Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for ViewPlus VP Columbia VPTT2113-01

- Page 1 VP Columbia User Manual Revision: 20160613...

-

Page 2: Table Of Contents

C. Machine status and alerts ........................34 VI. Paper Handling ............................36 A. Paper Loading ............................. 36 B. Paper Jams ............................36 VII. Braille, Translation and Printing ......................39 A. ViewPlus Tiger Software Suite ......................39 B. Fonts ..............................39... - Page 3 C. Math and Braille ..........................40 D. Printing ............................... 40 VIII. Software Packages ..........................41 A. Software Packages ..........................41 IX. Training, Warranty, Maintenance and Support ..................42 A. Training ............................... 42 B. Maintenance ............................42 C. Support ............................... 42 D.

-

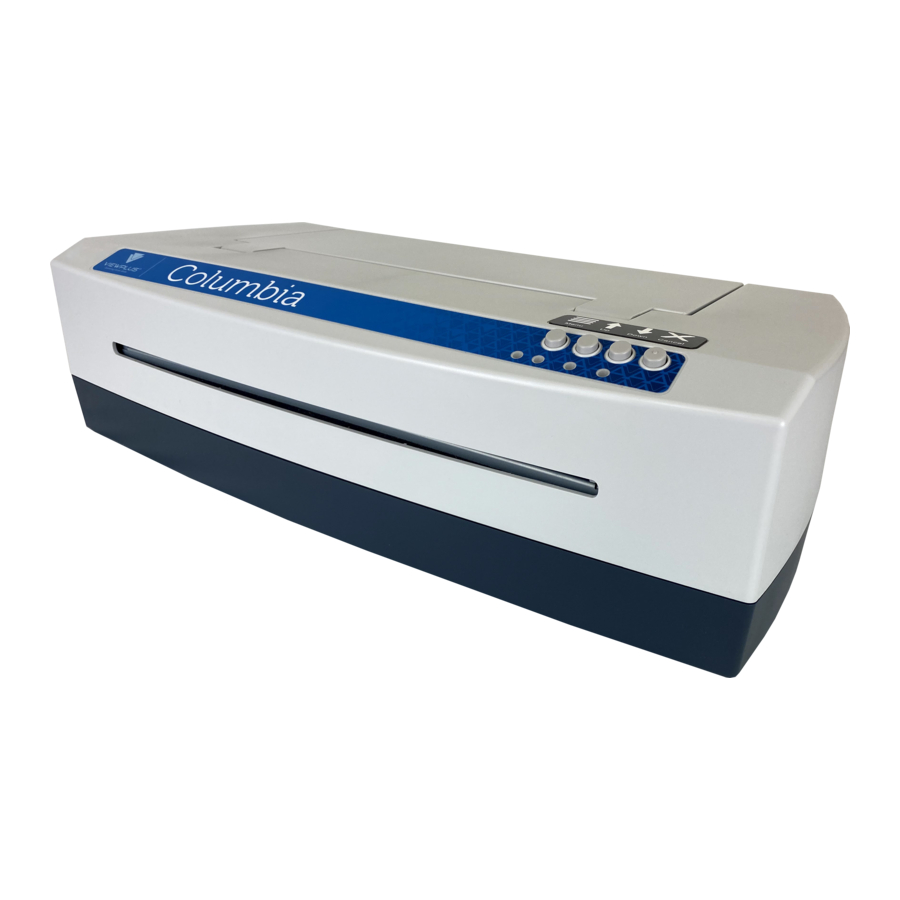

Page 4: Introduction

This embosser provides double sided embossing for Braille text with capabilities to include single sided tactile graphics. ViewPlus embossers use the standard Windows printer driver to mix text and graphics in mainstream Windows software like Word and Excel. Use the computer to adjust settings and preferences. Print documents exactly how they appear on the screen. -

Page 5: Compliance Statements

B. Compliance Statements FCC Compliance Statement (USA) This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation. - Page 6 Compliance Statement (Korea) This apparatus complies with CISPR32 requirements. International Compliance EN 55032:2012 Class B Emissions series EN 55024:2010 Immunity characteristics EN 61000-3-2:2014 Power line harmonics EN 61000-3-3:2013 Power line flicker EN 55024:2010 Electrostatic discharge EN 55024:2010 Radiated immunity EN 55024:2010 Electrical fast transient/burst EN 55024:2010 Surge...

