Summary of Contents for FujiFilm FRONTIER 390

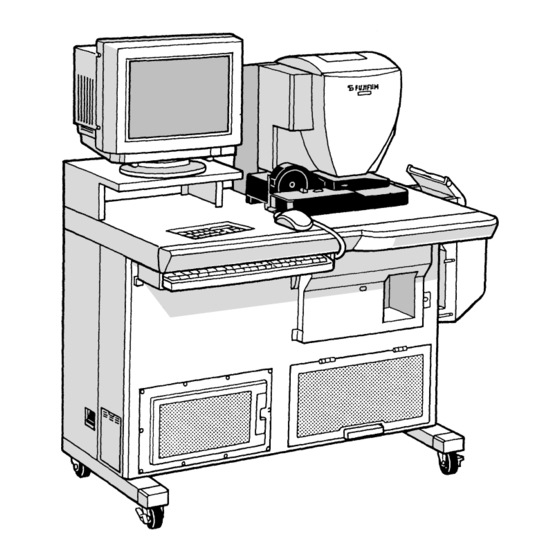

- Page 1 INSTRUCTION MANUAL DIGITAL MINILAB FRONTIER 390 SCANNER/IMAGE PROCESSOR SP2500 LASER PRINTER/PAPER PROCESSOR LP2500P Applied Operating Instructions LP2500P SP2500 Second Edition System Disk Ver.4.0 PP3-B166E2...

- Page 2 INTRODUCTION • This Instruction Manual — Applied Operating Instructions — explains the procedures for operating and maintaining the Fujifilm Digital Minilab FRONTIER 390 SP2500 and LP2500P, as well as precautions for use. • To ensure proper use and optimum performance of the SP2500 and LP2500P Digital Minilab and optional 135ANL (NF2500AG), read this manual thoroughly.

- Page 3 OPERATIONAL SAFETY AND USE CONDITIONS ADDITIONAL OPERATING INSTRUCTIONS SETUP AND MAINTENANCE DAILY MAINTENANCE PERIODICAL MAINTENANCE AND INSPECTION ERROR MESSAGES AND ACTION TO TAKE PAPER JAMMING NEGATIVE JAMMING IN 135ANL (OPTIONAL) STREAK MARKS ON PRINTS AND COUNTERMEASURES LIST OF CONSUMABLES INDEX...

-

Page 4: Table Of Contents

CONTENTS OPERATIONAL SAFETY AND USE CONDITIONS Safety .............................. 6 1.1.1 Basic Operating Precautions .................... 6 1.1.2 Caution regarding Electric Shock ..................6 Laser Radiation Safety ......................7 1.2.1 Laser Radiation Safety ...................... 7 1.2.2 Laser Warning Label ......................7 Safety Indication ........................ - Page 5 2.16 Paper Feed ..........................39 2.17 Custom Setting Selection ....................40 2.18 Forced Printing ......................... 43 SETUP AND MAINTENANCE “Setup and Maintenance” Menu Screen ............... 46 Production Information ......................47 Paper Condition Setup ......................49 Processing Solution Temperature Check ..............53 Control Strip Processing .....................

- Page 6 Cutter Loop Sensor Cleaning .................... 95 5.10 Replacing the Circulation Filters ..................96 5.11 Washing the Processing Racks ..................98 5.12 Cleaning the Film Cooling Air Compressor Filter ..........104 5.13 Cleaning the Light Source Optical Filters ..............106 5.14 Cleaning the Densitometer White Board ..............

-

Page 7: Operational Safety And Use Conditions

OPERATIONAL SAFETY AND USE CONDITIONS Before using the equipment, carefully read and thoroughly understand the precautions set forth in this section. The safety precautions are classified into WARNING and CAUTION categories. Supplementary operating instructions are given under IMPORTANT and NOTE categories. -

Page 8: Safety

• Use only Fujifilm-recommended replacement parts. IMPORTANT If parts other than those recommended by Fujifilm are used, the warranty will be voided. z Do not operate the machine with cover open/close sensors forced ON while the covers are open. These sensors serve as safety switches. If they are forced ON, the system mistakenly assumes that the open covers are “closed”... -

Page 9: Laser Radiation Safety

Laser Radiation Safety Laser Radiation Safety 1.2.1 This product is a Class 1 laser device for which biological hazards have not been established. Follow all warnings on the device label and in the manual. Laser Radiation Specification Class Laser Semi-conductor Solid-state Laser Wavelength 685 nm... -

Page 10: Safety Indication

Safety Indication On the machine, each location shown below is provided with a caution label concerning safety. When operating or maintaining the machine, take care to avoid burns or other personal injury. Caution Label Locations on Scanner/Image Processor 1.3.1 EZ1257... - Page 11 GD1550-1...

-

Page 12: Caution Label Locations On Printer/Paper Processor

Caution Label Locations on Printer/Paper Processor 1.3.2 GD1559 10 10... - Page 13 GD1560...

-

Page 14: Laser Caution Label Locations On Printer

Laser Caution Label Locations on Printer 1.3.3 CAUTION Visible laser radiation when open DO NOT STARE INTO BEAM CAUTION Visible laser radiation when open DO NOT STARE INTO BEAM GD1618 12 12... -

Page 15: Room Conditions

Room Conditions • Temperature: 15° to 30°C (59° to 86°F) Ambient room temperatures above 30°C (86°F) or below 15°C (59°F) will destabilize processing and replenisher solution temperatures to the detriment of processing performance. Pay special attention to room temperatures in wintertime and maintain solution temperatures within designated ranges. -

Page 16: Crt Monitor And Main Control Unit Handling Precautions

· Do not modify the data structure or data in the hard disk. · Do not open the main control unit without the consent of a Fujifilm service representative. · Do not add to or modify expansion cards or RAM cards. -

Page 17: Processing Chemical (Cp-48S) Handling

Processing Chemical (CP-48S) Handling Handling Precautions 1.6.1 Processing chemicals should be handled in accordance with the precautions indicated on the boxes and labels of the respective chemicals. Protective Gloves Safety Goggles Always wear protective gloves and safety goggles when handling chemicals with the above indications. -

Page 18: Certification And Identification Labels

Certification and Identification Labels Certification and Identification Label Locations 1.7.1 GD1436-1 ELECTRICAL RATING 200/210/220/230/240V~ 200/210/220/230/240V~ 200/210/220/230/240V~ 32/ 32/ 28/ 29/ 30A 32/ 32/ 28/ 29/ 30A 32/ 32/ 28/ 29/ 30A 50/ 60Hz 346/365/380/400/415V3~N 200/210/220/230/240V3~ 15/ 15/ 12/ 12/ 12A 23/ 24/ 20/ 21/ 21A 50/60Hz 346/365/380/400/415V3~N... - Page 19 GD1550-2...

