Table of Contents

Advertisement

Advertisement

Chapters

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Jungheinrich EZS 330

- Page 1 EZS 330/350 / XL 04.06 - Operating instructions 50468397 04.06...

- Page 2 Used to indicate standard equipment. Used to indicate optional equipment. Our trucks are subject to ongoing development. Jungheinrich reserves the right to alter the design, equipment and technical features of the truck. No guarantee of particular features of the truck should therefore be inferred from the present operating instructions.

-

Page 4: Table Of Contents

Table of Contents Correct use and application Truck Description Application ................... B 1 Assemblies ..................B 2 EN norms .................... B 3 Conditions of use ................B 3 Standard Version Specifications ............B 4 Performance data for standard trucks ..........B 4 Dimensions .................. - Page 5 Operation Safety Regulations for the Operation of Forklift Trucks ...... E 1 Controls and Displays ................. E 2 Starting up the truck ................E 4 Industrial Truck Operation ..............E 5 Safety regulations for truck operation ..........E 5 Travel, Steering, Braking ..............E 6 Pedestrian operation (o) ..............

- Page 6 Appendix JH Traction Battery Operating Instructions These operating instructions apply only to Jungheinrich battery models. If using another brand, refer to the manufacturer's operating instructions.

-

Page 8: A Correct Use And Application

A Correct use and application The “Guidelines for the Correct Use and Application of Industrial Trucks” (VDMA) are supplied with the truck. The guidelines form part of these operating instructions and must be observed. National regulations apply in full. The truck described in the present operating instructions is an industrial truck designed for lifting and transporting loads. -

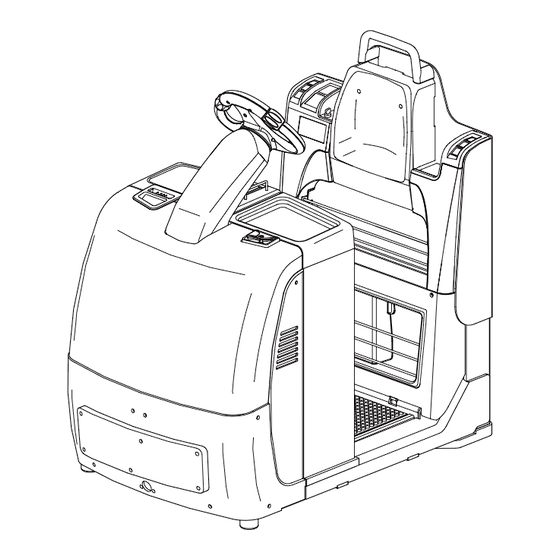

Page 10: B Truck Description

B Truck Description Application The truck is a three-wheel electric tow truck with a driver’s platform, equipped with a Jet Pilot. It is designed for transporting goods on level surfaces in buildings. The tow force is shown on the data plate. -

Page 11: Assemblies

Assemblies Item Description Item Description t Front panel o Reverse “pedestrian operation” switch t Battery panel o Stop button t Jet Pilot o Forward “pedestrian / walk- along operation” button t Main switch / isolator o Trailer coupling (emergency disconnect) t Controller t Storage compartment o CANCODE... -

Page 12: En Norms

EN norms Noise level: 66 dB(A) in accordance with EN 12053 as harmonized with ISO 4871. The noise emission level is calculated in accordance with standard procedures and takes into account the noise level when travelling, lifting and when idle. The noise level is measured at the driver’s ear. -

Page 13: Standard Version Specifications

Standard Version Specifications Technical specification details in accordance with VDI 2198. Technical modifications and additions reserved. Performance data for standard trucks Description EZS 330 EZS 350 EZS 330 XL EZS 350 XL Tow capacity 3000 5000 3000 5000 Rated tow force... - Page 14 4) Rated tow force 1335...

