Table of Contents

Advertisement

Installation, Operation and

Service Manual

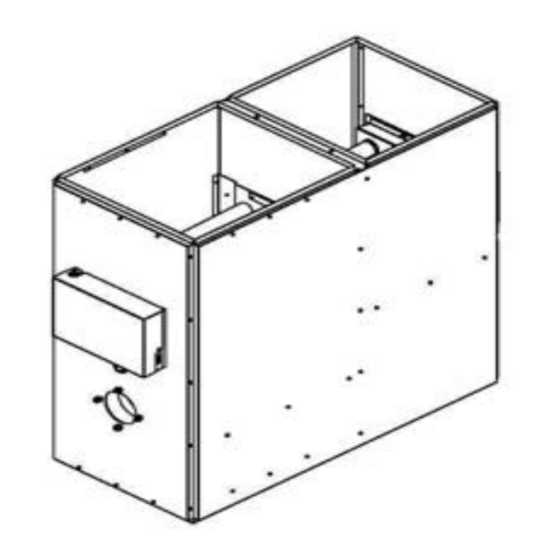

GEMINI 3T & 5T / ECLIPSE 3T

80% + EFFICIENCY

GAS FIRED

LOWBOY FURNACE

KLR- FRONT

KLR- REAR

KLR- REAR

KLF- FRONT

GEMINI 3T & 5T

ECLIPSE 3T

INSTALLATIONS MUST MEET ALL LOCAL AND FEDERAL

CODES THAT MAY DIFFER FROM THIS MANUAL

Please read the manual in its entirety before beginning installation.

This manual must be kept with the furnace for future reference.

GRANBY FURNACES INC.

PO Box 637

12118 Hwy 209

Parrsboro Nova Scotia Canada

B0M 1S0

902-254-2543

www.granbyindustries.com

04-07-2015

G2014-E7 Rev. A

Advertisement

Table of Contents

Summary of Contents for KERR GEMINI 3T

- Page 1 Installation, Operation and Service Manual GEMINI 3T & 5T / ECLIPSE 3T 80% + EFFICIENCY GAS FIRED LOWBOY FURNACE KLR- FRONT KLR- REAR KLR- REAR KLF- FRONT GEMINI 3T & 5T ECLIPSE 3T INSTALLATIONS MUST MEET ALL LOCAL AND FEDERAL CODES THAT MAY DIFFER FROM THIS MANUAL Please read the manual in its entirety before beginning installation.

-

Page 2: Table Of Contents

TABLE OF CONTENTS Gemini & Eclipse IMPORTANT SAFETY ADVICE PRODUCT INFORMATION FURNACE INSTALLATION ACCESSORIES INSTALLATION BURNER INSTALLATION AND SPECIFICATIONS 5.1 ASSEMBLY & INSTALLATION OF BURNER 5.2 GAS-FIRED FURNACE LIGHTING INSTRUCTIONS 18 5.3 TECHNICAL INFORMATION / SET-UP FURNACE OPERATION AND SETTINGS 6.1 BLOWER SETTING 6.2 FAN TIMER CONTROL BOARD (ST9103 A 1028) 6.3 (ST9103 A 1028) CONTROL BOARD SEQUENCE... - Page 3 WARNING: If the information in this manual is not followed exactly, a fire or explosion may result, causing property damage, personal injury or death. - Do not store or use gasoline or other flammable vapors or liquid in the vicinity of this or any other appliance.

-

Page 4: Important Safety Advice

1.0 IMPORTANT SAFETY ADVICE Please read and understand this manual before installing, operating or servicing the furnace. To ensure you have a clear understanding of the operating procedures of the unit please take the time to read the IMPORTANT SAFETY ADVICE section of this manual. •... - Page 5 IMPORTANT This manual contains instructional and operational information for the GEMINI 3T & 5T/ ECLIPSE 3T OIL-FIRED FRONT / REAR FURNACE. Read the instructions thoroughly before installing furnace or starting the burner.

