Table of Contents

Advertisement

This is a safety alert symbol and should never be ignored. When you see this symbol on labels or in

manuals, be alert to the potential for personal injury or death.

As with any mechanical equipment, personal injury can

result from contact with sharp sheet metal edges. Be

careful when you handle this equipment.

Unit Dimensions ............................................................ 2

A95UH2V/95G2UHV Parts Arrangement ..................... 3

A95UH2V/95G2UHV Gas Furnace ............................... 4

Shipping and Packing List ............................................ 4

Safety Information ......................................................... 4

Use of Furnace as a Construction Heater .................... 5

General ......................................................................... 6

Shipping Bolt Removal ................................................. 9

Setting Equipment ........................................................ 9

Removing Bottom Panel ............................................. 11

Upflow Application ONLY ............................................ 11

Horizontal Application ONLY ....................................... 11

Filters .......................................................................... 13

Duct System ................................................................ 13

Pipe and Fittings Specifications .................................. 13

Canadian Applications ONLY ...................................... 14

*P506878-01*

(P) 506878-01

506878-01

INSTALLATION INSTRUCTIONS

A95UH2V & 95G2UHV

Warm Air Gas Furnace

Upflow/Horizontal Left Air Discharge

Direct Vent & Non-Direct Vent

This manual must be left with the homeowner for future reference.

CAUTION

TABLE OF CONTENTS

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, personal injury

or loss of life. Installation and service must be performed

by a licensed professional installer (or equivalent), service

agency or the gas supplier.

Joint Cementing Procedure ........................................ 14

Venting Practices ........................................................ 16

Vent Piping Guidelines ................................................ 17

Gas Piping .................................................................. 36

Electrical ..................................................................... 39

Unit Start Up ................................................................ 47

Gas Valve Operation ................................................... 48

Heating Sequence of Operation ................................. 48

High Altitude Information ............................................. 50

Other Unit Adjustments ............................................... 50

Blower Data ................................................................. 52

Service ........................................................................ 56

Planned Service .......................................................... 58

Repair Parts List ......................................................... 59

Start Up Checklist ....................................................... 60

A Lennox International, Inc. Company

Issue 1139

WARNING

Manufactured By

Allied Air Enterprises, Inc.

215 Metropolitan Drive

West Columbia, SC 29170

Page 1 of 62

Advertisement

Table of Contents

Summary of Contents for Airease A95UH2V

-

Page 1: Table Of Contents

TABLE OF CONTENTS Unit Dimensions ............2 Joint Cementing Procedure ........14 A95UH2V/95G2UHV Parts Arrangement ..... 3 Venting Practices ............16 A95UH2V/95G2UHV Gas Furnace ....... 4 Vent Piping Guidelines ..........17 Shipping and Packing List ..........4 Gas Piping .............. -

Page 2: Unit Dimensions

A95UH2V & 95G2UHV Unit Dimensions - inches (mm) 1 NOTE - 20 C/D (5 Ton) size units installed in upflow applications that require air volumes of 1800 cfm (850 L/s) or greater must have one of the following: 1. Single side return air with transition, to accommodate 20 x 25 x 1 in. -

Page 3: A95Uh2V/95G2Uhv Parts Arrangement

EXPANDED VIEW Figure 1 506878-01 Issue 1139 Page 3 of 62... -

Page 4: A95Uh2V/95G2Uhv Gas Furnace

Installation and service must be performed by a licensed professional installer (or equivalent), service The A95UH2V/95G2UHV can be installed as either a agency or the gas supplier. Direct Vent or a Non-Direct Vent Gas Central Furnace. -

Page 5: Use Of Furnace As A Construction Heater

Installed Locations Heating Unit Installed Parallel to Air Handler Unit This furnace is CSA International certified for installation clearances to combustible material as listed on the unit nameplate and in the table in Figure 6. Accessibility and service clearances must take precedence over fire protection clearances. -

Page 6: General

Air filters must be installed in the system and must be • maintained during construction. WARNING • Air filters must be replaced upon construction completion. • The input rate and temperature rise must be set per the Product Contains Fiberglass Wool. furnace rating plate. - Page 7 air is brought into the house for combustion, negative infiltration. If the furnace is located in a building of tight pressure (outside pressure is greater than inside pressure) construction with weather stripping and caulking around the will build to the point that a down draft can occur in the furnace windows and doors, follow the procedures in the “Air from vent pipe or chimney.

