Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Miller Electric Big Blue 602P

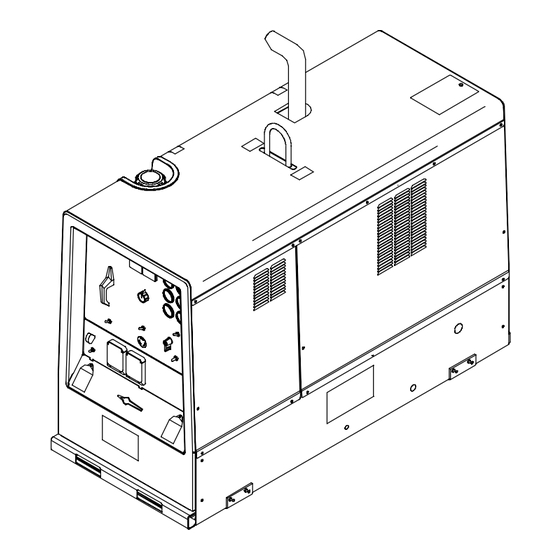

- Page 1 Visit our website at www.MillerWelds.com Big Blue 402P, 502P, 602P OM-491 190 355AP October 2003 Processes Stick (SMAW) Welding TIG (GTAW) Welding MIG (GMAW) Welding Flux Cored (FCAW) Welding Air Carbon Arc (CAC-A) Cutting and Gouging Description Engine Driven Welding Generator...

- Page 2 ISO 9001:2000 Quality System Standard. particular model are also provided. Miller Electric manufactures a full line of welders and welding related equipment. For information on other quality Miller products, contact your local Miller distributor to receive the latest full line catalog or individual catalog sheets.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SECTION 1 − SAFETY PRECAUTIONS − READ BEFORE USING 1-1. Symbol Usage ............... . 1-2. - Page 4 TABLE OF CONTENTS SECTION 8 − OPERATING AUXILIARY EQUIPMENT 8-1. 120 Volt And 240 Volt Receptacles 8-2. Connecting To Optional Three-Phase Generator (CC/CV Models Only) 8-3. Optional Generator Power Receptacles SECTION 9 − MAINTENANCE & TROUBLESHOOTING 9-1. Routine Maintenance ..............9-2.

-

Page 5: Om-491

SECTION 1 − SAFETY PRECAUTIONS − READ BEFORE USING Y Warning: Protect yourself and others from injury — read and follow these precautions. 1-1. Symbol Usage Means Warning! Watch Out! There are possible hazards with this procedure! The possible hazards are shown in the adjoining symbols. -

Page 6: Engine Hazards

WELDING can cause fire or explosion. Welding on closed containers, such as tanks, drums, or pipes, can cause them to blow up. Sparks can fly off from the welding arc. The flying sparks, hot workpiece, and hot equipment can cause fires and burns. Accidental contact of electrode to metal objects can cause sparks, explosion, overheating, or fire. -

Page 7: Compressed Air Hazards

STEAM AND HOT COOLANT can burn. D If possible, check coolant level when engine is cold to avoid scalding. D Always check coolant level at overflow tank, if pres- ent on unit, instead of radiator (unless told otherwise in maintenance section or engine manual). D If the engine is warm, checking is needed, and there is no overflow tank, follow the next two statements. -

Page 8: California Proposition 65 Warnings

READ INSTRUCTIONS. D Use only genuine MILLER/Hobart replacement parts. D Perform engine and air compressor (if applicable) maintenance and service according to this manual and the engine/air compressor (if applicable) manu- als. H.F. RADIATION can cause interference. D High-frequency (H.F.) can interfere with radio naviga- tion, safety services, computers, and communica- tions equipment. -

Page 9: Section 2 − Consignes De Sécurité − Lire Avant Utilisation

SECTION 2 − CONSIGNES DE SÉCURITÉ − LIRE AVANT Y Avertissement: Protégez vous et les autres des blessures − lisez et suivez ces précautions. 2-1. Signification des symboles Signifie Mise en garde ! Soyez vigilant ! Cette procédure présente des risques de danger ! Ceux-ci sont identifiés par des symboles adjacents aux directives. -