-

Page 20: Additional Operating Instructions

ADDITIONAL OPERATING INSTRUCTIONS This section provides additional operating instructions not described in “Basic Operating Instructions”. Manual Start-up ................20 IX240 Strip Film Printing ............21 Back Printing Selection and Custom Setup Back Printing Display ... 22 Front Printing ................25 2.4.1 Date/Time Printing ............... -

Page 21: Manual Start-Up

Manual Start-up q Press the start switch. Start Switch EZ1192 • “Starting up the system” message appears. • The “Main Menu” screen appears after approximately 10 minutes. It normally takes about one hour for the machine to warm up at the start of operation. For this reason, it is recommended that the weekly timer be used if the next start time is known in advance (see the “Basic Operating Instructions”). -

Page 22: Ix240 Strip Film Printing

IX240 Strip Film Printing Cut IX240 film cannot be fed. q Depress the inner end of the strip film Strip Film Guide guide. EZ1165 w Insert the strip film into the strip film guide Notch with its leader notch facing the opposite side. -

Page 23: Back Printing Selection And Custom Setup Back Printing Display

Back Printing Selection and Custom Setup Back Printing Display Select back printing pattern on the “135/120 Back Printing” or “IX240 Back Printing” screen. The custom setting numbers and back printing can be confirmed on the “Back Print of Custom Setting [Display]” screen. q On the printing screen, select “Printing (2)”... - Page 24 t Custom Setup Back Print Display: • The custom setting numbers and back printing table appears. y Click [OK]. • The dialog box disappears. Back Printing Format Film Size User ID + Correction Data + Sort No. ABC IARRWSSKK CMYDDD SORT + Double-character Frame No.

- Page 25 <Ex. of Correction Data> NA 010 ANA 0 NNN 0 XXXX Input Mode Sort No. Code Mode Density Correction Color Negative CMY Correction Color Reversal External Input Graduation Level Black & White Code Level Others Standard Automatic Correction Condition All Hard Code Level Hyper Tone...

-

Page 26: Front Printing

Front Printing Follow this procedure to select front printing for IX240-size film. Print date/time or title data if recorded in the IX information on the film by the camera or another tool. 2.4.1 Date/Time Printing q On the printing screen, select “Printing (2)” and “Front Printing (3)”... -

Page 27: Center Cropping

Center Cropping Follow this procedure to perform center cropping with a reduction ratio of up to 98% of the standard magnification. Magnification up to 42 times is possible. q On the printing screen, select “Printing (2)” and “Cropping (7)” on the menu bar. •... -

Page 28: Ix240-Size Reversal Film Print

IX240-size Reversal Film Print Follow this procedure to print IX240-size reversal film using the NC240AG auto film carrier. q Install the auto film carrier NC240AG. w On the printing screen, select “Scanner Op. (3)” and “Original Select (1)” on the menu bar. -

Page 29: Black & White Negative Printing

Black & White Negative Printing Follow this procedure to print 135-size and IX240-size black & white negatives using the NC135AG and NC240AG auto film carriers. q On the printing screen, select “Scanner Op. (3)” and “Original Select (1)” on the menu bar. -

Page 30: 1-Frame Image Display Printing

1-Frame Image Display Printing Follow this procedure to change the image frame mode on the printing screen from high-speed or six-frame mode to one-frame mode. q Press the [Shift] and [F4] keys at the same time. Shift • Pressing these keys selects “High-speed”, “6- frame”... - Page 31 • The color image appears in the frame. During the 1-frame screen, the frame return and feeding keys can be used. Preceding frame can be returned to printing. : Goes back 1 frame. : Goes forward 1 frame. r Proceed with printing using the same procedure as for normal printing (see “Basic Operating Instructions”).

-

Page 32: Sort Data Display/Setting

Sort Data Display/Setting Follow this procedure to display the sort data of the last order and change the sort number. q On the printing screen, select “Scanner Op. (3)” and “Sort Data Disp/Set(5)” on the menu bar. • The “Sort Data Display/Setting” dialog box appears. -

Page 33: Unexposed Frame-Detection Level Setup

2.10 Unexposed Frame-Detection Level Setup The detection level for unexposed frames can be selected. The unexposed frames are either printed in the index print or not, depending on the detection level. q Select “Scanner Op. (3)” and “Scanner Mode Set (6)” on the menu bar. •... -

Page 34: Tone Adjustment

2.11 Tone Adjustment Follow this procedure to select the tone adjustment and to turn the hypertone function “ON” or “OFF”. q Insert the film into the auto film carrier. w Press the [F6] key. • The “Tone Adjustment” dialog box appears. Or select “Image Correct (4)”... -

Page 35: Selecting Sharpness Level

2.12 Selecting Sharpness Level Follow this procedure to select the sharpness level. q Insert the film into the auto film carrier. w Press the [F5] key. • The “Sharpness” dialog box appears. Or select “Image Correct (4)” and “Sharpness (2)” on the menu bar. -

Page 36: Monotone Printing

2.13 Monotone Printing Monotone prints can be produced from either monotone or color films. 2.13.1 Making Monotone Prints from Monotone Film (for Color Development) q Insert the monotone film into the auto film carrier. • The scanner reads the DX code of the film and selects the correct film channel automatically if the film is set up in a special film channel. -

Page 37: Making Monotone Prints From Color Film

Making Monotone Prints from Color Film 2.13.2 q Insert the color film into the auto film carrier. w Select the frame to be printed with monotone correction. e Select “Image Correct (4)” and “Monotone Correct (3)” on the menu bar. •... -

Page 38: Rp-Tone Correction

2.14 RP-tone Correction RP-tone (Reversal Print-tone) prints can be made from a negative film by using the RP-tone correction mode. q Insert the film into the auto film carrier. w Proceed with printing until the frame to be printed with RP-tone correction appears. e Select “Image Correct (4)”... -

Page 39: Auto Correction On/Off

2.15 Auto Correction ON/OFF Sometimes auto color correction does not function for color-biased films or films taken under different kinds of light sources (fluorescent light, tungsten light, etc.). If this happens, select “OFF” for “Auto Correction” and correct the color of the image on the printing screen. -

Page 40: Paper Feed

2.16 Paper Feed This function feeds a single print length of unexposed paper. If accidental fogging has occurred on the paper, use this “paper feed” function to advance the fogged paper by the required number of print lengths. q On the printing screen, press [Alt] and [F1] keys at the same time. -

Page 41: Custom Setting Selection

2.17 Custom Setting Selection The prescribed finish condition can be selected by following the sequence below. Printing conditions are memorized at every auto film carrier. On the multi-film carrier MFC10Y, printing conditions are memorized at every mask. q Select “Image Correct (4)” and “Custom Setting No. - Page 42 • The “Key Step Width/BL-SL” panel appears. e Click the “Sharpness/Grain Control” tab to view the setting. • The “Sharpness/Grain Control” panel appears. r Click the “High-def/Density Correct” tab to view the setting. • The “High-def/Density Correct” panel appears. t Click [OK]. •...

- Page 43 • The selected custom setting number is displayed. t Insert the film into the carrier and proceed with printing. • Prints are made with the custom setup condition selected. y Select the “Image Correct (4)” and “Custom Setting No. Select (6)” on the menu bar. •...

