Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Indmar 5.7L MPI

- Page 1 Operator ’s Manual...

- Page 2 PROPOSITION 65 WARNING The engine exhaust from this product contains chemicals known State of California to cause cancer, birth defects or other reproductive harm.

-

Page 3: Important Safety Information

Indicates the presence of a hazard which result of your decision. CAN cause SEVERE injury, death or substan- tial property damage. Indmar Marine Engines... - Page 4 ENGINES COVERED The information in this manual applies to the following Indmar-branded GM-based engines, as well as the GM-based engines built specifically for our OEM Boat Builder Customers listed below: Axis MB Sports Malibu Moomba Sanger Supra Svfara Tigé The above list is subject to change as new customers become members of the Indmar family.

- Page 5 Dear Indmar Marine Engine Owner, Thank you for selecting a boat powered by an Indmar Marine Engine. Indmar is proud to provide the power to the best boat companies in the business and we hope that pride shows in the quality of our products. In the unlikely event that you have a defect related problem with your boat’s engine / drive train, you can...

- Page 6 INDMAR MARINE ENGINES COMPANY MISSION To produce the world’s finest, most advanced and most dependable gasoline inboard marine engines at the best possible price, while respecting the needs of our employees, customers, vendors and the precious environment we share. Indmar Marine Engines...

-

Page 7: Table Of Contents

Exhaust Hoses ........4-8 Indmar Marine Engines... - Page 8 Appendix B – Engine Specifications ..... . . B-1 Appendix C – Limited Warranty ......C-1 Indmar Marine Engines...

-

Page 9: Introduction

They have current specifications, parts and the special equipment needed to service your Indmar engine and drive line. To find your nearest Indmar dealer, please call (901) 353-9930 or visit our website at www.indmar.com. To ensure that the proper information is available, note the six digit engine serial number. - Page 10 The engine serial number is stamped into the block and should also be written on the inside of the back cover of this manual. Always retain a copy of the serial number for your personal records. Indmar Marine Engines viii...

- Page 11 If the trade-in and resale is handled by an authorized Power Squadron, state boating authorities, or the Indmar dealer, the dealer must fill out the warranty regis- American Red Cross. Know the law and your responsi- tration transfer form and send it and other paperwork bilities as a boat owner.

- Page 12 INDM-A042 • LS3 and LSA Engines 91 Octane Your Indmar manufactured engine has a special environ- • All other Indmar Engines 89 Octane mental label required by the California Air Resources Board (CARB). The label has 1, 2, 3 or 4 stars. A hang- tag, provided with your inboard engine, describes the meaning of the star system.

- Page 13 Fuel pressure regulator Additives – The only additive that is recommended by Manifold Absolute Pressure Sensor Indmar for use in your engine is Sta-Bil brand fuel sta- Throttle Position Sensor bilizer. This additive helps preserve the fuel in your Idle Air Control Valve tank and in the engine’s fuel system.

- Page 14 Emission Control Warranty may be excluded from Indmar for the remainder of the warranty period of the such warranty coverage if Indmar demonstrates that original part. All parts replaced under this limited warranty the engine has been abused, neglected, or improperly become the property of Indmar.

- Page 15 Indmar receives a proof that the former owner agreed Emission Maintenance Requirements to the transfer of ownership and we are provided with the information listed below. The following component maintenance is required to maintain the Emission Control System of your engine.

- Page 16 Spark Plug Wires: See Chapter 6, Maintenance Breather Hose: See Chapter 6, Maintenance Ignition Timing: See Chapter 6, Maintenance Carburetor Adjustment: See Chapter 6, Maintenance Emission Component Part Numbers Following are the Indmar Part numbers for the Emission Maintenance Components: Plug Engine Spark Oxygen...

- Page 17 Select emission control parts from model year 2009 and YOUR WARRANTY RIGHTS AND OBLIGATIONS later are warranted for 3 years. The California Air Resources Board and Indmar Products are pleased to explain the emission control system warranty on your inboard engine. In California, new inboard engines must be designed, built and equipped to meet the State’s stringent anti-smog standards.

- Page 18 Owner’s Warranty Responsibilities You are responsible for presenting your inboard engine to an Indmar Products service center as soon as a problem exists. The warranty repairs should be As the inboard engine owner, you are responsible for the completed in a reasonable amount of time, generally performance of the required maintenance listed in your within 30 days.