- Page 8 Air from Outside to 25 percent free area and metal louvers and grilles will If air from outside is brought in for combustion and ventilation, have 60 to 75 percent free area. Louvers and grilles must the confined space shall be provided with two permanent be fixed in the open position or interlocked with the equipment openings.

-

Page 9: Shipping Bolt Removal

Shipping Bolt Removal INSTALLATION Units with 1/2 hp blower motor are equipped with three Setting Equipment flexible legs and one rigid leg. The rigid leg is equipped with WARNING a shipping bolt and a flat white plastic washer (rather than the rubber mounting grommet used with a flexible mounting Do not connect the return air ducts to the back of the leg). - Page 10 Return Air Guidlines WARNING Return air can be brought in through the bottom or either side of the furnace installed in an upflow application. If the Improper installation of the furnace can result in personal furnace is installed on a platform with bottom return, make injury or death.

-

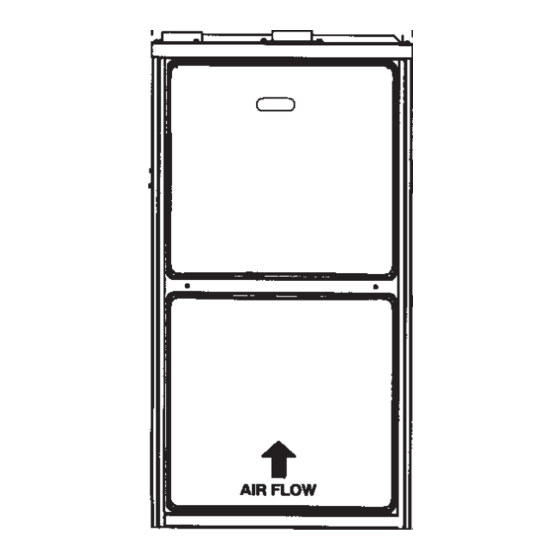

Page 11: Removing Bottom Panel

Optional Return Air Base (Upflow Applications Only) SIDE VIEW FRONT VIEW NOTE: Optional side return air filter kits are not for use with return air base. 1 Both the unit return air opening and the base return air opening must be covered by a single plenum or IAQ cabinet. Minimum unit side return air opening dimensions for units requiring 1800 cfm or more of air (W x H): 23 x 11 in. - Page 12 Typical Horizontal Application Horizontal Application Installation Clearances Right-Hand Discharge Figure 16 NOTE: When the furnace is installed on a platform or with * Front the horizontal suspension kit in a crawl space, it must be elevated enough to avoid water damage, accommodate drain Back trap and to allow the evaporator coil to drain.

-

Page 13: Filters

Duct System Use industry approved standards to size and install the supply and return air duct system. This will result in a quiet and low-static system that has uniform air distribution. NOTE: This furnace is not certified for operation in heating mode (indoor blower operating at selected heating speed) with an external static pressure which exceeds 0.8 inches w.c. -

Page 14: Canadian Applications Only

CAUTION IMPORTANT Solvent cements for plastic pipe are flammable liquids A95UH2V/95G2UHV exhaust and intake connections are and should be kept away from all sources of ignition. Do made of PVC. Use PVC primer and solvent cement when not use excessive amounts of solvent cement when using PVC vent pipe. -

Page 15: Joint Cementing Procedure

OUTDOOR TERMINATION KITS USAGE Table 3 Joint Cementing Procedure 1. Measure and cut vent pipe to desired length. All cementing of joints should be done according to the 2. Debur and chamfer end of pipe, removing any ridges or specifications outlined in ASTM D 2855. rough edges. -

Page 16: Venting Practices

6. Promptly apply solvent cement to end of pipe and inside Exhaust Piping socket surface of fitting. Cement should be applied 1. In areas where piping penetrates joist or interior walls, lightly but uniformly to inside of socket. Take care to hole must be large enough to allow clearance on all sides keep excess cement out of socket. -

Page 17: Vent Piping Guidelines

Exhaust Piping 3. Close all building doors and windows and all doors Route piping to outside of structure. Continue with installation between the space in which the appliances remaining following instructions given in piping termination section. connected to the common venting system are located and other spaces of the building. - Page 18 Use the following steps to correctly size vent pipe diameter. EXHAUST PIPE Horizontal Application NOTE: All horizontal runs of exhaust pipe must slope back toward unit. A minimum of 1/4” (6 mm) drop for each 12” (305 mm) of horizontal run is mandatory for drainage. NOTE: Exhaust pipe MUST be glued to furnace exhaust fittings.

