Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Parker 88-021610-01G

-

Page 2: User Information

Failure to do so can result in damage to equipment and/or serious injury to personnel. Aries Series products and the information in this user guide are the proprietary property of Parker Hannifin Corporation or its licensers, and may not be copied, disclosed, or used for any purpose not expressly authorized by the owner thereof. -

Page 3: Table Of Contents

Important User Information ... 11 Change Summary ... 12 Chapter 1 Introduction ... 16 Aries Products—Overview ... 17 Compatible Parker Products ... 18 Checking Your Shipment... 19 Illustrations in this Installation Guide ... 20 Assumptions of Technical Experience ... 20 Technical Support ... - Page 4 System Installation Overview ... 190 Regulatory Agencies ... 200 Standards of Compliance ... 200 Appendix D Servo Tuning Flow Diagram... 201 Servo Tuning Flow Diagram... 202 Appendix E VM26 Expansion Module ... 203 Overview... 204 Index ... 205 4 Aries User Guide Parker Hannifin...

-

Page 5: Table Of Tables

Table 47 Error Log⎯Enable/Disable ... 132 Table 48 Terminal Emulator Configuration for RS-232/485 Communication... 159 Table 49 Communications Port Errors and Resolutions ... 160 Table 50 Error Messages ... 163 Table 51 Configuring Hall Sensors... 167 Table 52 LED Short Circuit Fault... 170 Parker Hannifin... - Page 6 Parker Hannifin Table 53 LED Drive Over-Temperature Fault ... 170 Table 54 Reset Temperature Values ... 171 Table 55 LED Under-Voltage Fault ... 171 Table 56 LED Over-Voltage Fault ... 172 Table 57 Simplified Selection of External Power-Dump Resistor ... 176 Table 58 Drive Capacitor Absorption ...

-

Page 7: Table Of Figures

Table of Figures Figure 1 Cabinet Losses for AR-02xx when connected to a Parker BE231D motor ... 24 Figure 2 Cabinet losses for AR-08xx when connected to a Parker BE343J motor ... 25 Figure 3 Cabinet losses for AR-13xx when connected to a Parker MPM1421CSJ motor... 26 Figure 4 Cabinet losses for AR-30xE when connected to a Parker MPM1422CSJ motor ... - Page 8 Parker Hannifin Figure 53 Typical LVD/EMC Installation, AR-02xx to AR-13xx... 197 Figure 54 Typical LVD/EMC Installation, AR-20xE & AR-30xE ... 198 Figure 55 Panel Layout Dimensions for the Aries Drive ... 199 Figure 56 Servo Tuning Flow Diagram ... 202 Figure 57 VM26 Breakout Module...

- Page 9 Parker Hannifin Product Type... Aries Family AR-01Ax, 02Ax, 04Ax, ... Aries Family AR-01Sx, 02Sx, 04Sx, The above product complies with the requirements of directives: • EMC Directive 89/336/EEC • Low Voltage Directive 73/23/EEC • CE Marking Directive 93/68/EEC Provided the installation requirements described in this guide are met, and there are no special requirements of the installation and operating environment so that the application may be considered typical.

- Page 10 This may also void the warranty. Symbols Description Protective Earth Ground Functional Earth (Ground) Terminal Shield, Frame, or Chassis Terminal Caution Risk of Electrical Shock Caution, Refer to Accompanying Documentation 10 Aries User Guide Parker Hannifin...

-

Page 11: Important User Information

The information in this user guide, including any apparatus, methods, techniques, and concepts described herein, are the proprietary property of Parker Hannifin or its licensors, and may not be copied disclosed, or used for any purpose not expressly authorized by the owner thereof. -

Page 12: Change Summary

Change Summary Revision G Changes This document, 88-021610-01G, supersedes 88-021610-1F. Changes associated with Aries User Guide revisions, and document clarifications and corrections are as follows: Topic Electrical Installation Command Reference Troubleshooting 12 Aries User Guide Parker Hannifin Description Added note to... - Page 13 Parker Hannifin Revision F Changes This document, 88-021610-01F, supersedes 88-021610-1E. Changes associated with Aries User Guide revisions, and document clarifications and corrections are as follows: Topic Description Command Reference Additions to ERES, SFB, and TREV commands for Aries Resolver option.

- Page 14 Regeneration Protection DC Inductance Link Command Reference Error Messages 14 Aries User Guide Parker Hannifin Description Aries is no longer cUL compliant. Corrected to 14.07A In Appendix C, Table 62 Enclosure Mounting Clamps, corrected part number to read R CLAMP KIT.

- Page 15 Parker Hannifin Revision B Changes This document, 88-021610-01B, supersedes 88-021610-1A. Changes associated with Aries User Guide revisions, and document clarifications and corrections are as follows: Topic Description Fault Operation Enhancement: Added a discussion about fault operations for the connector- Correction: Simplified the circuit diagram for the...

-

Page 16: Chapter 1 Introduction

C H A P T E R O N E Introduction IN THIS CHAPTER Aries Products—Overview... 17 Compatible Parker Products... 18 Checking Your Shipment ... 19 Illustrations in this Installation Guide ... 20 Assumptions of Technical Experience... 20 Technical Support... 20... -

Page 17: Aries Products-Overview

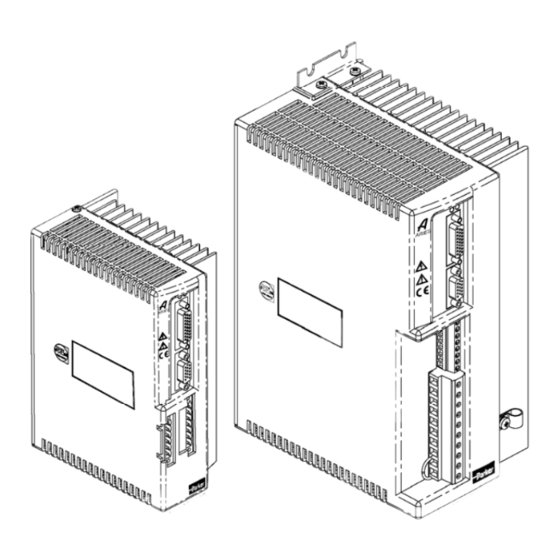

Parker Hannifin Aries Products—Overview The Aries drives are a family of super compact, super efficient digital servo drives. Their maximum continuous shaft power ranges from 100 Watts to 3000 Watts (3kW). Ready for direct panel mounting, you can select the precise power level needed for your application. -

Page 18: Compatible Parker Products

For the latest additions, see our website at www.parkermotion.com. Compatible Parker Products Servo Controller (±10V torque or velocity mode)... ACR series or other Parker Stepper Controller (S&D mode) ... ACR series or other Parker Software ... Aries Support Tool For information about cables, motors, etc., see “Chapter 2 Mechanical Installation”. -

Page 19: Checking Your Shipment

• Aries Hardware Installation Guide • Aries Support Tool Table 3 Ship Kit Items, AR-20xE and AR-30xE Motors You may have ordered a motor from one of the following families of Parker motors: • SE/SM Series • BE Series •... -

Page 20: Illustrations In This Installation Guide

If you cannot find the answer in this documentation, contact your local Automation Technology Center (ATC) or distributor for assistance. If you need to talk to our in-house Application Engineers, please contact us at the telephone numbers listed on page 2. 20 Aries User Guide Parker Hannifin... -

Page 21: Chapter 2 Mechanical Installation

Chapter 2 Mechanical Installation C H A P T E R T W O Mechanical Installation IN THIS CHAPTER Environment & Drive Cooling... 22 Dimensions ... 28 Weight... 30 Mounting Guidelines ... 31... -

Page 22: Environment & Drive Cooling

After installation, verify that the ambient air temperature directly below the top-most drive does not exceed the maximum Ambient Air Operating Temperature shown below. In addition, make sure that nothing obstructs the circulating airflow. 22 Aries User Guide Parker Hannifin shows the mounting orientation, as well as the... -

Page 23: Table 4 Environmental Specifications, Ar-01Xx Through Ar-08Xx, Ar-20Xe And Ar-30Xe

For cabinet cooling calculations, use Table 6 and Table 7 to determine the power dissipation per drive. AR-02xx The power dissipation in Table 6 for the AR-02xx has been measured using the Parker BE231D motor. Environmental Specifications (AR-01xx, AR-02xx, AR-04xx, AR-08xx, AR-20xE, and AR-30xE) Ambient Air 45°C (113°F) -