-

Page 15: Identification Points And Data Plates

Identification points and data plates XXXXXXXXX XXXXXXXXX XXXXXXXXX XXXXXXXXXXX XXXXXXXXXXXX XXXXXXXXX XXXXXXXXXXX XXXXXXXXXXXX XXXXXXXXX XXXXXXXXXX XXXXXXXXXXXXXX XXXXXXXXX XXXXXXXXXX XXXXXXXXXXXXXX XXXXXXXXX XXXXXXXXXX XXXXXXXXXXXXX XXXXXXXXX XXXXXXXXXX XXXXXXXXXXXXX XXXXXXXXX XXXXXXXXX XXXXXXXXX XXXXXXX XXXXXXXXX XXXXXXX Item Description Truck data plate “Caution, pushbutton operation” warning Accident prevention inspection label (Donly) Warning: Risk of trapping when reversing Attachment point of hooks for transportation by crane (inside) -

Page 16: Truck Data Plate

Truck data plate XXXXXXXXX XXXXXXXXX XXXXXXXXX XXXXXXXXX XXXXXXXXX XXXXXXXXXXX XXXXXXXXXXXX XXXXXXXXX XXXXXXXXXXX XXXXXXXXXXXX XXXXXXXXX XXXXXXXXXX XXXXXXXXXXXXXX XXXXXXXXX XXXXXXXXXX XXXXXXXXXXXXXX XXXXXXXXX XXXXXXXXXX XXXXXXXXXXXXX XXXXXXXXX XXXXXXXXXX XXXXXXXXXXXXX XXXXXXXXX XXXXXXXXX XXXXXXXXX XXXXXXX XXXXXXXXX XXXXXXX Item Description Max. supporting force (kg) Net weight w.o. battery (kg) Min./max. -

Page 18: C Transport And Commissioning

C Transport and Commissioning Lifting by crane Only lifting gear with sufficient capacity (for transport weight see truck data plate). Lifting gear attachment points are provided on the chassis (3) and the back wall (1) in case the truck is to be lifted or transported by crane. -

Page 19: Using The Truck For The First Time

Using the truck for the first time Only operate the truck with battery current. Rectified AC current will damage the electronic components. Cables connected to the battery (trailing cables) must be less than 6 meters in length. To prepare the truck after delivery or after transport, proceed as follows: –... -

Page 20: Operating The Truck Without Its Own Drive System

Operating the truck without its own drive system This operating mode is not permitted when negotiating inclines and gradients. If the truck has to be moved after a failure has rendered it immobile, proceed as follows: – Set the master switch to position “OFF”. –... -

Page 22: D Battery Maintenance, Charging & Replacement

D Battery Maintenance, Charging & Replacement Safety regulations for handling acid batteries Park the truck securely before carrying out any work on the batteries (see Chapter E). Maintenance personnel: Batteries may only be charged, serviced or replaced by trained personnel. The present operator manual and the manufacturer’s instructions concerning batteries and charging stations must be observed when carrying out the work. -

Page 23: Battery Types

Battery types The truck will be equipped with different battery types, depending on the application. The following table shows which combinations can be included as standard: LxWxH 798x212x784 mm; 370 kg 24 V EPzS battery 3 EPzS 420 Ah 24 volt EPzS battery 3 EPzS 450 Ah enhanced 24 volt EPzV battery... -

Page 24: Exposing The Battery

Exposing the battery Park the truck securely (see Chapter E). – Pull lever (1) upward while at the same time setting the tiller vertical. – Release the lever (1) again. – Flip up the battery latch (3) and open the battery cover (2). All covers and connections must be restored to the normal operating condition before the truck can operate again. -

Page 25: Charge The Battery

Charge the battery To charge the battery, the truck must be parked in a closed and properly ventilated room. – Expose the battery (see Section 3). The battery connector (5) and the charging cable (4) of the battery charging station must only be connected or disconnected with the truck and the battery charger switched off. -

Page 26: Battery Removal And Installation

Battery removal and installation The truck must be parked on level ground. To prevent short circuits, batteries with exposed terminals or connectors must be covered with a rubber mat. Place the battery connector or the battery cable in such a way that they will not get caught on the truck when the battery is withdrawn. -

Page 28: Safety Regulations For The Operation Of Forklift Trucks

E Operation Safety Regulations for the Operation of Forklift Trucks Driver authorisation The forklift truck may only be used by suitably trained personnel, who have demonstrated to the proprietor or his representative that they can drive and handle loads and have been authorised to operate the truck by the proprietor or his representative. -

Page 29: Controls And Displays

Controls and Displays Item Control / Display Function t Steers the truck. Jet Pilot t The truck brakes at the maximum possible Brake button deceleration rate until it comes to a halt. t Triggers a warning signal. “Horn” button t Controls the direction of travel as well as Controller the travel speed. - Page 30 9 10...