-

Page 19: Chapter 1: First Time Operation And Break-In

Exhaust – The drain hose must be connected. engine for the first time. If you have questions about any Transmission – The transmission oil cooler has one of these procedures, see your Indmar dealer for assis- drain plug. In addition, the Walters V-Drive and ZF tance. - Page 20 Blocked or 3. Make sure your battery is fully charged and the restricted water flow may damage the engine. cables are clean and tight. 4. Check engine oil for correct level. Refer to Chapter 6, Maintenance . Indmar Marine Engines...

- Page 21 Repeat above eight to ten times NOTICE The above procedure is only necessary for the first time the engine is started or in the event the fuel tank is run dry. Figure 1.4 – Raised Engine Cover Indmar Marine Engines...

- Page 22 Break-In • Report abnormal operation, noises or vibrations to your dealer. Taking care now to break-in your new Indmar engine is VERY important. When properly broken in, your engine Break-in Steps will last longer, run better and require fewer repairs over its lifetime.

- Page 23 Your Indmar dealer is best equipped to check the engine immediately after break-in. After the break-in procedure is over, your boat may be operated at any speed.

- Page 24 Indmar Marine Engines...

- Page 25 Operating a boat is a safe and enjoyable experience. Indmar marine engines use gasoline for fuel. The area under the engine and around the gasoline tank and sup- ply lines is not open to outside air. Ventilation around...

- Page 26 DO keep your boat’s engine well-maintained and regularly check to make sure carbon monoxide detectors in the Some Indmar engines are equipped with catalytic con- cabin are working properly. verters which significantly reduce harmful CO emissions, DO always wear a properly fitted life jacket while in or but it is important that all of the DO’s and DON’Ts still...

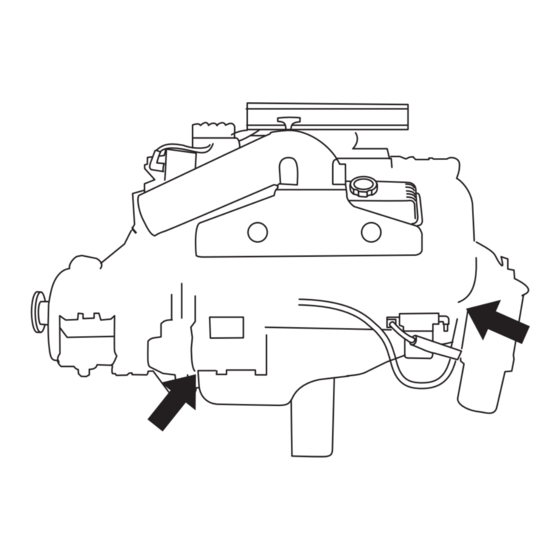

- Page 27 This work must be performed by your Indmar dealer’s technicians. INDM-A007 Figure 2.1 – Pre-Start Check Points Your Indmar Marine Engine is cooled by 1. Verify boat hull and/or garboard drain plug are in pumping water from the body of water that place.

- Page 28 9. Check alternator belt for wear and proper tension. 10. Verify that exhaust hoses are in good condition and clamped tight. 11. Ensure that the propeller shaft coupler bolts are tight. 12. Verify engine mounts are tight. Indmar Marine Engines...

- Page 29 Check wiring for signs of wear and abrasion. 14. Verify throttle/shift control is functional and properly adjusted. 15. Verify steering controls are functional and properly adjusted. 16. Verify battery connections are clean and securely fastened. INDM-A010 Figure 2.4 – Battery Connections Indmar Marine Engines...

- Page 30 Indmar Marine Engines...

-

Page 31: Chapter 3: Engine Starting Procedures

This work must be performed by your Indmar dealer’s technicians. Before starting engine operate bilge blower NOTICE at least 4 minutes and raise engine cover to Current fuel injected engines are equipped with a ventilate fumes. -

Page 32: How To Start Your Engine

Once the engine has started, immediately pulled out. check the oil pressure. Monitor the oil pressure and engine temperature closely for the first 10 minutes of operation. Indmar Marine Engines... -

Page 33: If Engine Does Not Start

1/4 of its total travel. Turn the key to START again and see if the engine starts. If your engine does not start after several attempts, it may have too much fuel and needs to be cleared. INDM-A016 Figure 3.3 – Typical Shift/Throttle Lever Indmar Marine Engines... -