-

Page 6: Product Information

Thermostat anticipator See thermostat instructions MOTOR/BLOWER Gemini 3T / Eclipse 3T: 1/2 hp 4 Speed / G10-8 DD or 1/2 hp ECM / G10-8 Gemini 5T: ¾ hp / G12-10 DD or ¾ hp ECM / G12-10 DD FAN/HIGH LIMIT CONTROL Honeywell ST9103A1028 Fan Center &... - Page 7 PLENUM (GEMINI 3T & 5T) REAR / FRONT Cold air return 19” x 20” (483 x 508 mm) Hot air supply 23-7/8” x 20” (606 x 508 mm) Plenum spacing 3T: 1-3/4” (45mm) 5T: 2-3/4” (70mm) GEMINI 3T/5T FRONT (KLF)

- Page 8 PLENUM (ECLIPSE 3T) REAR / FRONT Cold air return 18” x 20-3/4” (457 x 527 mm) Hot air supply 18” x 21-3/4” (457 x 552 mm) Plenum spacing 2” (50mm) ECLIPSE 3T FRONT (KLF) ECLIPSE 3T REAR (KLR)

-

Page 9: Furnace Installation

3.0 FURNACE INSTALLATION GAS PIPING Gas piping must conform to local requirements. Install according to the applicable code such as NATIONAL FUEL GAS CODE ANDSI Z223.1/NFPA 54 AND/OR NATIONAL GAS AND PROPANE INSTALLATION CODE CAN/CSA B149.1. The gas piping must be installed between the gas meter and the combination gas valve (located upstream of the Riello gas burner on the furnace. - Page 10 GAS SUPPLY PRESSURE • Maximum supply pressure: 13 inches W.C. • Minimum supply pressure: 7” inches W.C. • WARNING: • Do not expose the combination gas valve to gas pressures in excess of 14” W.C. The valve has a safety mechanism that interrupt the flow of gas over 14” W.C. In any event higher pressure could damage the valve seat, resulting in potentially hazardous conditions.

- Page 11 • If the gas supply pressure can exceed 14 inches of water column at any time, you must install a lockup type gas pressure regulator in the gas supply piping, ahead of the main manual gas valve on the burner. •...

- Page 12 PLACEMENT & VENTING THE INSTALLATION OF YOUR GAS-FIRED FURNACE MUST CONFORM TO THE REQUIREMENT OF THE AUTHORITY HAVING JURISDICTION OR IN THE ABSENCE OF SUCH REQUIREMENTS, TO THE NATIONAL FUEL GAS CODE ANDSI Z223.1/NFPA 54 AND/OR NATIONAL GAS AND PROPANE INSTALLATION CODE CAN/CSA B149.1.

- Page 13 5. Test for spillage at the draft regulator outlet / draft hood opening after 5 minutes of main burner operation. Use the flame of a match or candle, or smoke from a cigarette, cigar, or pipe. 6. After it has been determined that each appliance remaining connected to the common venting system properly vents when tested as outlined above, return doors, windows exhaust fans, fireplace dampers and any other gas-burning appliance to their previous condition of use.

- Page 14 Horizontal portions of the venting system shall be supported to prevent sagging by installing support every 36 inches. The horizontal runs must be sloping upwards not less than ¼ inch per foot from the boiler to the chimney connector. A furnace shall not be connected to a chimney flue serving a separate appliance designed to burn solid fuel.

- Page 15 DRAFT Use approved DOUBLE ACTING draft control supplied for 5” pipe. Set specified draft minimum pressure of -0.01” wc. THE CHIMNEY MUST BE EQUIPPED WITH A DOUBLE ACTING DRAFT REGULATOR. FAILURE TO COMPLY WITH THIS MAY RESULT IN IMPROPER OPERATION LEADING TO POTENTIAL DANGEROUS OPERATION OF UNIT AND INJURIES TO PERSON AND LOSS OF LIFE.