Page 24: Table 6 Ar-02Xx Power Dissipation

Figure 1 Cabinet Losses for AR-02xx when connected to a Parker BE231D motor Voltage 120 VAC 240 VAC * Drive enabled, zero torque. Table 6 AR-02xx Power Dissipation AR-08xx The power dissipation in Table 7 for the AR-08xx has been measured using the Parker BE343J motor. -

Page 25: Table 7 Ar-08Xx Power Dissipation

Parker Hannifin Figure 2 Cabinet losses for AR-08xx when connected to a Parker BE343J motor Voltage 120 VAC 240 VAC * Drive enabled, zero torque. Table 7 AR-08xx Power Dissipation AR-13xx The power dissipation in Table 8 for the AR-13xx has been measured using the Parker MPM1421CSJXXXN motor. -

Page 26: Table 8 Ar-13Xx Power Dissipation

Figure 3 Cabinet losses for AR-13xx when connected to a Parker MPM1421CSJ motor Voltage 120 VAC 240 VAC * Drive enabled, zero torque. Table 8 AR-13xx Power Dissipation AR-30xE The power dissipation in Table 9 for the AR-30xE has been measured using the Parker MPM1422CSJXXXN motor. -

Page 27: Table 9 Ar-30Xe Power Dissipation

Parker Hannifin Figure 4 Cabinet losses for AR-30xE when connected to a Parker MPM1422CSJ motor Voltage 240 VAC * Drive enabled, zero torque. Table 9 AR-30xE Power Dissipation Cabinet Cooling Calculations Use the motor’s speed torque curve to determine the torque when the motor is at running speed for your application. -

Page 28: Dimensions

Drive Dimensions—AR-01xx & AR-02xx Figure 5 Drive mounting for the AR-01xx & AR-02xx Drive AR-01xx AR-02xx Table 10 AR-01xx and AR-02xx Drive Dimensions 28 Aries User Guide Parker Hannifin Fin Height— Outside Width in (mm) (OW)—in (mm) 0.01 (0.25) 2.29 (58.2) 0.375 (9.5) -

Page 29: Table 11 Ar-01Xx , Ar-02Xx, & Ar-13Xx Drive Dimensions

Parker Hannifin Drive Dimensions—AR-04xx, AR-08xx, & AR-13xx Figure 6 Drive mounting for the AR-04xx, AR-08xx, and AR-13xx Fin Height— Drive in (mm) AR-04xx 0.625 (15.9) AR-08xx 1.00 (25.4) AR-13xx 2.00 (50.8) Table 11 AR-01xx , AR-02xx, & AR-13xx Drive Dimensions... -

Page 30: Weight

Weight Use Table 13 to determine the weight of your drive. Drive AR-01xx AR-02xx AR-04xx AR-08xx Table 13 Drive Weight 30 Aries User Guide Parker Hannifin Fin Height— Overall Width in (mm) (OW)—in (mm) 1.48 (37.5) 4.67 (118.5) Weight Drive pounds (kg) 1.68 (0.76) -

Page 31: Mounting Guidelines

Parker Hannifin Mounting Guidelines The Aries drive is a vented product. To prevent material spilling into the drive, mount it under an overhang or in a suitable enclosure. Aries products are made available under “Restricted Distribution” for use in the “Second Environment” as described in EN 61800-3 1996, page 9. -

Page 32: Chapter 3 Electrical Installation

Chapter 3 Electrical Installation C H A P T E R T H R E E Electrical Installation IN THIS CHAPTER Installation Safety Requirements... 33 System Installation Overview... 34 Power Supply... 35 Multiple Drive Installations ... 48 Brake Relay (Optional) ... 50 Regeneration Protection ... -

Page 33: Installation Safety Requirements

Auto-Configuration for Encoders The Aries drive recognizes “smart encoders” attached to Parker motors. You can apply power to the drive, and the drive reads all necessary motor parameters from the motor. The drive and motor are then ready to use. -

Page 34: System Installation Overview

Figure 9 Overview of System Installation for AR-01xx to AR-13xx Warning — This product has been developed for industrial environments. Due to exposed high voltage terminals, this product must not be accessible to users while under normal operation. 34 Aries User Guide Parker Hannifin... -

Page 35: Figure 10 Ar-01Xx To Ar-13Xx Factory Installed Jumpers

Parker Hannifin To operate the Aries drive with separate control and motor AC input, remove the factory installed external jumpers. With the jumpers installed, apply power to the motor power mains only. Figure 10 shows the location of the factory installed jumpers. -

Page 36: Figure 11 Overview Of System Installation For Ar-20Xe & Ar-30Xe

Figure 11 Overview of System Installation for AR-20xE & AR-30xE Warning — This product has been developed for industrial environments. Due to exposed high voltage terminals, this product must not be accessible to users while under normal operation. 36 Aries User Guide Parker Hannifin... -

Page 37: Figure 12 Ar-20Xe To Ar-30Xe Factory Installed Jumpers

Parker Hannifin To operate the Aries drive with separate control and motor AC input, remove the factory installed external jumpers. With the jumpers installed, apply power to the motor power mains only. Figure 12 shows the location of the factory installed jumpers. -

Page 38: Figure 13 Connectors On Aries Models Ar-01Xx To Ar-13Xx

Parker Hannifin Figure 13 Connectors on Aries Models AR-01xx to AR-13xx Figure 14 Connectors on Aries Models AR-20xE & AR-30xE 38 Aries User Guide... -

Page 39: Power Supply

Parker Hannifin Power Supply Input Power The mains motor power supply and control power supply for the Aries Drive must meet the following requirements. Model Motor Input Power AR-01xx, AR-02xx, AR-04xx, AR-08xx, AR-13xx (L1, L2) AR-20xE (L1, L2, L3) AR-30xE... -

Page 40: Figure 16 Motor And Control Mains Power Supply Connection

AC power connection. Jumpers are installed at the factory for this purpose. Remove the jumpers to apply separate control and motor mains power. Figure 16 Motor and Control Mains Power Supply Connection Note: See warnings on next page. 40 Aries User Guide Parker Hannifin... -

Page 41: Table 14 Motor Power Fuse Information

Parker Hannifin Warning — You must connect the drive’s protective conductor terminal, marked with the earth symbol , to a reliable system Protective Earth. Warning — The drive’s connector strip terminals have hazardous voltages when power is applied to the drive, and up to several minutes after power is removed. -

Page 42: Table 15 Fuse Part Numbers

120 VAC AR-08xx 240 VAC 120 VAC AR13xE 240 VAC AR-20xE 240 VAC AR-30xE 240 VAC Table 16 Drive Motor Power Inrush Current 42 Aries User Guide Parker Hannifin Ferraz Shawmut Littelfuse (formerly Gould) TR10R FLNR10 TR20R FLNR20 TR30R FLNR30... -

Page 43: Table 17 Output Power-Continuous And Peak

Parker Hannifin Output Power Table 17 contains the continuous and peak output power ratings for all Aries drive models. Continuous Output Drive Current (Amps, RMS) AR-01xx AR-02xx 1.75 AR-04xx AR-08xx AR-13xx 1300 AR-20xE 2000 AR-30xE 3000 * Maximum shaft power rating at 240 VAC... -

Page 44: Table 18 Wiring To Motors

Output Power Connection Figure 17 shows how to connect the motor cable to the drive. Use the screw terminal connector that is installed in the drive. Current Parker motor cables are marked with white numbers to indicate the phases. Connect Motor Phase... -

Page 45: Table 19 Ar-20Xe & Ar-30Xe Dc Link Inductors

Parker Hannifin Warning — The drive’s connector strip terminals have hazardous voltages when power is applied to the drive, and up to several minutes after power is removed. Lower voltages may still be present for several minutes after power is removed. During normal operation, these high voltage terminals must not be accessible to the user. - Page 46 Control Power Functions... Communications Control Power Connector AR-01xx, AR-02xx, AR-04xx, AR-08xx, AR-13xx Connector Type... Removable screw terminal 46 Aries User Guide Parker Hannifin equivalent UL listed fuse) Diagnostics Motor position feedback Fault output in fault mode Brake relay in brake mode Reset input Terminals ...7...

