Summary of Contents for Worcester Greenstore SC Cylinder 90 litre

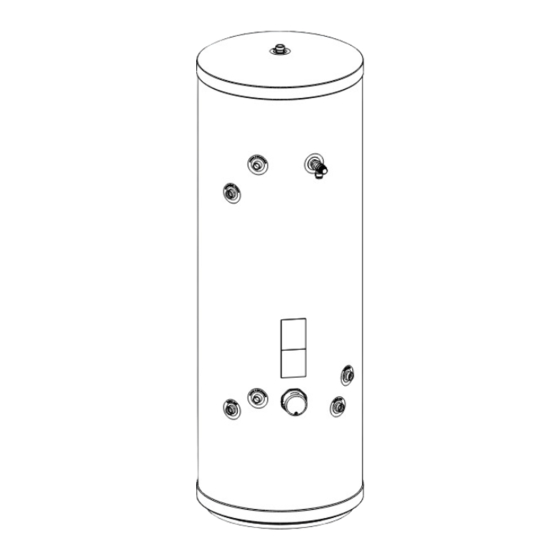

- Page 1 Installation and maintenance instructions Single Coil Indirect Unvented Hot Water Cylinder Greenstore SC Cylinder Series 90/120/150/180/210/250/300 litre...

-

Page 2: Table Of Contents

Contents Contents Key to symbols and safety precautions ....3 The Guarantee ........19 Explanation of symbols . -

Page 3: Key To Symbols And Safety Precautions

As a member of the HWA, Worcester adhere to the following statements. ▶ To supply fit for purpose products clearly and honestly described, ▶... -

Page 4: Product Details

Product details Standard delivery Product details Usage These cylinders are designed to accept input from a gas or oil boiler. The maximum cylinder heat input must not exceed the following values: Cylinder Max. cylinder heat input SC-90 31.9 kW SC-120 SC-150 SC-180 SC-210... -

Page 5: Physical And Connection Dimensions

Product details Physical and connection dimensions Fig. 2 Overview of connections Cylinder flow / return (Ø 22 mm) Sensor pocket, bottom (internal Ø 20.4 mm) DHW secondary circulation connection (Ø 22 mm) Fig. 3 Physical and connection dimensions (SC 150 to SC 300 cylinders only) Sensor pocket, top (internal Ø... - Page 6 Product details Clearance dimensions Fig. 4 Recommended minimum wall clearances (all dimensions in mm) 6 720 804 672 (2015/07)

-

Page 7: Specification

Product details Specification Cylinder type Greenstore SC-90 SC-120 SC-150 SC-180 SC-210 SC-250 SC-300 WRAS No. 1105064 1105064 1105064 1105064 1105064 1105064 1105064 WRc No. 15811 15811 15811 15811 15811 15811 15811 General characteristics Dual thermostat setting °C 10/70 10/70 10/70 10/70 10/70 10/70... -

Page 8: Energy Efficiency

Product details Pressure drop, internal indirect coil (in mbar) Pressure drop values resulting from the mains are not taken into account in the diagram. Δp / mbar 1000 1200 1400 1600 V / l/h 6 720 645 525-08.1O Fig. 5 SC-90, SC-120, SC-150 and SC-180 p Pressure drop... -

Page 9: Installation

Installation Installation Regulations Inlet control group connection This System has been approved to the Building Regulations for unvented hot water storage systems and the Local Authority must be notified of the intention to install. Therefore the installation must be carried out by a person competent to install unvented hot water systems. -

Page 10: Connection Diagram

Expansion relief anti-vac valve (G3 kit supplied) 1) Only the temperature limiter will be connected DHW connection 2) Part of the standard delivery of the Worcester optional Internal Diverter Valve kit WRAS approval automatic air vent (optional) (heating appliance accessory) -