- Page 19 Maximum Allowable Intake or Exhaust Vent Length in Feet *Size intake and exhaust pipe length separately. Values in table are for intake OR Exhaust, not combined total. Both Intake and Exhaust must be same pipe size. Table 5 506878-01 Issue 1139 Page 19 of 62...

- Page 20 Maximum Allowable Intake or Exhaust Vent Length in Feet *Size intake and exhaust pipe length separately. Values in table are for intake OR Exhaust, not combined total. Both Intake and Exhaust must be same pipe size. Table 6 Page 20 of 62 Issue 1139 506878-01...

- Page 21 TYPICAL EXHAUST PIPE CONNECTIONS IN UPFLOW DIRECT OR NON-DIRECT VENT APPLICATIONS * When transitioning up in pipe size, use the shortest length of 2” PVC pipe possible. NOTE: Exhaust pipe and intake pipe must be the same diameter. Figure 21 TYPICAL EXHAUST PIPE CONNECTIONS IN HORIZONTAL DIRECT OR NON-DIRECT VENT APPLICATIONS (RIGHT HAND DISCHARGE SHOWN)

- Page 22 TYPICAL AIR INTAKE PIPE CONNECTIONS IN UPFLOW DIRECT VENT APPLICATIONS * When transitioning up in pipe size, use the shortest length of 2” PVC pipe possible. NOTE: Exhaust pipe and intake pipe must be the same diameter. Figure 23 TYPICAL AIR INTAKE PIPE CONNECTIONS IN HORIZONTAL DIRECT VENT APPLICATIONS (RIGHT HAND DISCHARGE SHOWN) * When transitioning up in pipe size, use the shortest length of 2”...

- Page 23 Follow the next two steps when installing the unit in Direct Typical Air Intake Pipe Connections Vent applications, where combustion air is taken from outdoors and flue gases are discharged outdoors. The Horizontal Non-Direct Vent Applications (Horizontal Right-Hand Air Discharge Application Shown) provided air intake screen must not be used in direct vent applications (outdoors).

- Page 24 At vent termination, care must be taken to maintain Follow the next two steps when installing the unit in Non– protective coatings over building materials (prolonged Direct Vent applications where combustion air is taken exposure to exhaust condensate can destroy protective from indoors and flue gases are discharged outdoors.

- Page 25 VENT TERMINATION CLEARANCES FOR NON-DIRECT VENT INSTALLATIONS IN THE USA AND CANADA Figure 27 506878-01 Issue 1139 Page 25 of 62...

- Page 26 VENT TERMINATION CLEARANCES FOR DIRECT VENT INSTALLATiONS IN THE USA AND CANADA Figure 28 Page 26 of 62 Issue 1139 506878-01...

- Page 27 EXHAUST PIPE TERMINATION SIZE REDUCTION Details of Intake and Exhaust Piping Terminations for Direct Vent Installations NOTE: In Direct Vent installations, combustion air is taken from outdoors and flue gases are discharged to outdoors. NOTE: Flue gas may be slightly acidic and may adversely * units with the flush mount termination must use the 1-1/2”...

- Page 28 FIELD SUPPLIED WALL TERMINATION Figure 31 Page 28 of 62 Issue 1139 506878-01...

- Page 29 Figure 32 506878-01 Issue 1139 Page 29 of 62...

- Page 30 FLUSH-MOUNT SIDE WALL TERMINATION FIELD SUPPLIED WALL TERMINATION 51W11 Figure 34 Figure 33 Page 30 of 62 Issue 1139 506878-01...

- Page 31 DIRECT VENT CONCENTRIC ROOFTOP DIRECT VENT APPLICATION TERMINATION USING EXISTING CHIMNEY 71M80, 69M29 or 60L46 (US) 41W92 or 41W93 (Canada) NOTE: Do not discharge exhaust gases directly into any chimney Figure 35 or vent stack. If vertical discharge through an existing unused chimney or stack is required, insert piping inside chimney until the pipe open end is above top of chimney and terminates as illustrated.

- Page 32 Non-Direct Vent Roof Termination Kit Non-Direct Vent Field Supplied Wall (15F75 or 44J41) Termination Extended Figure 39 * Use wall support every 24” (610). Use two supports if extension is greater than 24” but less than 48”. Figure 41 Non-Direct Vent Field Supplied Wall Termination Non-Direct Vent Application Using Existing Chimney Figure 40...

- Page 33 Condensate Piping NOTE: If necessary the condensate trap may be installed This unit is designed for either right or left side exit of up to 5’ away from the furnace. Use PVC pipe to connect condensate piping in upflow applications. In horizontal trap to furnace condensate outlet.