-

Page 47: Figure 19 Mains Control Input Power

Parker Hannifin AR-20xE, AR-30xE Connector Type... Non-Removable screw terminal Control Power Connection Figure 19 shows how to connect the Control power source to the drive. Use the screw terminal connector that is supplied with the drive. Figure 19 Mains Control Input Power Warning —... -

Page 48: Multiple Drive Installations

Protective Earth ground. Safety Earth Connections AR-01xx, AR-02xx, AR-04xx, AR-08xx, and AR-13xx For multiple drive installations, Parker Hannifin recommends a single point or “star” safety earth configuration. Figure 20 represents a typical star safety earth connection for Aries models AR-01xx through AR-13xx. -

Page 49: Figure 21 Multiple Drives Ar-20Xe & Ar-30Xe: Single Point Safety Earth

Parker Hannifin Figure 21 Multiple Drives AR-20xE & AR-30xE: Single Point Safety Earth Chapter 3 Electrical Installation 49... -

Page 50: Brake Relay (Optional)

On all models, this set of terminals is optically isolated from the drive’s internal logic. Figure 22 Typical Brake Relay Connection Important warnings: 50 Aries User Guide Parker Hannifin Terminals ...6 Pitch ... 0.200 in (5.08 mm) Wire range ...12-26 AWG ...14-27 SWG ...(0.12-3.30 mm... -

Page 51: Figure 23 Brake Relay Connection For Parker Motors

During normal operation, these high voltage terminals must not be accessible to the user. Motor with Full Wave Rectifiers Some Parker brake motors (BE, SM, SE, NeoMetric, and J series motors, serial numbers greater than 010904xxxxx) contain full wave rectifiers, so connection polarity is not an issue during installation. -

Page 52: Figure 24 Brake Relay Connection For Non-Parker Motors

Consult the specifications or the manufacturer of your motor. Connecting the Brake Relay 1. Connect one red/blue brake wire (Parker Motor cable or equivalent) to the BK terminal of the Motor connector (Aries drive). 2. Connect the second red/blue brake wire (Parker Motor cable or equivalent) to the 24V return on your power supply. -

Page 53: Table 20 Brake Relay Operation

Parker Hannifin Relay Operation Drive Condition Enabled Faulted No AC power on L1 and L2*, or drive not enabled * Mains Control power on C1 and C2 does not affect the relay. With mains power applied to C1 and C2, the relay remains open if AC power is not applied to the L1 and L2 terminals. -

Page 54: Regeneration Protection

Lower voltages may still be present for several minutes after power is removed. During normal operation, these high voltage terminals must not be accessible to the user. 54 Aries User Guide Parker Hannifin and R− when you connect the... -

Page 55: Table 21 Regeneration Absorption

Parker Hannifin Internal Regeneration Capability The internal regeneration resistor of the AR-20xE and AR-30xE is capable of dissipating 1kW for 1 second and up to 100 Watts continuously (depending upon heatsink temperature). If the calculated temperature of the internal regeneration resistor exceeds 150°C (302°F), the drive turns off the regeneration circuit and may experience an over-voltage fault. -

Page 56: Leds⎯Drive Status Indicators

Yellow & 2 Green (flashing) Yellow & 3 Green (flashing) Yellow & 4 Green (flashing) Yellow & 5 Green (flashing) Table 23 LED Status Indicator-Internal Drive Fault 56 Aries User Guide Parker Hannifin LED–Right What it means Green Power on, enabled Green Power on, regeneration active Power on, disabled–No Fault... -

Page 57: Connector Descriptions

Parker Hannifin Connector Descriptions Motor Mains Power Connector The drive’s Mains screw terminal connector provides a connection for AC Mains power to your drive. (For connection information, see “Input Power” on page 39.) The connector differs between the two largest Aries models and the others. - Page 58 Mains/Input Power Connector AR-01xx, AR-02xx, AR-04xx, AR-08xx, AR-13xx... Amphenol PCD: OSTTJ075102 Parker Hannifin Part Number... 43-021069-01 Connector Type... Removable screw terminal AR-20xE, AR-30xE ... Molex: 39960-0110 Parker Hannifin Part Number... N/A Connector Type... Non-Removable screw terminal 58 Aries User Guide Parker Hannifin Terminals ...7...

-

Page 59: Figure 27 Output ( Motor ) Power Connector

Parker Hannifin Output Power Connector The drive’s Motor screw terminal connector provides output power to your motor. (For connection information, see “Output Power” on page 43.) The connector differs between the two largest Aries models and the others. Specifications for the connectors follow in this section. - Page 60 AR-08xx, AR-13xx ... Amphenol PCD: OSTTJ075102 Parker Hannifin Part Number... 43-021068-01 Connector Type... Removable screw terminal AR-20xE, AR-30xE ... Molex: 39960-0110 Parker Hannifin Part Number... N/A (not replaceable) Connector Type... Non-Removable screw terminal 60 Aries User Guide Parker Hannifin Terminals ...6 Pitch ...

-

Page 61: Figure 28 Ar-20Xe & Ar30Xe Control Connector

“Control Power Supply” on page Relay (Optional)” on page 50. Figure 28 AR-20xE & AR30xE Control Connector AR-20xE, AR-30xE ... PCD: ELM021100 Parker Hannifin Part Number... N/A (not replaceable) Connector Type... Non-Removable screw terminal ), a control XTERNAL... -

Page 62: Figure 29 Motor Feedback Connector, Female Drive Connector Pinout

15-pin Motor Feedback connector. Figure 29 MOTOR FEEDBACK Important — Encoder inputs use a DS26LV32 differential line receiver. Parker Hannifin recommends 26LS31 (or compatible) differential line driven encoders. Single ended encoders are not compatible. Figure 30 MOTOR FEEDBACK... -

Page 63: Table 24 Motor Feedback Connector Pinout

Parker Hannifin Pinout— Connector MOTOR FEEDBACK Note: A box surrounding pins indicates a requirement for twisted pair wiring. Signal ENC Z+ / Data+ ENC Z– / Data– DGND +5 VDC +5 VDC DGND ENC A– / SIN– ENC A+ / SIN+... - Page 64 Manufacturer ... KYCON or equivalent Connector Type... 15-Pin High Density KYCON Part Number... K66-E15S-NR Connector Specification—Mating Connector Mating connectors are not provided with Aries drives. Parker cables are available with mating connectors attached. Manufacturer ... AMP or equivalent Connector Type... 15-Pin High Density D-Subminiature Cable Kit...

-

Page 65: Figure 31 Motor Feedback Connector, Female Drive Connector Pinout

Parker Hannifin Motor Feedback Connector—Resolver Inputs for the encoder feedback, motor thermal switch, and hall effects are located on the 15-pin Motor Feedback connector. Figure 31 connector, female drive connector pinout MOTOR FEEDBACK Figure 32 connector for resolver option, internal circuit diagram... -

Page 66: Table 26 Motor Feedback Connector Pinout For Resolver Option

Enable input is optically isolated with both Anodes (+) and Cathodes (–) available. • Reset input is optically isolated with both Anodes (+) and Cathodes (–) available. 66 Aries User Guide Parker Hannifin Connector for Resolver Option Description — — Motor thermal switch/thermistor... -

Page 67: Table 28 Fault Output Operation

Parker Hannifin • Fault output is optically isolated with both Collector (+) and Emitter (–) available. No Optical Isolation The following describes which I/O signals are not optically isolated: • Step and Direction inputs are 5V differential compatible (RS-422 logic level compatible. -

Page 68: Figure 34 Drive I / O Connector, Internal Circuit Diagram

Parker Hannifin Figure 34 connector, internal circuit diagram DRIVE I 68 Aries User Guide... -

Page 69: Table 29 Drive I / O Connector Pinout

Parker Hannifin Pinout— Connector DRIVE I Note: A box surrounding pins indicates a requirement for twisted pair wiring. Signal ENABLE+ ENABLE– DGND ENC A+ ENC A– ENC B+ ENC B– ENC Z+ ENC Z– FAULT+ * FAULT– STEP+ STEP– DIRECTION+ DIRECTION–... -

Page 70: Table 30 Inputs-Enable And Reset Electrical/Timing Characteristics

Output Saturation Voltage (at 1.0 mA) * Based on 120Ω differential load impedance. Note: All parameters are at the connector pin. Table 32 Outputs— Fault outputs Electrical/Timing Characteristics 70 Aries User Guide Parker Hannifin – – – – – –... -

Page 71: Table 33 Inputs-Step & Direction Electrical/Timing Characteristics

Manufacturer ... KYCON or equivalent Connector Type... 26-Pin High Density KYCON Part Number... K66-A26S-NR Connector Specification—Mating Connector Mating connectors are not provided with Aries drives. Parker cables are available with mating connectors attached. Manufacturer ... AMP or equivalent Connector Type... 26-Pin High Density D-Subminiature Cable Kit... -

