamp*2, (position) indicator lamp or “A/T” on “ENGINE”...

- Page 51 ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION [RE4F04B] Detected items TCM self-diagnosis OBD-II (DTC) (Screen terms for CONSULT-II, “SELF Available by malfunc- Available by A/T check DIAGNOSIS” test mode) Malfunction is detected when... tion indicator lamp*2, (position) indicator lamp or “A/T” on “ENGINE”...

- Page 52 ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION [RE4F04B] Monitor item Selec- Item Display Description Remarks Main tion Input signals from signals menu PN position (PNP) PN POSI SW ON/OFF state com- switch [ON/OFF] puted from signal of — PN position SW is displayed.

- Page 53 ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION [RE4F04B] Monitor item Selec- Item Display Description Remarks Main tion Input signals from signals menu Gear position GEAR Gear position data used for computa- — tion by TCM, is dis- played. Line pressure duty LINE PRES...

- Page 54 ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION [RE4F04B] Monitor item Selec- Item Display Description Remarks Main tion Input signals from signals menu Value measured by pulse probe is dis- played. If measure- ment is impossible, "#" sign is displayed. Frequency [Hz] —...

- Page 55 ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION [RE4F04B] Touch “A/T”. If "AT" is not indicated, go to GI-39, "Consult-II Data Link Con- nector (DLC) Circuit" BCIA0030E Touch “DTC WORK SUPPORT”. BCIA0031E Touch select item menu (1ST, 2ND, etc.). SAT018K Touch “START”. SAT589J...

- Page 56 ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION [RE4F04B] Perform driving test according to “DTC CONFIRMATION PRO- CEDURE” in “TROUBLE DIAGNOSIS FOR DTC”. SAT019K When testing conditions are satisfied, CONSULT-II screen changes from “OUT OF CONDITION” to “TESTING”. SAT591J 10. Stop vehicle. If “NG” appears on the screen, malfunction may exist.

- Page 57 ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION [RE4F04B] 11. Perform test drive to check gear shift feeling in accordance with instructions displayed. SAT594J 12. Touch “YES” or “NO”. SAT595J 13. CONSULT-II procedure ended. SAT596J SAT593J If “NG” appears on the screen, a malfunction may exist. Go to “DIAGNOSTIC PROCEDURE”.

- Page 58 ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION [RE4F04B] DTC work support item Description Check item Following items for “A/T 1st gear function (P0731)” can be con- Shift solenoid valve A firmed. Shift solenoid valve B 1ST GR FNCTN P0731 Self-diagnosis status (whether the diagnosis is being conducted...

-

Page 59: Diagnostic Procedure Without Consult-Ii

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION [RE4F04B] CAN DIAGNOSTIC SUPPORT MONITOR CONSULT-II Setting Procedure Turn ignition switch OFF. Connect CONSULT-II and CONSULT II CONVERTER to data link connector, which is located in left side dash panel. LCIA0042E Turn ignition switch ON. (Do not start engine.) Touch “START (NISSAN BASED VHCL)”. - Page 60 ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION [RE4F04B] TCM SELF-DIAGNOSTIC PROCEDURE (NO TOOLS) CHECK A/T CHECK (POSITION) INDICATOR LAMP Move selector lever to P position. Start engine and warm it up to normal engine operating temper- ature. Turn ignition switch to OFF position.

- Page 61 ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION [RE4F04B] JUDGEMENT PROCEDURE STEP 2 Move selector lever to 1 position. Depress brake pedal. Depress accelerator pedal fully and release it. The A/T check (position) indicator lamp will begin to flash. >> GO TO 4.

- Page 62 ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION [RE4F04B] A/T check (position) indicator lamp: 4th judgement flicker is longer than others. 5th judgement flicker is longer than others. LCIA0053E LCIA0054E Shift solenoid valve A circuit is short-circuited or disconnected. Shift solenoid valve B circuit is short-circuited or disconnected.

- Page 63 ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION [RE4F04B] A/T check (position) indicator lamp: 12th judgement flicker is longer than others. LCIA0061E The ECM-A/T communication line is open or shorted. Þ Go to AT-190, "DTC U1000 CAN COMMUNICATION LINE" Lamp turns off. Flickers as shown below.

-

Page 64: Trouble Diagnosis - Introduction

TROUBLE DIAGNOSIS - INTRODUCTION [RE4F04B] TROUBLE DIAGNOSIS - INTRODUCTION PFP:00000 Introduction ECS00966 The TCM receives a signal from the vehicle speed sensor, ECM (throttle opening) or park/neutral position (PNP) switch and provides shift control or lock-up control via A/T solenoid valves. - Page 65 TROUBLE DIAGNOSIS - INTRODUCTION [RE4F04B] DIAGNOSTIC WORKSHEET Information from Customer KEY POINTS WHAT ..Vehicle & A/T model WHEN ..Date, Frequencies WHERE ..Road conditions HOW ..Operating conditions, Symptoms Customer name MR/MS Model & Year Trans. model Engine...

- Page 66 TROUBLE DIAGNOSIS - INTRODUCTION [RE4F04B] Diagnostic Worksheet Read the Fail-safe and listen to customer complaints. AT-12 CHECK A/T FLUID AT-71 Leakage (Follow specified procedure) Fluid condition Fluid level Perform STALL TEST and PRESSURE TEST. AT-74, AT-77 Stall test — Mark possible damaged components/others.

- Page 67 TROUBLE DIAGNOSIS - INTRODUCTION [RE4F04B] Check at idle AT-80 1. A/T Check (Position) Indicator Lamp Does Not Come On, AT-217 2. Engine Cannot Be Started In P and N Position, AT-219 3. In P Position, Vehicle Moves Forward or Backward When Pushed, AT-220 4.

-

Page 68: Work Flow

TROUBLE DIAGNOSIS - INTRODUCTION [RE4F04B] Perform the Diagnostic Procedures for all remaining items marked NG. Repair or replace the damaged parts. AT-49 Refer to the Symptom Chart when you perform the procedures. (The chart also shows some other possible AT-59 symptoms and the component inspection orders.) - Page 69 TROUBLE DIAGNOSIS - INTRODUCTION [RE4F04B] WORK FLOW CHART SAT086JI AT-65 AT-66 AT-12 AT-71 AT-74, AT-77 AT-78 AT-48 AT-44 AT-44 *10: AT-110 *11: AT-211 *12: AT-213 AT-69 Revision: November 2006 2006 Altima...

- Page 70 TROUBLE DIAGNOSIS - INTRODUCTION [RE4F04B] *13: AT-254 *14: AT-93 *15: AT-46 *16: AT-110 *17: AT-194 *18: ! Hyper-link Error ! , ! Hyper-link Error ! AT-70 Revision: November 2006 2006 Altima...

-

Page 71: Trouble Diagnosis - Basic Inspection

TROUBLE DIAGNOSIS - BASIC INSPECTION [RE4F04B] TROUBLE DIAGNOSIS - BASIC INSPECTION PFP:00000 A/T Fluid Check ECS00968 FLUID LEAKAGE CHECK Clean area suspected of leaking. — for example, mating surface of converter housing and transaxle case. Start engine, apply foot brake, place selector lever in D position and wait a few minutes. - Page 72 TROUBLE DIAGNOSIS - BASIC INSPECTION [RE4F04B] Disconnect the fluid cooler inlet and outlet rubber hoses from the steel cooler tubes or bypass valve. NOTE: Replace the cooler hoses if rubber material from the hose remains on the tube fitting. Allow any A/T fluid that remains in the cooler hoses to drain into the oil pan.

- Page 73 TROUBLE DIAGNOSIS - BASIC INSPECTION [RE4F04B] Insert the extension adapter hose of a can of Transmission Cooler Cleaner (Nissan P/N 999MP-AM006) into the cooler out- let hose. CAUTION: Wear safety glasses and rubber gloves when spraying the Transmission Cooler Cleaner.

-

Page 74: Stall Test

TROUBLE DIAGNOSIS - BASIC INSPECTION [RE4F04B] If one or more pieces of debris are found that are over 1mm in size and/or peeled clutch facing material is found in the coffee filter, the fluid cooler is not serviceable. The radiator/fluid cooler must be replaced and the inspection procedure is ended. - Page 75 TROUBLE DIAGNOSIS - BASIC INSPECTION [RE4F04B] Move selector lever to N position. Cool off ATF. Run engine at idle for at least one minute. 10. Repeat steps 5 through 9 with selector lever in 2, 1 and R posi- tions.

- Page 76 TROUBLE DIAGNOSIS - BASIC INSPECTION [RE4F04B] Poor acceleration during starts..One-way clutch seizure in torque converter SCIA3256E AT-76 Revision: November 2006 2006 Altima...