-

Page 16: Accessories Installation

4.0 ACCESSORIES INSTALLATION BLOCKED VENT SWITCH (BVSO) FOR CANADIAN APPLICATION ONLY Oil-fired appliances installed in Canada require a blocked vent switch system when installed on a chimney. A safety switch is included with the furnace to perform this function. It is the installer’s responsibility to install the switch in accordance with the instructions provided. - Page 17 Height of the coil above the unit supply shall be at least 4” (102 mm) for the ECLIPSE and 0’’ for the GEMINI. 4 inch 0’’ minimu GEMINI 3T/5T ECLIPSE 3T See A/C coil Manufacturers Requirements. To check the AC coil total air flow resistance, see procedure at page 33 HUMIDIFIER If a humidifier is installed ensure that no water can drip or run from it into the furnace.

-

Page 18: Burner Installation And Specifications

5.0 BURNER INSTALLATION AND SPECIFICATIONS 5.1 ASSEMBLY & INSTALLATION OF BURNER CONSULT THE BURNER INSTRUCTION MANUAL THAT IS INCLUDED IN THE BURNER BOX. In case of differences between the instructions on the burner instruction manual and this manual, the furnace instruction manual (this manual) must be followed. The instructions in the gas burner instruction manuals are detailed mounting, wiring, adjusting, testing and maintenance instructions that are specific to the burner used (Riello or Carlin). -

Page 19: Gas-Fired Furnace Lighting Instructions

• To restart the furnace, open again the manual gas shut-off valve that you closed a few steps back.. • Press the red button on the ignition control. The burner should then retry its ignition and light the burner. If this sequence is not respected, consult the burner manual 5.2 GAS-FIRED FURNACE LIGHTING INTRUCTIONS... -

Page 20: Technical Information / Set-Up

5.3 TECHNICAL INFORMATION / SET-UP KLR/KLF Series (KLR) ECLIPSE 3T / GEMINI 3T REAR (KLF) ECLIPSE 3T / GEMINI 3T FRONT G-120 Gas G-120 Gas Riello Burner Unit Model KLR-E1-*087-03 (N/P) KLF-E1-*087-03 (N/P) Input (BTU/h) 105,000 105,000 Output (BTU/h) 87,000... -

Page 21: General Information

KLR/KLF Series GEMINI 5T REAR GEMINI 5T FRONT G-200 Gas G-200 Gas Riello Burner KLR-E3-*131-05 (N/P) KLF-E3-*131-05 (N/P) Unit Model Input (BTU/h) 155,000 155,000 Output (BTU/h) 131,000 131,000 Manifold Pressure 4.5’’ W.C. Natural /3.8’’ W.C. Propane 4.5’’ W.C. Natural /3.8’’ W.C. Propane Orifice Size B5 Natural / B16 Propane B5 Natural / B16 Propane... -

Page 22: Furnace Operation And Settings

6.0 FURNACE OPERATION AND SETTINGS SHUTTING FURNACE DOWN POWER OFF Turn off main power breaker or disconnect. FUEL OFF Shut off manual gas supply valve. Always keep manual gas supply valve shut off if the burner is shut down for an extended period of time. -

Page 23: Fan Timer Control Board (St9103A 1028)

6.2 FAN TIMER CONTROL BOARD (ST9103A 1028) o “FAN OFF” Dip Switches adjustment Dip Switches COMFORT ADJUSTMENTS o Outlet air consistently too warm or too cold - change the blower motor speed to give the specified air temperature rise. o Outlet air gets too warm and burner shuts down - increase air by changing the blower motor speed to give the specified temperature rise. -

Page 24: St9103A 1028 Control Board Sequence

6.3 ST9103A 1028 CONTROL BOARD SEQUENCE ST9103 Heating Sequence 1) Thermostat calls for Heat. 2) Burner starts 3) Blower starts after 45 seconds 4) Burner shuts down after call for heat is satisfied 5) Blower stops according to adjusted (FAN OFF) Dip switch selection ST9103 Cooling Sequence 1) Thermostat calls for cooling 2) Blower starts immediately... -