Page 34: Engine Restart

4. If it does not start, wait two minutes and try the system. Before adding electrical equipment, consult sequence again. your Indmar dealer. ENGINE RESTART 1. If your engine is already warm and will not re-start, turn key to ON position and wait for about 20 seconds (not necessary with carbureted engine). -

Page 35: Chapter 4: Normal Operation

Component damage due loading may not be covered by the engine’s limited to water is not covered by the warranty. warranty. 2. Follow the starting procedures outlined in Chapter 3, Engine Starting Procedures . Indmar Marine Engines... - Page 36 3. Once the engine is started, allow it to reach operating temperatures of at least 120°-140°F INDM-A014 (49°-60°C) before accelerating to speeds above 3000 RPM. Figure 4.2 – Typical Oil Pressure Gauge INDM-A015 Figure 4.1 – Typical Temperature Gauge Indmar Marine Engines...

-

Page 37: Operating The Controls

Avoid using the throttle when in reverse. the shift / throttle control is in the NEUTRAL position and This can force water backwards into the try again. exhaust system and into the engine cylinders with major damage. Indmar Marine Engines... -

Page 38: Unusual Vibration

FUEL SYSTEM The Indmar fuel system uses high quality marine grade HYDROSTATIC LOCK: If water collects in the components. These components will tolerate small engine cylinder for any reason, it can cause amounts of water without sustaining damage. Your hydrostatic lock, not allowing the pistons in engine will misfire and run poorly, however, if water is in the engine to move properly. -

Page 39: Service Required" Or "Check Engine" Indicator (Efi Engines Only)

Check Engine light. This alerts you when the ECM (Engine Control Module) detects a possible engine prob- lem. If the indicator goes on, return to dealer for service. CHECK ENGINE INDM-A010 Figure 4.4 – Typical Marine Battery INDM-A018 Figure 4.5 – Typical Check Engine Light Indmar Marine Engines... -

Page 40: Check Transmission Light

V-Drive oil level is sufficient. If the oil level is normal and the light stays lit above 2000 RPM, take the boat to your Indmar dealer for service. Schedule engine service at once when this light is illuminated. - Page 41 Running engine without adequate cooling can cause engine to overheat and may result in fire, explosion, death and/or personal seri- ous injury. Running the engine during the RPM reduc- tion phase may cause severe damage to your engine. Indmar Marine Engines...

-

Page 42: Exhaust Hoses

WOT operating range, you must select a pro- peller (propping) with the proper diameter and pitch. The propeller which was supplied with your boat was chosen by the boat builder for best all-around performance under average conditions. Indmar Marine Engines... - Page 43 WOT RPMs. An engine that is over-revving may quickly cific high-elevation locations. experience catastrophic damage. Indmar suggests that if you do require a different pro- If the WOT RPM is lower than the minimum RPM in your peller, consult the dealer you bought the boat from. The engine’s WOT operating range, the boat is over-propped.

- Page 44 Indmar Marine Engines 4-10...

-

Page 45: Chapter 5: Fuel

Gasoline vapors are highly flammable and fuel of 89 octane or higher. The LSA and LS3 require 91 explosive. octane or higher. Indmar recommends purchasing fuel • Never smoke while refueling. Keep sparks from a supplier that advertises that the fuel meets “TOP and flames away from fuel. -

Page 46: Using Oxygenated Fuels Or Fuels With Alcohol

USING OXYGENATED FUELS OR FUELS WITH FUELS IN OTHER COUNTRIES ALCOHOL If you operate your Indmar engine outside the USA or Canada, unleaded fuels may be difficult to obtain. Ethyl alcohol, ethanol or grain alcohol is acceptable as Leaded fuels must not be used in engines with catalytic long as it is a blend and the blended fuel contains no converters or serious damage will occur. -

Page 47: Chapter 6: Maintenance

Your Indmar dealer is your best source for engine repair installed and tightened. If not, any electrical or ignition and maintenance. Indmar certified technicians attend... - Page 48 Boats that are operated in these severe conditions will be required to have more frequent oil and filter changes (every 25 hours instead of every 50 hours). Indmar Marine Engines...