-

Page 77: Line Pressure Test

TROUBLE DIAGNOSIS - BASIC INSPECTION [RE4F04B] Line Pressure Test ECS0096B LINE PRESSURE TEST PORTS Location of line pressure test ports are shown in the illustration. Always replace pressure plugs as they are self-sealing bolts. SAT301FA LINE PRESSURE TEST PROCEDURE Check A/T fluid and engine oil levels. If necessary, add fluid and oil. -

Page 78: Road Test

TROUBLE DIAGNOSIS - BASIC INSPECTION [RE4F04B] Start engine and measure line pressure at idle and stall speed. When measuring line pressure at stall speed, follow the stall test procedure. AT-77, "Line Pressure : Refer to SDS, AT-379, Test" "Line Pressure"... - Page 79 TROUBLE DIAGNOSIS - BASIC INSPECTION [RE4F04B] Before road test, familiarize yourself with all test procedures and items to check. Conduct tests on all items until specified symptom is found. Troubleshoot items which check out No Good after road test. Refer AT-44, "ON...

- Page 80 TROUBLE DIAGNOSIS - BASIC INSPECTION [RE4F04B] 1. CHECK BEFORE ENGINE IS STARTED CHECK A/T CHECK (POSITION) INDICATOR LAMP Park vehicle on flat surface. Move selector lever to P position. Turn ignition switch to OFF position. Wait at least 5 seconds.

- Page 81 TROUBLE DIAGNOSIS - BASIC INSPECTION [RE4F04B] CHECK ENGINE START Turn ignition switch to ACC position. Move selector lever to D, 1, 2 or R position. Turn ignition switch to START position. Is engine started? Yes or No >> Mark the box on the DIAGNOSTIC WORKSHEET. Go to AT-219, "2.

- Page 82 TROUBLE DIAGNOSIS - BASIC INSPECTION [RE4F04B] CHECK SHIFT LOCK Apply foot brake. SAT797A Move selector lever to R position. Is there large shock when changing from N to R position? Yes or No >> Mark the box on the DIAGNOSTIC WORKSHEET. Go to AT-223, "5.

- Page 83 TROUBLE DIAGNOSIS - BASIC INSPECTION [RE4F04B] With CONSULT-II Using CONSULT-II, conduct a cruise test and record the result. Print the result and ensure that shifts and lock-ups take place as per Shift Schedule. Refer to AT-378, "Shift Schedule" SAT601J CONSULT-II Setting Procedure...

- Page 84 TROUBLE DIAGNOSIS - BASIC INSPECTION [RE4F04B] Touch “DATA MONITOR”. BCIA0031E Touch “MAIN SIGNALS” or “TCM INPUT SIGNALS”. See “Numerical Display”, “Barchart Display” or “Line Graph Dis- play”. SAT175K Touch “SETTING” to set recording condition (“AUTO TRIG” or “MANU TRIG”) and touch “BACK”.

- Page 85 TROUBLE DIAGNOSIS - BASIC INSPECTION [RE4F04B] 12. After finishing cruise test part 1, touch “STOP”. SAT135K 13. Touch “STORE” and touch “BACK”. SAT987J SAT974J 14. Touch “DISPLAY”. 15. Touch “PRINT”. 16. Check the monitor data printed out. 17. Continue cruise test part 2 and 3.

- Page 86 TROUBLE DIAGNOSIS - BASIC INSPECTION [RE4F04B] Cruise Test — Part 1 CHECK STARTING GEAR (D ) POSITION Drive vehicle for approximately 10 minutes to warm engine oil and ATF up to operating temperature. ATF operating tempera- :50 - 80°C (122 - 176°F) ture Park vehicle on flat surface.

- Page 87 TROUBLE DIAGNOSIS - BASIC INSPECTION [RE4F04B] CHECK SHIFT UP (D TO D Does A/T shift from D to D at the specified speed? Read gear position, throttle opening and vehicle speed. Specified speed when :Refer to AT-378, "Shift shifting from D to D Schedule"...

- Page 88 TROUBLE DIAGNOSIS - BASIC INSPECTION [RE4F04B] CHECK LOCK-UP (D TO D L/U) Does A/T perform lock-up at the specified speed? Read vehicle speed, throttle opening when lock-up duty becomes 94%. Specified speed when :Refer to AT-378, "Shift lock-up occurs Schedule"...

- Page 89 TROUBLE DIAGNOSIS - BASIC INSPECTION [RE4F04B] Cruise Test — Part 2 CHECK STARTING GEAR (D ) POSITION Confirm gear selector lever is in D position. Accelerate vehicle by half throttle again. Does vehicle start from D Read gear position. Yes or No >>...

- Page 90 TROUBLE DIAGNOSIS - BASIC INSPECTION [RE4F04B] CHECK SHIFT UP (D TO D ) AND ENGINE BRAKE Release accelerator pedal after shifting from D to D Does A/T shift from D to D and does vehicle decelerate by engine brake? Read gear position, throttle opening and vehicle speed.

- Page 91 TROUBLE DIAGNOSIS - BASIC INSPECTION [RE4F04B] Cruise Test — Part 3 VEHICLE SPEED (D ) POSITION Confirm gear selector lever is in D position. Using half-throttle, accelerate vehicle until it shifts into D SAT812A Release accelerator pedal. Move gear selector lever from D position to 3 position while driv-...

- Page 92 TROUBLE DIAGNOSIS - BASIC INSPECTION [RE4F04B] CHECK SHIFT DOWN (3 TO 2 Move selector lever from 3 to 2 position while driving in 3 Does A/T shift from 3 to 2 Read gear position. Yes or No >> GO TO 4.

-

Page 93: Trouble Diagnosis - General Description

TROUBLE DIAGNOSIS - GENERAL DESCRIPTION [RE4F04B] TROUBLE DIAGNOSIS - GENERAL DESCRIPTION PFP:00000 Symptom Chart ECS0096D Numbers are arranged in order of inspection. Perform inspections starting with number one and work up. Items Symptom Condition Diagnostic Item Reference Page 1. Throttle position sensor [accelerator pedal... - Page 94 TROUBLE DIAGNOSIS - GENERAL DESCRIPTION [RE4F04B] Items Symptom Condition Diagnostic Item Reference Page 1. Throttle position sensor [accelerator pedal EC-81 position (APP) sensor] adjustment 2. Line pressure test AT-77 Too sharp a ON vehicle 3. Accumulator servo release AT-283 shock in change...

- Page 95 TROUBLE DIAGNOSIS - GENERAL DESCRIPTION [RE4F04B] Items Symptom Condition Diagnostic Item Reference Page 1. Vehicle speed sensor·A/T (Revolution Kickdown oper- AT-122, AT-201 sensor) and vehicle speed sensor·MTR ates or engine overruns when 2. Throttle position sensor [accelerator pedal EC-81 depressing pedal...

- Page 96 TROUBLE DIAGNOSIS - GENERAL DESCRIPTION [RE4F04B] Items Symptom Condition Diagnostic Item Reference Page 1. Park/neutral position (PNP) switch adjust- AT-269 ment 2. Throttle position sensor [accelerator pedal EC-81 position (APP) sensor] adjustment Failure to change 3. Overrun clutch solenoid valve...

- Page 97 TROUBLE DIAGNOSIS - GENERAL DESCRIPTION [RE4F04B] Items Symptom Condition Diagnostic Item Reference Page 1. Park/neutral position (PNP) switch adjust- AT-269 ment 2. Control cable adjustment AT-270 Failure to change ON vehicle 3. Shift solenoid valve A AT-172 gear from D 4.

- Page 98 TROUBLE DIAGNOSIS - GENERAL DESCRIPTION [RE4F04B] Items Symptom Condition Diagnostic Item Reference Page 1. Fluid level AT-71 2. Line pressure test AT-77 ON vehicle 3. Line pressure solenoid valve AT-166 Vehicle will not run in D, 1, 2 4. Control valve assembly...

- Page 99 TROUBLE DIAGNOSIS - GENERAL DESCRIPTION [RE4F04B] Items Symptom Condition Diagnostic Item Reference Page 1. Fluid level AT-71 2. Throttle position sensor [accelerator pedal EC-81 position (APP) sensor] adjustment Almost no shock ON vehicle or slipping in 3. Line pressure test...

- Page 100 TROUBLE DIAGNOSIS - GENERAL DESCRIPTION [RE4F04B] Items Symptom Condition Diagnostic Item Reference Page 1. Fluid level AT-71 2. Throttle position sensor [accelerator pedal EC-81 position (APP) sensor] adjustment ON vehicle Races extremely 3. Line pressure test AT-77 fast or slips in 4.