Page 72: Installation Test

If the motor does not spin, a wiring or configuration error possibly exists. 1. Start the Aries Support Tool. 2. Under Menu, click Operating System Update. 3. Click Auto Run Test Wizard. 72 Aries User Guide Parker Hannifin... -

Page 73: Chapter 4 Communications

Chapter 4 Communications C H A P T E R F O U R Communications IN THIS CHAPTER Terminal Emulator Configuration... 74 Establishing Communications ... 74 RS-232 Communications... 75 RS-485 Communications... 75 RS-485 Multi-Drop ... 76 RS-232/485 Dongle for Communications Setup ... 77... -

Page 74: Rs-232/485 Communications

PC to simultaneously communicate with the Aries drive while also connected to a controller. For more information, see “RS-232/485 Dongle for Communications Setup” on page 77. 74 Aries User Guide Parker Hannifin RS-485 * 2-wire plus ground (Talk+, Talk–, Gnd) -

Page 75: Table 36 Rs-232 Connector Pinout

Parker Hannifin Depending on the communications protocol you are using, Aries can automatically configure itself. • If using RS-232, Aries will automatically detect and configure itself for that communications protocol. • If using RS-485 (two-wire) and the standard bias configuration, Aries will automatically detect and configure itself for that communications protocol. -

Page 76: Figure 36 Rs-485 Multi-Drop Connections

5. After installing and connecting the drives to the multi-drop network, test each drive—use safe methods suitable for your particular application— to ensure each functions correctly. To test each unit, send the i_TREV command, where i represents the address of a drive. 76 Aries User Guide Parker Hannifin... - Page 77 Parker Hannifin Warning — Risk of damage and/or personal injury When testing the installation of drives, use safe methods suitable for your particular application. Replacing a Unit in the Network If you need to replace a drive, do the following: 1.

-

Page 78: Chapter 5 Tuning

Chapter 5 Tuning CHAPTER FIVE Tuning IN THIS CHAPTER Servo Tuning Overview ... 79 Position Variable Overview... 80 Servo Response Overview ... 81 Servo System Gains ... 83 Servo Tuning Example ... 86... -

Page 79: Servo Tuning Overview

Parker Hannifin Servo Tuning Overview The drive uses a digital control algorithm to control and maintain the position and velocity. The digital control algorithm consists of a set of numerical equations used to periodically (once every servo sampling period) calculate the value of the control output. -

Page 80: Position Variable Overview

Parker Hannifin Position Variable Overview In a servo system, the controller uses two types of position information: commanded position and actual position. As these positions change with time, you can use the position values to determine if the system is positioning as you expect. -

Page 81: Servo Response Overview

Parker Hannifin commanded position. Under these circumstances, a position error will accumulate no matter how high the gains are set. Servo Response Overview Stability The first objective of tuning is to stabilize the system. The formal definition of system stability is when a bounded input is introduced to the system, the output of the system is also bounded. -

Page 82: Table 38 Position Response Types

(Note the settling time definition here is different from that of a control engineering text book, but the goal of the performance measurement is still intact.). 82 Aries User Guide Parker Hannifin Description Profile (position/time) A critically-damped... -

Page 83: Servo System Gains

Parker Hannifin Servo System Gains Proportional Feedback Control (SGP) Proportional feedback is the most important feedback for stabilizing a servo system. When the controller uses proportional feedback, the control signal is linearly proportional to the position error (the difference between the commanded position and the actual position—see TPER command). -

Page 84: Figure 39 Integrator Windup (Without Using Sgilim Command)

Parker Hannifin Controlling Integral Windup If you are using integral control (SGI) and there is an appreciable position error that persists long enough during the transient period (time taken to reach the setpoint), the control signal generated by the integral action can end up too high;... -

Page 85: Figure 40 Integrator Windup (Using The Sgilim Command)

Parker Hannifin Figure 40 Integrator Windup (using the SGILIM Command) Chapter 5 Tuning 85... -

Page 86: Servo Tuning Example

Parker Hannifin Servo Tuning Example The example below illustrates how to experimentally obtain the highest possible proportional feedback (SGP) and velocity feedback (SGV) gains. For a Servo Tuning flow diagram, see “Appendix A Additional Specifications” on page 168. The motion command used for this example is a step command with a step size of 200. - Page 87 Parker Hannifin Step 3 Step 3 With SGV equal to 2, the response is fairly well damped (see plot). At this point, the SGP should be raised again until oscillation or excessive overshoot appears. Step 4 As we iteratively increase...

- Page 88 Parker Hannifin Step 6 Lowering the SGV gain to 3 does not help reduce the chattering by much. Therefore, we should lower the SGP gain until chattering stops. Step 7 Chattering stops after reducing the gain to 4 However, the overshoot is still a little too high.

- Page 89 Parker Hannifin Step 9 After lowering the SGV gain to 3 (even less than in Step 7—3.5), chattering stops. Next we should lower the SGP gain. Step 10 Overshoot is reduced very little after lowering the SGP gain to 3.5. (The SGV gain might have been lowered too much in Step 9.)

-

Page 90: Auto-Tuning

Put the drive in position mode (DMODE6 or 7). On the drive’s ±10V Analog Input, apply a command voltage greater than 3V, then reset the drive. To return to normal operation, remove the command voltage and reset the drive. 90 Aries User Guide Parker Hannifin... -

Page 91: Chapter 6 Command Reference

Chapter 6 Command Reference CHAPTER SIX Command Reference IN THIS CHAPTER Description of Format ... 92 Syntax – Letters and Symbols... 92 Syntax – General Guidelines... 94 Command Descriptions ... 95... -

Page 92: Aries Communications Set-Up

<*>4ØØØ. The <*> only appears for RS-485 communication, and does not appear for RS-232 communication. See Also: Commands related or similar to the command described are listed here. Table 39 Commands-Description of Format 92 Aries User Guide Parker Hannifin Product Aries... -

Page 93: Syntax - Letters And Symbols

* The ASCII character b can also be used within a command to precede a binary number. When the b is used in this context, it is not to be replaced with a Ø or 1. For example, comparisons such as ERROR= b1x1. Table 40 Commands-Syntax Parker Hannifin Product Aries Chapter 6 Command Reference 93... -

Page 94: Syntax - General Guidelines

Hexadecimal Values Note: The command line is limited to 32 characters (including spaces). Table 41 Syntax Guidelines 94 Aries User Guide Parker Hannifin Examples All commands must be separated by a delimiter. A carriage return is the most commonly used. -

Page 95: Command Descriptions

4. Connect the drive to become unit 4. Through a terminal emulator, send the following command: Ø_ADDR4 If you need to replace a unit in the multi-drop network, connect to the individual device and send the Ø_ADDRi command, where “i” Parker Hannifin Product Aries Chapter 6 Command Reference 95... - Page 96 These parameters are stored in the drive. If you want to store them in a smart encoder, type the ESTORE command into the terminal and press Enter. It takes a couple of seconds to store the motor data in the motor. 96 Aries User Guide Parker Hannifin ENCOFF ENCPOL P163...

- Page 97 DCMDZ when command when The commanded velocity, Vel using DMVSCL as follows: command when command DCMDZ when command when Parker Hannifin , using DMTSCL as follows: DMTSCL − − DCMDZ ANICDB > DCMDZ+ ANICDB ≤ ≤ ANICDB DCMDZ DMTSCL −...

- Page 98 In addition, the encoder counts positive for counter clockwise rotation with CMDDIR1. Note: This command does not take effect until you cycle power to the drive, or send the RESET 98 Aries User Guide Parker Hannifin ERROR TANI TDHRS TDMIN TERRLG...

-

Page 99: Figure 41 Clockwise/Counter-Clockwise Rotation

Warning E1—Motor Configuration Error E3—Max Inductance = Ø E4—Rated Speed = Ø E5—DPOLE = Ø E6—Resistance = Ø E7—Ke = Ø E8—Continuous Current = Ø Parker Hannifin “Chapter 2 Figure 41 Clockwise/ “Chapter 3 Electrical Counter-clockwise rotation DMTW ERROR Resolution The motor rating is too high for the drive, and the drive is using its own limits for safety reasons. -

Page 100: Table 42 Configuration Errors And Warnings

E18 – Lag Freq < 2Ø Hz E19–E24 Table 42 Configuration Errors and Warnings 100 Aries User Guide Parker Hannifin Resolution This parameter is set to zero (0). To correct the error, you must set a non-zero value. Refer to your motor specifications for the correct value. - Page 101 When used in conjunction with IAUTO1, this command sets the current loop bandwidth. Higher values of DIBW will give a faster response to changes in commanded current, at the expense of some overshoot. Lower values of DIBW, will give a slower response, with much less overshoot. Parker Hannifin Product Aries Product...