Page 11: Installation

Installation Installation To ensure safe DHW outlet temperatures thermostatic mixing valves may be required. Guidance must be taken All hydraulic cylinder connections are suitable for 22 mm from current regulations. pipes. ▶ Make connections with the compression fittings supplied. Thermal disinfection Guidance must be taken from current regulations to ensure the risk of 3.7.1 Connection of the secondary appliance... -

Page 12: Discharge Arrangement

Installation 3.7.6 Discharge Arrangement – Ideally below the fixed grating and above the water seal in a trapped gulley. – Downward discharges at a low level; i.e. up to 100 mm above external surfaces such as car parks, hard standing, grassed areas etc. -

Page 13: Electrical Connections

Installation The table below is based on copper tube. Plastic pipes may be of different bore and resistance. Sizes and maximum lengths of plastic should be calculated using data prepared for the type of pipe being used. Maximum resistance allowed, expressed as a Minimum size of discharge Minimum size of discharge length of straight pipe... - Page 14 Installation 6 720 645 525-04.2GX Fig. 12 Variant dual thermostat wiring: wiring diagram 2 port zone valve (S-plan) 6 720 645 525-10.3GX Fig. 13 Variant dual thermostat wiring: wiring diagram 3 port mid position valve (Y-plan) + 2 port valve 6 720 804 672 (2015/07)

- Page 15 Installation Using the Worcester optional Internal Diverter valve • The installation will use the cylinder sensor supplied with the Integral • The high limit thermal cut out of the dual thermostat MUST be wired Diverter Valve kit to control the hot water temperature.

- Page 16 Outdoor sensor with FW100 on ly Cylinder NTC Sensor Inte lligent controller option WORCESTER TIME & TEMPERATURE CONTROL Stand ard RF plug in fascia controls PRE WIRED LINK Inte lligent controls 6 720 804 672-10.1GX Fig. 15 Greenstar i System Compact wiring example...

- Page 17 Installation Connecting the immersion heater (Heaters conform to EN60335.2.73) ▶ Ensure the mains voltage corresponds to the voltage rating of the heater as shown on the rating label on the terminal cover. ▶ Only use rigid wires 1.5 mm for main supply. Flexible wire may cause poor electrical connection to AQU-32-3W the heater, resulting in overheat.

-

Page 18: Commissioning

Commissioning Shutting down NOTICE: When draining either the domestic hot water system or the cylinder ensure the cold water supply is isolated and that at least two hot water draw off points are opened. One of these hot water draw off points must be the one closest to the cylinder in height terms. -

Page 19: Inspection/Maintenance

& Conditions. To read the full Terms & Conditions please visit us online the cylinder while it is drained down. at www.worcester-bosch.co.uk/guarantee. The Guarantee Registration ▶ Isolate the cold water supply. form is available on this same page and can be completed and submitted ▶... - Page 20 Notes 6 720 804 672 (2015/07)

- Page 21 NOTES 6 720 804 672 (2015/07)

- Page 22 MAINS PRESSURE HOT WATER STORAGE SYSTEM COMMISSIONING CHECKLIST This Commissioning Checklist is to be completed in full by the competent person who commissioned the storage system as a means of demonstrating compliance with the appropriate Building Regulations and then handed to the customer to keep for future reference. Failure to install and commission this equipment to the manufacturer’s instructions may invalidate the warranty but does not affect statutory rights.

-

Page 23: Service Record

Service Record It is recommended that your heating system is serviced regularly and that the appropriate Service Interval Record is completed. Service Provider Before completing the appropriate Service Record below, please ensure you have carried out the service as described in the manufacturer’s instructions. - Page 24 0330 123 9119 TRAINING: 0330 123 0166 SALES: 0330 123 9669 Worcester, Bosch Group Cotswold Way, Warndon, Worcester WR4 9SW. Tel. 0330 123 9559 Worcester, Bosch Group is a brand name of Bosch Thermotechnology Ltd. worcester-bosch.co.uk 6 720 804 672...

Need help?

Do you have a question about the Greenstore SC Cylinder 90 litre and is the answer not in the manual?

Questions and answers