-

Page 44: Forced Printing

2.18 Forced Printing The image can be printed on paper that does not match the selected size. For example, 89.0mm × 127mm size print can be printed on 127mm width paper, but the print (127.0mm × 127mm) has 19mm length white blanks on both sides. q Select the print size (see “Basic Operating Instructions”). -

Page 45: Setup And Maintenance

SETUP AND MAINTENANCE “Setup and Maintenance” Menu Screen ...... 46 Production Information ............47 Paper Condition Setup ............49 Processing Solution Temperature Check ....53 Control Strip Processing ............54 3.5.1 Control Strip Preparation ............. 54 3.5.2 Control Strip Processing ............56 3.5.3 Control Strip Storage and Handling Precautions .... -

Page 46: Setup And Maintenance" Menu Screen

“Setup and Maintenance” Menu Screen Open the “Setup and Maintenance” menu screen by doing the procedure below. q On the “Main Menu”, select “4. Setup and Maintenance” and click [OK]. • The "Login" dialog box appears. w Click [OK]. • The menu for “4 Setup and Maintenance” appears. -

Page 47: Production Information

Production Information q Select “1) System Operation Setup and Check”. (See section 3.1). w Select “1 Production Information 1”. e Click [START]. • The “[411] Production Information 1” screen appears. The information can be changed by selecting “Negative”, “Reversal”, “Digital Image” or “All” in the “Input Type”... - Page 48 t Click [OK]. • Operation returns to the “4 Setup and Maintenance” screen. y Select “END [1] on the menu bar. • Operation returns to the “Main Menu” screen.

-

Page 49: Paper Condition Setup

Paper Condition Setup When loading new paper, follow the procedure below to set the new paper condition. q Install the paper magazine for which Magazine Lock Lever conditions are to be set. GD1304 w Move the large-size tray to its use position. Large-size Tray GD1378 e Select “2) Print Condition Setup and... - Page 50 y Click [Print]. • After about 5 minutes, a condition setup print is fed out to the large-size tray. u After the condition setup print has come out, press the [Dens Measure] button. i Adjust the guide of the densitometer Densitometer Guide according to the width of the condition...

- Page 51 o Insert the condition setup print into the Densitometer densitometer. Condition Setup Print EZ635 !0 Press the [START] button on the densitometer. [START] Button EZ636 • The measurement of density is automatically started and the measurement result is displayed. !1 Click [OK]. •...

- Page 52 !2 Click [Cancel]. • The “4 Setup and Maintenance” screen appears. !3 Select “END [1]” on the menu bar. • Control returns to the “Main Menu”.

-

Page 53: Processing Solution Temperature Check

Processing Solution Temperature Check q Open the “2) Print Condition Setup and Check” menu. (See section 3.1) w Select “2 Processor Temperature Check”. e Click [START]. • The “[422] Processor Temperature Check” screen appears. r Click [OK]. • Operation returns to the “4 Setup and Maintenance”... -

Page 54: Control Strip Processing

Control Strip Processing The processing solution performance should be evaluated by processing a control strip, measuring the processed strip densities, and comparing them with the reference strip densities. Control Strip Preparation 3.5.1 q Take the control strip package out of the freezer and let it sit for about one hour to bring it to room temperature. - Page 55 y Place the control strip holder on the leader Control Strip Holder splice stand. Leader Splice Stand GD1310 u Place the control strip leader so that its Control Strip Control Strip Leader trailing end (without vinyl guide) contacts the end of the control strip and join the ends with splicing tape for negative film processing.

-

Page 56: Control Strip Processing

Control Strip Processing 3.5.2 Perform steps 3 to 11 in “Pre-operation Check”. q Open the “2) Print Condition Setup and Check” menu. (See section 3.1.) w Select “3 Control Strip Processing”, and then click [START]. • The “[423] Control Strip Processing” screen appears. - Page 57 r Remove the processor cover. t Place the control strip holder on the Control Strip Holder crossover racks by aligning its first rib with the grooves in the No.2 crossover rack. Grooves in No.2 Corssover Rack GD1313 y Insert the end of the control strip leader into Control Strip Leader the No.

- Page 58 i Reinstall the processor cover. Processor Cover GD1306 o Move the large-size tray to its use position. Large-size Tray !0 Press the [ENTER] key on the operating panel on the printer twice. • The processor starts and control strip processing begins. •...

-

Page 59: Control Strip Storage And Handling Precautions

!3 Click [Cancel]. • Control returns to the “4 Setup and Maintenance” screen. For the daily morning pre-operation check, operation returns to the “Printing Condition Upkeep” screen. !4 Select “END [1]” on the menu bar. • Control returns to the “Main Menu” screen. Control Strip Storage and Handling Precautions 3.5.3 REFERENCE:... -

Page 60: Scanning Lamp/Reflector Replacement

Scanning Lamp/Reflector Replacement If the scanning lamp burns out or output deteriorates, replace it as follows. Wait until the scanning lamp cools down. IMPORTANT To prevent fingerprints, always wear clean gloves when handling the lamp (bulb) and reflector. q Open the “3) Scanner Adjustment/ Maintenance”... - Page 61 • After about five minutes, the screen shown at the left appears. t Release the latch and open the light source section cover. Latch Light Source Section Cover EZ870 y Disconnect the safety thermostat connector Safety Thermostat Connector Lock and lamp connector by releasing the locks. Lock Lamp Connector GD1421...

- Page 62 u Remove the two screws securing the lamp Lamp Unit unit. Screws EZ873 i Hold the bottom of the lamp unit, shift the Lamp Unit unit to the front and remove it. EZ874 o Remove the first IR filter bracket by First IR Filter Bracket loosening the screw.

- Page 63 !3 Push the reflector against the three Stoppers stoppers, and tighten the screw to secure the retaining plate. Retaining Plate Screw EZ589 !4 Install a new lamp. IMPORTANT To prevent fingerprints, always wear clean gloves when handling the lamp. EZ581 !5 Reinstall the first IR filter bracket while aligning its tang with the slot and tighten Slot...

- Page 64 !6 Install the lamp unit by engaging its Pins notches with the two pins on the filter unit. Notches Lamp Unit EZ875 !7 Hang the lamp unit as shown, and tighten the two screws. Screws EZ876 !8 Connect the two connectors Safety Thermostat Connector Lamp Connector EZ877...

- Page 65 !9 Secure the light source section cover with Latch the latch. Light Source Secton Cover EZ878 @0 Click [OK]. • The machine initializes the scanning lamp, and updates the replacement date. Operation returns to the “4 Setup and Maintenance” menu. @1 Perform: - Lamp Position Adjustment (see section 3.7).