- Page 49 Spark Plug Wires* Raw Water Pump Impeller Replace Breather Hose* Clean Starter Bendix* Grease Inspect/Clean Heat Exchanger Zinc Anodes Inspect * Services best accomplished by your Indmar dealer. Severe use applications (see special note on previous page) Indmar Marine Engines...

-

Page 50: Engine Oil

... it’s the nature of about 2 minutes after you turn off the engine to allow the the beast. oil to drain into the oil pan, giving you a more accurate reading. INDM-A003 Figure 6.2 – Dipstick Indmar Marine Engines... - Page 51 5. After reading is complete, return dipstick to tube. damaged. 6. Add oil if necessary. Indmar uses and recommends marine 15W40 in all 5.7L Adding Oil and 6.0L engines and Mobil 1 5W30 in all 6.2L engines. These oils meet or exceed the API Service CI-4 and SL.

- Page 52 Synthetic Oil For the engines that come from Indmar with conventional oil, synthetic oil that meets our viscosity requirements and meets or exceeds API SL/SJ/CI-4, CH-4, CG-4 is acceptable to use after 100 hours of operation with the recommended oil. The use of syn- thetic oil does not change the requirement of 50 hour (25 hour in severe conditions) oil change intervals.

- Page 53 Oil Additives Do not use oil additives. Indmar engines do not need oil Engine oil is hot. Be careful not to burn yourself. additives. Use of recommended oil, along with regular oil and oil filter changes, will protect your engine adequately.

-

Page 54: Engine Flame Arrestor

ENGINE COOLING Periodically inspect flame arrestor to prevent clogging by dirt or corrosion. There are two types of flame arrestors used in Indmar engines, metal and paper. Running engine without adequate cooling can cause engine to overheat and may result in fire, explosion, death and/or personal serious injury. - Page 55 Fresh water cooled engines are shipped from A typical home water supply cannot supply the Indmar factory filled with a 50/50 mix of enough water to operate the engine at high Sierra brand antifreeze and water. This mix- RPM. Do not run the engine above 1000 RPM ture provides freeze protection down to –26°...

- Page 56 (1, Figure 6.6) when the engine is cold. • The coolant system should be flushed and coolant replaced every two years. This should be performed by a qualified Indmar service technician. Indmar Marine Engines 6-10...

- Page 57 Salt and Hard Water Operation salt water corrosion if operated in brackish or salt water. All Indmar Marine engines are capable of operating in Factory-installed closed cooling systems are available for brackish or salt water as well as in hard water or water the 6.0L and the 6.2L LS3 engines.

-

Page 58: Internal (Cooling System) Care

To keep your engine engine but raw water in the exhaust manifolds is referred looking like new, Indmar recommends applying an anti- to as a half-system. Although the engine is protected, it corrosion compound. Regular application (every 3... - Page 59 Inspect the zinc anode associated with the two piece manifold/riser assemblies. often during use and replace when it is 3/4" (19 mm) or less. Indmar Marine Engines 6-13...

-

Page 60: Fuel System

High water levels can also allow water intru- sion into the transmission causing severe damage. Indmar engines are equipped with one of these marine INDM-A036 transmissions: Figure 6.8 – Raw Water Pump Impeller •... - Page 61 1. Dipstick 1. Dipstick Figure 6.10 – Stern Mount, ZF Hurth Ski-Vee or Indmar-Vee Throughshaft Models Figure 6.9 – Midships Mount, ZF Hurth Marine In-Line Indmar Marine Engines 6-15...

- Page 62 1. Dipstick Figure 6.11 – Stern Drive, Walters V-Drive and 1. Dipstick ZF Hurth In-Line Figure 6.12 – Stern Mount, ZF Hurth Ski-Vee or Indmar-Vee Undershaft Models Indmar Marine Engines 6-16...

- Page 63 Overfilling the transmission with fluid will cause the seals to leak, and eventually lead to overheating. When there NOTE: Refer to page 6-18 for correct transmission and is too little fluid, over-heating will result. fluid capacities for your model of transmission. Indmar Marine Engines 6-17...

- Page 64 1.0 qt (1.06 L) V-Drive Unit Dexron ATF Walters V-Drive RV-26D-71V 0.5 qt (0.5 L) 15W40 Motor Oil 2.3 qt (2.18 L) Main Gearbox Dexron ATF Indmar V – 1.25 qt (1.18 L) V-Drive Unit Mobil Delvac Synthetic 50 Indmar Marine Engines 6-18...

