Table of Contents

Advertisement

Compatibility

This engine will operate on any traditional

O-31 Gauge track system, including

M.T.H.'s RealTrax

traditional tubular track. It is also compatible

with most standard AC transformers. (See

page 23 for a complete list of compatible

transformers and wiring instructions.)

PLEASE READ BEFORE USE AND SAVE

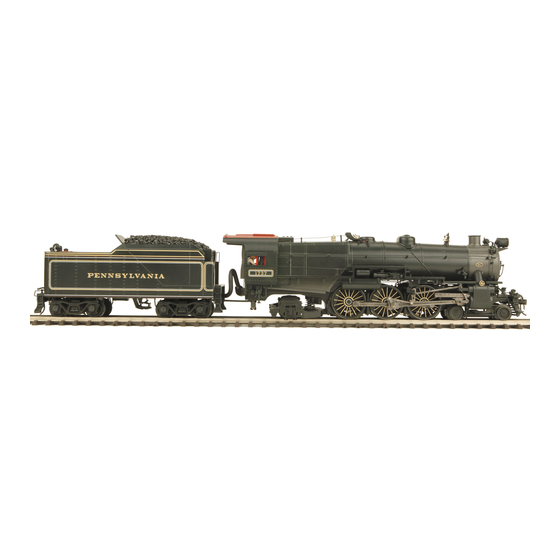

RailKing 4-6-2

PRR K4 Steam

Locomotive

OPERATOR'S MANUAL

®

™

or ScaleTrax

or

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for MTHTrains RailKing 4-6-2 PRR K4 Steam Locomotive

- Page 1 RailKing 4-6-2 PRR K4 Steam Locomotive OPERATOR’S MANUAL Compatibility This engine will operate on any traditional O-31 Gauge track system, including ® ™ M.T.H.’s RealTrax or ScaleTrax traditional tubular track. It is also compatible with most standard AC transformers. (See page 23 for a complete list of compatible transformers and wiring instructions.) PLEASE READ BEFORE USE AND SAVE...

-

Page 2: Table Of Contents

Table of Contents Set Up Checklist....................3 Lubrication.....................3 Priming The Smoke Unit............... 3 Checking The Battery................4 Basic Operation....................5 Activating Features................5 Proto-Sound 2.0 Operating Instructions............7 Activating Proto-Sound 2.0 Conventional Mode Features....7 Passenger Station Announcements (PSA)..........8 Proto-Coupler® Operation..............9 Speed Control.................. -

Page 3: Set Up Checklist

Set Up Checklist • Lubricate the locomotive • Prime the smoke unit • Check to see whether the battery needs to be charged for full sound effects • Apply power to run as described in the Basic Operating Section of this manual Lubrication DO NOT OVER OIL... -

Page 4: Checking The Battery

Placing The Engine On The Track Place the engine on the track, then insert the reverse unit plug that extends out of the tender into the receptacle at the back of the boiler cab (Figure 3. WARNING: DO NOT CONNECT THIS ENGINE TO A TENDER FROM ANOTHER ENGINE; IT MAY CAUSE SERIOUS DAMAGE. -

Page 5: Basic Operation

Basic Operation The Throttle knob controls how fast your train will travel. Turn the throttle knob up ½-way, until the engine and caboose lights shine bright. Put the engine into motion by pressing the Direction button on your transformer once. (hold it for approximately 1 second) If the engine does not begin to move as soon as you firmly press the Direction button, you may not have sent enough voltage to the track to make the train move. - Page 6 Manual Volume Control To adjust the volume of all sounds made by this engine, turn the master volume control knob located next to the fuel tank clockwise to increase the volume and counter-clockwise to decrease the volume. Proto-Sound 2.0 Volume Adjustment Knob Figure 4: Manually Adjusting The Volume RailKing 4-6-2 PRR K4 Steam Engine...