-

Page 66: Scanning Lamp Position Adjustment

Scanning Lamp Position Adjustment q Install the auto film carrier NC135AG. w Open the menu for “3) Scanner Adjustment/Maintenance”. (See section 3.1.) e Select “2 Lamp Position Adjustment”. r Click [START]. • The “[432] Lamp Position Adjustment” screen appears. t Turn the right side adjusting screw first and Front Adjusting Screw Hexagonal Wrench then the front adjusting screw using the 3... - Page 67 • Control returns to the “4 Setup and Maintenance” menu. u Perform: - 135 Light Source Aperture Table (see section 3.8). - 120 Light Source Aperture Table (If 120- size films are printed with the MFC10Y multi-film carrier.) - Scanner Correction and Upkeep Printing of the Pre-operational Check (see “Basic Operating Instructions”).

-

Page 68: Light Source Aperture Table

135 Light Source Aperture Table q Install the 135 mirror box and auto film carrier NC135AG or NC240AG. w Open the menu for “3) Scanner Adjustment/Maintenance”. (See section 3.1.) e Select “3 135 Light Source Aperture Table”. r Click [START]. •... -

Page 69: 135Anl (Optional) Negative Catcher Section Cleaning

135ANL (Optional) Negative Catcher Section Cleaning q Open the menu for “4) Carrier Adjustment/ Maintenance”. (See section 3.1.) w Select “6 135ANL Negative Catcher Section Cleaning”. • The “[446] 135ANL Negative Catcher Section Cleaning” screen appears. e Remove the auto film carrier NC135AG. Auto Film Carrier NC135AG GD142 r Insert the cleaning tape into the negative... - Page 70 y Hold the cleaning tape until the feed rollers stop. u Click [End]. • Control returns to the “4 Setup and Maintenance” menu. i Click “End [1]” on the menu bar. • Control returns to the “Main Menu” screen.

-

Page 71: Replenisher Pump Output Measurement

3.10 Replenisher Pump Output Measurement Reduced replenisher pump output may result in improper processing and a drop in level of solution in the processing tank. Processing solutions may irritate the eyes and skin. When handling processing solutions, wear protective goggles, a rubber apron, rubber gloves, rubber boots and other protective gear as appropriate to prevent any solution from coming in contact with the body. - Page 72 t Click [Start] for the “PS-R” box. • The alarm beeps intermittently for 10 seconds. Click [Cancel] to stop the operation. y Before the pump starts discharging, PS-R Replenisher Nozzle disconnect the PS-R replenisher nozzle and insert it into the measuring cylinder. •...

- Page 73 !2 Click [OK]. • Operation returns to the “4 Setup and Maintenance” screen. !3 Select “END [1]” on the menu bar. • Control returns to the “Main Menu” screen. !4 Reinstall the sub-tank cover. !5 Clean the measuring cylinder.

-

Page 74: Daily Maintenance

DAILY MAINTENANCE This section describes daily maintenance operations, replacement of consumables, and emergency power OFF procedures. Ink Ribbon Replacement ............76 Turning Power OFF in an Emergency ......80 4.2.1 Turning Power OFF in an Emergency (Mechanical/Software Abnormality) ........80 4.2.2 Manual Shut-off of Scanner Power ........ -

Page 75: Ink Ribbon Replacement

Ink Ribbon Replacement When the printing on the back of the prints becomes faint, replace the ink ribbon cassette as follows. q If exposed paper remains in the reservoir, perform “All Process”. (See “Basic Operating Instructions”.) w Press the [REW] key twice. •... - Page 76 t Loosen the screw and shift the back Screw printing unit to the right. Back Printing Unit GD1319 y Press the lock and open the ink ribbon Lock cassette retaining plate. u Remove the ink ribbon cassette assembly. Ink Ribbon Cassette Assembly Retaining Plate GD1320...

- Page 77 !0 Fit the drive coupling and bracket to a new New Ink Ribbon Cassette ribbon cassette. Bracket Drive Coupling EZ668 Front Ink Ribbon !1 Install the front ink ribbon cassette onto the Bracket Cassette bracket, with the drive coupling aligned with the groove.

- Page 78 !5 Close the retaining plate. Retaining Plate GD1322 !6 Shift the back printing unit to the left and Back Printing Unit tighten the screw. Screw GD1323 !7 Close the printer left door. Printer Left Door !8 Turn the knob clockwise, close the printer right door and then turn the knob counterclockwise.

-

Page 79: Turning Power Off In An Emergency

Turning Power OFF in an Emergency Turning Power OFF in an Emergency (Mechanical/Software Abnormality) 4.2.1 When operation freezes, try removing and reinstalling the film carrier. If this does not solve the problem, follow the steps described below to shut down the system. q Click the emergency stop switch in the upper right of the screen with the left mouse button. -

Page 80: Manual Shut-Off Of Scanner Power

Manual Shut-off of Scanner Power 4.2.2 If a strange odor or unusual sound emanates, abnormal heat is generated or smoke appears from the scanner, follow the steps described below immediately, and consult your technical representative. q Turn OFF the built-in circuit breaker. w Turn OFF the main power circuit breaker. -

Page 81: Periodical Maintenance And Inspection

PERIODICAL MAINTENANCE AND INSPECTION This section describes the periodical maintenance and inspections required to keep the FRONTIER 390 operating at peak performance. Maintenance Schedule ............84 Power OFF/ON ................86 5.2.1 Turning OFF/ON Scanner ............ 86 5.2.2 Turning OFF/ON Printer ............87 Cleaning the Light Source Section Air Filter ..... -

Page 82: Maintenance Schedule

Maintenance Schedule On the day when the regular inspection is due, a message will appear during the pre- operation check stage. To keep the FRONTIER 390 operating at peak performance, conduct regular maintenance and inspections as indicated in the table below. - Page 83 Light Source Optical Filters Light Source Section Air Filter Film Cooling Scanner Power Supply Section Air Filter Air Compressor Filter EZ619 Processing Racks Printer Section Air Filters Squeegee Rack Cutter Loop Sensor Circulation Filters Densitometer White Board Processing Solution Heater Printer Power Source Section Cooling Air Filters Dryer Section Air Filter...

-

Page 84: Power Off/On

Power OFF/ON Turning OFF/ON Scanner 5.2.1 Power OFF q Perform “Post-operation Check”. • The system changes to STANDBY. w Turn OFF the built-in circuit breaker. e Turn OFF the main power circuit breaker. Built-in Circuit Breaker EZ933 Power ON q Turn ON the main power circuit breaker. w Turn ON the built-in circuit breaker. -

Page 85: Turning Off/On Printer

Turning OFF/ON Printer 5.2.2 Power OFF q Perform “Post-operation Check”. • The system changes to STANDBY. w Turn the power switch to STANDBY. Power Switch GD1284 e Turn OFF the built-in circuit breaker. r Turn OFF the main power circuit breaker. Built-in Circuit Breaker GD1282 Power ON... - Page 86 e Turn ON the power switch. Power Switch GD1283 r Turn the power switch to STANDBY after the letters appears on the operation panel display of the printer. Power Switch GD1284...