-

Page 65: Electrical System

If the fuse blows again, there is a problem with the elec- trical system. Take your boat immediately to your Indmar dealer for repair. All Indmar engines are equipped with a 40 A Maxi-Fuse (1, Figure 6-14) to protect the engine electrical system NOTICE and components from overload. -

Page 66: Wiring

The battery leads or reversed jumper leads. These types of excessive current draw can overheat the diodes and failures are not covered by Indmar’s Limited Warranty. cause them to fail. Indmar Marine Engines... - Page 67 Indmar dealer. 5. OVERLOADED: Never use the alternator to bring a dead or undercharged battery to a fully charged con- dition.

- Page 68 Indmar Marine Engines 6-22...

-

Page 69: Chapter 7: Storage And Winter Lay-Up

Damage that is the result of improper warranty! storage is not covered under terms of Indmar’s limited warranty. To properly winterize your engine, you MUST be able to bring the engine up to operating temperature. To accom-... -

Page 70: General Preparation

(Fresh Water Cooled Engines Only) the engine compartment is well ventilated • Propylene Glycol Anti Freeze (As required for Fresh and that no fuel leaks are present. Water Cooled Engines Only) Indmar Marine Engines... - Page 71 Placing all drain plugs, impeller, etc. in a plastic bag On catalytic converter-equipped engines, and attaching the bag to the steering wheel of the Indmar does not recommend applying fog- boat is a good reminder to reinsert the plugs when ging oil while the engine is running. The fog- you recommission the boat in the spring.

- Page 72 3. Remove the raw water pump impeller from the pump INDM-A038 housing. Replace annually. Figure 7.1 – Quick Disconnect 4. Remove the hose from the lower (rear) end of the transmission cooler. Inspect the cooler for any debris such as weeds, plastic, etc. Indmar Marine Engines...

- Page 73 Drive Train Preparation 1. Change the transmission fluid following the instruc- tions in the transmission owner’s manual. 2. Drain the water from the cooling section of the V-drive transmission. INDM-0024a Figure 7.4 – ZF Ski-Vee Water Drains Indmar Marine Engines...

- Page 74 ZF Through-Shaft Ski-Vee. On these models, c. Indmar-Vee. On these models, you must remove you must remove the hose from the fitting that is the plug from the rear of the V-drive to drain the pointed toward the engine to drain the cooler.

- Page 75 V-drive to drain the cooler. water drain plugs. INDM-0026 Figure 7.8 – Walter V-Drive Drain Plugs INDM-0022 Figure 7.7 – Indmar-Vee Through Shaft Drain Plug Indmar Marine Engines...

- Page 76 3. Disconnect the large diameter hose that runs from the water-circulating pump to the thermostat housing. Make sure all of the water drains from the hose. IND-A005A Figure 7.9 – Anti Knock Sensor Indmar Marine Engines...

- Page 77 3. Remove the drain plugs from the ends of the heat the housing. exchanger and drain the raw water from the exchang- er. One of the drain plugs in the heat exchanger is a Indmar Marine Engines...

-

Page 78: Reactivating Engine After Extended Storage

11. Check condition of the distributor cap and rotor on damage electrical components. These dam- 5.7L engines, and replace if worn, damaged or cor- ages are not covered by your warranty. roded. Indmar Marine Engines 7-10... - Page 79 If no leaks are found, the boat is ready for operation. " 0 . 0 INDM-A037 Figure 7.12 – Prop Shaft Flange Alignment Indmar Marine Engines 7-11...

-

Page 80: Extended Storage

11. Apply water to the engine’s cooling system and start authorized Indmar dealer. the engine. While the engine is warming up, check for leaks and smooth engine operation. Monitor the 1. -

Page 81: Chapter 8: Troubleshooting

In most 6. Lack of fuel at carburetor (carbureted engines only) cases, you will need the assistance of your Indmar deal- 7. Battery cables loose or corroded er to correct the cause of the problem. - Page 82 3. Plugged positive crankcase ventilation system ratchet 4. Engine in need of tune-up 5. Engine needs to be adjusted for high altitude operations 6. Engine needs to be adjusted for temperature extremes 7. Carburetor out of adjustment (carbureted engines only) Indmar Marine Engines...