- Page 34 Condensate line must slope downward away from the trap to drain. If drain level is above condensate trap, condensate CAUTION pump must be used. Condensate drain line should be routed within the conditioned space to avoid freezing of condensate A separate drain line must be run to the drain from the and blockage of drain line.

- Page 35 TRAP / DRAIN ASSEMBLY USING 1/2” PVC or 3/4” PVC Figure 47 506878-01 Issue 1139 Page 35 of 62...

-

Page 36: Gas Piping

6. In some localities, codes may require installation of a Gas Piping manual main shut-off valve and union (furnished by installer) external to the unit. Union must be of the CAUTION ground joint type. If a flexible gas connector is required or allowed by the IMPORTANT authority that has jurisdiction, black iron pipe shall be installed at the gas valve and extend outside the furnace... - Page 37 NOTE: BLACK IRON PIPE ONLY TO BE ROUTED INSIDE OF CABINET Figure 49 HORIZONTAL APPLICATIONS POSSIBLE GAS PIPING CONFIGURATIONS Figure 50 506878-01 Issue 1139 Page 37 of 62...

- Page 38 GAS PIPE CAPACITY - FT³/HR (kL/HR) NOTE: Capacity given in cubic feet of gas per hour (kilo liters of gas per hour) and based on 0.60 specific gravity gas. Table 8 Page 38 of 62 Issue 1139 506878-01...

-

Page 39: Electrical

Electrical The unit is equipped with a field makeup box. The makeup ELECTROSTATIC DISCHARGE (ESD) box may be moved to the right side of the furnace to facilitate Precautions and Procedures installation. Seal unused openings on left side with plugs removed from right side. - Page 40 7. One line voltage “EAC” 1/4" spade terminal is provided Electrical Wiring on the furnace integrated control. Any electronic air cleaner or other accessory rated up to one amp can be connected to this terminal with the neutral leg of the WARNING circuit being connected to one of the provided neutral Risk of electrical shock.

- Page 41 If continuous blower operation has been selected, the (A95UH2V or 95G2UHV). To activate this option, move the variable speed motor will slowly ramp down until it reaches jumper pin (see Figure 53) to desired setting (5 minutes or the airflow for that mode.

- Page 42 Adjust Tap Primary and Secondary Limits Airflow amounts may be increased or decreased by 10% by The primary limit is located on the heating compartment moving the ADJUST jumper plug (see Figure 54) from the vestibule panel. The secondary limits (if equipped) are NORM position to the (+) or (-) position.

-

Page 43: Emergency Replacement Motor Operation

The igniter energizes and is allowed to warm up for 20 If the active dehumidification feature is enabled, the seconds before the gas valve energizes on 1 stage and circulating blower runs at 70% of the selected cooling speed burners ignite. 45 seconds after the control confirms ignition as long as there is a call for dehumidification. -

Page 44: Troubleshooting

Connect the desired speed tap to the “EAC” terminal and the FAILURE CODES - Red LED neutral tap to the neutral terminal on the ignition control (refer to the furnace wiring diagram). The ignition control will control the motor’s operation, including a nominal 20 second “on” delay with a call for heat and a nominal 180 second “off”... - Page 45 High Heat State LED On A95UH2V and 95G2UHV models, a green LED is provided on the control board to indicate high heat state (see Table 11). CFM LED On A95UH2V and 95G2UHV models equipped with a variable speed motor, an amber LED is provided on the control board to display CFM.

- Page 46 TYPICAL WIRING DIAGRAM Figure 56 Page 46 of 62 Issue 1139 506878-01...

-

Page 47: Unit Start Up

Unit Start-Up FOR YOUR SAFETY READ BEFORE OPERATING CAUTION Before attempting to perform any service or maintenance, turn the electrical power to unit OFF at disconnect switch. WARNING Do not use this furnace if any part has been underwater. BEFORE LIGHTING the unit, smell all around the furnace A flood-damaged furnace is extremely dangerous. -

Page 48: Gas Valve Operation

Gas Valve Operation Turning Off Gas to Unit 1. STOP! Read the safety information at the beginning of 1. Set the thermostat to the lowest setting. this section. 2. Turn off all electrical power to the unit if service is to be 2. - Page 49 Gas Pressure Adjustment Manifold Pressure Measurement 1. A manifold post located on the gas valve provides access Gas Flow (Approximate) to the manifold pressure. See Figure 57. Back out the 3/32 Hex screw one turn, connect a piece of 5/16” tubing and connect to a manometer to measure manifold pressure.