-

Page 87: Cleaning The Light Source Section Air Filter

Cleaning the Light Source Section Air Filter The light source section air filter is provided to ensure that clean air is introduced into the light source section. Clean it once a week. IMPORTANT If the light source air filter is clogged, the temperature in the light source section will rise, shortening the service life of the scanning lamp. -

Page 88: Cleaning The Scanner Power Supply Section Air Filter

Cleaning the Scanner Power Supply Section Air Filter The scanner power supply section air filter is provided to ensure that clean air is introduced into the power supply section. Clean it once a week. IMPORTANT If the scanner power supply section air filter is clogged, the temperature in the power supply section will rise, causing circuit boards to malfunction. -

Page 89: Cleaning The Printer Section Air Filters

Cleaning the Printer Section Air Filters The printer section air filters are provided to ensure that clean air is introduced into the printer section. Clean them once a week. IMPORTANT If the printer section air filters are clogged, the temperature in the electrical equipment section will rise, causing circuit boards to malfunction. -

Page 90: Cleaning The Printer Power Source Section Air Filters

Cleaning the Printer Power Source Section Air Filters The printer power source section air filters are provided to ensure that clean air is introduced into the printer power source section. Clean them once a week. IMPORTANT If the printer power source section air filters are clogged, the temperature in the power supply section will rise, causing power supply circuit board to malfunction. -

Page 91: Cleaning The Processing Solution Cooling Air Filters

Cleaning the Processing Solution Cooling Air Filters The processing solution cooling air filters are provided to ensure that clean air is introduced into the processing solution cooling fans. Clean them once a week. IMPORTANT If the processing solution cooling air filters become clogged, temperature control will be impaired. q Turn OFF the power to the printer. -

Page 92: Dryer Section Air Filter

Dryer Section Air Filter The dryer section air filter is provided to ensure that clean air is introduced into the dryer section. Clean it once a week. IMPORTANT If the dryer section air filter becomes clogged, temperature control will be impaired. q Turn OFF the power to the printer. -

Page 93: Cutter Loop Sensor Cleaning

Cutter Loop Sensor Cleaning If the cutter loop sensor is dirty, the cutter loop will not detect properly. Clean the sensor once a week. q Wipe the lower cutter loop sensor with a clean dry cloth. Cutter Loop Sensor GD1325... -

Page 94: Replacing The Circulation Filters

5.10 Replacing the Circulation Filters The circulation filters are provided to filter out any dirt or sediment contained in the circulating solutions in the processing tank. The filters should be replaced once a month, irrespective of how much paper has been processed. Processing solutions may irritate the eyes and skin. - Page 95 r Remove the filter from the holder. Filter Holder Filters t Install a new filter into the holder. Tray GD1334 y Install the holder by aligning its fastening Fastening Tab tab with the cutout, and turn it 90 degrees clockwise to secure it. Cutout GD1278 u Replace the P1-2, P2-1, P2-2, PS1, PS2,...

-

Page 96: Washing The Processing Racks

5.11 Washing the Processing Racks To maintain developing performance, wash the processing racks once a month. Processing solutions may irritate the eyes and skin. When handling processing solutions, wear protective goggles, a rubber apron, rubber gloves, rubber boots and other protective gear, as appropriate, to prevent any solution from coming in contact with the body. - Page 97 r Remove the No.1 to No.9 crossover racks. Crossover Racks No.8 No.6 No.4 No.2 No.9 No.7 No.5 No.3 No.1 GD1337 t Install the contamination prevention cover Contamination Prevention Cover over the P1-2 and P1-1 racks. GD1338 y Loosen the screw securing the large-size tray and remove the tray.

- Page 98 u Place the rack tray near the PS4 processing tank. i Carefully pull up the PS4 rack and wait until solution stops dripping from it. Be careful when removing the processing rack because it is heavy. o Place the rack carefully on the rack tray. !0 Take the rack with the tray to the sink.

- Page 99 !3 Widen the paper width guides and wipe Paper Width Guides clean the grooves in the guides using the Sponge sponge soaked in water as shown. Paper Width Guide GD-1630 !4 Wipe clean the inside surfaces of the front Sponge and rear guides using the sponge soaked in water.

- Page 100 IMPORTANT When installing the P2-1 rack, take special care to prevent overflow of the P2 solution into the P1 solution. !7 Remove the contamination prevention cover . !8 Repeat steps 4 to 13 to wash the P1-2 and P1-1 racks. Contamination Prevention Cover GD1342 !9 Reinstall the No.1 to No.6 crossover racks...

- Page 101 @1 Reinstall the squeegee rack while aligning Lock Squeegee Rack its grooves with the guide pins. @2 Secure the squeegee rack with the lock. Guide Pins (4) GD1329 @3 Reinstall the squeegee rack cover, then the Squeegee Rack Cover processor cover. Processor Cover GD1343...

-

Page 102: Cleaning The Film Cooling Air Compressor Filter

5.12 Cleaning the Film Cooling Air Compressor Filter The film cooling air compressor filter is provided to ensure that clean air is introduced into the compressor. Clean it every 3 months. q Turn OFF the power to the scanner. (See section 5.2.1.) w Remove the air filter cover. - Page 103 t Wash the air filter with tap water. Air Filter EZ931 y Squeeze the air filter and allow it to dry naturally. u Reinstall the air filter into the case. i Reinstall the filter case with its air intake Air Filter Case Air Intake upward, and tighten the wing screw.

-

Page 104: Cleaning The Light Source Optical Filters

5.13 Cleaning the Light Source Optical Filters Clean the light source optical filters every 3 months. The light source section becomes very hot during operation. Wait until the printing lamp cools down. q Open the light source section cover by releasing the latch. - Page 105 y Remove the lamp unit (see section 3.6) First IR Filter and blow off any dirt or dust on the first IR filter using the blower. Reinstall the lamp unit. EZ1215 u Blow off any dirt or dust adhering to the Second IR Filter second IR filter using the blower.

- Page 106 !0 Reinstall the filter unit and tighten the two Filter Unit Screws screws. EZ1216 !1 Connect the motor connector. Motor Connector EZ1262 !2 Close the light source cover, and close the latch. !3 Perform “Scanner Correction” on the “Pre- operation Check” menu.

-

Page 107: Cleaning The Densitometer White Board

5.14 Cleaning the Densitometer White Board Clean the densitometer white board every 3 months. q Withdraw the table and remove the Densitometer densitometer. Table GD1433 w Turn OFF the power to the densitometer. Densitometer Switch GD1434 e Remove the white board cover by sliding it White Board Cover to the right while depressing it with thumb. - Page 108 r Clean the white board with a cotton swab. Cotton Swab White Board EZ700 t Reinstall the white board cover. y Turn ON the densitometer power. u Place the densitometer on the table and push in the table.