-

Page 7: Safety Instructions

C. Safety Instructions Read all of these safety instructions before using the embossing printer. In addition, follow all warnings and instructions marked on the embossing printer itself. o Do not place embossing printer on an unstable surface. o Do not place embossing printer near a radiator or heat source. o Do not block or cover slots and openings in the embossing embosser's cabinet;... -

Page 8: General Information

II. General Information A. Embosser specifications VP Columbia Embosser Print Speed Up to 100 CPS, double sided Tactile Resolution 100 DPI Embossed Dot Density Up to 17 DPI Braille Dot Spacing Selectable from 5 international Standards Tactile Graphic Dot Heights 7 steps for color representation Braille Dot Heights Adjustable in 3 heights... -

Page 9: Tigerplus Technology

100 DPI. This allows to provide a special setting with this embosser that is not available with other ViewPlus embosser models. The setting of the Braille dot spacing to one of the five following international braille standards:... -

Page 10: Printer Setup

Inspect the ViewPlus embosser and its packaging for any damage. If noticeable damage occurred, please report to your ViewPlus product supplier immediately. o Save the packing material and box. The packing material must be used to ship the ViewPlus embosser for warranty maintenance service. -

Page 11: Cable Attachment

o Also, if any damage occurred during shipping, most shipping companies require the box and the packing material in order to settle the insurance claim. For further embosser setup also follow the VP Columbia Setup Instructions included with your other materials. B. - Page 12 USB port. You may also use a LAN cable to connect the ViewPlus Columbia to your network. The embosser is not shipped with a LAN cable. To use this connection method, attach one end of a LAN cable to the connection port furthest towards the back of the machine when facing the front, and attach the other end to a network data port.

-

Page 13: Software Installation

NOTE: DO NOT CONNECT YOUR COLUMBIA TO THE COMPUTER DURING INSTALLATION OF THE WINDOWS PRINTER DRIVER, OR TURN IT OFF WHEN ALREADY CONNECTED. Run the driver setup from the USB, or download the current Columbia driver from the ViewPlus website, . Follow the instructions from the installation program. - Page 14 The Network Printer Installation Utility can also be run outside the printer driver installation from the Windows start menu, under ViewPlus program folder. After your VP Columbia printer driver installed successfully, you may also install the ViewPlus Tiger Software Suite from the included USB flash drive. For installation, please follow the instructions from the...

- Page 15 Printer Driver and Device Removal If you wish to remove the VP Columbia printer driver application from your computer, you can either run the printer driver setup program again, which will give you the option to remove the driver, or use Windows uninstall option under system control panel 'Programs and Features'.

-

Page 16: Printer Properties

IV. Printer Properties A. Introduction The ViewPlus printer driver uses a standard Windows printer driver interface to provide user access to setting options on the ViewPlus embosser from a local or networked computer. The printer properties are accessible through the Windows system control panel 'Devices and Printers'. Select the VP Columbia in the list of printers and get to the printer properties through the context menu. - Page 17 Shows Device Settings Tab Form To Tray Assignment Tractor Feed: The first section of the Device Settings tab shows the Columbia's 'tray assignment'. Feel free to ignore this as it is a Windows default item that can't be hidden, but it does not have any relevance for your printing.

- Page 18 Form Length: This field shows the page length. For standard page sizes, this field is informational only. If the Form Size is set to Custom, this field is editable. Top Margin: Set the top margin to be used when printing in legacy mode. NOTE: IF YOU ARE PRINTING FROM AN APPLICATION THAT SENDS MARGIN INFORMATION WITH THE PRINT JOB, SET THE TOP MARGIN TO 0.