-

Page 31: Starting Up The Truck

Starting up the truck Before the truck can be commissioned or operated, the driver must ensure that there is nobody within the hazardous area. The electronic traction controller and optionally the steering controller monitor their own operation. In the event of an error, travel and steering are interrupted. The error that has occurred must be eliminated by the manufacturer's service department. -

Page 32: Industrial Truck Operation

Industrial Truck Operation Safety regulations for truck operation Travel routes and work areas: Only use lanes and routes specifically designated for truck traffic. Unauthorised third parties must stay away from work areas. Loads must only be stored in places specially designated for this purpose. Travel conduct: The driver must adapt the travel speed to local conditions. -

Page 33: Travel, Steering, Braking

Travel, Steering, Braking Be extremely careful when driving and steering, especially when operating outside the geometry of the truck. The electric steering system is self-monitoring. The steering controller monitors the fault frequency over a certain period. If the same fault is detected several times during this period, the steering controller reduces the travel speed of the truck to slow travel. - Page 34 Travel Do not drive the truck unless the panels are closed and properly locked. – Start up the truck (refer to section 3). – Set the controller (22) to the desired travel direction: forward (V) or reverse (R). The truck starts to travel in the direction selected. The travel speed is governed by the controller (22).

- Page 35 Brakes The brake pattern of the truck depends largely on the state of the ground. The driver must take this into account when operating the truck. The driver must be looking ahead when travelling. If there is no hazard, brake moderately to avoid moving the load and to prevent the trailer from veering out.

-

Page 36: Pedestrian Operation (O)

Pedestrian operation (o) When travelling in pedestrian mode you must make sure – while walking alongside – that the steering system is set to straight ahead travel and that the operator cannot be trapped between the truck and an obstacle. In pedestrian mode the truck can be operated by the operator from all sides while walking alongside. -

Page 37: Coupling Types

Coupling Types When attaching and uncoupling trailers the tow truck and trailer must be on level ground. All controls must be set to neutral. The tow truck and trailer must be secured to prevent any accidental movement. Risk of trapping! When coupling a trailer do not trap your hands between any truck components. -

Page 38: Travelling With Trailers

Uncoupling the trailer – Make sure that the trailer cannot move accidentally. – Pull the retaining needle (32) out from the side of the bolt (31). Pull the bolt out of the coupling from the top. Bring the tow eye out from the side of the coupling. Reinsert the bolt into the coupling and secure it. -

Page 39: Seat O (Xl Only)

Seat o (XL only) The seat (35) is incorporated into the backrest when folded up. When unfolded, the seat allows the operator to take up a comfortable position for driving and operating. The height of the seat is adjustable and can be locked into one of four positions. –... -

Page 40: Display Instrument (Candis) (O)

Display instrument (CANDIS) (o) The instrument indicates: – Remaining battery charge (LED bars (36)), – Service hours (LCD display (38)). It also displays error messages for the electronic components parameter changes. Discharge status display Setting limits for the additional “Warning” (39) and “Stop” (37)displays will depend on the battery type. -

Page 41: Power Up Test

Display for parameter changes (travel programs) The LC display (38) is used in conjunction with the operator keyboard (CANCODE (o)) to display the setting parameters. The first three digits of the display show the parameter numbers, the last three digits indicate the parameter value. Settings of parameter group 0XX (code lock) are not displayed. -

Page 42: Keypad (Cancode) (O)

Keypad (CANCODE) (o) The keypad consists of 10 digit keys, a Set key and a o key. Activation of the travel programs is indicated through green LEDs on keys 1, 2 and 3. The o key indicates operational status through a red/green LED. - Page 43 Starting the truck for the first time After switching on the isolator and if necessary the key switch, the LED (44) turns red. When you enter the correct operator code (factory setting 2-5-8-0) the LED (44) turns green. If the wrong code is entered LED (44) flashes red for two seconds. The correct code can then be entered.