Page 10: Dangers Existant En Relation Avec Le Moteur

LES ACCUMULATIONS DE GAZ ris- quent de provoquer des blessures ou même la mort. D Fermer l’alimentation du gaz protecteur en cas de non utilisation. D Veiller toujours à bien aérer les espaces confinés ou se servir d’un respi- rateur d’adduction d’air homologué. LES RAYONS DE L’ARC peuvent pro- voquer des brûlures dans les yeux et sur la peau. -

Page 11: Dangers Liés À L'air Comprimé

L’EXPLOSION DE LA BATTERIE peut RENDRE AVEUGLE. D Toujours porter une protection faciale, des gants en caoutchouc et vêtements de protection lors d’une in- tervention sur la batterie. D Arrêter le moteur avant de débrancher ou de brancher les câbles de batterie. -

Page 12: Principales Normes De Sécurité

LE SURCHAUFFEMENT peut endom- mager le moteur électrique. D Arrêter ou déconnecter l’équipement avant de dé- marrer ou d’arrêter le moteur. D Ne pas laisser tourner le moteur trop lentement sous risque d’endommager le moteur électrique à cause d’une tension et d’une fréquence trop faibles. D Ne pas brancher de moteur de 50 ou de 60 Hz à... -

Page 13: Section 3 − Definitions

SECTION 3 − DEFINITIONS 3-1. Symbols And Definitions Stop Engine Starting Aid Check Injectors/ Pump Positive Amperes Engine Stick (SMAW) Welding Time Three Phase Electrode Connection SECTION 4 − SPECIFICATIONS NOTE A CC/DC model is shown in this manual. Fast (Run, Weld/ Slow (Idle) Power) Engine Oil... -

Page 14: Weld, Power, And Engine Specifications

4-1. Weld, Power, And Engine Specifications Welding Weld Output Rated Welding Mode Range Output 55 − 600 A (CC Models) CC/DC 400 A, 40 Volts DC, 20 − 600 A 100% Duty Cycle (CC/CV Models) 500 A, 40 volts DC, 500 A, 40 volts DC, 60% Duty Cycle 60% Duty Cycle... -

Page 15: Volt-Ampere Curves For Cc Models

4-3. Volt-Ampere Curves For CC Models Ranges 300−Max 185−425 125−320 85−190 55−90 DC AMPERES Return To Table Of Contents The volt-ampere curve shows the minimum and maximum voltage and amperage output capabilities of the welding generator. Curves of all other settings fall between the curves shown. -

Page 16: Volt-Ampere Curves For Cc/Cv Models

4-4. Volt-Ampere Curves For CC/CV Models A. Stick Mode B. MIG Mode 100 200 300 400 500 600 700 800 900 1000 C. TIG Mode 100 150 200 250 300 350 400 450 500 OM-491 Page 12 Ranges 300−Max 185−425 125−320 85−190 55−90... -

Page 17: Fuel Consumption

4-5. Fuel Consumption 1800 RPM IDLE 100 150 200 250 300 350 400 450 500 DC WELD AMPERES AT 100% DUTY CYCLE 4-6. Duty Cycle And Overheating 100% Duty Cycle At 400 Amperes Continuous Welding Return To Table Of Contents The curve shows typical fuel use under weld or power loads. -

Page 18: Ac Generator Power Curve

4-7. AC Generator Power Curve AC AMPERES IN 240V MODE AC AMPERES IN 120V MODE 4-8. Optional Three-Phase Generator Curves A. 12 kVA/kW Single-Phase AC Output (No Weld Load) B. 20 kVA/kW Three-Phase AC Output (No Weld Load) OM-491 Page 14 AC AMPERES AC AMPERES Return To Table Of Contents... -

Page 19: Section 5 − Installation

SECTION 5 − INSTALLATION 5-1. Installing Welding Generator Movement Location Grounding GND/PE Airflow Clearance 18 in (460 mm) 18 in (460 mm) Electrically bond generator frame to vehicle frame by metal-to-metal contact. Y Bed liners, shipping skids, and some running gears insulate the welding generator from the vehicle frame. -

Page 20: Mounting Welding Generator

5-2. Mounting Welding Generator Supporting The Unit Inadequate support. Y Do not use flexible mounts. Using Mounting Brackets Tools Needed: 9/16 in OM-491 Page 16 Welding Unit In Place Bolting Unit In Place Return To Table Of Contents Y Do not weld on base. Weld- ing on base can cause fuel tank fire or explosion. -