- Page 19 Custom Media Lowest Force: Enter the hammer force value to be used for the lowest dots on a custom media type. See also 'Media Types' section within 'Printer Extension Program' explanations below on how to best determine the correct value. Custom Media Highest Force: Enter the hammer force value to be used for the highest dots on a custom media type.

- Page 20 was written to the printer last will be referred to as Custom table and stay on-board as custom table until another file is written to the printer, taking the place of Custom table. The custom braille table can be chosen as file type *.bct, *.dis, or *.rbt. The file browser dialog will default to the location of the Braille tables being used within Tiger Software Suite.

- Page 21 Shows selection of active Braille Table Braille Dot Height: Select 'Low', 'Normal', or 'High' to control how tall the Braille dots will emboss. Duplex: Choose whether to print single sided or double sided (interpoint).

-

Page 22: Service Tab

Service tab The Service tab of the printer properties dialog window provides information about the connected ViewPlus Columbia at the bottom left. When contacting ViewPlus Support, please have the driver version, printer serial number, and firmware version available. Shows Printer Properties Service Tab ... - Page 23 Print Test Page: Initiates the printing of an on-board test page from the embosser. Make sure the embosser is properly connected to your computer, and paper is loaded when trying to print a test page. Enable Status Monitoring Status messages of the embosser will be displayed and updated permanently as long as the checkbox is checked and the embosser is properly communicating with the computer.

- Page 24 Skew: If on embossed Braille text, dots 1, 2, 3, or 4, 5, 6 do not appear in a straight line underneath each other, this could be caused by the 'Skew' setting being off. In this case make sure to have paper loaded in the embosser, and initiate a test print clicking button 'Print Skew Calibration'.

-

Page 25: Printing Preferences

C. Printing Preferences The Printing Preferences contain settings for printing from Windows programs to your ViewPlus Columbia, which will affect the output of individual print jobs. To open the printing preferences dialog, choose the 'Preferences…' button on the 'General' tab of the 'Printer Properties' dialog. - Page 26 Shows Layout Tab Output Single Sided: Select this option if you do not want the back sides of the pages printed. Double Sided (Interpoint): Select this option if you want the back sides of the pages printed. If 'Double Sided (Interpoint)' is selected, the following option also becomes available: o Insert an empty page to the front or back of a graphics page: If this is selected, a blank page will be inserted automatically on the back of every page that contains...

- Page 27 Print Collate: When the collate box is checked and multiple copies of a document are printed, one complete document will be embossed at a time. If the collate box is not checked, all copies of each page will be embossed before embossing all copies of the next page of the document. Preview: If this option is checked, a preview of how the document will print and emboss will be shown in Tiger Viewer.

-

Page 28: Paper/Media Tab

Paper/Media tab The Paper/Media tab contains options related to the type of paper or media being used for printing. Select the desired options for your media. Shows Paper/Media Tab Paper and Media Paper size: Select the paper size you are using from the list, or leave the setting at 'Automatic Select' to allow the paper size setting from the application you are printing from to be applied. - Page 29 Advanced … : The 'Advanced...' button will bring up another dialog, which allows you to create and manage custom media types and paper sizes. Shows Advanced options in Paper/Media settings o Media Type The drop down list will show all media types currently available. This list can be edited using the buttons underneath.

- Page 30 Edit the name of your new custom media type if you like to. Then choose a hammer force value for the highest dots to be embossed, and the lowest dots to be embossed on your outputs. Edit: This will bring up the same dialog as 'Add', but with the constraint to editing the 'Lowest' and 'Highest Dot Value' only for an existing custom media type from the list.

-

Page 31: Tiger Tab

Tiger tab The Tiger tab contains controls for Braille and print output options as follows. Shows Tiger Tab How to Print Dot Quality: Select 'Draft', 'Standard' or 'Best'. Printing with draft dot quality is the faster option. Standard or best dot quality will produce rounder, smoother dots, but will slow down the printing process. Braille Height: Select 'Low', 'Normal' or 'High' Braille dot height. - Page 32 Braille Standard: Choose from five different standards to define dot spacing for Braille text. More Options … : This button will brings up a new dialog with the following options. Shows the More Options dialog window o Images Invert Colors: Check this option if you want colors to emboss inverted, meaning lighter colors will emboss in higher dots, and darker colors will emboss in lower dots.