-

Page 109: Error Messages And Action To Take

ERROR MESSAGES AND ACTION TO TAKE In the event of an operational error or machine failure, an error message appears on the screen and an alarm sounds. When an error message is displayed, proceed with the action indicated in the manual. If the machine does not return to normal operation after the action has been taken, consult your technical representative. - Page 110 Message Action to Take W-1101 Film or mask not installed. Install the film or mask. Install film or mask. W-1102 Light source cover is opened. Close the light source section cover. Close cover. I-1103 Stabilizing lamp. Wait until the message disappears. Please wait.

- Page 111 Message Action to Take W-1115 Dark correction not performed. Perform “Scanner Correction” in the “Pre- Perform scanner correction in “Pre-operational operational Check” menu. Check”. W-1116 Brightness correction not performed. Perform scanner correction in “Pre-operational Check”. E-1117 Lens registration not performed. Consult technical representative.

- Page 112 Message Action to Take W-1133 Incorrect carrier ID. Install the proper film carrier. Install correct carrier. W-1134 Mirror box not installed. Install the proper mirror box. Install mirror box. W-1135 Incorrect mirror box. Install correct mirror box. W-1136 Density measurement for ND filter failed. Remove foreign matter and re-try.

- Page 113 Message Action to Take W-1199 Auto focus failed. Make sure the film is inserted. If the film is Check if the film is installed. inserted, consult a technical representative. If problems persist even if the film exists, take measurements referring to the manual. W-1201 Perforation rupture exists.

- Page 114 Message Action to Take W-1224 Cartridge improperly installed. Remove the cartridge, check that no Remove cartridge, check and reinstall it. irregularity is found, then reinstall it. W-1225 Carrier’s sensor incorrectly calibrated. Remove the film carrier, clean the sensors Remove carrier, clean and reinstall it. and re-try.

- Page 115 Message Action to Take W-1241 Carrier removed. Remove the film and re-try. Remove film and re-start from pre-scanning. W-1243 Cartridge reshaped. Remove the film from the cartridge and load Process it with strip. it as a strip film. W-1244 Carrier’s magnetic head is stained. Clean the magnetic head of the film carrier.

- Page 116 Message Action to Take E-1423 Downloading image processing section See subsection 4.2.1. program failed. Restart the system. E-1424 Downloading carrier program failed. Restart the system. W-1425 Printer initialization failed. Call technical Make sure the printer processor is in normal representative. condition.

- Page 117 Message Action to Take W-1446 Error occurred while retrieving parameters Click [Scan Cancel], and re-try pre- from image processing module. scanning. Press [Scan Cancel] and retry pre-scanning. W-1447 FID cannot be read. Click [Cancel], check FID and reload the Press [Cancel] to rewind film. Check CID, and film.

- Page 118 Message Action to Take I-1477 “Series Scene” film loaded. Click [OK] and resume printing. W-1478 “Series Scene” magnetic information incorrect. Continue processing. Process continued. W-1479 Template image size does not match print Confirm print size and template size. size. Confirm print size and template size. W-1480 Cannot be printed with this cropping.

- Page 119 Message Action to Take I-1507 Data backup completed abnormally. Re-try. I-1508 Cancel data backup. W-1509 Not enough free space on hard disk. Continue operation. Unnecessary files have been deleted. W-1510 Date value exceeds the limit. Enter present date and time properly. (1998/01/01 00:00:00 - 2100/12/31 23:59:59) W-1511 Next timer-ON time exceeds the limit.

- Page 120 Message Action to Take E-1537 Cannot be serviced. Refer to the DI operating instructions. Consult technical representative. W-1538 F-DI registration not performed. To complete registration, perform the pre- operational check. E-1539 Cannot be serviced. Consult technical representative. I-1540 No order can be printed with the selected paper width.

- Page 121 Message Action to Take W-1568 Exceeds the available times of scanning. Press the [SORT] key, remove the film and Press [Sort] key to feed out film, and then reload it. insert film into carrier again. I-1569 The “Q’ty” value is set to “0”. Click [OK] to set the correct value, and then Press [OK] to set a correct value, and then continue operation.

- Page 122 Message Action to Take W-1592 Frame not detected. Remove film and make sure there is no abnormality. I-1593 %TEMPLATE%. Wait until the message disappears. Wait. %TEMPLATE_MESSAGE% I-1594 Reading service name list. Refer to the DI operating instructions. Wait. I-1595 Connect to Imaging Controller for updating data.

- Page 123 Message Action to Take W-1612 Feeding film failed in the feeder side of the Open the upper guide and negative holder 135ANL switch guide section. cover. Remove the film and install it in the Open the upper guide or negative holder negative holder again (see section 8.1).

- Page 124 Message Action to Take W-1620 The 135ANL catcher side nip cannot be With the NC135AG installed, open the released. pressure cover, upper guide and negative Open the carrier cover with the 135AFC set to holder cover. Remove the film (see section FRONTIER, and open the upper guide or 8.2).

- Page 125 Message Action to Take W-1638 Film inserted except from the 135ANL. Set the 135ANL to the waiting position. When the 135ANL is not used, set it to the waiting position. W-1639 Because the 135ANL position change is Set the 135ANL to the operating position. detected, the 135ANL continuous process is cancelled.

- Page 126 Message Action to Take W-1801 Perform scanner correction. Remove the film, and remove the carrier Remove the film, and remove the carrier and and install it again. install it again. E-1802 Process is cancelled because an error Consult technical representative. occurred during the setup of the scanner correction table.

- Page 127 Message Action to Take W-1936 An error occurred in generating image in the Restart from pre-scanning. high-speed mode. Re-start from pre-scan. E-1937 Initializing 135ANL failed. Consult technical representative. Consult your technical representative. W-1938 Print size exceeds the limit. Change print size. Change print size.

- Page 128 Message Action to Take E-2301 Request not accepted by printer. Turn OFF power supply (see subsection Request rejected. 4.2.1) and restart the system. If the error appears again, consult technical representative. W-2302 Printer is off-line. Request rejected. Change the printer to on-line condition. Change printer to online and perform operation.

- Page 129 Message Action to Take W-2403 Paper jamming occurred in the exposure Remove paper (see section 7.1). section feed unit. Remove paper. W-2404 Paper jamming occurred in the unit 2. Remove paper. W-2405 Paper jamming occurred in the unit 4. Remove paper. W-2406 Paper jamming occurred in the unit 5.

- Page 130 Message Action to Take E-2426 Loop 4 guide plate in the unit 3 malfunctions. Consult technical representative. Call technical representative. E-2427 Loop 5 guide plate in the unit 5 malfunctions. Call technical representative. E-2428 Paper width guide in the paper feed unit malfunctions.

- Page 131 Message Action to Take W-2446 Back printer is not installed. Position the back printer properly. Refer to manual for guidance. E-2447 A communication error occurred in printer Consult a technical representative. (main circuit board to paper feeding system A). Call technical representative. E-2448 A communication error occurred in printer (main circuit board to paper feeding system B).

- Page 132 Message Action to Take I-2469 Magazine installed. Press [OK] to resume printing. Resume printing. E-2501 Anti-dust shutter abnormal. Consult technical representative. Call technical representative. E-2502 Anti-dust fan malfunction. Call technical representative. E-2503 Polygon malfunctions. Call technical representative. E-2504 AOM driver cooling fan malfunctions. Call technical representative.

