Table of Contents

Advertisement

Quick Links

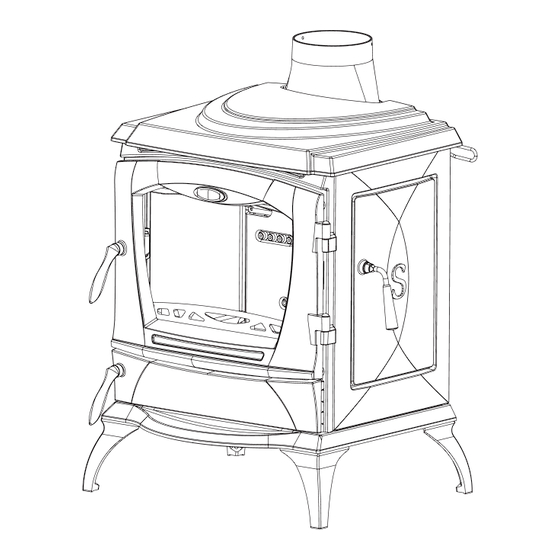

Reginald

Non Boiler Wood Burning Stove

INSTALLATION AND OPERATING INSTRUCTIONS

This appliance is hot while in operation and retains its heat for a long period of time after use. Children,

aged or infirm persons should be supervised at all times and should not be allowed to touch the hot

working surfaces while in use or until the appliance has thoroughly cooled.

When using the stove in situations where children, aged and/or infirm persons are present a fireguard

appoved to the relevant standard must be used to prevent accidental contact with the stove.

Advertisement

Table of Contents

Summary of Contents for Falcon Reginald

- Page 1 Reginald Non Boiler Wood Burning Stove INSTALLATION AND OPERATING INSTRUCTIONS This appliance is hot while in operation and retains its heat for a long period of time after use. Children, aged or infirm persons should be supervised at all times and should not be allowed to touch the hot working surfaces while in use or until the appliance has thoroughly cooled.

-

Page 2: Table Of Contents

TABLE OF CONTENTS PAGE NO. General ............... 2 Handling . -

Page 3: General

THE REGINALD WOOD BURNER NON BOILER STOVE INSTALLATION INSTRUCTIONS FLUES GENERAL Flues should be vertical wherever possible and When installing and maintaining your Stove respect where a bend is necessary, it should not make an basic standards of fire safety. Read these instruc- angle of more than 45 with the vertical. -

Page 4: Flue Pipes

FLUE PIPES Fig.3 A flue pipe should only be used to connect an appli- ance to a chimney and should not pass through any Flue Liner roof space. Sleeve Flue pipes in cast iron, stainless steel or enamelled Flue Flue Pipe steel are suitable for use on this appliance. -

Page 5: Chimney

Fig.6 Fig.5 CHIMNEY Do not connect to a chimney serving another appliance. Soot Door The stove is a radiant room heater and must be con- nected to a chimney of the proper size and type. Any existing chimney must be clear of obstruction The chimney must have a diameter of at least and have been swept clean immediately before... - Page 6 Combustible material should not be located where Fig.7 the heat dissipating through the walls of fireplaces or flues could ignite it. Therefore when installing the stove in the presence of combustible materials due account must be taken of the guidance on the sepa- ration of combustible material given in Building Regulations.

-

Page 7: Clearances To Combustibles

CLEARANCE TO COMBUSTIBLES ALCOVE INSTALLATION Fig.9 Fig.12 FIREPLACE INSTALLATION FLUE CLEARANCES CORNER INSTALLATION Fig.10 Fig.13 MINIMUM COMBUSTIBLE ALCOVE Fig.14 MANTLE CLEARANCE Fig.11... -

Page 8: Installation Clearances

If it is found that there is excessive draught in the Air vents in internal walls should not communicate chimney then a draught stabiliser should be fitted. with bedrooms, bedsits, toilets, bathrooms or rooms Fitting of a draught stabiliser will affect the require- containing a shower. -

Page 9: External Ducted Air

EXTERNAL DUCTED AIR The vent pipe should be located to prevent the ingress of moisture and in a location where it will not The primary air supply can be ducted from outside. get blocked with leaves or any other debris. As wind An aluminium flexible duct is available to order for effects can create suction and pressure zones of connection to the stove. -

Page 10: Location

FLUE LOCATIONS LOCATION There are several conditions to be considered in Flue outlet to suit 150mm internal diameter flue pipe. selecting a location for your Reginald Stove. Fig.17 a. Position in the area to be heated, central locations are usually best. -

Page 11: Technical Data

TECHNICAL DATA WOOD Room Nominal Output: (kW) 10 kW Typical refuelling intervals to obtain nominal .75 hrs outputs: Flue Gas Mass Flow: 8.9 g/s Flue Gas Temperature at Nominal Output: Gross Weight: 250kgs Flue Outlet: 150mm Flue Draught: 12 Pascals Max. -

Page 12: Installation Check List

INSTALLATION CHECK LIST Tick Flue System 1. Minimum Flue Height of 4.5 metres. 2. Appliance should be connected to a minimum of 1.8 metres of 150mm. flue pipe with a horizontal run not exceeding 150mm. 3. Appliance should be connected to a chimney of less than 200mm in diameter (otherwise the chimney must be lined with a 150mm flue liner). -

Page 13: Operating Instructions

THE REGINALD WOOD BURNER NON BOILER STOVE OPERATING INSTRUCTIONS When operating and maintaining your Stove respect 7. Keep all combustible materials a safe distance basic standards of fire safety. Read these instruc- away from unit, please see section for clear- tions carefully. -

Page 14: Lighting

LIGHTING Before lighting the stove check with the installer that the installation work and commissioning checks described in the installation instructions have been carried out correctly and that the chimney has been swept clean, is sound and free from any obstructions. -

Page 15: Recommended Fuels

RECOMMENDED FUELS or beyond as is required to control the heat output, the secondary air inlet can remain open at all times All fuels should be stored under cover and kept except when a very low output fire is required where as dry as possible prior to use. -

Page 16: De-Ashing & Disposal

Fig.24 DE-ASHING & DISPOSAL De-Ashing must be carried out when the stove is cold. Brush the ashes through the grate into the ashpan below. The ashpan should be emptied every day. If ashes are allowed to build to grate level you could damage the firebars by overheating. -

Page 17: Ventilation

GLASS CLEANING VENTILATION The glass will self clean when there is sufficient heat This appliance requires air for combustion which generated by the burning fuel. If a build-up of cre- must be either ducted from outside or provided osote occurs on the glass it may be due to draft con- through ventilation openings, ventilation and air inlet ditions, poor quality fuel or very low burning for a grilles must be kept free from blockage. -

Page 18: Exploded View

EXPLODED VIEW... -

Page 19: Parts List

PARTS LIST OPERATING TOOL B00009DZZ SPARE PARTS TOP FLUE OUTLET - B00053AZZ FLUE BLANKING PLATE - B00064AZZ For supply of spare parts please contact you local STOVE LEG - B000595AZZ distributor. Use only spare parts recommended by - B00599AZZ the manufacturer. Any modification to the appliance HOB FILLER PIECE - B00601AZZ other than that recommended by the manufacturer is... - Page 20 Manufactured by Waterford Stanley Ltd., Unit 210, IDA Industrial Estate, Cork Road, Waterford, Ireland. Tel: (051) 302300 Fax (051) 302315 N00562AXX DP 141223...

Need help?

Do you have a question about the Reginald and is the answer not in the manual?

Questions and answers