Summary of Contents for EUCHNER MGB-L0xx-AR Series

- Page 1 Operating Instructions Safety Systems MGB-L0…-AR.-… MGB-L0…-AP.-… from V3.0.0...

-

Page 2: Table Of Contents

Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… Contents About this document ..................... 4 1.1. Scope ............................4 1.1.1. Notes on older product versions ..................4 1.2. Target group ..........................4 1.3. Key to symbols ..........................4 1.4. Supplementary documents ......................5 Correct use ......................6 2.1. - Page 3 Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… 11.10. Operation in an AR switch chain .....................28 11.11. Notes on operation in an AR switch chain ..................29 11.11.1. System times .......................29 11.11.2. Wiring an AR switch chain ....................29 11.11.3. Number of devices in the switch chains ................29 11.11.4.

-

Page 4: About This Document

This section applies on operation as MGB-AP This section applies on operation as MGB-AR In this section attention must be paid to the DIP switch setting Printed document Document is available for download at www.euchner.de Document on CD Safety precautions Danger of death or severe injuries... -

Page 5: Supplementary Documents

Important! Always read all documents to gain a complete overview of safe installation, setup and use of the device. The documents can be downloaded from www.euchner.de. Enter the document number in the search box for this purpose. 112657-12-01/15 (translation of the original operating instructions) -

Page 6: Correct Use

The safety system MGB can only be combined with the intended modules in the MGB system family. On the modification of system components, EUCHNER provides no warranty for function. Interlocking modules with the configuration MGB-AR can be integrated into an AR switch chain. -

Page 7: Main Differences Between Mgb-Ap And Mgb-Ar

Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… Table 1: Possible combinations for MGB components Handle module Evaluation unit MGB-H-... from V2.0.0 MGB…AR/AP from V3.0.0 Key to symbols Combination possible 2.1. Main differences between MGB-AP and MGB-AR System family Symbol Optimized for operation in safe control systems. MGB-AP If series connection is not necessary, the number of terminals can be reduced using this system family. -

Page 8: Description Of The Safety Function

Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… 3. Description of the safety function Devices from this series feature the following safety functions: Monitoring of the safety guard position (interlocking device according to EN ISO 14119) Ì Safety function: The safety outputs are switched off when the safety guard is open (see chapter 6. Function on page 10). -

Page 9: Exclusion Of Liability And Warranty

Prior to use, read the operating instructions and keep these in a safe place. Ensure the operating instructions are always available during mounting, setup and servicing. EUCHNER cannot provide any warranty in relation to the readability of the CD for the storage period required. For this reason you should archive a printed copy of the operating instructions. -

Page 10: Function

Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… 6. Function Together with a handle module, the interlocking module makes it possible to monitor the position of moving safety guards. The combination also serves as a mechanical door stop at the same time. The following switch-on condition applies to the safety outputs FO1A and FO1B (also see chapters 14.2. -

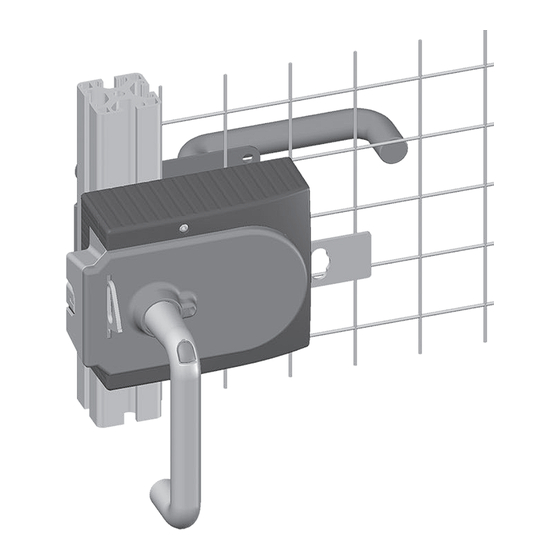

Page 11: System Overview

Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… 7. System overview 7.1. Interlocking module MGB-L0-… Key: Cover for mechanical release LED indicator DIP switches Terminals X2-X5 Depending on version Cable entry M20x1.5 or plug connector Internal reset Auxiliary marking for maximum permitted mounting distance Notice: Depending on the version, additional controls and indicators may be integrated into the cover and a mounting plate can be included. -