Page 21: Using Lifting Eye

5-3. Using Lifting Eye 5-4. Installing Exhaust Pipe Tools Needed: 1/2 in Return To Table Of Contents Lifting Eye Carriage Bolt Raise lifting eye until it snaps in place. Lower lifting eye when not needed. To lock the lifting eye in the upright position, insert a 3/8-16 x 1-1/2 in carriage bolt through slot in bracket and secure with nut (bolt and nut not... -

Page 22: Activating The Dry Charge Battery (If Applicable)

5-5. Activating The Dry Charge Battery (If Applicable) 5 A For 30 Minutes 30 A For 12 Minutes OM-491 Page 18 − Return To Table Of Contents Remove battery from unit. Eye Protection − Safety Glasses Or Face Shield Rubber Gloves Vent Caps Sulfuric Acid Electrolyte (1.265 Specific Gravity) -

Page 23: Connecting The Battery

5-6. Connecting The Battery Reinstall cover after connecting battery. Y Connect Negative (−) Cable Last. − Tools Needed: 1/2 in 802 168-E / Ref. 202 705 / 802 313 / S-0756-C Notes Return To Table Of Contents OM-491 Page 19... -

Page 24: Engine Prestart Checks

5-7. Engine Prestart Checks Check radiator coolant level when fluid is low in recovery tank. Capacity: 12 qt (11.4L) Check all engine fluids daily. Engine must be cold and on a level surface. Unit is shipped with 20W break-in oil. The Automatic shutdown system stops en- gine if fuel level or oil pressure is too low, or coolant temperature is too high. -

Page 25: Connecting To Weld Output Terminals

5-8. Connecting To Weld Output Terminals 5-9. Selecting Weld Cable Sizes* Weld Output Terminals Y Stop engine before Welding connecting to weld out- Amperes put terminals. Y Do not use worn, dam- aged, undersized, or poorly spliced cables. This chart is a general guideline and may not suit all applications. If cables overheat (normally you can smell it), use next size larger cable. **Weld cable size (AWG) is based on either a 4 volts or less drop or a current density of at least 300 circular mils per ampere. -

Page 26: Connecting To Remote Amperage Adjust Receptacle Rc13 On Cc Models

5-10. Connecting To Remote Amperage Adjust Receptacle RC13 On CC Models 5-11. Connecting To Remote 14 Receptacle RC14 On CC/CV Models New! LDR-14 long New! LDR-14 long distance remote (includes 120 V receptacle) receptacle) *The remaining sockets are not used. OM-491 Page 22 Socket* 24 VOLTS AC... -

Page 27: Section 6 − Operating Welding Generator − Cc Models

SECTION 6 − OPERATING WELDING GENERATOR − CC MODELS 6-1. Front Panel Controls For CC Models (See Section 6-2) 10 11 202 705 / 802 169-F Return To Table Of Contents OM-491 Page 23... -

Page 28: Description Of Front Panel Controls For Cc Models (See Section 6-1)

6-2. Description Of Front Panel Controls For CC Models (See Section 6-1) Engine Starting Controls Magnetic Shutdown Switch Use switch during start-up to bypass engine shutdown system. System stops engine if oil pressure or fuel level is too low or coolant tem- perature is too high. -

Page 29: Remote Amperage Control On Cc Models (Optional)

6-3. Remote Amperage Control On CC Models (Optional) Example: Combination Remote Amperage Control (Stick) Set Switches Set Range 6-4. Weld Control/Arc Condition Information Label Max = About 223 A DC (50% of 125 to 320) Set Control Return To Table Of Contents Remote Amperage Adjust Receptacle RC13 Connect optional remote control to... - Page 30 Notes OM-491 Page 26 Return To Table Of Contents...

-

Page 31: Section 7 − Operating Welding Generator − Cc/Cv Models

SECTION 7 − OPERATING WELDING GENERATOR − CC/CV MODELS 7-1. Front Panel Controls For CC/CV Models (See Section 7-2) 10 11 202 706 / 802 311-D Return To Table Of Contents OM-491 Page 27... -

Page 32: Description Of Front Panel Controls For Cc/Cv Models (See Section 7-1)

7-2. Description Of Front Panel Controls For CC/CV Models (See Section 7-1) Engine Starting Controls Magnetic Shutdown Switch Use switch during start-up to bypass engine shutdown system. System stops engine if oil pressure is too low or engine temperature is too high. -