- Page 101 TROUBLE DIAGNOSIS - GENERAL DESCRIPTION [RE4F04B] Items Symptom Condition Diagnostic Item Reference Page Vehicle runs in N ON vehicle 1. Control cable adjustment AT-270 position. 2. Forward clutch AT-328 AT-221 OFF vehicle 3. Reverse clutch AT-321 4. Overrun clutch AT-328 1.

- Page 102 TROUBLE DIAGNOSIS - GENERAL DESCRIPTION [RE4F04B] Items Symptom Condition Diagnostic Item Reference Page 1. Fluid level AT-71 2. Park/neutral position (PNP) switch adjust- AT-269 ment ON vehicle 3. Shift solenoid valve A AT-172 4. Shift solenoid valve B AT-177 Maximum speed 5.

-

Page 103: Tcm Terminals And Reference Value

TROUBLE DIAGNOSIS - GENERAL DESCRIPTION [RE4F04B] Items Symptom Condition Diagnostic Item Reference Page ON vehicle 1. Fluid level AT-71 2. Reverse clutch AT-321 ATF shoots out during operation. 3. High clutch AT-324 White smoke 4. Brake band AT-283 emitted from... - Page 104 TROUBLE DIAGNOSIS - GENERAL DESCRIPTION [RE4F04B] TCM INSPECTION TABLE (Data are reference values.) Judgement Termi- Wire color Item Condition standard nal No. (Approx.) When releasing accelerator pedal after warming 1.5 - 3.0V up engine. Line pressure solenoid valve When depressing accelerator pedal fully after warming up engine.

- Page 105 TROUBLE DIAGNOSIS - GENERAL DESCRIPTION [RE4F04B] Judgement Termi- Wire color Item Condition standard nal No. (Approx.) When moving at 20 km/h (12 MPH), use the CONSULT-II pulse frequency measuring func- tion.*1 CAUTION: 450 Hz Connect the diagnosis data link cable to the Revolution sensor vehicle diagnosis connector.

-

Page 106: Can Communication

TROUBLE DIAGNOSIS - GENERAL DESCRIPTION [RE4F04B] CAN Communication ECS0096F For details, refer to LAN-20, "CAN COMMUNICATION" AT-106 Revision: November 2006 2006 Altima... -

Page 107: Trouble Diagnosis For Power Supply

TROUBLE DIAGNOSIS FOR POWER SUPPLY [RE4F04B] TROUBLE DIAGNOSIS FOR POWER SUPPLY PFP:00000 Wiring Diagram — AT — MAIN ECS0096G BCWA0137E AT-107 Revision: November 2006 2006 Altima... -

Page 108: Diagnostic Procedure

TROUBLE DIAGNOSIS FOR POWER SUPPLY [RE4F04B] TCM TERMINALS AND REFERENCE VALUE MEASURED BETWEEN EACH TERMINAL AND 25 OR 48 (TCM GROUND) TERMINAL WIRE COLOR ITEM CONDITION DATA (APPROX.) IGNITION ON BATTERY VOLTAGE POWER SOURCE IGNITION OFF IGNITION ON BATTERY VOLTAGE... - Page 109 TROUBLE DIAGNOSIS FOR POWER SUPPLY [RE4F04B] CHECK TCM GROUND CIRCUIT Turn ignition switch to OFF position. Disconnect TCM harness connector. Check continuity between TCM terminals 25, 48 and ground. Refer to AT-107, "Wiring Diagram — AT — MAIN" Continuity should exist.

-

Page 110: Dtc P0705 Park/Neutral Position Switch

DTC P0705 PARK/NEUTRAL POSITION SWITCH [RE4F04B] DTC P0705 PARK/NEUTRAL POSITION SWITCH PFP:32006 Description ECS0096I The park/neutral position (PNP) switch includes a transaxle range switch. The transaxle range switch detects the selector lever position and sends a signal to the TCM. - Page 111 DTC P0705 PARK/NEUTRAL POSITION SWITCH [RE4F04B] WITH GST Follow the procedure “With CONSULT-II”. AT-111 Revision: November 2006 2006 Altima...

-

Page 112: Wiring Diagram - At - Pnp/Sw

DTC P0705 PARK/NEUTRAL POSITION SWITCH [RE4F04B] Wiring Diagram — AT — PNP/SW ECS0096M WCWA0221E AT-112 Revision: November 2006 2006 Altima... -

Page 113: Diagnostic Procedure

DTC P0705 PARK/NEUTRAL POSITION SWITCH [RE4F04B] TCM TERMINALS AND REFERENCE VALUE MEASURED BETWEEN EACH TERMINAL AND 25 OR 48 (TCM GROUND) TERMINAL WIRE COLOR ITEM CONDITION DATA (APPROX.) WHEN SETTING SELECTOR BATTERY VOLTAGE LEVER IN 1 POSITION PNP SWITCH PU/W... - Page 114 DTC P0705 PARK/NEUTRAL POSITION SWITCH [RE4F04B] DETECT MALFUNCTIONING ITEM Check the following item: Park/neutral position (PNP) switch Check continuity between park/neutral position (PNP) switch F29 terminals 1 and 2 and between terminals 3 and 4, 5, 6, 7, 8 and 9 while moving manual shaft through each position.

- Page 115 DTC P0705 PARK/NEUTRAL POSITION SWITCH [RE4F04B] CHECK PARK/NEUTRAL POSITION (PNP) SWITCH CIRCUIT (WITHOUT CONSULT-II) Without CONSULT-II Turn ignition switch to ON position. (Do not start engine.) Check voltage between TCM terminals 26, 27, 34, 35, 36 and ground while moving selector lever through each position.

-

Page 116: Dtc P0710 A/T Fluid Temperature Sensor Circuit

DTC P0710 A/T FLUID TEMPERATURE SENSOR CIRCUIT [RE4F04B] DTC P0710 A/T FLUID TEMPERATURE SENSOR CIRCUIT PFP:31940 Description ECS0096O The A/T fluid temperature sensor detects the A/T fluid temperature and sends a signal to the TCM. SAT283HB SAT021J CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE Remarks: Specification data are reference values. - Page 117 DTC P0710 A/T FLUID TEMPERATURE SENSOR CIRCUIT [RE4F04B] WITH CONSULT-II Turn ignition switch ON and select “DATA MONITOR” mode for “A/T” with CONSULT-II. BCIA0030E BCIA0031E Select "ECM INPUT SIGNALS" touch "START". Start engine and maintain the following conditions for at least 10 minutes (Total). (It is not necessary to maintain continuously.)

-

Page 118: Wiring Diagram - At - Fts

DTC P0710 A/T FLUID TEMPERATURE SENSOR CIRCUIT [RE4F04B] Wiring Diagram — AT — FTS ECS0096S BCWA0139E AT-118 Revision: November 2006 2006 Altima... - Page 119 DTC P0710 A/T FLUID TEMPERATURE SENSOR CIRCUIT [RE4F04B] TCM TERMINALS AND REFERENCE VALUE MEASURED BETWEEN EACH TERMINAL AND 25 OR 48 (TCM GROUND) TERMINAL WIRE COLOR ITEM CONDITION DATA (APPROX.) SENSOR GROUND — — IGNITION ON AND ATF TEMPER- 1.5V ATURE IS 20°C (68°F)

-

Page 120: Diagnostic Procedure

DTC P0710 A/T FLUID TEMPERATURE SENSOR CIRCUIT [RE4F04B] Diagnostic Procedure ECS0096T INSPECTION START Do you have CONSULT-II? Yes or No >> GO TO 2. >> GO TO 6. CHECK INPUT SIGNAL OF A/T FLUID TEMPERATURE SENSOR (WITH CONSULT-II) With CONSULT-II Start engine. - Page 121 DTC P0710 A/T FLUID TEMPERATURE SENSOR CIRCUIT [RE4F04B] DETECT MALFUNCTIONING ITEM Remove oil pan. Check the following items: A/T fluid temperature sensor – Check resistance between two terminals while changing temper- ature as shown in figure. Temperature Resistance (Approx.) 20 (68) 25kΩ...

-

Page 122: Dtc P0720 Vehicle Speed Sensor·a/T (Revolution Sensor)

DTC P0720 VEHICLE SPEED SENSOR·A/T (REVOLUTION SENSOR) [RE4F04B] DTC P0720 VEHICLE SPEED SENSOR·A/T (REVOLUTION SENSOR) PFP:32702 Description ECS0096U The revolution sensor detects the revolution of the idler gear parking pawl lock gear and emits a pulse signal. The pulse signal is sent to the TCM which converts it into vehicle speed. - Page 123 DTC P0720 VEHICLE SPEED SENSOR·A/T (REVOLUTION SENSOR) [RE4F04B] Drive vehicle and check for an increase of “VHCL/S SE·MTR” value. If the check result is NG, go to AT-125, "Diagnostic Procedure" If the check result is OK, go to following step.