-

Page 102: Table 43 Current Foldback Ratings

(300% of continuous), foldback occurs after 3.375 seconds. Note: For model AR-13xx, foldback occurs after 8.64 seconds at its peak rating (225% of continuous). Figure 42 Time until current foldback occurs 102 Aries User Guide Parker Hannifin AR-02xx AR-04xx AR-08xx AR-13xx 1.75... -

Page 103: Figure 43 Linear Motor Track

<*>2 Response none See Also Use the DMODE command to select the drive control mode for your Aries drive. For drive mode descriptions and drive compatibility, see Table 44. Parker Hannifin command. Chapter 6 Command Reference 103 Product Aries Product... -

Page 104: Table 44 Drive Control Mode

NB: DRES change requires a reset to take effect. DMPSCL works immediately so the user could use DMPSCL0 to enable DRES support then enable DMPSCL and have both features working at once. 104 Aries User Guide Parker Hannifin Description Rotates the motor at 1 rps/mps. Current is reduced by 10%. - Page 105 Auto-Setup: When using a Parker motor and the Aries Support Tool, this command is automatically set for the selected motor. If you did not use the Aries Support Tool, are using non-Parker motors, or sent an RFS command to the drive, the parameter is set to zero (0)—you must manually set this parameter to a non-zero number.

- Page 106 Auto-Setup: When using a Parker motor and the Aries Support Tool, this command is automatically set for the selected motor. If you did not use the Aries Support Tool, are using non-Parker motors, or sent an RFS command to the drive, the parameter is set to zero (0)—you must manually set this parameter to a non-zero number.

- Page 107 Auto-Setup: When using a Parker motor and the Aries Support Tool, this command is automatically set for the selected motor. If you did not use the Aries Support Tool, are using non-Parker motors, or sent an RFS command to the drive, the parameter is set to zero (0)—you must manually set this parameter to a non-zero number.

- Page 108 Auto-Setup: When using a Parker motor and the Aries Support Tool, this command is automatically set for the selected motor. If you did not use the Aries Support Tool, are using non-Parker motors, or sent an RFS command to the drive, the parameter is set to zero (0)—you must manually set this parameter to a non-zero number.

-

Page 109: Table 45 Peak Current Rating For Aries Drives

Auto-Setup: When using a Parker motor and the Aries Support Tool, this command is automatically set for the selected motor. If you did not use the Aries Support Tool, are using non-Parker motors, or sent an RFS command to the drive, the parameter is set to zero (0)—you must manually set this parameter to a non-zero number. - Page 110 Auto-Setup: When using a Parker motor and the Aries Support Tool, this command is automatically set for the selected motor. If you did not use the Aries Support Tool, are using non-Parker motors, or sent an RFS command to the drive, the parameter is set to zero (0)—you must manually set this parameter to a non-zero number.

- Page 111 Auto-Setup: When using a Parker motor and the Aries Support Tool, this command is automatically set for the selected motor. If you did not use the Aries Support Tool, are using non-Parker motors, or sent an RFS command to the drive, the parameter is set to zero (0)—you must manually set this parameter to a non-zero number.

- Page 112 Auto-Setup: When using a Parker motor and the Aries Support Tool, this command is automatically set for the selected motor. If you did not use the Aries Support Tool, are using non-Parker motors, or sent an RFS command to the drive, the parameter is set to zero (0)—you must manually set this parameter to a non-zero number.

- Page 113 Parker Hannifin When you select a specific Parker motor using the Aries Support Tool, the DMTR setting and various motor parameters (see Servo Motor Data Parameters below) are automatically configured for the associated motor. Using the Aries Support Tool, you can save the parameters in a configuration file.

- Page 114 Auto-Setup: When using a Parker motor and the Aries Support Tool, this command is automatically set for the selected motor. If you did not use the Aries Support Tool, are using non-Parker motors, or sent an RFS command to the drive, the parameter is set to zero (0)—you must manually set this parameter to a non-zero number.

- Page 115 Auto-Setup: When using a Parker motor and the Aries Support Tool, this command is automatically set for the selected motor. If you did not use the Aries Support Tool, are using non-Parker motors, or sent an RFS command to the drive, the parameter is set to zero (0)—you must manually set this parameter to a non-zero number.

- Page 116 Auto-Setup: When using a Parker motor and the Aries Support Tool, this command is automatically set for the selected motor. If you did not use the Aries Support Tool, are using non-Parker motors, or sent an RFS command to the drive, the parameter is set to zero (0)—you must manually set this parameter to a non-zero number.

- Page 117 Auto-Setup: When using a Parker motor and the Aries Support Tool, this command is automatically set for the selected motor. If you did not use the Aries Support Tool, are using non-Parker motors, or sent an RFS command to the drive, the parameter is set to zero (0)—you must manually set this parameter to a non-zero number.

- Page 118 Auto-Setup: When using a Parker motor and the Aries Support Tool, this command is automatically set for the selected motor. If you did not use the Aries Support Tool, are using non-Parker motors, or sent an RFS command to the drive, the parameter is set to zero (0)—you must manually set this parameter to a non-zero number.

- Page 119 Auto-Setup: When using a Parker motor and the Aries Support Tool, this command is automatically set for the selected motor. If you did not use the Aries Support Tool, are using non-Parker motors, or sent an RFS command to the drive, the parameter is set to 4.00—you must manually set this parameter to a non-zero number.

-

Page 120: Figure 44 Notch Filter Topology

(magnitude and phase) of the internal commanded torque/force vs. the user commanded torque/force. In this example, the notch frequency is set to 150 Hz (DNOTAF15Ø) and the “Q” is set to 1 (DNOTAQ1). 120 Aries User Guide Parker Hannifin DNOTBD DNOTBF DNOTBQ,... -

Page 121: Figure 46 Notch Filter A

DNOTAF See Also DNOTLD DNOTLG The DNOTBD command sets the depth for the commanded torque/force notch filter B. For information about the notch filter depth, see DNOTAD. Parker Hannifin DNOTBD DNOTBF DNOTBQ, DNOTAQ DNOTBF DNOTBQ, Chapter 6 Command Reference 121... - Page 122 See Also DNOTLG The DNOTLD command sets the break frequency of the lead filter. This filter cannot be used alone, but must be used in conjunction with the DNOTLG lag 122 Aries User Guide Parker Hannifin DNOTAQ DNOTBD DNOTBQ, DNOTBD...

-

Page 123: Figure 47 Notch Lead Filter Break Frequency

(but not overwritten), the configuration warning bit (E17) is set, and the last valid DNOTLG value is used internally. This warning is cleared with RESET command or by cycling power to the drive. This filter operates in all Parker Hannifin settings, except Autorun (DMODE1). DMODE DNOTAQ DNOTBD DNOTBF settings, except Autorun (DMODE1). - Page 124 Auto-Setup: When using a Parker motor and the Aries Support Tool, this command is automatically set for the selected motor. If you did not use the Aries Support Tool, are using non-Parker motors, or sent an RFS command to the drive, the parameter is set to zero (0)—you must manually set this parameter to a non-zero number.

- Page 125 “fault” output and open the dry contact relay (“RELAY N.O.”): • Certain axis “fault” conditions – refer to the status bits denoted with an asterisk (*) in the ERROR description. Parker Hannifin Product Aries (DMODE6 Product...

- Page 126 ENCFLT: <*>0 Response None See Also For increased noise immunity, rotary motors have increased filtering on the encoder input. The maximum input frequency in 1.02 MHz pre-quadrature for 126 Aries User Guide Parker Hannifin Product Aries Product Aries Product Aries...

- Page 127 See Also The ENCOFF command specifies the encoder offset. All standard (non-smart) Parker encoders have an encoder offset of 0 degrees. The smart encoders store the encoder offset in the motor, which the drive reads (and stores in the ENCOFF parameter) upon power-up. The offset can vary from –180 degrees (corresponding to ENCOFF=-32768) to +180 degrees...