- Page 133 Message Action to Take E-2521 G laser (G-SHG) current exceeded. Consult a technical representative. Call technical representative. E-2522 B laser (B-SHG) current exceeded. Call technical representative. E-2523 R laser (R-LD) current measurement value outside specified range. Call technical representative. E-2524 G laser (G-SHG) current measurement value outside specified range.

- Page 134 Message Action to Take W-2537 The laser’s temperature adjustment cannot be Adjust room temperature to within indicated performed, because the ambient temperature range. is too low(high). Adjust the ambient temperature between 15-C and 30-C. (The laser’s temperature adjustment is started if the ambient temperature exceeds 5-C.) W-2539 Transferring images from scanner has not...

- Page 135 Message Action to Take W-2616 Processor cover is open. Remove paper and restart processing. Processing stopped. Remove paper and restart processing. W-2617 Squeeze cover is open. Processing stopped. Remove paper and restart processing. W-2618 Processing tank section cover open. Close the processing tank section cover. Close cover.

- Page 136 Message Action to Take E-2635 P2 safety thermostat activated. Consult technical representative. Heater turned off. Call technical representative. E-2636 PS1 safety thermostat activated. Heater turned off. Call technical representative. E-2637 PS2 safety thermostat activated. Heater turned off. Call technical representative. E-2638 PS3 safety thermostat activated.

- Page 137 Message Action to Take I-2683 Processing paper. Wait. Please wait. I-2684 Temperature adjustment of processing tanks is process. Please wait. I-2685 Processing paper. Cannot be processed due to different width of paper. Please wait. I-2686 Switching paper width guide in processor. Please wait.

- Page 138 Message Action to Take E-2706 P1R Replenisher cartridge cleaning or dilution Consult technical representative. valve abnormal. Call technical representative. About 780 3R-size sheets can still be printed without replenishment. E-2707 P2RA Replenisher cartridge cleaning valve abnormal. Call technical representative. About 780 3R-size sheets can still be printed without replenishment.

- Page 139 Message Action to Take I-2723 Mixing replenisher. Wait until the message disappears. Please wait. W-2730 P1R replenisher solution level has fallen. Add replenisher. Printing can continue a little further. W-2731 P2R replenisher solution level has fallen. Printing can continue a little further. W-2732 PSR replenisher solution level has fallen.

- Page 140 Message Action to Take W-4109 This order already contains the specified sort Refer to the DI operating instructions. Quit this service, change the sort No., and then resume the operation. W-4110 This order No. cannot be modified, because it is not registered. Enter a correct order No.

-

Page 141: Paper Jamming

PAPER JAMMING This section describes the corrective actions for paper jamming. In the event of paper jamming, the printer processor stops paper feeding and an error message appears on the monitor of the scanner. Also, the location where paper has jammed is displayed on the printer operation panel. -

Page 142: Paper Jammed In Printer

Paper Jammed in Printer Paper Magazine Removal 7.1.1 q Press the [ENTER] key. • The alarm is cleared. w Turn the magazine lock lever clockwise. • The paper magazine lock is released. Paper Magazine Magazine Lock Lever GD1448 e Cut the paper at the exit guide of the Paper magazine. -

Page 143: Paper Jammed In Paper Feed Unit (W-2401)

Paper Jammed in Paper Feed Unit (W-2401) 7.1.2 q Remove the paper magazine (see subsection 7.1.1). w Open the printer right and left doors. e Remove the paper from the paper feed Paper Feed Unit unit. Paper GD1450 Paper Jammed in Unit 1 (W-2402) 7.1.3 q Remove the paper magazine (see subsection 7.1.1). -

Page 144: Paper Jammed In Exposure Section Feed Unit (W-2403)

t Turn the knob clockwise and remove the Unit 1 paper from unit 1. Paper GD1447 Paper Jammed in Exposure Section Feed Unit (W-2403) 7.1.4 q Remove the paper magazine (see subsection 7.1.1). w Open the printer right and left doors. e Follow steps 1 through 4 of “Paper Jammed in Unit 1”... -

Page 145: Paper Jammed In Unit 2 (W-2404)

t Turn the knob on unit 1 clockwise and Unit 1 remove the paper from unit 1. Paper GD1447 y Remove the paper from the exposure Exposure Section Feed Unit section feed unit. Paper GD1445 Paper Jammed in Unit 2 (W-2404) 7.1.5 q Follow steps 1 through 5 of “Paper Exposure Section Feed Unit... - Page 146 e Remove the paper from the exposure Exposure Section Feed Unit section feed unit. Paper GD1445 r Push the lever to the left to lower the Reservoir Loop Guide Plate reservoir loop guide plate. Lever GD1442 t Turn the knob on unit 2 counterclockwise Unit 2 and remove the paper from unit 2.

-

Page 147: Paper Jammed In Unit 4/5 (W-2405/W-2406)

Paper Jammed in Unit 4/5 (W-2405/W-2406) 7.1.6 q Follow steps 1 through 3 of “Paper Jammed in Unit 2” (see subsection 7.1.5). w Cut the paper at loop 4 (reservoir loop). Loop 4 Unit 4 Unit 3 GD1439 e Push the lever to the left to lower the Reservoir Loop Guide Plate reservoir loop guide plate. - Page 148 t Turn the knob on unit 4 clockwise and Unit 4 remove the paper from unit 4. If the paper cannot be seen, follow the steps below. Paper Knob GD1440 q Loosen the two screws and remove the Guide Plate Screws guide plate from unit 4.

-

Page 149: Paper Jammed At Loop 1/2/3/4/5

Paper Jammed at Loop 1/2/3/4/5 7.1.7 If paper is jammed at loop 1, 2, 3, 4 or 5, perform the procedure indicated in the table below. Loop Procedure Refer to W-2407 Loop 1 Paper Jammed in Paper Feed Unit 7.1.2 Paper Jammed in Unit 1 7.1.3 W-2407... -

Page 150: Paper Jammed In Processor

Paper Jammed in Processor Paper Jammed in Processor or Dryer (W-2601) 7.2.1 Processing solution may irritate the eyes and skin. When handling processing solutions, wear protective goggles, a rubber apron, rubber boots and other protective gear as appropriate to prevent any solution from coming in contact with the body. - Page 151 e Cut the paper at the processor inlet if it is visible. Paper GD1575 r Release the lock, lift the squeegee rack Squeegee Rack and cut the paper at the No.9 crossover rack. Paper GD1565 t Remove the paper from the squeegee rack. Squeegee Rack Paper GD1566...

- Page 152 y Remove the No.1 and No.2 crossover No.1 No.2 Crossover Crossover Rack racks. Rack GD1307 u Lift the P1-1 rack approximately 5 cm (2 Knob in.) and turn the knob counterclockwise until the paper comes out and it can be removed.