-

Page 124: Wiring Diagram - At - Vssa/T

DTC P0720 VEHICLE SPEED SENSOR·A/T (REVOLUTION SENSOR) [RE4F04B] Wiring Diagram — AT — VSSA/T ECS0096Y BCWA0140E AT-124 Revision: November 2006 2006 Altima... -

Page 125: Diagnostic Procedure

DTC P0720 VEHICLE SPEED SENSOR·A/T (REVOLUTION SENSOR) [RE4F04B] TERMINALS AND REFERENCE VALUE MEASURED BETWEEN EACH TERMINAL TERMINAL WIRE COLOR ITEM CONDITION DATA (DC) VEHICLE MOVING AT 20 KM/H (12 MPH). USE THE CONSULT-II PULSE FREQUENCY MEASURING FUNCTION. A CIRCUIT TESTER... - Page 126 DTC P0720 VEHICLE SPEED SENSOR·A/T (REVOLUTION SENSOR) [RE4F04B] CHECK TCM INSPECTION Perform TCM input/output signal inspection. If NG, recheck TCM pin terminals for damage or loose connection with harness connector. OK or NG >> INSPECTION END >> Repair or replace damaged parts.

-

Page 127: Dtc P0725 Engine Speed Signal

DTC P0725 ENGINE SPEED SIGNAL [RE4F04B] DTC P0725 ENGINE SPEED SIGNAL PFP:24825 Description ECS00970 The engine speed signal is sent from the ECM to the TCM. On Board Diagnosis Logic ECS00971 Diagnostic trouble code ENGINE SPEED SIG with CONSULT-II or P0725 without CONSULT-II is detected when TCM does not receive the proper voltage signal from ECM. -

Page 128: Wiring Diagram - At - Engss

DTC P0725 ENGINE SPEED SIGNAL [RE4F04B] Wiring Diagram — AT — ENGSS ECS00974 BCWA0141E AT-128 Revision: November 2006 2006 Altima... -

Page 129: Diagnostic Procedure

DTC P0725 ENGINE SPEED SIGNAL [RE4F04B] TCM TERMINALS AND REFERENCE VALUE MEASURED BETWEEN EACH TERMINAL AND 25 OR 48 (TCM GROUND) TERMINAL WIRE COLOR ITEM CONDITION DATA ENGINE SPEED SIGNAL EC-109, "ECM INSPECTION TABLE" Diagnostic Procedure ECS00975 CHECK DTC WITH ECM Check P code. - Page 130 DTC P0725 ENGINE SPEED SIGNAL [RE4F04B] CHECK INPUT SIGNAL (WITHOUT CONSULT-II) Without CONSULT-II Start engine. Check voltage between TCM terminal 39 and ground. Voltage :0.6 (Idle speed) - 2.2V (3,000 rpm) OK or NG >> GO TO 6. >> GO TO 5.

-

Page 131: Dtc P0731 A/T 1St Gear Function

DTC P0731 A/T 1ST GEAR FUNCTION [RE4F04B] DTC P0731 A/T 1ST GEAR FUNCTION PFP:31940 Description ECS00976 This is an OBD-II self-diagnostic item and not available in TCM self-diagnosis. This malfunction will not be detected while the A/T check (position) indicator lamp is indicating another self-diagnosis malfunction. - Page 132 DTC P0731 A/T 1ST GEAR FUNCTION [RE4F04B] WITH CONSULT-II Start engine and select “DATA MONITOR” mode for “A/T” with CONSULT-II. Make sure that output voltage of A/T fluid temperature sensor is within the range below. FLUID TEMP SEN: 0.4 - 1.5V...

-

Page 133: Wiring Diagram - At - 1Stsig

DTC P0731 A/T 1ST GEAR FUNCTION [RE4F04B] Wiring Diagram — AT — 1STSIG ECS0097A LCWA0010E AT-133 Revision: November 2006 2006 Altima... -

Page 134: Diagnostic Procedure

DTC P0731 A/T 1ST GEAR FUNCTION [RE4F04B] TCM TERMINALS AND REFERENCE VALUE MEASURED BETWEEN EACH TERMINAL AND 25 OR 48 (TCM GROUND) TERMINAL WIRE COLOR ITEM CONDITION DATA (APPROX.) WHEN SHIFT SOLENOID VALVE A IS OPERATING (DRIVING IN D BATTERY VOLTAGE... - Page 135 DTC P0731 A/T 1ST GEAR FUNCTION [RE4F04B] CHECK CONTROL VALVE Disassemble control valve assembly. Refer to AT-306, "Control Valve Assembly" Check to ensure that: Valve, sleeve and plug slide along valve bore under their own – weight. Valve, sleeve and plug are free from burrs, dents and scratches.

-

Page 136: Dtc P0732 A/T 2Nd Gear Function

DTC P0732 A/T 2ND GEAR FUNCTION [RE4F04B] DTC P0732 A/T 2ND GEAR FUNCTION PFP:31940 Description ECS0097C This is an OBD-II self-diagnostic item and not available in TCM self-diagnosis. This malfunction will not be detected while the A/T check (position) indicator lamp is indicating another self-diagnosis malfunction. - Page 137 DTC P0732 A/T 2ND GEAR FUNCTION [RE4F04B] WITH CONSULT-II Start engine and select “DATA MONITOR” mode for “A/T” with CONSULT-II. Make sure that output voltage of A/T fluid temperature sensor is within the range below. FLUID TEMP SEN: 0.4 - 1.5V...

-

Page 138: Wiring Diagram - At - 2Ndsig

DTC P0732 A/T 2ND GEAR FUNCTION [RE4F04B] Wiring Diagram — AT — 2NDSIG ECS0097G LCWA0011E AT-138 Revision: November 2006 2006 Altima... -

Page 139: Diagnostic Procedure

DTC P0732 A/T 2ND GEAR FUNCTION [RE4F04B] TCM TERMINALS AND REFERENCE VALUE MEASURED BETWEEN EACH TERMINAL AND 25 OR 48 (TCM GROUND) TERMINAL WIRE COLOR ITEM CONDITION DATA (APPROX.) WHEN SHIFT SOLENOID VALVE B IS OPERATING (DRIVING IN D BATTERY VOLTAGE... - Page 140 DTC P0732 A/T 2ND GEAR FUNCTION [RE4F04B] CHECK DTC Perform AT-136, "Diagnostic Trouble Code (DTC) Confirmation Procedure" OK or NG >> INSPECTION END >> Check control valve again. Repair or replace control valve assembly. AT-140 Revision: November 2006 2006 Altima...

-

Page 141: Dtc P0733 A/T 3Rd Gear Function

DTC P0733 A/T 3RD GEAR FUNCTION [RE4F04B] DTC P0733 A/T 3RD GEAR FUNCTION PFP:31940 Description ECS0097I This is an OBD-II self-diagnostic item and not available in TCM self-diagnosis. This malfunction will not be detected while the A/T check (position) indicator lamp is indicating another self-diagnosis malfunction. - Page 142 DTC P0733 A/T 3RD GEAR FUNCTION [RE4F04B] WITH CONSULT-II Start engine and select “DATA MONITOR” mode for “A/T” with CONSULT-II. Make sure that output voltage of A/T fluid temperature sensor is within the range below. FLUID TEMP SEN: 0.4 - 1.5V...

-

Page 143: Wiring Diagram - At - 3Rdsig

DTC P0733 A/T 3RD GEAR FUNCTION [RE4F04B] Wiring Diagram — AT — 3RDSIG ECS0097M LCWA0012E AT-143 Revision: November 2006 2006 Altima... -

Page 144: Diagnostic Procedure

DTC P0733 A/T 3RD GEAR FUNCTION [RE4F04B] TCM TERMINALS AND REFERENCE VALUE MEASURED BETWEEN EACH TERMINAL AND 25 OR 48 (TCM GROUND) TERMINAL WIRE COLOR ITEM CONDITION DATA (APPROX.) WHEN SHIFT SOLENOID VALVE A IS OPERATING (DRIVING IN D BATTERY VOLTAGE... - Page 145 DTC P0733 A/T 3RD GEAR FUNCTION [RE4F04B] CHECK DTC Perform AT-141, "Diagnostic Trouble Code (DTC) Confirmation Procedure" OK or NG >> INSPECTION END >> Check control valve again. Repair or replace control valve assembly. AT-145 Revision: November 2006 2006 Altima...