- Page 128 Auto-Setup: When using a Parker motor and the Aries Support Tool, this command is automatically set for the selected motor. If you did not use the Aries Support Tool, are using non-Parker motors, or sent an RFS command to the drive, the parameter is set to zero (0)—you must manually set this parameter to a non-zero number.

- Page 129 (E25 through E46) that currently prevent the drive from enabling. To re-enable the drive correct the specified fault, then reset the drive or cycle power to it. Table 46 contains the possible errors appearing in the text-based report and their descriptions. Parker Hannifin DMEPIT resolution count 42000...

- Page 130 E43-Excessive Speed at Enable E44-Excessive Position Error 130 Aries User Guide Parker Hannifin Description The command voltage (at the ANI+ terminal) was too high when the drive was enabled. Lower the voltage at the ANI+ terminal. Try using the fault on startup voltage.

-

Page 131: Table 46 Error Status⎯Text Based Report

“n” is the error bit number and “b” is either one (1) to enable or zero (Ø) to disable. Use the TERRLG command to view the error log. Use the CERRLG command to clear the error log. Parker Hannifin Description Commanded velocity. Actual Velocity is greater than the value set by SMVER. -

Page 132: Table 47 Error Log⎯Enable/Disable

Note: The ESTORE command stores the following parameters in the encoder: DMTD, DMTIC, DMTIND, DMTINF, DMTJ, DMTKE, DMTLIM, DMTRES, DMTRWC, DMVLIM, DPOLE, DPWM, DTHERM, ENCOFF, ENCPOL, INTLIM, PGAIN, P163. 132 Aries User Guide Parker Hannifin Enable/Disable DMTSCL, DMTSWT, DMTTCW, DMTTWM, DMTW, Product Aries DMTR, IGAIN,... - Page 133 The IANI command inverts the polarity of the analog input to the drive. This has the effect of reversing any torque or velocity command. It can be useful when using custom wiring during initial setup of the drive. Parker Hannifin DCMDZ TANI...

- Page 134 INPOSTM See Also Use the INPOS command to replace the Fault output with an In-Position output when using the drive in step & direction modes (DMODES6 and 7). If 134 Aries User Guide Parker Hannifin Product Aries Product Aries Product...

- Page 135 System Load-to System Load-to-Rotor/Forcer Inertia/Mass Ratio Tuning Type <a_>LJRAT<i> Syntax Load to Rotor Inertia Ratio Units Ø.Ø – 1ØØ.Ø Range Ø.Ø Default LJRAT: <*>Ø.ØØ Response IGAIN PGAIN See Also Parker Hannifin TPER Chapter 6 Command Reference 135 Product Aries Product Aries Product Aries...

- Page 136 If the motor has trouble turning smoothly with the drive in “auto run” mode (DMODE1), that is a good indication that OHALL4 will be unsuccessful. 136 Aries User Guide Parker Hannifin (velocity mode) and DMODE4 DMODE6 Product Aries 2.10...

- Page 137 P163=1 specifies that the hall sensors count in the opposite direction as the encoder counts in the +ve direction. This command has the same effect as swapping hall wires A and B to the drive. Parker Hannifin ENCPOL IANI Chapter 6 Command Reference 137...

- Page 138 ; happens to be, consider that position to have an ; absolute position of zero. RESET Reset Communication Interface Type <a_>RESET Syntax Units Range Default RESET: (Displays power applied message) Response TREV See Also 138 Aries User Guide Parker Hannifin Product Aries Product Aries Product Aries...

- Page 139 In operating systems 2.0 or earlier, the SFB value reflected the type of motor that the drive auto-detected. In operating system 2.10 and beyond, you also can set a feedback type with the SFB command. Parker Hannifin DRIVE I Product...

- Page 140 SGILIM: <*>1 Response See Also This command is only valid in (position mode). If integral control (SGI) is used and an appreciable position 140 Aries User Guide Parker Hannifin IGAIN (velocity mode) and DMODE4 (velocity mode) and DMODE4 Product Aries...

- Page 141 Using velocity feedback, the controller's output signal is made proportional to the velocity, or rate of change, of the feedback device position. Since it acts on the rate of change of the position, the action of this Parker Hannifin PGAIN (velocity mode) and...

- Page 142 The value of SGVF can be adjusted from zero to as high as five (5) times (SGVF5) the theoretical value. Example SGVF2 ; Set velocity feedforward to 200% of theoretical value 142 Aries User Guide Parker Hannifin ⋅ torque DMTD velocity SGVF value...

- Page 143 The position error, monitored once per system update period, is the difference between the commanded position and the actual position as read by the feedback device selected with the last SFB command. When the Parker Hannifin command. (velocity mode). SMAV allows you to...

- Page 144 You can check the actual velocity error with the TVER command. If the SMVER value is set to zero (SMVERØ), the velocity error condition is not monitored, allowing the velocity error to accumulate without causing a fault. 144 Aries User Guide Parker Hannifin TVELA TVER (velocity mode). SMVER determines...

- Page 145 TANI: <*>-4.34 Response ANICDB CMDDIR See Also The TANI command returns the voltage level present at the ANI analog input. The value reported with the TANI command is measured in volts. Parker Hannifin TDTEMP TMTEMP TREV TVBUS DCMDZ DMTSCL IANI...

- Page 146 Range Default TDICNT: <*>1Ø Response DMTIC DMTICD See Also The TDICNT command reports the continuous current rating of the drive in amps rms. 146 Aries User Guide Parker Hannifin DMTIP TDICNT TDIMAX DMTIP TDIMAX Product Aries Product Aries Product Aries...

- Page 147 TDHRS TDMIN See Also The TDSEC command reports the milliseconds portion of the lifetime operating hours that the Aries drive has had power applied (AC Mains or Control power). Parker Hannifin TDICNT Chapter 6 Command Reference 147 Product Aries Product...

- Page 148 148 Aries User Guide Parker Hannifin E27-Bridge Hardware Fault ERROR ERRORL...

- Page 149 THALL values Ø and 7 are invalid and will fault the drive, and report E37–Bad Hall State. For a complete description on how to troubleshoot Hall sensors, especially for non-Parker Hannifin motors, see Hall Sensor Configuration/Troubleshooting on page 164. Note: For auto-configured “smart encoders”, the THALL only reports the initial hall state of the encoder when power is applied.

- Page 150 In OS 2.10, If DMTSWT equals 3, and the thermal temperature is greater than 60°C, TMTEMP reports the higher of the motor model thermistor temperature or the NTC thermistor temperature. If you are using a non-Parker motor, the TMTEMP value depends on parameters you supply for DMTRWC, DMTTCM and DMTTCW. TOUT...

- Page 151 62.5 µs. Note: When the drive is set to DMODE6 or DMODE7, the position error is the difference between the commanded position and the actual position read by Parker Hannifin (velocity mode) and DMODE4 SMPER (position mode).The TPER...

- Page 152 The Aries Resolver option reflects the Resolver feedback capability by stating ‘Aries Resolver’ in the software revision reportback instead of ‘Aries’. Updating the drive’s operating system: The operating system file is located in the “Support & Downloads” section on the Parker Hannifin Motion Online website (www.parkermotion.com). TSSPD...

- Page 153 Syntax Volts Units Range Default <*>17Ø.45 Response ERROR STATUS See Also The TVBUS command reports the DC bus voltage available from the drive in Volts. Parker Hannifin TTRQA TTRQ Chapter 6 Command Reference 153 Product Aries Product Aries Product Aries...

-

Page 154: Figure 48 Clockwise/Counter-Clockwise Rotation

(assuming CMDDIR = Ø, and that you connected the feedback device according to instructions provided in Mechanical Installation” and Installation”). 154 Aries User Guide Parker Hannifin DMVLIM IANI TVELA (velocity mode) and DMODE4 DMVLIM IANI “Chapter 2... - Page 155 In velocity mode (DMODE4), TVEL reports the commanded ±10V value from the user before any internal limits are checked. In position mode (DMODE6-7), TVEL reports the internal velocity command and is limited by DMVLIM. Parker Hannifin Product Aries (velocity mode) and...