-

Page 33: Operator Panel

V. Operator Panel A. Button functions LED1 LED2 LED3 and LED4 yellow green Shows the operator panel with LED lights (The buttons are described from left to right order.) Menu: In offline state press this button to enter the on-board menu to adjust settings for printing in legacy mode, for example when printing from a note taker instead of a Windows PC. -

Page 34: Operator Panel Menu

Cancel: Holding this button during power on of the embosser will yield to embossing a demo page. Pressing this button during printing will stop the print job or clear error status. During stand-by, this button will switch the embosser between online and offline mode. B. -

Page 35: Machine Status And Alerts

The following table shows all menu items and their value range Menu item Description Values Form Size Paper form size 11.5x11 inches, letter, custom, German standard fanfold Language Menu language English IP address Will state IP address, but no change possible Double sided Set double sided or single sided print Short edge, long edge (both for... - Page 36 Carriage stall: If the carriage stalls, turn the embosser off and see if the paper path is clear following instructions in VI.B below to remove jammed paper. Turn the embosser back on. If this does not clear the error status, contact ViewPlus Support. Any failure that can't be identified: Turn the embosser off and contact ViewPlus Support.

-

Page 37: Paper Handling

VI. Paper Handling A. Paper Loading Your ViewPlus Columbia comes with a tractor mechanism, feeding paper from the back. Follow the instructions below to load tractor feed paper: o Open the paper cover by lifting the back edge of the housing top and rotating it towards the front of the printer. - Page 38 o Open the tractor feeder lid and release paper from the tractor pins if still engaged. o Pull on visible paper on the output (front) side of the machine, take care to distribute pulling force evenly across the paper to prevent tearing. o If the paper does not completely pull out the front, remove any remaining paper from the rear of the embosser, take care to distribute pulling force evenly across the paper to prevent tearing.

- Page 39 o In the rare event, there are still scraps of paper left behind in the embosser, fold a thick sheet of paper in half, insert the sheet into the embosser over the tractor feed, and move the sheet from side to side to free paper remnants. o Once the paper jam is clear, insert paper again, engage tractors, close the lid and reprint the document.

-

Page 40: Braille, Translation And Printing

Braille font as further described under B. below. A. ViewPlus Tiger Software Suite Within MS Office Word, and Excel the ViewPlus Tiger Software Suite (TSS) provides direct tools for text to Braille translation in numerous languages and contraction grades. TSS includes easy translation of charts and graphs in MS Excel and provides further tools to easily create and edit tactile graphics originating from other Windows applications. -

Page 41: Math And Braille

In general, ViewPlus printers follow the principle "What you see is what you get". The screen image is converted to tactile resolution and colors are converted to different dot heights on the embossed output, where darker colors are embossed with higher dots (black = highest dot), and lighter colors are embossed with lower dots (white = no dot). -

Page 42: Software Packages

A. Software Packages Tiger Software Suite (TSS) The ViewPlus Tiger Software Suite (TSS) is the complete solution for producing Braille and tactile graphics by harnessing the full power of MS Word and Excel. The press of a button automatically converts and formats documents that were originally created for an ink printer. -

Page 43: Training, Warranty, Maintenance And Support

Contact your ViewPlus embosser sales representative if you did not purchase directly from ViewPlus Technologies o E-mail to support@viewplus.com, or o Call the ViewPlus support hotline at +1 (866) 836 2184, or the ViewPlus Technologies office at +1 541 754 4002 (Pacific Standard Time Zone). D. Warranty For information on your product warranty, please visit our website and select the warranty details link under category support.

Need help?

Do you have a question about the VP Columbia VPTT2113-01 and is the answer not in the manual?

Questions and answers