Summary of Contents for PCI EFP-500

- Page 1 CLEN218 EFP-500 Endo-Flush Endoscope Flushing Pump Instruction Manual Safety in Practice...

- Page 2 Endo-Flush # EFP-500 Instruction Manual 04/2011 Printed in the United States of America No part of this publication may be reproduced without the express written permission of PCI medical inc. PCI medical inc. Location: 8 Inspiration Lane, Chester, CT 06412...

-

Page 3: Table Of Contents

SETTING UP YOUR EFP-500 ................7 Wall Mounting your EFP-500 ......................8 OPERATION ..................... 9 Start-Up ..............................9 Connecting Your Endoscope to the EFP-500 ................. 10 Channel Selection Process ......................11 Flushing with Detergent ....................... 12 Flushing with Water ........................13 Flushing with Air .......................... -

Page 4: Introduction

2 each Type 5 x 20 mm SloBlo 2 amp 250VAC externally mounted. The EFP-500 is tested and listed to the following standards: The EFP-500 was tested by Met Laboratories, a Nationally Recognized Testing Laboratory (NRTL), and was certified to UL 61010-1 and CSA C22.2 No 61010-1 safety standards. -

Page 5: Important Information

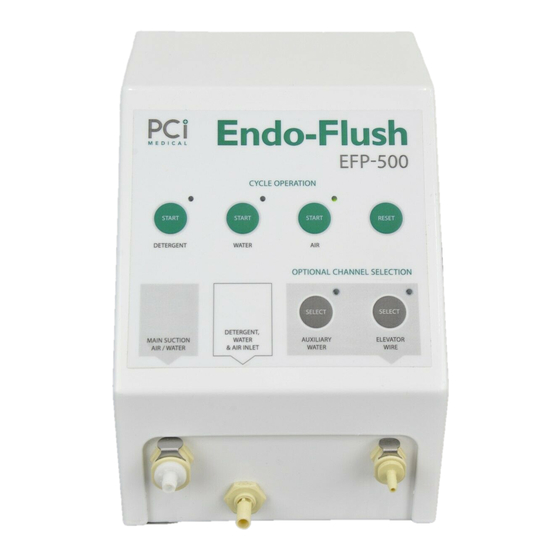

Please Read Before Use Product Overview The Endoscope Flushing Pump (EFP-500) is a compact unit that contains a single pump. It is used to replace the manually operated syringe for flushing detergent, rinse water and air through endoscope channels during the manual cleaning phase of endoscope reprocessing. The pump flushes the Suction/Instrument, Air/Water channels and the Auxiliary Water or Elevator-Wire channels. -

Page 6: Safety Precautions

The EFP-500 is an electrical device, do not immerse in water. WARNING Follow the installation instructions to secure the device in a safe location. The EFP-500 is not to be used with flammable liquids. Do not WARNING flush with alcohol. CAUTION Disconnect power before moving the EFP-500. -

Page 7: Setting Up Your Efp-500

CLEN218 Setting up your EFP-500 Included with your new EFP-500 system are the following parts: Wall-mounting Bracket & EFP-500 Assembly Container Hose Assembly for Suction/Instrument & Air/Water Channels Instruction Manual Power Cord Inlet Hose Assembly Hose Assembly for Auxiliary Water or... -

Page 8: Wall Mounting Your Efp-500

4. For masonry walls, use suitable lead or plastic anchors and bolts. These anchors are not supplied. 5. Place the EFP-500 on wall bracket. Check to ensure that it is securely mounted. 6. If mounting on a stud, use the two center locations. -

Page 9: Operation

CLEN218 Operation The EFP-500 is designed to flush the internal channels of Olympus flexible endoscopes in accordance with Olympus reprocessing instructions. NOTE: The EFP-500 is intended for use with the endoscope manufacturer’s manual cleaning instructions. The EFP-500 is a substitute for... -

Page 10: Connecting Your Endoscope To The Efp-500

Then plug the other end of the Assembly into the right side quick-disconnect fitting on the EFP-500. Plug the Inlet Hose into the connection marked “INLET” on the EFP-500. Place the end with the screen into the bottom of the container with detergent. -

Page 11: Channel Selection Process

CLEN218 Push the power switch on the right side of the EFP-500 to activate the unit. The switch will illuminate when the device is on. You are now ready to flush your endoscope with the EFP-500. NOTE: If problems occur when inserting connectors, make sure the metal release buttons on the EFP-500 are depressed before inserting. -

Page 12: Flushing With Detergent

Suctioning, brushing and external cleaning are still required according to manufacturer’s instructions. 1. With the endoscope submerged in fresh detergent, push the Detergent Start button on the EFP-500 to pump detergent through the Channel Assemblies. The LED light will flash during pumping operations. NOTE To prevent spraying liquid, ensure that the distal end of the endoscope is submerged prior to activating the pump. -

Page 13: Flushing With Water

Air Start button. The LED indicator light will flash to indicate the air cycle is running. The EFP-500 will stop after the time parameters have been met for air flush. The LED will stop flashing and remain lit to indicate the air cycle is complete. -

Page 14: Routine Maintenance

Then wipe with a clean cloth dampened with water to remove detergent. Dry with a clean cloth. Hard to clean spots may be cleaned with a light abrasive such as “Soft Scrub”. NOTE The housing of the EFP-500 is water resistant and can be cleaned as described above. However, never immerse the EFP-500 in any fluid. -

Page 15: Efp-500 Decontamination

Fill a container with enough high-level disinfectant to immerse the inlet hose and channel assemblies. Place the screened end of the Inlet Hose into the container and attach the quick-disconnect into the connection marked “INLET” on the EFP-500. - 15 -... -

Page 16: Flow Verification

Store channel assemblies hanging vertically. Flow Verification Verifying the flow of the EFP-500 can be easily done and should be checked daily to make sure the unit is operating to output specifications. Flow verification is performed without the EFP-500 connected to an endoscope. -

Page 17: Quick Troubleshoot & Faqs

Frequently Asked Questions 1. Can my hoses from my EFP250 be used on the EFP-500? No. The hoses on the EFP-500 are not compatible due to the difference in pressure (psi) of the unit. 2. Can the EFP be used for disinfection at clinics that manually disinfect their equipment? No, the machine is designed and has an intended use to replace syringe flushing during manual cleaning. -

Page 18: Limited Warranty

The electronics and pumps are covered for eighteen months. The connectors on the EFP-500 are covered for 90 days. If the system is not working correctly or is defective, contact PCI medical inc. and we will repair or replace the unit at our option during the warranty period. -

Page 19: Compatible Endoscopes

Specifications and Technical Data Electrical: 115 V 50/60Hz 0.7A The EFP-500 was tested by Met Laboratories, a Nationally Recognized Testing Laboratory (NRTL), and was certified to UL 61010-1 and CSA C22.2 No 61010-1 safety standards. File # E112640 Construction: Frame ..........Steel, Powder Coated Wall bracket ........

Need help?

Do you have a question about the EFP-500 and is the answer not in the manual?

Questions and answers