-

Page 156: Chapter 7 Troubleshooting

Chapter 7 Troubleshooting CHAPTER SEVEN Troubleshooting IN THIS CHAPTER Troubleshooting Guidelines ... 157 LEDs ...158 RS-232/485 Communication Problems ... 159 Smart Encoders ... 163 Hall Sensor Configuration/Troubleshooting... 164... -

Page 157: Troubleshooting Guidelines

Parker Hannifin Troubleshooting Guidelines If your system is not functioning properly, try the following steps. First Troubleshooting Steps (verify LEDs) • Is the Right LED illuminated? If not, look for problems with AC power. Check the AC power source. Also check connections at the L1, L2, and mains connector, and at the C1 and C2 terminals of the control mains connector). -

Page 158: Leds⎯Drive Status Indicators

This ensures you have a backup copy of the drive configuration. To save a backup configuration file, use the Aries Support Tool. 158 Aries User Guide Parker Hannifin LED–Right What it means Green... -

Page 159: Rs-232/485 Communication Problems

Parker Hannifin Reconfigure the Drive To verify proper configuration, you may wish to reconfigure the drive. Pay particular attention to selecting proper configuration settings for the motor that you have installed, as motor configuration problems can cause a variety of errors. Download the new configuration to the drive; the changes take effect after you send the RESET command or cycle power. -

Page 160: Error Messages

In the Menu, select Status Panel. You can view the errors under Bit Status. The following is a list of Error messages and a brief corrective action: 160 Aries User Guide Parker Hannifin Resolution Select a different COM port No COM port has been specified, or the COM port is being used by other software. - Page 161 Parker Hannifin Error EØ—Motor Configuration Warning E1—Motor Configuration Error E3—Max Inductance = Ø E4—Rated Speed = Ø E5—DPOLE = Ø E6—Resistance = Ø E7—Ke = Ø E8—Continuous Current = Ø E9—Peak Current = Ø E1Ø—Continuous Current Too High E11—Torque Rating Too High for Drive E12—Peak Current Too High...

- Page 162 Fault E36—Motor Temperature Fault E37—Bad Hall State E38-Feedback Failure 162 Aries User Guide Parker Hannifin Resolution The notch filter settings caused an internal calculation error. The last valid value was used. Try different values for the notch filter parameters. (DNOTAF, DNOTAQ, DNOTBF, DNOTBQ) The lead filter setting (DNOTLD) must be greater than or equal to the lag filter setting.

-

Page 163: Smart Encoders

3. Apply power to the Aries drive. a. Send the SFB command. It should report 5. If the response is not <*>5, then check the feedback cable (if using a non-Parker cable, check that it is correctly wired). If the cable is correctly wired and connected, the problem might be the encoder. -

Page 164: Hall Sensor Configuration/Troubleshooting

Use Procedure 1 to fix this problem by changing the motor wires. Use Procedure 2 to fix this problem by changing the Hall wires. 5. The Hall wires or the encoder wires may have loose connections, causing intermittent faults. 164 Aries User Guide Parker Hannifin... -

Page 165: Figure 49 Hall Connection Diagram

Parker Hannifin 6. Noise induced on the Hall signals from routing the motor feedback cable next to high-voltage cables (for example, strapped to motor power cables). Procedure 1 Use this procedure to connect your motor wires to the Aries. 1. With the motor’s feedback cable connected to the Aries drive, randomly connect two motor power wires and slowly apply a positive voltage with respect to the third. - Page 166 Hall states that match the “Correct” column. If instead THALL reports Hall states that match the “Use SHALL1” column, enter SHALL1 and reset the drive. The Hall states should now match the “Correct” column. For more information, see Figure 50. 166 Aries User Guide Parker Hannifin...

-

Page 167: Table 51 Configuring Hall Sensors

Parker Hannifin Phase – – – – – – – – – Table 51 Configuring Hall Sensors Figure 50 illustrates the alignment of phases U, V, and W with Halls 1, 2, and 3 as viewed from the front of the shaft. The illustration assumes the following: •... -

Page 168: Appendix A Additional Specifications

Appendix A Additional Specifications APPENDIX A Additional Specifications IN THIS CHAPTER Amplifier ... 169 Feedback ... 169 Protective Circuits... 170 Cables... 173... -

Page 169: Amplifier

Parker Hannifin Amplifier Control Power: all models... 120/240 VAC Single Phase AR-01xx, AR-02xx, AR-04xx, AR-08xx, and AR-13xx ... Single Phase AC Input, Current Loop Update Rate... 62.5 μs Velocity and Position Loop... 250 μs AR-20xE and AR-30xE ... Single or Three Phase AC Input Current Loop Update Rate... -

Page 170: Protective Circuits

AR-01xx, AR-02xx, AR-04xx, AR-08xx, and AR-13xx ... 80°C (176°F) AR-20xE and AR-30xE ... 90°C (194°F) Results of Fault ... Power to motor is turned off 170 Aries User Guide Parker Hannifin Phase-to-earth short circuit Fault output is activated LED Left LED Right Yellow &... -

Page 171: Table 54 Reset Temperature Values

Parker Hannifin Resetting the fault After the internal temperature has dropped below the values shown in Table 54, you can clear the latched fault. There are two methods available: ► Cycle power to the Aries drive. –or– ► Open the Aries Support Tool. Then select Operating System Update from the menu and click Reset Drive. -

Page 172: Table 56 Led Over-Voltage Fault

Warning — Over-voltage protection monitors only the motor output terminals (DC motor bus). It does not protect against an over voltage on the AC input terminals, which can permanently damage the drive. 172 Aries User Guide Parker Hannifin Fault output is activated LED Left LED Right Yellow &... -

Page 173: Cables

Figure 51 Time until current foldback occurs Cables EMC Ready Cables Many Parker cables are EMC installation ready. If installed according to instructions provided under “A Highly-Immune, Low-Emission Installation – Meeting the Requirements of the Electromagnetic Compatibility (EMC) Directive” on page 192, these cables are designed to aid the user in gaining European Compliance, and are thus an integral part of a CE system solution. -

Page 174: Appendix B External Power-Dump Resistor Selection

Appendix B External Power-Dump Resistor Selection APPENDIX B External Power-Dump Resistor Selection IN THIS CHAPTER Simplified Resistor Selection ... 175 Calculating Resistance—Rotary Motors... 177 Resistor Specifications ... 181 Calculating Resistance—Linear Motors ... 183 Resistor Specifications ... 187... -

Page 175: External Power-Dump Resistor Selection

Table 57 contains recommended power-dump resistors for specific Aries drive and Parker Hannifin motor combinations. The recommendations are based on the calculations presented in the section titled “Calculating Resistance—Rotary Motors”. These recommendations assume a worst-case load-to-rotor inertia ratio of 10 to 1, maximum duty cycle and maximum deceleration from maximum velocity for that specific motor/drive pairing. -

Page 176: Table 57 Simplified Selection Of External Power-Dump Resistor

3. Minimum resistance allowed for AR-13 is 22 Ohms, therefore the maximum deceleration rate and/or duty cycle may need to be reduced. 4. Isotek resistor or equivalent Table 57 Simplified Selection of External Power-Dump Resistor 176 Aries User Guide Parker Hannifin Resistor Resistor Rating rating... -

Page 177: Calculating Resistance-Rotary Motors

Parker Hannifin Calculating Resistance—Rotary Motors Because there are different types of motion profiles and application specific conditions, you may need to modify the results to suit your particular application. To keep it simple, the formulas assume a trapezoidal move profile, in which the deceleration event is a single constant deceleration to zero (0) velocity. - Page 178 120 VAC * Fortunately, for a given drive the capacitance and voltages are fixed. Table 58 provides the needed information and results from the above calculation. 178 Aries User Guide Parker Hannifin − TRIP = 170 VDC) ; for...

-

Page 179: Table 58 Drive Capacitor Absorption

Parker Hannifin Capacitance Drive (uF) AR-01xx AR-02xx AR-04xx AR-08xx 1100 AR-13xx 1590 AR-20xE 2240 AR-30xE 2240 When the voltage drops below 385 VDC, the Aries drive stops dissipating power through the power dump resistor. Table 58 Drive Capacitor Absorption Energy Dissipated in Motor Winding Resistance Some energy is dissipated in the motor windings. - Page 180 (Joules) energy dissipated in the motor windings (Joules) – copper losses energy dissipated by the load (Joules) – load losses 180 Aries User Guide Parker Hannifin ω ⋅ ) are not easily determined, you can −...

-

Page 181: Resistor Specifications⎯Rotary Motors

Parker Hannifin Resistor Specifications⎯Rotary Motors Having determined the amount of energy to dump (E calculate the resistor specifications. • Maximum resistance • Peak dissipation • Average dissipation Maximum Resistance This calculation determines the maximum value of resistance needed for the external power-dump resistor. - Page 182 200 °C. Keep the resistor away from thermally sensitive components, such as cables or plastic hardware. Proper installation may require the use of thermal compound and proper thermal connection to a heat absorbing metal surface. 182 Aries User Guide Parker Hannifin PEAK ⋅ PEAK ) must...