-

Page 50: High Altitude Information

High Altitude Information Electrical 1. Check all wiring for loose connections. NOTE: In Canada, certification for installations at elevations over 4500 feet (1372 m) is the jurisdictiion of local authorities. 2. Check for the correct voltage at the furnace (furnace operating). - Page 51 Testing for Proper Venting and Sufficient Combustion Air for Non-Direct Vent Applications 6. Follow the lighting instruction to place the appliance being inspected into operation. Adjust thermostat so WARNING appliance will operate continuously. CARBON MONOXIDE POISONING HAZARD 7. Use the flame of match or candle to test for spillage of Failure to follow the steps outlined below for each flue gases at the draft hood relief opening after 5 appliance connected to the venting system being placed...

-

Page 52: Blower Data

BLOWER DATA Heating CFM @ .50 w.c. Motor Blower Temp Model Size (hp) Size Rise Setting "D" Setting "C" Setting "B" Setting "A" 1005 35-65 A95UH2V045B12S 10x9 20-50 Cooling CFM @ .50 w.c. Cooling Speed Model Stage Adjustment Setting "D" Setting "C"... - Page 53 BLOWER DATA Heating CFM @ .50 w.c. Motor Blower Temp Model Size (hp) Size Rise Setting "D" Setting "C" Setting "B" Setting "A" 1060 1135 1240 1430 60-90 1040 1120 1310 1175 A95UH2V090C12S 10x9 1040 1120 1310 35-65 1195 1080 Cooling CFM @ .50 w.c.

- Page 54 BLOWER DATA Heating CFM @ .50 w.c. Motor Blower Temp Model Size (hp) Size Rise Setting "D" Setting "C" Setting "B" Setting "A" 1450 1565 1725 1865 40-70 1310 1450 1585 1690 1155 1305 1450 1545 A95UH2V090C20S 11x11 1120 1265 1420 1520 30-60...

- Page 55 BLOWER DATA Heating CFM @ .50 w.c. Motor Blower Temp Model Size (hp) Size Rise Setting "D" Setting "C" Setting "B" Setting "A" 1560 1760 1905 2080 45-75 1415 1610 1740 1930 1285 1485 1560 1745 A95UH2V110C20S 11x11 1155 1325 1420 1565 35-65...

-

Page 56: Service

Service Winterizing and Condensate Trap Care 1. Turn off power to the furnace. WARNING 2. Have a shallow pan ready to empty condensate water. 3. Remove the clean out cap from the condensate trap ELECTRICAL SHOCK, FIRE, and empty water. Inspect the trap then reinstall the clean OR EXPLOSION HAZARD. - Page 57 21. Remove two screws from the front cabinet flange at the 43. Reconnect wires to gas valve. blower deck. Spread cabinet sides slightly to allow 44. Replace the blower compartment access panel. clearance for removal of heat exchanger. 45. Refer to instruction on verifying gas and electrical 22.

-

Page 58: Planned Service

PLANNED SERVICE A service technician should check the following items during an annual inspection. Power to the unit must be shut off for safety. Fresh air grilles and louvers (on the unit and in the room where the furnace is installed) - Must be open and unobstructed to provide combustion air. -

Page 59: Repair Parts List

REPAIR PARTS LIST The following repair parts are available through Allied Air dealers. When ordering parts, include the complete furnace model number listed on the CSA nameplate. All service must be performed by a licensed professional installer (or equivalent), service agency, or gas supplier. Cabinet Parts Heating Parts Upper Access Panel... -

Page 60: Start Up Checklist

Start-Up & Performance Check List UNIT SET UP Page 60 of 62 Issue 1139 506878-01... - Page 61 UNIT OPERATION Heating Mode Cooling Mode 506878-01 Issue 1139 Page 61 of 62...

- Page 62 REQUIREMENTS for COMMONWEALTH of MASSACHUSETTS Modifications to NFPA-54, Chapter 10 4. INSPECTION. The state or local gas inspector of the Revise NFPA-54 section 10.8.3 to add the following side wall, horizontally vented, gas-fueled equipment requirements: shall not approve the installation unless, upon inspection, the inspector observes carbon monoxide For all side wall, horizontally vented, gas-fueled equipment detectors and signage installed in accordance with the...

Need help?

Do you have a question about the A95UH2V and is the answer not in the manual?

Questions and answers

What year was this model made?