-

Page 44: Travel Programs

Travel programs Press the digit keys 1, 2, and 3 to select any of three travel programs. The activated programme is indicated by the green LEDs (40), (41), (42) in the corresponding key. The travel programmes differ with respect to travelling speed, acceleration, and deceleration. -

Page 45: Parameter Settings

Parameter Settings To change the truck setting you must enter the master code. The factory setting for the master code is 7-2-9-5. When starting the truck for the first time, change the master code (see Section 6.1). Safety notes for trucks with indicator instrument (CANDIS (o)) –... - Page 46 Setting procedure for trucks with and without display instrument (CANDIS (o)): – Enter the three digit parameter number and confirm with set key (45). – The display instrument (CANDIS (o)) continues to display the operating hours. If the display changes, cancel the setting procedure with the o key (43) and restart from the beginning.

- Page 47 Function Setting Standard Comments range setting Procedure Code Lock 002 Change user code 0000 - 9999 (LED 40 flashes) Enter current code 00000 - 99999 Confirm (Set) 000000 - 999999 (LED 41 flashes) Enter a new code Confirm (Set) (LED 42 flashes) Repeat code entry Confirm...

- Page 48 Function Setting Standard Comments range setting Procedure Code Lock 020 Start 0 – There is no start program travel program 1 – Travel program 1 = Start travel program 2 – Travel program 2 = Start travel program 3 – Travel program 3 = Start travel program 021 Travel program 1* 0 or 1...

-

Page 49: Travel Parameters

Travel parameters For trucks without a display instrument (CANDIS (o)) the code lock parameters can only be set by the manufacturer's service department. The following example shows the parameter setting for the acceleration of travel program 1 (parameter 101). Acceleration example Enter the three-digit parameter number (101) and confirm with the Set key (45). - Page 50 Travel is disabled while the parameters are being entered. If the setting is to be checked in programming mode, follow this sequence: – Select the edited travel program after changing the parameter value, confirm with the Set key (45). – The truck is now in travel mode and can be checked. –...

- Page 51 Function Setting Standard Comments range setting Travel program 2 200 Acceleration in 0 - 9 Value of parameter 201 >= Parameter Pedestrian mode 201 Acceleration in 0 - 9 Rider mode 202 Coasting brake in 0 - 9 rider mode 203 Coasting brake in 0 - 9 Value of parameter...

- Page 52 Function Setting Standard Comments range setting Travel program 3 300 Acceleration in 0 - 9 Value of parameter 301 >= Parameter Pedestrian mode 301 Acceleration in 0 - 9 Rider mode 302 Coasting brake in 0 - 9 rider mode 303 Coasting brake in 0 - 9 Value of parameter...

- Page 53 Program-independent parameters For trucks without a display instrument (CANDIS (o)) the parameters can BATTERY only be set by the manufacturer's service department. The parameters are set in the same way as for the travel parameters. The following parameters may be entered. Function Setting Standard...

-

Page 54: Troubleshooting

Troubleshooting This chapter is designed to help the user identify and rectify basic faults or the results of incorrect operation. When locating a fault, proceed in the order shown in the table. Fault Possible cause Action Truck – Battery connector –... - Page 55 E 28...

-

Page 56: F Industrial Truck Maintenance

F Industrial Truck Maintenance Operational safety and environmental protection The servicing and inspection duties contained in this chapter must be performed in accordance with the intervals indicated in the maintenance checklists. Any modification to the forklift truck assemblies, in particular the safety mechanisms, is prohibited. - Page 57 Electrical System: Only suitably trained personnel may operate on the truck’s electrical system. Before working on the electrical system, take all precautionary measures to avoid electric shocks. For battery-operated trucks, also de-energise the truck by removing the battery connector. Welding: To avoid damaging electric or electronic components, remove these from the truck before performing welding operations.