-

Page 7: Activating Proto-Sound 2.0 Conventional Mode Features

Proto-Sound 2.0 Operating Instructions This manual contains the operating instructions for Proto-Sound 2.0 in conventional mode only. Instructions for accessing DCS command mode features accompany the DCS Remote Control System equipment. Activating Proto-Sound 2.0 Conventional Mode Features Proto-Sound 2.0 features are activated by sequences of Bell and Horn button pushes described below. - Page 8 Freight Yard Sounds (FYS) Your engine is equipped with a sound package of freight yard sounds that you can play when you pull into a yard. Each sequence described below will play as long as it is left on, randomly generating sounds, but be sure to allow approximately 30 seconds between the button pushes described below to allow the FYS sufficient time to run through each sequence.

-

Page 9: Proto-Coupler® Operation

Tips on Using FYS • You can terminate FYS at any time by turning off power to the track for 15 seconds. • You do not have to be in Forward to use FYS. At the conclusion of the full sequence, the train will pull away from the station in whatever direction you were going when you activated the feature. -

Page 10: Speed Control

Front Coupler: To fire the front coupler (if your engine has one), quickly tap the Bell button once followed by four quick taps of the Horn button, allowing approximately ½ second to lapse between each quick button press. The sound of the liftbar and air line depletion will play, and the knuckle will be released. -

Page 11: Locking Locomotive Into A Direction

Locking Locomotive Into A Direction You can lock your engine into a direction (forward, neutral, or reverse) so that it will not change directions. To do this, put the engine into the direction you want (or into neutral to lock it into neutral), run it at a very slow crawl (as slowly as it will move without halting), and quickly but firmly tap the Horn button once followed by three quick taps of the Bell button, allowing approximately ½... -

Page 12: Maintenance

Maintenance Lubricating and Greasing Instructions The engine should be well oiled and greased in order to run properly. DO NOT You should regularly lubricate all side rods, linkage components and OVER OIL pickup rollers to prevent them from squeaking. Use light household oil and follow the lubrication points marked “L”... -

Page 13: Cleaning The Wheels, Tires And Track

Body Mount Screws Body Mount Screws Figure 6: Removing The Body And Lubricating The Grease Points Unscrew these screws to access the gear box Figure 7: Motor Gearing Grease Plate Screws Cleaning The Wheels, Tires and Track Periodically check the locomotive wheels and pickups for dirt and buildup, which can cause poor electrical contact and traction as well as prematurely wear out the neoprene traction tires. -

Page 14: Traction Tire Replacement Instructions

Traction Tire Replacement Instructions 1. Remove the side rods from the wheels in order to slip the new tire over the grooved drive wheel. Make sure to note the position of all rods before removing. 2. Make sure the old tire has been completely removed from the groove in the drive wheel, using a razor blade or small flathead screwdriver to pry away any remains. -

Page 15: Headlight Replacement Instructions

Headlight Replacement Instructions The locomotive’s lights are controlled by a constant voltage circuit in the engine. They are easy to remove and replace when they burn out. See the diagrams and directions below for instructions on accessing and replacing the light bulbs in this locomotive. You can obtain replacement bulbs directly from the M.T.H. -

Page 16: Self Charging Battery Back-Up

Self Charging Battery Back-Up The special NiCad 7-cell 8.4v self-charging battery recharges continuously during train operation and should last for up to five years. The battery is a dry battery that should not leak or cause any damage to your engine. Depending upon when your engine was built, it may need to be charged right out of the box. - Page 17 Unhook Wires, Remove and Replace Battery Figure 10 AC Battery Recharging Jack Figure 11: Battery Recharging Jack RailKing 4-6-2 PRR K4 Steam Engine...

-

Page 18: Protosmoke® Unit Operation

ProtoSmoke® Unit Operation This Premier steam locomotive contains a self-powered smoke unit that outputs smoke through the smokestack on the roof of the engine. The smoke unit is essentially a small heating element and wick that soaks up and then heats a mineral oil-based fluid that emits a harmless smoke. - Page 19 heating element. To remove the smoke unit you will first have to remove the boiler shell (by removing the body mounting screws shown in Fig. 5 on pg. 12), board and bracket that block the smoke unit assembly from being accessed. To do this, follow these instructions: 1.