-

Page 146: Dtc P0734 A/T 4Th Gear Function

DTC P0734 A/T 4TH GEAR FUNCTION [RE4F04B] DTC P0734 A/T 4TH GEAR FUNCTION PFP:31940 Description ECS0097O This is an OBD-II self-diagnostic item and not available in TCM self-diagnosis. This malfunction will not be detected while the A/T check (position) indicator lamp is indicating another self-diagnosis malfunction. - Page 147 DTC P0734 A/T 4TH GEAR FUNCTION [RE4F04B] NOTE: If “DTC Confirmation Procedure” has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test. TESTING CONDITION: Always drive vehicle on a level road to improve the accuracy of test.

-

Page 148: Wiring Diagram - At - 4Thsig

DTC P0734 A/T 4TH GEAR FUNCTION [RE4F04B] Wiring Diagram — AT — 4THSIG ECS0097S BCWA0142E AT-148 Revision: November 2006 2006 Altima... -

Page 149: Diagnostic Procedure

DTC P0734 A/T 4TH GEAR FUNCTION [RE4F04B] TCM TERMINALS AND REFERENCE VALUE MEASURED BETWEEN EACH TERMINAL AND 25 OR 48 (TCM GROUND) TERMINAL WIRE COLOR ITEM CONDITION DATA (APPROX.) WHEN ACCELERATOR PEDAL 1.5 - 3.0V IS RELEASED WHILE DRIVING LINE PRESSURE SOLENOID... - Page 150 DTC P0734 A/T 4TH GEAR FUNCTION [RE4F04B] CHECK VALVE RESISTANCE Remove control valve assembly. Refer to AT-267, "Control Valve Assembly and Accumulators" Shift solenoid valve A – Shift solenoid valve B – Check resistance between two terminals. Resistance Solenoid valve Terminal No.

- Page 151 DTC P0734 A/T 4TH GEAR FUNCTION [RE4F04B] CHECK VALVE RESISTANCE Remove control valve assembly. Refer to AT-267, "Control Valve Assembly and Accumulators" Line pressure solenoid valves – Check resistance to the terminal and ground. Resistance Solenoid valve Terminal No. (Approx.)

- Page 152 DTC P0734 A/T 4TH GEAR FUNCTION [RE4F04B] CHECK DTC Perform AT-146, "Diagnostic Trouble Code (DTC) Confirmation Procedure" OK or NG >> INSPECTION END >> Perform “Cruise test — Part 1” again and return to the start point of this test group.

-

Page 153: Dtc P0740 Torque Converter Clutch Solenoid Valve

DTC P0740 TORQUE CONVERTER CLUTCH SOLENOID VALVE [RE4F04B] DTC P0740 TORQUE CONVERTER CLUTCH SOLENOID VALVE PFP:31940 Description ECS0097U The torque converter clutch solenoid valve is activated, with the gear in D , by the TCM in response to signals sent from the vehicle speed and the ECM (throttle opening). - Page 154 DTC P0740 TORQUE CONVERTER CLUTCH SOLENOID VALVE [RE4F04B] Select “DATA MONITOR” mode for “A/T” with CONSULT-II and wait at least 1 second. BCIA0031E WITH GST Follow the procedure “With CONSULT-II”. AT-154 Revision: November 2006 2006 Altima...

-

Page 155: Wiring Diagram - At - Tcv

DTC P0740 TORQUE CONVERTER CLUTCH SOLENOID VALVE [RE4F04B] Wiring Diagram — AT — TCV ECS0097Y LCWA0014E AT-155 Revision: November 2006 2006 Altima... -

Page 156: Diagnostic Procedure

DTC P0740 TORQUE CONVERTER CLUTCH SOLENOID VALVE [RE4F04B] TCM TERMINALS AND REFERENCE VALUE MEASURED BETWEEN EACH TERMINAL AND 25 OR 48 (TCM GROUND) TERMINAL WIRE COLOR ITEM CONDITION DATA (APPROX.) WITH TORQUE CONVERTER 8 - 15V LOCK-UP TORQUE CONVERTER CLUTCH SOLENOID VALVE... - Page 157 DTC P0740 TORQUE CONVERTER CLUTCH SOLENOID VALVE [RE4F04B] CHECK DTC Perform AT-153, "Diagnostic Trouble Code (DTC) Confirmation Procedure" OK or NG >> INSPECTION END >> GO TO 5. CHECK TCM INSPECTION Perform TCM input/output signal inspection. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

-

Page 158: Dtc P0744 A/T Tcc S/V Function (Lock-Up)

DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP) [RE4F04B] DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP) PFP:31940 Description ECS00980 This is an OBD-II self-diagnostic item and not available in TCM self-diagnosis. This malfunction will not be detected while the A/T check position indicator lamp is indicating another self- diagnosis malfunction. - Page 159 DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP) [RE4F04B] WITH CONSULT-II Start engine and select “DATA MONITOR” mode for “A/T” with CONSULT-II. Make sure that output voltage of A/T fluid temperature sensor is within the range below. FLUID TEMP SEN: 0.4 - 1.5V If out of range, drive vehicle to decrease voltage (warm up the fluid) or stop engine to increase voltage (cool down the fluid).

-

Page 160: Wiring Diagram - At - Tccsig

DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP) [RE4F04B] Wiring Diagram — AT — TCCSIG ECS00984 BCWA0143E AT-160 Revision: November 2006 2006 Altima... -

Page 161: Diagnostic Procedure

DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP) [RE4F04B] TCM TERMINALS AND REFERENCE VALUE MEASURED BETWEEN EACH TERMINAL AND 25 OR 48 (TCM GROUND) TERMINAL WIRE COLOR ITEM CONDITION DATA (APPROX.) WHEN ACCELERATOR PEDAL 1.5 - 3.0V IS RELEASED WHILE DRIVING... - Page 162 DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP) [RE4F04B] CHECK CONTROL VALVE Disassemble control valve assembly. Refer to AT-306, "Control Valve Assembly" Check to ensure that: Valve, sleeve and plug slide along valve bore under their own – weight. Valve, sleeve and plug are free from burrs, dents and scratches.

- Page 163 DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP) [RE4F04B] CHECK VALVE OPERATION Remove control valve assembly. Refer to AT-267, "Control Valve Assembly and Accumulators" Line pressure solenoid valve – Check solenoid valve by listening for its operating sound while applying battery voltage to the terminal and ground.

- Page 164 DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP) [RE4F04B] CHECK VALVE RESISTANCE Remove control valve assembly. Refer to AT-267, "Control Valve Assembly and Accumulators" Torque converter clutch solenoid valve – Check resistance to the terminal and ground. Resistance Solenoid valve Terminal No.

- Page 165 DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP) [RE4F04B] CHECK DTC Perform AT-158, "Diagnostic Trouble Code (DTC) Confirmation Procedure" OK or NG >> INSPECTION END >> Perform “Cruise test — Part 1” again and return to the start point of this test group.

-

Page 166: Dtc P0745 Line Pressure Solenoid Valve

DTC P0745 LINE PRESSURE SOLENOID VALVE [RE4F04B] DTC P0745 LINE PRESSURE SOLENOID VALVE PFP:31940 Description ECS00986 The line pressure solenoid valve regulates the oil pump discharge pressure to suit the driving condition in response to a signal sent from the TCM. -

Page 167: Revision: November 2006 At

DTC P0745 LINE PRESSURE SOLENOID VALVE [RE4F04B] Depress accelerator pedal completely and wait at least 1 sec- ond. BCIA0031E WITH GST Follow the procedure “With CONSULT-II”. AT-167 Revision: November 2006 2006 Altima... -

Page 168: Wiring Diagram - At - Lpsv

DTC P0745 LINE PRESSURE SOLENOID VALVE [RE4F04B] Wiring Diagram — AT — LPSV ECS0098A BCWA0468E AT-168 Revision: November 2006 2006 Altima... -

Page 169: Diagnostic Procedure

DTC P0745 LINE PRESSURE SOLENOID VALVE [RE4F04B] TCM TERMINALS AND REFERENCE VALUE MEASURED BETWEEN EACH TERMINAL AND 25 OR 48 (TCM GROUND) TERMINAL WIRE COLOR ITEM CONDITION DATA (APPROX.) WHEN ACCELERATOR PEDAL 1.5 - 3.0V IS RELEASED WHILE DRIVING LINE PRESSURE SOLENOID... - Page 170 DTC P0745 LINE PRESSURE SOLENOID VALVE [RE4F04B] CHECK POWER SOURCE AND DROPPING RESISTOR CIRCUIT Turn ignition switch to OFF position. Disconnect TCM harness connector. Check resistance between terminal 4 and TCM harness connec- tor terminal 2. Resistance : 10 - 15Ω...

