Summary of Contents for Berkel BG+30T

- Page 1 BG+30T SELF - FEEDING MINCER AUTHORISED DEALER USE AND MAINTENANCE MANUAL UM - CODE S31 - REV 0.0 UM - CODE S31 - REV 0.0...

- Page 2 UM - CODE S31 - REV 0.0 UM - CODE S31 - REV 0.0...

- Page 3 UM - CODE S31 - REV 0.0 UM - CODE S31 - REV 0.0...

-

Page 4: Table Of Contents

Index - Check protections and safety devices are in place and have not been damaged during transport. With the machine working 1. Delivery and Warranty Terms - Check protections and safety devices are efficient; the machine must stop when the Foreword protection grille is opened (raised);... - Page 5 5. Starting and Stopping Checking Power Supply Connection Checking efficiency and fitting of Safety Devices and Protections Starting the machine Stopping the machine 7 Maintenance Reversing rotation 7.1 - Provisions 6. Using the Machine Any machine maintenance or cleaning operations must be performed only with the Provisions machine disconnected from the power supply.

- Page 6 provided with long life grease which does not require changing. 7.8 - Scrapping As the majority of the machine components are manufactured from stainless steel they are not subject to specific waste treatment management. - disconnect the general differential power switch and unwire the plug from the cable. Proceed with machine disassembly.

-

Page 7: Delivery And Warranty Terms 7

meat, a grinder plate "2", a knife "3" coupled to plate "4", a second knife "5" with a 1 Delivery and Warranty Terms holed plate "6". B Assembly "B" , (half unger), a spacer "7" replaces knife “5” and plate “6” 1.1 - Foreword C Normal assembly "A"... -

Page 8: Machine Description

model; - non-observance of the instructions and provisions provided in this manual. Reversing rotation Press pushbutton “3” to reverse paddle rotation. To stop press pushbutton “2” Stop. To reverse mincing assembly rotation press pushbutton “6” on the mincer pushbutton 1.4 - Machine description panel and maintain pressed until the mincer assembly starts rotating. -

Page 9: Machine Data And Specifications

the Stop button “2“ Fig. 5.1.1. The machine should stop immediately. machine from the power supply: electrical hazard—electrocution - Starting the machine - DO NOT process quantities of meat that cannot be contained in the hopper. Connect the power cable to mains power supply, to - DO NOT wear clothing which does not conform to safety standards. -

Page 10: Safety Protections And Devices

3.3.3 - Moving the machine ATTENTION! Handle the machine carefully and with extreme ATTENTION, avoiding that it acciden- tally falls, which could seriously damage it. Due to the solid weight of the machine, at CAUTION! Do not touch electrical components with the machine connected to the least two people are required for moving it. -

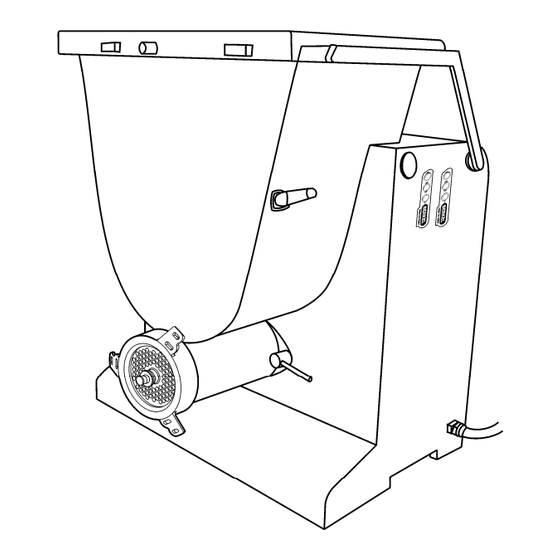

Page 11: Main Parts

Your machine has been tested at our factory to ensure efficient and correct operation and Ingombro (mm) Technical Specifications settings. BG+30T 2.1 - Main parts 3.2 - Delivery and Handling of the machine For reading purposes and better understanding All the equipment delivered is thoroughly checked of the machine, the main machine components before delivery to the forwarding agent or carrier. -

Page 12: Noise Level

Fig. 2.5.1 2.4 - Noise level The noise level of this machine results to be less than 70 dBA. Upon request, the manufacturer can provide a copy of the noise level test. Wiring Diagrams 2.5 - 2.5.1 - Three-phase wiring diagram for 400 V - Three-phase wiring diagram connected to 230 V UM - CODE S31 - REV 0.0 UM - CODE S31 - REV 0.0...

Need help?

Do you have a question about the BG+30T and is the answer not in the manual?

Questions and answers