-

Page 20: Troubleshooting Proto-Sound® 2.0 Problems

Troubleshooting Proto-Sound® 2.0 Problems Although Proto-Sound 2.0 has been designed and engineered for ease of use, you may have some questions during initial operation. The following table should answer most questions. If your problem cannot be resolved with this table, contact M.T.H. for assistance (telephone: 410-381-2580;... - Page 21 Cab Chatter Remedy Sometimes the Cab Chatter sounds Cab Chatter plays only in neutral at don’t play. random intervals. Lock-out Remedy I can’t get the engine to run after I The engine is locked into the neutral power up the transformer. It sits still position.

- Page 22 Remedy Once in FYS, the engine doesn’t go So that FYS effects can be as realistic into reverse. Proto-Sound 2.0 as possible, disables the reversing unit whenever FYS is enabled. This way the engine remains still at its stop as the operator cycles through the FYS sequences.

-

Page 23: Transformer Compatibility And Wiring Chart

Transformer Compatibility and Wiring Chart Proto-Sound 2.0 is designed to work with most standard AC transformers. The chart below lists the many compatible transformers. Note that many of the operational commands described in these instructions require a bell button, so if your transformer does not have its own bell button, you should consider adding one to get the full benefit of the system. - Page 24 Additional Features Accessible With The DCS Remote Control System (Additional equipment required) While conventional mode operation of a Proto-Sound 2.0 engine yields wonderfully realistic sound and several train control features, command mode operation allows the user to access a world of command functions never before accessible to O Gauge railroaders.

-

Page 25: Service & Warranty Information

Service & Warranty Information How to Get Service Under the Terms of the Limited One-Year Warranty For warranty repair, follow the instructions below to obtain warranty service. First, e-mail, write, call or fax an Authorized M.T.H. Service Center in your area or M.T.H. Electric Trains to obtain Repair Authorization. - Page 26 AUTHORIZED SERVICE CENTER 7020 Columbia Gateway Dr. - Columbia, MD 21046 Information: 410-381-2580 Fax: 410-381-6122 www.mth-railking.com PARTICIPATING RETAILER LIST ALABAMA FLORIDA LOUISIANA SOUTHERLAND STATION DEPOT HOBBY SHOP AMERICA'S TRAIN YARD HUNTSVILLE LAKE WORTH BATON ROUGE 256-533-4720 561-585-1982 225-926-5592 railway@bellsouth.net jimmyt1982@aol.com www.depothobbies.com MAINE ARIZONA...

- Page 27 MISSOURI COUNTRY AND STUFF RICK'S TOY TRAINS SWITCH STAND ANDOVER TOLEDO SAINT LOUIS 973-786-7086 419-478-0171 314-781-4458 stuff@crystal.palace.net r41877@earthlink.com T & K HOBBY SHOP RIDGEFIELD HOBBY BRIDGEPORT RIDGEFIELD 740-633-6607 MARK TWAIN HOBBY CENTER ST. CHARLES 201-943-2636 salea@tkhobbies.com 636-946-2816 www.tkhobbies.com webmaster@hobby1.com COLUMBUS TRAIN STATION www.hobby1.com COLUMBUS TRAINS-N- THINGS...

- Page 28 THE STATION T E NNESSEE WISCONSIN NEW CUMBERLAND MODEL RAILROAD & HOBBY SHOP SOMMERFELD'S TRAINS 717-774-7096 MEMPHIS BUTLER station@paonline.com 901-384-6500 262-783-7797 BUSSINGER TRAINS mrhs99@earthlink.net questions@sommerfelds.com AMBLER www.modelrailroadandhobby.com www.sommerfelds.com 215-628-2366 T EXAS choochoos@icdc.com G B T V & TRAINS www.icdc.com/~btrains HOBBY TIME GREEN BAY AMARILLO 920-496-9697...

Need help?

Do you have a question about the RailKing 4-6-2 PRR K4 Steam Locomotive and is the answer not in the manual?

Questions and answers