-

Page 58: Servicing And Inspection

Servicing and inspection Thorough and expert servicing is one of the most important requirements for the safe operation of the industrial truck. Failure to perform regular servicing can lead to truck failure and poses a potential hazard to personnel and equipment. The service intervals stated are based on single shift operation under normal operating conditions. -

Page 59: Maintenance Checklist

Maintenance checklist Maintenance intervals = t W A B C Standard Cold Store Chassis/ 1.1 Check all load bearing components for damage Super- 1.2 Check screw connections structure: 1.3 Test the operator platform and check for damage Drive unit: 2.1 Check the transmission for noise and leakage Wheels 3.1 Check wheels for wear and damage 3.2 Check suspension and attachment... - Page 60 Maintenance intervals = t W A B C Standard Cold Store Battery 9.1 Check acid density, acid level and cell voltage 9.2 Check terminals are securely attached, and apply grease 9.3 Clean the battery connections; make sure they are secure 9.4 Check battery cables for damage, replace if necessary.

-

Page 61: Lubrication Schedule

Lubrication Schedule 1.4l Contact surfaces Grease nipple Transmission oil filler neck Transmission oil drain plug Cold store application Compound ratio for cold store usage 1:1... -

Page 62: Consumables

Consumables Handling consumption type material: Consumables must always be handled correctly. Follow the manufacturer’s instructions. Improper handling is hazardous to health, life and the environment. Consumables must only be stored in appropriate containers. They may be flammable and must therefore not come into contact with hot components or naked flames. Only use clean containers when filling up with consumables. -

Page 63: Maintenance Instructions

Maintenance Instructions Preparing the truck for maintenance and repairs All necessary safety measures must be taken to avoid accidents when carrying out maintenance and repairs. The following preparations must be made: – Park the truck securely (see Chapter E). – Disconnect the battery so that the truck cannot be started by unauthorised persons (refer to chapter D). -

Page 64: Remove The Front Panel

Remove the front panel – Open battery cover (refer to chapter D). – Remove the hex socket screws (5) located under the battery cover using the hex socket wrench (6). – Lift up the front panel (4) and put it to one side. Installation is the reverse order. -

Page 65: Checking Electrical Fuses

Checking electrical fuses – Prepare the truck for maintenance and repairs (see Chapter 6.1). – Remove the front panel (see Section 6.3). – Referring to the table, check all fuses for correct rating and damage; replace fuses where required. Item Description To protect: Rating... -

Page 66: Recommissioning

Recommissioning The truck may only be restored to service after cleaning or repair work, once the following operations have been performed. – Test horn. – Test main switch operation. – Test brakes. – Lubricate the truck in accordance with the lubrication schedule. Decommissioning the industrial truck If the industrial truck is to be decommissioned for more than two months, e.g. -

Page 67: Returning The Truck To Operation After Decommissioning

Returning the truck to operation after decommissioning – Thoroughly clean the truck. – Lubricate the truck in accordance with the lubrication schedule (see Chapter F). – Clean the battery, grease the terminals and connect the battery. – Charge the battery (see Chapter D). –... - Page 68 Jungheinrich traction battery Table of contents Jungheinrich traction battery ..........2-6 with positive tubular plates type EPzS and EPzB Type plate Jungheinrich traction battery..........7 Instruction for use ............8-12 Aquamatic/BFS III water refilling system Jungheinrich traction battery Maintenance free traction batteries with positive tubular plates type EPzV ....................13-17...

-

Page 69: Jungheinrich Traction Battery

Jungheinrich traction battery with positive tubular plates type EPzS and EPzB Rating Data 1. Nominal capacity C5: See type plate 2. Nominal voltage: 2,0 V x No of cells 3. Discharge current:: C5/5h 4. Nominal S.G. of electrolyte* Type EPzS:... - Page 70 Ignoring the operation instructions, repair with non-original parts or using additives for the electrolyte will render the warranty void. For batteries in classes I and II the instructions for maintaining the appropriate protection class during operation must be complied with (see relevant certificate). 1.

- Page 71 Battery container lids and the covers of battery compartments must be opened or re- moved. The vent plugs should stay on the cells and remain closed. With the charger switched off connect up the battery, ensuring that the polarity is cor- rect.