Page 12: Dimension Drawing

Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… (translation of the original operating instructions) 112657-12-01/15... -

Page 13: Lockout Mechanism

Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… 7.5. Lockout mechanism If the lockout mechanism is pivoted out/extended, the bolt tongue cannot be extended. The lockout mechanism can be secured with padlocks (see Figure 5). To pivot out, press the grooved part (only possible with bolt tongue retracted). ¨... -

Page 14: Escape Release (Optional)

Align escape release axis at right angles to the handle module. See Figure 4 and Figure 7. 7.6.1. Preparing escape release (also see Figure 6: Preparing escape release on page 15) Profile width Length required for Which EUCHNER parts are required? Necessary work steps actuation axis Without plates With mounting... - Page 15 Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… Example with mounting plates: Actuation axis Protective sleeve Mounting plates 1 Fit door handle. 2 Insert actuation axis. The locking ring A must be in contact with the escape release B. 3 Tighten setscrew to 2 Nm. 4 Fit protective sleeve.

-

Page 16: Mounting

Surface mounting Tip! Ì You will find an animation on the mounting process at www.euchner.de. Ì The color and labeling of pushbuttons and indicators can be modified. For mounting steps, see Figure 7 and Figure 8 to Figure 13. -

Page 17: Mounting Color Cover

Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… 8.1. Mounting color cover Mounting 90° Click! Removing Color cover 112657-12-01/15 (translation of the original operating instructions) - Page 18 Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… 2x M6 1 Nm (6x) Cutout for escape release Tightening torque 6 Nm 4x M6 0,5 Nm Recommended fixing material: For mounting on the mounting plate: DIN 912-M6X25-8.8 ZN CYLINDER HEAD SCREW Figure 7: Installation example for door hinged on the right (general view) (translation of the original operating instructions) 112657-12-01/15...

-

Page 19: Changing Actuating Direction (Here: From Right To Left)

Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… 9. Changing actuating direction (here: from right to left) Important! It is only possible to make this change when the bolt tongue is not extended and an escape release is not yet mounted. As supplied, the handle module is set either for doors hinged on the right or for doors hinged on the left. -

Page 20: Protection Against Environmental Effects

Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… 3 mm CLOSED 9 Remove cover and undo hexagon socket screw. OPEN AT Reposition the door handle by 90° in clockwise direction and fasten it again. AK Tighten hexagon socket head screw to 3 Nm. A... -

Page 21: Electrical Connection

Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… 11. Electrical connection WARNING In case of an error, loss of the safety function through incorrect connection. Ì To ensure safety, both safety outputs (FO1A and FO1B) must always be evaluated. Ì The monitoring outputs must not be used as safety outputs. Ì... -

Page 22: Notes About

The mounting of conduits directly on the MGB is not allowed. Cables are only allowed to be connected via suitable cable glands. For this purpose use EUCHNER cable gland of type EKPM20/06U. Equivalent cable glands can be used if they are UL-listed (QCRV) and are suitable for the related cable diameter (22 AWG –... -

Page 23: Requirements For Connection Cables

Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… 11.4. Requirements for connection cables CAUTION Risk of damage to equipment or malfunctions as a result of incorrect connection cables. Ì On the usage of other connection components, the requirements in the following table apply. EU- CHNER provides no warranty for safe function in case of failure to comply with these requirements. -

Page 24: Changing Device Configuration (Using Dip Switches)

MGB-L0…-AR.-… and MGB-L0…-AP.-… 11.6. Changing device configuration (using DIP switches) Tip! You will find an animation on device configuration at www.euchner.de. DIP switches The devices can be configured using the DIP switches. The following settings are possible: Ì Changing system family (AR/AP switching) -

Page 25: Notes On Operation With Control Systems

Always connect inputs FI1A and FI1B directly to a power supply unit or to outputs FO1A and FO1B of another EUCHNER AR device (series connection). Pulsed signals must not be present at inputs FI1A and FI1B. The test pulses are also present when the safety outputs are switched off (only on FO1A). Depending on the inertia of the connected device (control system, relay, etc.), this can lead to short switching processes. -