-

Page 83: Appendix A - Maintenance Components And Fluids

15W-40 motor oil, API Service SL/SJ/CI-4, CH-4, CG-4 Indmar-Vee (Shifting Transmission – Dexron ATF) (V-Drive Mobil Delvac Synthetic Transmission Fluid 50) Engine Fuel (for storage) Marine Formula STA-BIL fuel stabilizer Engine Cables (for corrosion protection) Corrosion protectant and lubricant Starter Bendix Multipurpose grease Indmar Marine Engines... - Page 84 All 5.7L Raw Water Cooled – Indmar 985009 All 5.7L Fresh Water Cooled – Indmar 986034 All 6.0L and 6.2L LS3 Raw Water Cooled – Indmar 985009 All 6.0L and 6.2L LS3 Fresh Water Cooled – Indmar 986115 All 6.2L LSA – Indmar 986115 Spark Plugs All 5.7L Carbureted Engines 41-101 (.030)

-

Page 85: Appendix B - Engine Specifications

Appendix – B ENGINE SPECIFICATIONS See page ii for engine models 5.7L MPI Number of Cylinders Displacement 350 CID (5.7L) 364 CID (6.0L) 376 CID (6.2L) 4.0012 x 3.480 in. 4.0012 x 3.622 in. 4.065 x 3.622 in. Bore/Stroke (101.63 x 88.39 mm) (101.63 x 92 mm) - Page 86 Fluid Capacities 5.7L Carbureted 5.7L MPI Crankcase (With Filter) 5.5 Quarts (5.25L)* 6.0 Quarts (5.7L) 8.5 Quarts (8.0L) Closed Cooling System 12-14 Quarts (11.4-13.3L) In-Line 1:1 Transmission 1.7 Quarts (1.6L) Dexron 3 ATF In-Line Reduction Gear 2.12 Quarts (2L) 15W40 ZF Ski Vee Transmission 2.12 Quarts (2L) Main Gearbox, 1.0 Quart (1.06L) V-Drive - Dexron 3...

- Page 87 Indmar product attains more than 50 hours of use regardless of the source of such use.

- Page 88 (h) Transportation charges and travel time incurred by dealer to fulfill any of its obligations pursuant to this Limited Product Warranty. (i) Service or work to the Product as requested by the Customer that is as determined solely by Indmar to be beyond the scope of this Limited Product Warranty.

- Page 89 (o) Defects to the Product as determined solely by Indmar to be caused by the use of fuels and lubricants that are not suitable for use with or on the Product or its fuel system components that was damaged or rendered inoperable from stale gasoline.

- Page 90 Product. In the case of a leased boat, a copy of the lease contract showing the length of the lease must be delivered to Indmar. In the case of a warranty transfer to a subsequent owner or lessor, the new owner/lessor’s information along with the appropriate payment...

- Page 91 (c) When damage to the Product results from cases not arising from defects in material and/or workmanship and Indmar in its sole discretion determines the same. 10. Notices. Any notice to Indmar set forth pursuant to this Limited Product Warranty shall be delivered to the following address: Indmar Products Co., Inc.

- Page 92 Customs charges, import duties, taxes and VAT on warranty replacement parts INTERNATIONAL WARRANTY PROCEDURES Indmar is excited to expand internationally with our boat builder partners and continually stands behind and supports its power packages that are sold outside the United States and Canada. To provide this support, Indmar Marine engines would like to ask international customers to help us provide the best quality customer service by adhering to all respon- sibilities that our North American owners comply with as outlined in this warranty.

- Page 93 Date of Purchase: ______________________ Owner Name: _____________________________________________ Address: __________________________________________________ City: ________________________________ State/Province: ___________________________ Zip/Postal Code:____________ Country: ____________________ Engine Serial Number: _____________________________ Transmission Serial Number: _______________________ 10-20 Hour Service Every 100 Hour Service Every 300 Hour/Annual Service Date:___________ Hours:____________ Date:___________ Hours:____________ Date:___________ Hours:____________ By:_______________________________ By:_______________________________...

- Page 94 The first production inboard equipped with catalytic converters. 5400 Old Millington Road Millington, TN 38053 w w w. i n d m a r. c o m Ken Cook Co. Part No. OME0502-15 Printed in U.S.A.

Need help?

Do you have a question about the 5.7L MPI and is the answer not in the manual?

Questions and answers