- Page 171 DTC P0745 LINE PRESSURE SOLENOID VALVE [RE4F04B] CHECK TCM INSPECTION Perform TCM input/output signal inspection. If NG, recheck TCM pin terminals for damage or loose connection with harness connector. OK or NG >> INSPECTION END >> Repair or replace damaged parts.

-

Page 172: Dtc P0750 Shift Solenoid Valve A

DTC P0750 SHIFT SOLENOID VALVE A [RE4F04B] DTC P0750 SHIFT SOLENOID VALVE A PFP:31940 Description ECS0098C Shift solenoid valves A and B are turned ON or OFF by the TCM in response to signals sent from the park/neutral position (PNP) switch, vehicle speed and ECM (throttle opening). - Page 173 DTC P0750 SHIFT SOLENOID VALVE A [RE4F04B] Start engine. Drive vehicle in D position and allow the transaxle to shift 1 → 2 (“GEAR”). BCIA0031E WITH GST Follow the procedure “With CONSULT-II”. AT-173 Revision: November 2006 2006 Altima...

-

Page 174: Wiring Diagram - At - Ssv/A

DTC P0750 SHIFT SOLENOID VALVE A [RE4F04B] Wiring Diagram — AT — SSV/A ECS0098G LCWA0017E AT-174 Revision: November 2006 2006 Altima... -

Page 175: Diagnostic Procedure

DTC P0750 SHIFT SOLENOID VALVE A [RE4F04B] TCM TERMINALS AND REFERENCE VALUE MEASURED BETWEEN EACH TERMINAL AND 25 OR 48 (TCM GROUND) TERMINAL WIRE COLOR ITEM CONDITION DATA (APPROX.) WHEN SHIFT SOLENOID VALVE A IS OPERATING (DRIVING IN D BATTERY VOLTAGE... - Page 176 DTC P0750 SHIFT SOLENOID VALVE A [RE4F04B] CHECK DTC Perform AT-172, "Diagnostic Trouble Code (DTC) Confirmation Procedure" OK or NG >> INSPECTION END >> GO TO 5. CHECK TCM INSPECTION Perform TCM input/output signal inspection. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

-

Page 177: Dtc P0755 Shift Solenoid Valve B

DTC P0755 SHIFT SOLENOID VALVE B [RE4F04B] DTC P0755 SHIFT SOLENOID VALVE B PFP:31940 Description ECS0098I Shift solenoid valves A and B are turned ON or OFF by the TCM in response to signals sent from the park/neutral position (PNP) switch, vehicle speed and ECM (throttle opening). - Page 178 DTC P0755 SHIFT SOLENOID VALVE B [RE4F04B] Start engine. Drive vehicle in D position and allow the transaxle to shift 1 → 2 → 3 (“GEAR”). BCIA0031E WITH GST Follow the procedure “With CONSULT-II”. AT-178 Revision: November 2006 2006 Altima...

-

Page 179: Wiring Diagram - At - Ssv/B

DTC P0755 SHIFT SOLENOID VALVE B [RE4F04B] Wiring Diagram — AT — SSV/B ECS0098M LCWA0018E AT-179 Revision: November 2006 2006 Altima... -

Page 180: Diagnostic Procedure

DTC P0755 SHIFT SOLENOID VALVE B [RE4F04B] TCM TERMINALS AND REFERENCE VALUE MEASURED BETWEEN EACH TERMINAL AND 25 OR 48 (TCM GROUND) TERMINAL WIRE COLOR ITEM CONDITION DATA (APPROX.) WHEN SHIFT SOLENOID VALVE B IS OPERATING (DRIVING IN D BATTERY VOLTAGE... - Page 181 DTC P0755 SHIFT SOLENOID VALVE B [RE4F04B] CHECK DTC Perform AT-177, "Diagnostic Trouble Code (DTC) Confirmation Procedure" OK or NG >> INSPECTION END >> GO TO 5. CHECK TCM INSPECTION Perform TCM input/output signal inspection. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

-

Page 182: Dtc P1705 Throttle Position Sensor [Accelerator Pedal Position (App) Sen- Sor]

DTC P1705 THROTTLE POSITION SENSOR [ACCELERATOR PEDAL POSI- TION (APP) SENSOR] [RE4F04B] DTC P1705 THROTTLE POSITION SENSOR [ACCELERATOR PEDAL POSITION (APP) SENSOR] PFP:22560 Description ECS0098O Electric throttle control actuator consists of throttle control motor, accelerator pedal position sensor, throttle position sensor, etc. The actuator sends signals to the ECM, and ECM sends signals to TCM via CAN communication. -

Page 183: Diagnostic Procedure

DTC P1705 THROTTLE POSITION SENSOR [ACCELERATOR PEDAL POSI- TION (APP) SENSOR] [RE4F04B] Diagnostic Procedure ECS0098T CHECK CAN COMMUNICATIN LINE Perform the self-diagnosis check. Refer to AT-49, "SELF-DIAGNOSTIC RESULT TEST MODE" AT-59, "Diagnostic Procedure Without CONSULT-II" Is any malfunction of the "U1000 CAN COMM CIRCUIT" indicated? >>... - Page 184 DTC P1705 THROTTLE POSITION SENSOR [ACCELERATOR PEDAL POSI- TION (APP) SENSOR] [RE4F04B] CHECK TCM INSPECTION Perform TCM input/output signal inspection. If NG, recheck TCM pin terminals for damage or loose connection with harness connector. OK or NG >> INSPECTION END >>...

-

Page 185: Dtc P1760 Overrun Clutch Solenoid Valve

DTC P1760 OVERRUN CLUTCH SOLENOID VALVE [RE4F04B] DTC P1760 OVERRUN CLUTCH SOLENOID VALVE PFP:31940 Description ECS0098U The overrun clutch solenoid valve is activated by the TCM in response to signals sent from the park/neutral position (PNP) switch, overdrive control switch, vehicle speed and ECM (throttle opening). - Page 186 DTC P1760 OVERRUN CLUTCH SOLENOID VALVE [RE4F04B] Release accelerator pedal completely with selector lever in 3 position. Verify operation of "OVERRUN/C S/V". BCIA0031E WITH GST Follow the procedure “With CONSULT-II”. AT-186 Revision: November 2006 2006 Altima...

-

Page 187: Wiring Diagram - At - Ovrcsv

DTC P1760 OVERRUN CLUTCH SOLENOID VALVE [RE4F04B] Wiring Diagram — AT — OVRCSV ECS0098Y WCWA0053E AT-187 Revision: November 2006 2006 Altima... -

Page 188: Diagnostic Procedure

DTC P1760 OVERRUN CLUTCH SOLENOID VALVE [RE4F04B] TCM TERMINALS AND REFERENCE VALUE MEASURED BETWEEN EACH TERMINAL AND 25 OR 48 (TCM GROUND) TERMINAL WIRE COLOR ITEM CONDITION DATA (APPROX.) WHEN OVERRUN CLUTCH BATTERY VOLTAGE SOLENOID VALVE OPERATES OVERRUN CLUTCH SOLE-... - Page 189 DTC P1760 OVERRUN CLUTCH SOLENOID VALVE [RE4F04B] CHECK DTC Perform AT-185, "Diagnostic Trouble Code (DTC) Confirmation Procedure" OK or NG >> INSPECTION END >> GO TO 5. CHECK TCM INSPECTION Perform TCM input/output signal inspection. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

-

Page 190: Dtc U1000 Can Communication Line

DTC U1000 CAN COMMUNICATION LINE [RE4F04B] DTC U1000 CAN COMMUNICATION LINE PFP:23710 Description ECS00990 CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul- tiplex communication line with high data communication speed and excellent error detection ability. Many elec- tronic control units are equipped onto a vehicle, and each control unit shares information and links with other control units during operation (not independent). - Page 191 DTC U1000 CAN COMMUNICATION LINE [RE4F04B] Wait at least 6 seconds or start engine and wait at least 6 sec- onds. Perform self-diagnosis. Refer to AT-60, "TCM SELF-DIAGNOS- TIC PROCEDURE (NO TOOLS)" LCIA0075E AT-191 Revision: November 2006 2006 Altima...