- Page 72 3. Maintenance 3.1 Daily Charge the battery after every discharge. Towards the end of charge the electrolyte level should be checked and if necessary topped up to the specified level with purified water. The electrolyte level must not fall below the anti-surge baffle or the top of the separator or the electrolyte „min“...

- Page 73 5. Storage If batteries are taken out of service for a lengthy period they should be stored in the fully charged condition in a dry, frost-free room. To ensure the battery is always ready for use a choice of charging methods can be made: 1.

-

Page 74: 7. Type Plate, Jungheinrich Traction Battery

7. Type plate, Jungheinrich traction battery Baujahr T ype Year of manufacture Serien-Nr. Lieferanten Nr. Serial-Nr. Supplier No. Nennspannung Kapazität Nominal V oltage Capacity Zellenzahl Batteriegewicht min/max Number of Cells Battery mass min/max Hersteller Jungheinrich AG, D-22047 Hamburg, Germany Manufacturer... -

Page 75: Aquamatic/Bfs Iii Water Refilling System

Aquamatic/BFS III water refilling system for Jungheinrich traction battery with EPzS and EPzB cells with tubular positive plates Aquamatic plug arrangement for the Operating Instructions Cell series* Aquamatic plug type (length) EPzS EPzB Frötek (yellow) (black) 2/120 – 10/ 600 2/ 42 –... - Page 76 Diagrammatic view Equipment for the water refilling system 1. Water tank 2. Level switch 3. Discharge point with ball valve 4. Discharge point with sole- noid valve 5. Charger 6. Sealing coupler 7. Closing nipple 8. Ion exchange cartridge with conductance meter and solenoid valve 9.

- Page 77 4. Filling (manual/automatic) The batteries should be filled with battery water as soon as possible before the battery charging comes to an end; this ensures that the refilled water quantity is mixed with the electrolyte. In normal operation it is usually sufficient to fill once a week. 5.

- Page 78 8. Battery hose connections Hose connections for the individual plugs are laid along the existing electric circuit. No changes may be made. 9. Operating temperature The temperature limit for battery operation is set at 55° C. Exceeding this temperature damages the batteries. The battery filling systems may be operated within a tempe- rature range of >...

- Page 79 10.2.1 Clamping ring tool The clamping ring tool is used to push on a clamping ring to increase the contact pres- sure of the hose connection on the plugs' hose couplings and to loosen it again. 10.3 Filter element For safety reasons a filter element (ident no.: 50307282) can be fitted into the batte- ry's main supply pipe for supplying battery water.

-

Page 80: Jungheinrich Traction Battery

Jungheinrich traction batterie Maintenance free Jungheinrich traction batterie with positive tubular plates type EPzV and EPzV-BS Rating Data 1. Nominal capacity C5: See type plate 2. Nominal voltage: 2,0 Volt x No of cells 3. Discharge current: C5/5h 4. Rated temperature: 30°... - Page 81 Ignoring the operation instructions, repair with non-original parts and non authorised interventions will render the warranty void. For batteries in classes I and II the instructions for maintaining the appropriate protection class during operation must be complied with (see relevant certificate). 1.

- Page 82 With the charger switched off connect up the battery, ensuring that the polarity is cor- rect (positive to positive, negative to negative). Now switch on the charger. When charging the temperature of the battery rises by about 15° C, so charging should only begin if the battery temperature is below 35°...

- Page 83 3.2 Weekly Visual inspection after recharging for signs of dirt and mechanical damage. 3.3 Quarterly After the end of the charge and a rest time of 5 h following should be measured and recorded: • the voltages of the battery •...

-

Page 84: 7. Type Plate, Jungheinrich Traction Battery

Batteries with this sign must be recycled. Batteries which are not returned for the recycling process must be disposed of as hazardous waste! We reserve the right make technical modification. 7. Type plate, Jungheinrich traction battery Baujahr T ype Year of manufacture Serien-Nr.

Need help?

Do you have a question about the EZS 330 and is the answer not in the manual?

Questions and answers