- Page 153 i Remove the No.3 crossover rack. o Lift the P1-2 rack approximately 5 cm (2 Knob in.) and turn the knob counterclockwise. If the knob is hard to turn, remove the P1-2 rack and the paper. P1-2 Rack GD1570 Paper GD1571 !0 Install the contamination prevention cover Contamination Prevention Cover...

- Page 154 !1 Try to remove the crossover racks from No.4 to No.9. If a crossover rack cannot be removed, it means paper is jammed in the rack. Crossover Rack !2 Cut the paper at the crossover rack that cannot be removed. !3 Lift the rack slightly, turn the knob counterclockwise until the paper comes out and can be removed.

-

Page 155: Paper Jammed In Cutter Section (W-2602)

Paper Jammed in Cutter Section (W-2602) 7.2.2 q Pull out the paper from the loop guide Loop Guide Plate section. w Press the “PROCESSOR DRIVE” [ON/ OFF] key twice. • The processor is driven and paper in the processor will be fed out through the dryer section. -

Page 156: Negative Jamming In 135Anl (Optional)

NEGATIVE JAMMING IN 135ANL (OPTIONAL) This Section describes the corrective actions for negative jamming in the 135ANL. In the event of negative jamming, the 135ANL stops negative feed and an error message appears on the monitor of the scanner. Negative Jamming during Pre-scanning ..... -

Page 157: Negative Jamming During Pre-Scanning

Negative Jamming during Pre-scanning q Open the negative holder cover. Negative Holder Cover GD157 w Press the button to open the upper guide. Loop Section Take care not to damage the negative at the loop section. Upper Guide Lock Release Button GD158 e Pull the release lever as shown in the Release Lever... - Page 158 t Close the pressure cover and pull the lever Lever Pressure Cover to remove the film carrier. Film Carrier GD161 y Reinstall the film carrier. u Click [OK] on the monitor screen. • The error message disappears. i Reinstall the negatives to the negative holder.

-

Page 159: Negative Jamming During Fine-Scanning

Negative Jamming during Fine-scanning q Pull the release lever as shown in the Release Lever figure to release the pressure cover of the Pressure Cover film carrier. GD159 w Open the negative loop guide on the carrier Loop Guide inlet guide and remove the negative from the 135ANL. - Page 160 r Close the pressure cover and pull the lever Lever Pressure Cover to remove the film carrier. Film Carrier GD161 t Reinstall the film carrier. y Click [OK] on the monitor screen. • The error message disappears. u Reinstall the negatives to the negative holder.

-

Page 161: Streak Marks On Prints And Countermeasures

STREAK MARKS ON PRINTS AND COUNTERMEASURES This section describes the corrective actions to take for streake marks on prints. Types of Streak Marks ............166 9.1.1 Pressure Cover Section of Auto Film Carrier ....... 166 9.1.2 Mask Section of Auto Film Carrier ........166 9.1.3 Mirror Box ................ -

Page 162: Types Of Streak Marks

Types of Streak Marks Dirt or dust adhering to the film carrier may cause streak marks on prints. Streak marks on the prints may run in the same direction as the paper feed. Pressure Cover Section of Auto Film Carrier 9.1.1 Dust adheres to the lower section of the pressure cover opening. -

Page 163: Mirror Box

Dust on the mask has been dragged by film. Distinct colored, curving streak marks appear on prints. This type of streak mark appears when dust is present during the scanner correction at the pre-operational check stage, but is not present during fine scanning. -

Page 164: Countermeasures

Countermeasures If streak marks appear on prints, remove the dust or dirt by following the steps below. q Clean the mirror box (see “Basic Operating Instructions”). w Clean the auto film carrier NC240AG (see “Basic Operating Instructions”). e Clean the auto film carrier NC135AG (see “Basic Operating Instructions”). -

Page 165: List Of Consumables

LIST OF CONSUMABLES 10.1 Scanner ................... 170 10.2 Printer Processor ..............171... -

Page 166: Scanner

10.1 Scanner Scanning Lamp Part No.: 122S0026 GD1550 Scanner Power Supply Section Air Filter Light Source Section Air Filter Reflector Part No.: 374D890211C Part No.: 602S0001 Part No.: 374D895509C *Product innovations may result in part number and shape changes without prior notice. -

Page 167: Printer Processor

10.2 Printer Processor Back Printer Ink Ribbon Cassette Part No.: 345A9049781 2 pieces Power Source Section Air Filters Part No.: 4B5482292 4 pieces Circulation Filter Part No.: 376G03101 GD1435 Printer Section Air Filters 8 pieces Part No.: 4B5482292 6 pieces Processing Section Heater Cooling Filters Part No.: 4B5482292 5 pieces... -

Page 168: Index

INDEX Index ....................174 Index of Basic Operating Instructions ......176... - Page 169 Index 1-Frame Image Display Printing ......2.8 Laser Caution Label Locations on Printer ..1.3.3 135ANL (Optional) Negative Catcher Section Laser Radiation Safety ......1.2, 1.2.1 Cleaning ............3.9 Laser Warning Label ........1.2.2 135 Light Source Aperture Table ......3.8 List of Consumables ..........

- Page 170 Scanning Lamp Position Adjustment ....3.7 Scanning Lamp/Reflector Replacement ..... 3.6 Selecting Sharpness Level ....... 2.12 Setup and Maintenance ........3 “Setup and Maintenance” Menu Screen .... 3.1 Sort Data Display/Setting ........2.9 Streak Marks on Prints and Countermeasures ..9 Title Printing ............

- Page 171 Index of Basic Operating Instructions 135ANL (Option) Cleaning ......3.2.5 High-speed (Three-frame) Mode ...... 4.22 135ANL Preparation ........6.2.1 Holding Conditions ........... 4.15 135 Half-size Frame Printing ......4.20 135 Reorder Printing (by Frame No.) .... 4.17.2 Image Frame Display Mode Change ....4.5 135 Reorder Printing (by Frame Order) ..

- Page 172 Printing Screen ........... 2.4 Printing Status Bar .......... 2.4.4 Printing Using the 135 ANL ......6.2.3 Printing with 8.9 cm to 15.2 cm Wide Paper ... 4.2.1 Printing with More than 17.8 cm Wide Paper or 255 mm Feed Length ....... 4.2.2 Printintg With Optional 135ANL ......

- Page 173 Heesenstrasse 31, 40549 Dusseldorf, Germany FUJI PHOTO FILM (U.K.) LTD. Fuji Film House, 125 Finchley Road, Swiss Cottage, London NW3 6JH, England FUJIFILM ESPAÑA, S.A. Aragon, 180, 08011-Barcelona, Spain FUJIFILM FRANCE SA Parc d'Activites du Pas-du-Lac-2, Avenue Franklin, St.Quentin-en-Yvelines Cedex, France in South America FUJI PHOTO FILM DO BRASIL LTDA.

Need help?

Do you have a question about the FRONTIER 390 and is the answer not in the manual?

Questions and answers