-

Page 192: Wiring Diagram - At - Can

DTC U1000 CAN COMMUNICATION LINE [RE4F04B] Wiring Diagram — AT — CAN ECS00994 BCWA0469E AT-192 Revision: November 2006 2006 Altima... -

Page 193: Diagnostic Procedure

DTC U1000 CAN COMMUNICATION LINE [RE4F04B] Diagnostic Procedure ECS00995 CHECK CAN COMMUNICATION CIRCUIT With CONSULT-II Turn ignition switch to “ON” position. (Do not start engine.) Select “DATA MONITOR” mode for “A/T” with CONSULT-II. The “CAN COMM CIRCUIT” is detected. Yes or No >>... -

Page 194: Dtc Batt/Fluid Temp Sen (A/T Fluid Temp Sensor Circuit And Tcm Power Source)

DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP SENSOR CIRCUIT AND TCM POWER SOURCE) [RE4F04B] DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP SENSOR CIRCUIT AND TCM POWER SOURCE) PFP:31940 Description ECS00996 The A/T fluid temperature sensor detects the A/T fluid temperature and sends a signal to the TCM. - Page 195 DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP SENSOR CIRCUIT AND TCM POWER SOURCE) [RE4F04B] Select “DATA MONITOR” mode for “A/T” with CONSULT-II. BCIA0030E Drive vehicle under the following conditions: Selector lever in D, vehicle speed higher than 20 km/h (12 MPH).

-

Page 196: Wiring Diagram - At - Ba/Fts

DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP SENSOR CIRCUIT AND TCM POWER SOURCE) [RE4F04B] Wiring Diagram — AT — BA/FTS ECS0099A BCWA0470E AT-196 Revision: November 2006 2006 Altima... -

Page 197: Diagnostic Procedure

DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP SENSOR CIRCUIT AND TCM POWER SOURCE) [RE4F04B] TERMINALS AND REFERENCE VALUE MEASURED BETWEEN EACH TERMINAL TERMINAL WIRE COLOR ITEM CONDITION DATA (APPROX.) IGNITION ON BATTERY VOLTAGE POWER SOURCE IGNITION OFF IGNITION ON BATTERY VOLTAGE... - Page 198 DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP SENSOR CIRCUIT AND TCM POWER SOURCE) [RE4F04B] CHECK TCM POWER SOURCE STEP 1 Turn ignition switch to ON position. (Do not start engine.) Check voltage between TCM harness connector terminals 10, 19, 28 and ground.

- Page 199 DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP SENSOR CIRCUIT AND TCM POWER SOURCE) [RE4F04B] DETECT MALFUNCTIONING ITEM Remove oil pan. Check the following items: A/T fluid temperature sensor – • Check resistance between two terminals while changing temper- ature as shown.

- Page 200 DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP SENSOR CIRCUIT AND TCM POWER SOURCE) [RE4F04B] CHECK TCM INSPECTION Perform TCM input/output signal inspection. If NG, recheck TCM pin terminals for damage or loose connection with harness connector. OK or NG >> INSPECTION END >>...

-

Page 201: Dtc Vehicle Speed Sensor Mtr

DTC VEHICLE SPEED SENSOR MTR [RE4F04B] DTC VEHICLE SPEED SENSOR MTR PFP:24814 Description ECS0099C The vehicle speed sensor·MTR is built into the speedometer assem- bly. The sensor functions as an auxiliary device to the revolution sen- sor when it is malfunctioning. The TCM will then use a signal sent from the vehicle speed sensor·MTR. - Page 202 DTC VEHICLE SPEED SENSOR MTR [RE4F04B] Drive vehicle under the following conditions: Selector lever in D and vehicle speed higher than 25 km/h (16 MPH). Perform self-diagnosis. Refer to AT-60, "TCM SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)" WCIA0058E AT-202 Revision: November 2006...

-

Page 203: Wiring Diagram - At - Vssmtr

DTC VEHICLE SPEED SENSOR MTR [RE4F04B] Wiring Diagram — AT — VSSMTR ECS0099G BCWA0471E AT-203 Revision: November 2006 2006 Altima... -

Page 204: Diagnostic Procedure

DTC VEHICLE SPEED SENSOR MTR [RE4F04B] Diagnostic Procedure ECS0099H CHECK INPUT SIGNAL With CONSULT-II Start engine. Select “TCM INPUT SIGNALS” in “DATA MONITOR” mode for “A/T” with CONSULT-II. Read out the value of “VHCL/S SE·MTR” while driving. Check the value changes according to driving speed. -

Page 205: Dtc Turbine Revolution Sensor

DTC TURBINE REVOLUTION SENSOR [RE4F04B] DTC TURBINE REVOLUTION SENSOR PFP:31935 Description ECS0099I The turbine revolution sensor detects forward clutch drum rpm (revo- lutions per minute). It is located on the input side of the automatic transaxle. The vehicle speed sensor A/T (Revolution sensor) is located on the output side of the automatic transaxle. -

Page 206: Wiring Diagram - At - Trsa/T

DTC TURBINE REVOLUTION SENSOR [RE4F04B] Wiring Diagram — AT — TRSA/T ECS0099J BCWA0149E AT-206 Revision: November 2006 2006 Altima... -

Page 207: Diagnostic Procedure

DTC TURBINE REVOLUTION SENSOR [RE4F04B] TCM TERMINALS AND REFERENCE VALUE MEASURED BETWEEN EACH TERMINAL AND 25 OR 48 (TCM GROUND) TERMINAL WIRE COLOR ITEM CONDITION DATA (DC) WHEN MOVING AT 20 KM/H (12 MPH), USE THE CONSULT-II PULSE FREQUENCY MEASUR- ING FUNCTION.*1... -

Page 208: Component Inspection

DTC TURBINE REVOLUTION SENSOR [RE4F04B] CHECK DTC Perform AT-205, "DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION PROCEDURE" OK or NG >> INSPECTION END. >> GO TO 4. CHECK TCM INSPECTION Perform TCM input/output signal inspection. If NG, recheck TCM pin terminal for damage or loose connection with harness connector. -

Page 209: Dtc Control Unit (Ram), Control Unit (Rom)

DTC CONTROL UNIT (RAM), CONTROL UNIT (ROM) [RE4F04B] DTC CONTROL UNIT (RAM), CONTROL UNIT (ROM) PFP:31036 Description ECS0099M The TCM consists of a microcomputer and connectors for signal input and output and for power supply. The unit controls the A/T. -

Page 210: Diagnostic Procedure

DTC CONTROL UNIT (RAM), CONTROL UNIT (ROM) [RE4F04B] Diagnostic Procedure ECS0099Q INSPECTION START With CONSULT-II Turn ignition switch ON and select “SELF DIAGNOSIS” mode for A/T with CONSULT-II. Touch “ERASE”. Perform AT-209, "Diagnostic Trouble Code (DTC) Confirmation Procedure" Is the “CONTROL UNIT (RAM)” or “CONTROL UNIT (ROM)” displayed again? Yes or No >>... -

Page 211: Dtc Control Unit (Eep Rom)

DTC CONTROL UNIT (EEP ROM) [RE4F04B] DTC CONTROL UNIT (EEP ROM) PFP:31036 Description ECS0099R The TCM consists of a microcomputer and connectors for signal input and output and for power supply. The unit controls the A/T. SAT574J ON BOARD DIAGNOSIS LOGIC Diagnostic trouble code Malfunction is detected when ... -

Page 212: Diagnostic Procedure

DTC CONTROL UNIT (EEP ROM) [RE4F04B] Diagnostic Procedure ECS0099S CHECK DTC With CONSULT-II Turn ignition switch “ON” and select “SELF DIAGNOSIS” mode for A/T with CONSULT-II. Move selector lever to “R” position. Depress accelerator pedal (Full throttle position). Touch “ERASE”. -

Page 213: Trouble Diagnosis For Symptoms

TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] TROUBLE DIAGNOSIS FOR SYMPTOMS PFP:00007 Wiring Diagram — AT — NONDTC ECS0099T BCWA0472E AT-213 Revision: November 2006 2006 Altima... - Page 214 TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] TCM TERMINALS AND REFERENCE VALUE MEASURED BETWEEN EACH TERMINAL AND 25 OR 48 (TCM GROUND) TERMINAL WIRE COLOR ITEM CONDITION DATA (APPROX.) IGNITION ON AND SELECTOR BATTERY VOLTAGE LEVER IN 1 POSITION PNP SWITCH PU/W...

- Page 215 TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] BCWA0473E AT-215 Revision: November 2006 2006 Altima...

- Page 216 TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] TCM TERMINALS AND REFERENCE VALUE MEASURED BETWEEN EACH TERMINAL AND 25 OR 48 (TCM GROUND) TERMINAL WIRE COLOR ITEM CONDITION DATA (APPROX.) BR/Y DATA LINK CONNECTOR — — DATA LINK CONNECTOR — — AT-216 Revision: November 2006...