Page 26: Terminal Assignment And Contact Description

Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… 11.8. Terminal assignment and contact description LEDs State Power Figure 15: Connections and indicator LED Terminal Designation Description X3.1 to X3.3 See the enclosed data sheet X3.4 Power supply for monitoring outputs and cover assembly, DC 24 V, must be permanently present. X3.5 Ground, DC 0 V (connected internally to X5.5). -

Page 27: Operation As Separate Device

Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… 11.9. Operation as separate device +24 V DC FI1A FI1B X3:4 X5:6 X4:1 X4:2 X4:6 X2:3 X2:4 X3:1 X3:3 Safety Inputs Safety Monitoring Outputs Outputs X5:5 X3:5 X4:4 X4:5 X5:1 X5:2 X5:4 X2:1 X2:2 X2:6 X2:7... -

Page 28: Operation In An Ar Switch Chain

Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… 11.10. Operation in an AR switch chain +24 V DC FI1A FI1B X3:4 X5:6 X4:1 X4:2 X4:6 X2:3 X2:4 X3:1 X3:3 Safety Inputs Safety Monitoring Outputs Outputs X5:5 X3:5 X4:4 X4:5 X5:1 X5:2 X5:4 X2:1 X2:2... -

Page 29: Notes On Operation In An Ar Switch Chain

Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… 11.11. Notes on operation in an AR switch chain 11.11.1. System times The interlocking module has longer reaction times than a CES-AR switch (see chapters 13. Technical data on page 32 and 13.1. Typical system times on page 33). 11.11.2. -

Page 30: Setup

Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… 12. Setup 12.1. Teach-in operation (only for MGB unicode) The handle module must be assigned to the interlocking module using a teach-in function before the system comprising interlocking module and handle module forms a functional unit. During a teach-in operation the safety outputs are switched off. -

Page 31: Electrical Function Test

Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… 12.3. Electrical function test WARNING On usage in a switch chain with different AR devices (e.g. CES-AR, CET-AR), also follow the procedure for the functional check in the related operating instructions. 1. Switch on operating voltage. The interlocking module carries out a self-test. -

Page 32: Technical Data

Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… 13. Technical data NOTICE If a product data sheet is included with the product, the information on the data sheet applies in case of discrepancies with the operating instructions. Parameter Value Unit Housing material Glass fiber reinforced plastic;... -

Page 33: Typical System Times

Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… 13.1. Typical system times Important! The system times given are maximum values for one device. Ready delay: In case of AR configuration the following applies: After switching on, the unit carries out a self-test for 10 s. The system is ready for operation only after this time. -

Page 34: Mgb-Ar System Status Table

Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… 14.2. MGB-AR system status table (translation of the original operating instructions) 112657-12-01/15... -

Page 35: Mgb-Ap System Status Table

Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… 14.3. MGB-AP system status table 112657-12-01/15 (translation of the original operating instructions) -

Page 36: Troubleshooting And Assistance

¨ 15.2. Help on troubleshooting in the Internet You will find a help file on troubleshooting under “Support” in the service area at www.euchner.de. 15.3. Help on mounting in the Internet You will find an animation on the mounting process at www.euchner.de. -

Page 37: Inspection And Service

Loss of the safety function because of damage to the system. In case of damage, the affected module must be replaced completely. Only accessories or spare parts that can be ordered from EUCHNER may be replaced. Regular inspection of the following is necessary to ensure trouble-free long-term operation: Ì... -

Page 38: Declaration Of Conformity

Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… 18. Declaration of conformity (translation of the original operating instructions) 112657-12-01/15... - Page 39 Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… 112657-12-01/15 (translation of the original operating instructions)

- Page 40 112657-12-01/15 Title: Operating Instructions Safety Systems MGB-L0…-AR.-… and MGB-L0…-AP.-… from V3.0.0 (translation of the original operating instructions) Copyright: © EUCHNER GmbH + Co. KG, 01/2015 Subject to technical modifications; no responsibility is ac- cepted for the accuracy of this information.

Need help?

Do you have a question about the MGB-L0xx-AR Series and is the answer not in the manual?

Questions and answers