Page 25: Servicing - Fan Timer St9103A 1028

6.4 Servicing - Fan Timer ST9103A 1028 Trouble shooting the Honeywell electronic board ST9103 Before trouble shooting the board, check for the 5 amp. fuse For accurate trouble shooting, follow step by step the Trouble Shooting Chart. Step Possible Cause Check-out procedure Corrective action No Heat... - Page 26 Step Possible Cause Check-out procedure Corrective action No Heat Check for 120 Volts on the Yes - Move to next step Riello burner black wire, contact (COM) No - Back to step # 4 or check for bad application on the burner activation connection relay Check if oil primary control...

-

Page 27: Service

Step Possible Cause Check-out procedure Corrective action Electronic air filter and Humidifier Check for 24 volts between Condensing unit terminal Y and C on the Yes - Compressor ON electronic fan control No - Check thermostat and wiring Check for 120 Volts on Electronic air filter terminal ''EAC'' of the Yes - Electronic filter failure... - Page 28 BLOWER REMOVAL This furnace has a blower sealing system, which is designed to be tight and rattle free. Refer to the instructions and pictures below. 1) Shut off oil and power to furnace. 2) Open blower compartment. 3) Remove air filter for easy maitenance. 4) Disconnect the wiring to the blower motor.

- Page 29 CLEANING HEAT EXCHANGER Heat exchanger must be inspected every heating season. Refer to instructions and pictures below. GEMINI 3T/5T AND ECLIPSE 3T ( REAR) HEAT EXCHANGER Step 1: Remove breech plate Step 4: Remove burner Step 2: Remove baffles Step 3:...

- Page 30 BURNER CLEANING NOTES Your burner manufacturer has supplied instructions for servicing and maintenance should be performed as instructed. Riello 40 G120 Gas Burner Carlin EZGas PRO Burner Burner PERFORM COMBUSTION TEST Perform an annual combustion check on the gas burner. Electronic combustion tester...

-

Page 31: Electrical / Wiring Diagram

8.0 ELECTRICAL / WIRING DIAGRAMS HEATING & COOLING Connection for Carlin Burner, check the Carlin burner instruction manual... -

Page 32: Heating Only

HEATING ONLY (2 WIRES THERMOSTAT) Riello burner electrical connection, see page 30 Connection for Carlin Burner, check the Carlin burner instruction manual... -

Page 33: Start-Up Test Results

10. START-UP TEST RESULTS Model: Serial Number: Lowboy KLR________ Lowboy KLF_______ Date of installation: Installer (name & address): START-UP TEST RESULTS Size of unit (Btu/h): Input: Manifold Pressure: Chimney__________ DVSystem__________ Combustion Results: Chimney draft: “ W.C. Ambient temperature: ° F Gross flue temperature: °... -

Page 34: Test Procedures

TEST PROCEDURES External Total Static Pressure Reading Total Static Pressure = Supply Pressure (Ps) + Return Pressure (Pr) A/C Coil Total Resistance Reading A/C coil total resistance = Coil Pressure (Pc) - Supply Pressure (Ps) Temperature Rise Reading *** Temperature rise = Supply Temp. (Ts) - Return Temp. (Tr) *** Probe must not be in direct sight of heat exchanger. - Page 35 Kerr products manufactured by Granby Furnaces Inc. offer a full line of furnaces and boilers built proudly in Parrsboro, Nova- Scotia, Canada at its 70,000 square feet facility. Kerr products are sold across Canada through a wide distribution network. Our team of engineers, designers and technicians continually research and develop products to go beyond the demanding specifications of today’s certifications.

Need help?

Do you have a question about the GEMINI 3T and is the answer not in the manual?

Questions and answers