-

Page 217: A/T Check (Position) Indicator Lamp Does Not Come On

TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] 1. A/T Check (Position) Indicator Lamp Does Not Come On ECS0099U SYMPTOM: A/T check (position) indicator lamp does not come on for about 2 seconds when turning ignition switch to ON. CHECK TCM POWER SOURCE Turn ignition switch to ON position. - Page 218 TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] CHECK TCM GROUND CIRCUIT Turn ignition switch to OFF position. Disconnect TCM harness connector. Check continuity between TCM harness connector terminals 25, 48 and ground. Continuity should exist. OK or NG >> GO TO 5.

-

Page 219: Engine Cannot Be Started In P And N Position

TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] 2. Engine Cannot Be Started In P and N Position ECS0099V SYMPTOM: Engine cannot be started with selector lever in P or N position. Engine can be started with selector lever in D, 2, 1 or R position. -

Page 220: 3. In P Position, Vehicle Moves Forward Or Backward When Pushed

TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] 3. In P Position, Vehicle Moves Forward or Backward When Pushed ECS0099W SYMPTOM: Vehicle moves when it is pushed forward or backward with selector lever in P position. CHECK PARKING COMPONENTS Check parking components. Refer to AT-278, "OVERHAUL"... -

Page 221: In N Position, Vehicle Moves

TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] 4. In N Position, Vehicle Moves ECS0099X SYMPTOM: Vehicle moves forward or backward when selecting N position. CHECK PARK/NEUTRAL POSITION (PNP) SWITCH CIRCUIT With CONSULT-II Does “TCM INPUT SIGNALS” in “DATA MONITOR” show damage to park/neutral position (PNP) switch cir-... - Page 222 TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] CHECK A/T FLUID CONDITION Remove oil pan. Check A/T fluid condition. OK or NG >> GO TO 7. >> GO TO 6. SAT171B DETECT MALFUNCTIONING ITEM Disassemble A/T. Check the following items: Forward clutch assembly –...

-

Page 223: Large Shock. N → R Position

TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] 5. Large Shock. N → R Position ECS0099Y SYMPTOM: There is large shock when changing from N to R position. CHECK SELF-DIAGNOSTIC RESULTS Does self-diagnosis show damage to A/T fluid temperature sensor, line pressure solenoid valve or throttle position sensor [accelerator... - Page 224 TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] DETECT MALFUNCTIONING ITEM Remove control valve assembly. Refer to AT-267, "Control Valve Assembly and Accumulators" Check the following items: Valves to control line pressure (Pressure regulator valve, pressure modifier valve, pilot valve and pilot fil- –...

-

Page 225: Vehicle Does Not Creep Backward In R Position

TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] 6. Vehicle Does Not Creep Backward In R Position ECS0099Z SYMPTOM: Vehicle does not creep backward when selecting R position. CHECK A/T FLUID LEVEL Check A/T fluid level again. OK or NG >> GO TO 2. - Page 226 TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] DETECT MALFUNCTIONING ITEM Remove control valve assembly. Refer to AT-267, "Control Valve Assembly and Accumulators" Check the following items: Valves to control line pressure (Pressure regulator valve, pressure modifier valve, pilot valve and pilot fil- –...

- Page 227 TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] CHECK A/T FLUID CONDITION Remove oil pan. Check A/T fluid condition. OK or NG >> GO TO 9. >> GO TO 8. SAT171B DETECT MALFUNCTIONING ITEM Remove control valve assembly. Refer to AT-267, "Control Valve Assembly and Accumulators"...

-

Page 228: Vehicle Does Not Creep Forward In D, 3, 2 Or 1 Position

TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] 7. Vehicle Does Not Creep Forward in D, 3, 2 or 1 Position ECS009A0 SYMPTOM: Vehicle does not creep forward when selecting D, 3, 2 or 1 position. CHECK A/T FLUID LEVEL Check A/T fluid level again. - Page 229 TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] CHECK LINE PRESSURE Check line pressure at idle with selector lever in D position. Refer to AT-77, "Line Pressure Test" OK or NG >> GO TO 6. >> GO TO 5. SAT494G DETECT MALFUNCTIONING ITEM Remove control valve assembly.

- Page 230 TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] DETECT MALFUNCTIONING ITEM Remove control valve assembly. Refer to AT-267, "Control Valve Assembly and Accumulators" Check the following items: Valves to control line pressure (Pressure regulator valve, pressure modifier valve, pilot valve and pilot fil- –...

-

Page 231: Vehicle Cannot Be Started From D

TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] 8. Vehicle Cannot Be Started From D ECS009A1 SYMPTOM: Vehicle cannot be started from D on Cruise test — Part 1. CHECK SYMPTOM Is “6. Vehicle Does Not Creep Backward In R Position” OK? Yes or No >>... - Page 232 TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] DETECT MALFUNCTIONING ITEM Remove control valve assembly. Refer to AT-267, "Control Valve Assembly and Accumulators" Check the following items: Shift valve A – Shift valve B – Shift solenoid valve A – Shift solenoid valve B –...

- Page 233 TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] CHECK SYMPTOM Check again. OK or NG >> INSPECTION END >> GO TO 9. CHECK TCM INSPECTION Perform TCM input/output signal inspection. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

-

Page 234: A/T Does Not Shift: D Or Does Not Kickdown: D

TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] → D → D 9. A/T Does Not Shift: D or Does Not Kickdown: D ECS009A2 SYMPTOM: A/T does not shift from D to D at the specified speed. A/T does not shift from D to D when depressing accelerator pedal fully at the specified speed. - Page 235 TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] CHECK A/T FLUID CONDITION Remove oil pan. Check A/T fluid condition. OK or NG >> GO TO 7. >> GO TO 6. SAT171B DETECT MALFUNCTIONING ITEM Remove control valve. Refer to AT-267, "Control Valve Assembly and Accumulators"...

- Page 236 TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] CHECK TCM INSPECTION Perform TCM input/output signal inspection. If NG, recheck TCM pin terminals for damage or loose connection with harness connector. OK or NG >> INSPECTION END >> Repair or replace damaged parts. AT-236...

-

Page 237: 10. A/T Does Not Shift: D

TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] → D 10. A/T Does Not Shift: D ECS009A3 SYMPTOM: A/T does not shift from D to D at the specified speed. CHECK SYMPTOM Are 7. Vehicle Does Not Creep Forward In D, 3, 2 or 1 Position and 8. Vehicle Cannot Be Started From D Yes or No >>... - Page 238 TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] CHECK A/T FLUID CONDITION Remove oil pan. Check A/T fluid condition. OK or NG >> GO TO 6. >> GO TO 5. SAT171B DETECT MALFUNCTIONING ITEM Remove control valve assembly. Refer to AT-267, "Control Valve Assembly and Accumulators"...

- Page 239 TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] CHECK TCM INSPECTION Perform TCM input/output signal inspection. If NG, recheck TCM pin terminals for damage or loose connection with harness connector. OK or NG >> INSPECTION END >> Repair or replace damaged parts. AT-239...

-

Page 240: 11. A/T Does Not Shift: D

TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] → D 11. A/T Does Not Shift: D ECS009A4 SYMPTOM: A/T does not shift from D to D at the specified speed. A/T must be warm before D to D shift will occur. CHECK SYMPTOM Are “7. - Page 241 TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] CHECK A/T FLUID CONDITION Remove oil pan. Check A/T fluid condition. OK or NG >> GO TO 6. >> GO TO 5. SAT171B DETECT MALFUNCTIONING ITEM Remove control valve assembly. Refer to AT-267, "Control Valve Assembly and Accumulators"...

- Page 242 TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] CHECK TCM INSPECTION Perform TCM input/output signal inspection. If NG, recheck TCM pin terminals for damage or loose connection with harness connector. OK or NG >> INSPECTION END >> Repair or replace damaged parts. AT-242...

-

Page 243: 12. A/T Does Not Perform Lock-Up

TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] 12. A/T Does Not Perform Lock-up ECS009A5 SYMPTOM: A/T does not perform lock-up at the specified speed. CHECK SELF-DIAGNOSTIC RESULTS Does self-diagnosis show damage to torque converter clutch sole- noid valve circuit after cruise test? Yes or No >>... - Page 244 TROUBLE DIAGNOSIS FOR SYMPTOMS [RE4F04B] CHECK TCM INSPECTION Perform TCM input/output signal inspection. If NG, recheck TCM pin terminals for damage or loose connection with harness connector. OK or NG >> INSPECTION END >> Repair or replace damaged parts. AT-244...

-

Page 245: 13. A/T Does Not Hold Lock-Up Condition