-

Page 183: Calculating Resistance-Linear Motors

Parker Hannifin Calculating Resistance—Linear Motors Because there are different types of motion profiles and application specific conditions, you may need to modify the results to suit your particular application. To keep it simple, the formulas assume a trapezoidal move profile, in which the deceleration event is a single constant deceleration to zero (0) velocity. - Page 184 120 VAC * Fortunately, for a given drive the capacitance and voltages are fixed. Table 59 on page 185 provides the needed information and results from the above calculation. 184 Aries User Guide Parker Hannifin − = 170 VDC)

-

Page 185: Table 59 Drive Capacitor Absorption

Parker Hannifin Capacitance Drive (uF) AR-01xx AR-02xx AR-04xx AR-08xx 1100 AR-13xx 1590 AR-20xE 2240 AR-30xE 2240 When the voltage drops below 385 VDC, the Aries drive stops dissipating power through the power dump resistor. Table 59 Drive Capacitor Absorption Energy Dissipated in Motor Winding Resistance Some energy is dissipated in the motor windings. - Page 186 (Joules) EW = energy dissipated in the motor windings (Joules) – copper losses EL = energy dissipated by the load (Joules) – load losses 186 Aries User Guide Parker Hannifin ⋅ ⋅ − − −...

-

Page 187: Resistor Specifications⎯Linear Motors

Parker Hannifin Resistor Specifications⎯Linear Motors Having determined the amount of energy to dump (ER), you can then calculate the resistor specifications. • Maximum resistance • Peak dissipation • Average dissipation Maximum Resistance This calculation determines the maximum value of resistance needed for the external power-dump resistor. - Page 188 200 °C. Keep the resistor away from thermally sensitive components, such as cables or plastic hardware. Proper installation may require the use of thermal compound and proper thermal connection to a heat absorbing metal surface. 188 Aries User Guide Parker Hannifin ⋅...

-

Page 189: Appendix C Regulatory Compliance-Ul And Ce

Appendix C Regulatory Compliance–UL and CE APPENDIX C Regulatory Compliance UL and CE IN THIS CHAPTER System Installation Overview... 190 General Safety Considerations... 190 General EMC Considerations... 190 Installing the Aries Drive ... 191 Regulatory Agencies... 200 Standards of Compliance ... 200... -

Page 190: System Installation Overview

It should be stressed that although these recommendations are based on the expertise acquired during the design and development of the Aries products, and on tests carried out on similar products, it is impossible for Parker to guarantee compliance of any particular installation. This will be strongly influenced by the physical and electrical details of the installation and the performance of other system components. -

Page 191: Installing The Aries Drive

Parker Hannifin Installing the Aries Drive Only qualified, skilled electrical technicians familiar with local safety requirements should install this product. For service, the drive must be returned to an authorized service center. There are no user serviceable parts inside the chassis. In certain circumstances, opening the cover may void the product warranty. - Page 192 RF bonded to the enclosure entrance point using an R-Clamp, bulkhead clamshell clamp, or other 360° bonding technique. This ensures that no stray noise will enter or exit the enclosure. The following drawing illustrates 360° bonding techniques. 192 Aries User Guide Parker Hannifin...

-

Page 193: Figure 52 360° Bonding Techniques

Parker Hannifin Figure 52 360° Bonding Techniques All braid termination connections must remain secure. For small diameter cables, it may be necessary to fold back the braid to increase the effective diameter of the cable so that R-Clamps are secure. -

Page 194: Table 60 Control Power Filter Selection

Control power is 1 Amp, maximum. Any of the following filters works with all models of the drive. Filter 6EP1 (160937-5) 10EP1 (160937-7) FN2070-10/06 1. Available from Parker: Table 60 Control Power Filter Selection Mains Motor Power Filter Continuous Current... - Page 195 The selected cable must have a temperature rating which is adequate for the expected operating temperature of the motor case. All cables must maintain high integrity 360 degree shielding. Parker CE cables are fully shielded and provide the required screening. When you install limit switches and other inputs/outputs, you must observe these noise immunity procedures and practices.

-

Page 196: Table 62 Enclosure Mounting Clamps

Some installations may require that you take additional EMC measures. To further increase product immunity and reduce product emissions, you may add clip-on ferrite absorbers to all cables. Parker recommends ferrites with at least 200 ohm impedance at 100 MHz, such as the... -

Page 197: Figure 53 Typical Lvd/Emc Installation, Ar-02Xx To Ar-13Xx

Parker Hannifin Panel Installation, AR-02xx to AR-13xx Figure 53 Typical LVD/EMC Installation, AR-02xx to AR-13xx Warning — This product has been developed for industrial environments. Due to exposed high voltage terminals, this product must not be accessible to users while under normal operation. -

Page 198: Figure 54 Typical Lvd/Emc Installation, Ar-20Xe & Ar-30Xe

Figure 54 Typical LVD/EMC Installation, AR-20xE & AR-30xE Warning — This product has been developed for industrial environments. Due to exposed high voltage terminals, this product must not be accessible to users while under normal operation. 198 Aries User Guide Parker Hannifin... -

Page 199: Figure 55 Panel Layout Dimensions For The Aries Drive

Parker Hannifin Panel Mounting The mounting clearance requirements are the same for all Aries drive models. They are shown in Figure 55. Figure 55 Panel Layout Dimensions for the Aries Drive Appendix C Regulatory Compliance – UL and CE 199... -

Page 200: Regulatory Agencies

Table 63 Regulatory Agencies Standards of Compliance CE for LVD CE for EMC 200 Aries User Guide Parker Hannifin Additional Steps User Must Take Mains fuses Mains fuses; earth connection for drive and motor (if applicable), proper installation Varistors, mains filter, EMC cabling, EMC ready motor,... -

Page 201: Appendix D Servo Tuning Flow Diagram

Appendix D Servo Tuning Flow Diagram APPENDIX D Servo Tuning Flow Diagram IN THIS CHAPTER Servo Tuning Flow Diagram ... 202... -

Page 202: Servo Tuning Flow Diagram

Parker Hannifin Servo Tuning Flow Diagram Figure 56 Servo Tuning Flow Diagram 202 Aries User Guide... -

Page 203: Appendix E Vm26 Expansion Module

Appendix E VM26 Expansion Module A P P E N D I X E VM26 Expansion Module IN THIS CHAPTER Overview ...204... -

Page 204: Overview

Parker Hannifin Overview The VM26 expansion module provides screw-terminal connections for the Drive I/O connectors on the Aries drive. The VM26 comes with a 2-foot cable (609.6 mm) that provides easy connection between the VM26 module and the drive’s 26-pin I/O connectors. The VM26 expansion module is ordered separately (part number “VM26-PM”). -

Page 205: Index

(TANI) ...145 wiring ...69 auto-configure, smart encoder ... 33, 163 autorun... 72, 104 binary value identifier (b)...94 brake brake relay ...50 non-Parker motors ...52 output delay (OUTBD) ...137 Parker motors ...51 bus voltage, report (TVBUS)...153 cables EMC ...173 non-EMC...173 routing ... - Page 206 Incoming Pulse Scaling (DMPSCL) ...104 inductance motor max (DMTIND)...107 motor min (DMTINF) ...108 input resolution, analog ...169 206 Aries User Guide Parker Hannifin inrush current ... 42 installation LVD/EMC...197, 198 installation category ... 22 installation, overview...35, 36, 37 jumper wires, pre-installed ... 35, 37 lead/lag filters lag ...

- Page 207 (ERES) ...128 resolver ...169 return to factory settings (RFS) ...139 revision level, operating system (TREV) ...152 revision of this manual...12, 13, 14, 15 rotor inertia, motor ...109 Parker Hannifin RS-232 communications... 75 dongle ... 77 wiring ... 74 RS-232/485 connector ...

- Page 208 (TVER) ...155 continuous current rating (TDICNT)...146 d quadrature current (TCI) ...149 208 Aries User Guide Parker Hannifin drive temperature (TDTEMP) ... 148 error log (TERRLG) ... 148 hall sensor values (THALL) ... 149 maximum current rating (TDIMAX) ... 147 motor temperature (TMTEMP) ...

Need help?

Do you have a question about the 88-021610-01G and is the answer not in the manual?

Questions and answers