Page 33: Process/Contactor Switch On Cc/Cv Models

7-3. Process/Contactor Switch On CC/CV Models Switch Setting Switch Setting GTAW With HF Unit, Pulsing Remote − TIG Device, Or Remote Control Remote − Stick Stick (SMAW) With Remote On/Off Remote − MIG MIG (GMAW) Electrode Hot − MIG MIG (GMAW) Stick (SMAW), Electrode Hot −... -

Page 34: Remote Voltage/Amperage Control On Cc/Cv Models (Optional)

7-4. Remote Voltage/Amperage Control On CC/CV Models (Optional) Example: Combination Remote Amperage Control (Stick) Set Remote Set V/A Adjust Switch Process Example: Combination Remote Amperage Control (TIG) Set V/A Set Remote Adjust Switch Process OM-491 Page 30 Process = Stick (Using Remote On/Off) Set Range Control Not Used In Remote... -

Page 35: Section 8 − Operating Auxiliary Equipment

SECTION 8 − OPERATING AUXILIARY EQUIPMENT 8-1. 120 Volt And 240 Volt Receptacles Return To Table Of Contents 120 V 20 A AC GFCI Receptacle GFCI1 240 V 30 A AC Twistlock Receptacle RC1 Receptacles supply 60 Hz single- phase power at weld/power speed. If a ground fault is detected, GFCI Reset button... -

Page 36: Connecting To Optional Three-Phase Generator (Cc/Cv Models Only)

8-2. Connecting To Optional Three-Phase Generator (CC/CV Models Only) Single-Phase Power Connection Three-Phase Power Connection Y Close panel opening if no connections are made to generator. Remove plug before inserting leads. Reinstall bushing. 120V 120V OM-491 Page 32 Single Phase Output Volts 120/240... -

Page 37: Optional Generator Power Receptacles

8-3. Optional Generator Power Receptacles European Receptacle Australian Receptacle South African Receptacle Return To Table Of Contents 120 V 20 A AC GFCI Receptacle GFCI1 240 V 16 A AC European Receptacle RC1 240 V 15 A AC Australian Receptacle RC1 240 V 15 A AC South African Receptacle RC1 Receptacles supply 60 Hz single-... -

Page 38: Section 9 − Maintenance & Troubleshooting

SECTION 9 − MAINTENANCE & TROUBLESHOOTING 9-1. Routine Maintenance Note Follow the storage procedure in the engine owner’s manual if the unit will not be used for an extended period. Wipe Spills. Clean Air Filter. See Section 9-3. Check air cleaner hoses for cracks and loose clamps. - Page 39 Every 400 h Check Radiator Change Oil Change Oil. See Fluid Level. See Filter. See Section 9-6. Section 5-7. Section 9-6. Change Fuel Check Filters. See Valve Section 9-6. Clearance.* Every 500 h Repair Or Replace Damaged Cables. Every 800 h Clean/Set Injectors.* Every 1000 h...

-

Page 40: Maintenance Label

9-2. Maintenance Label OM-491 Page 36 Return To Table Of Contents... -

Page 41: Servicing Air Cleaner

9-3. Servicing Air Cleaner Keep nozzle 2 in (51 mm) from element. Blow Optional Inspect aircleaner1 9/00 − ST-153 929-B / ST-153 585 / Ref. S-0698-B / Ref. 202 705 Return To Table Of Contents Y Stop engine. Y Do not run engine without air cleaner or with dirty element. -

Page 42: Inspecting And Cleaning Optional Spark Arrestor Muffler

9-4. Inspecting And Cleaning Optional Spark Arrestor Muffler Tools Needed: 3/8 in OM-491 Page 38 Return To Table Of Contents Y Stop engine and let cool. Spark Arrestor Muffler Cleanout Plug Remove plug and remove any dirt covering cleanout hole. Exhaust Pipe Start engine and run at idle speed to blow out cleanout hole. -

Page 43: Adjusting Engine Speed

9-5. Adjusting Engine Speed Engine Speed (No Load) 1850 rpm Weld/Power (61.6 Hz) 1500 rpm Idle (50 Hz) Standard Models Models With Automatic Idle (Optional) Return To Table Of Contents Y Stop engine and let cool. Engine speed is factory set and should not require adjustment. -

Page 44: Servicing Fuel And Lubrication Systems

9-6. Servicing Fuel And Lubrication Systems OM-491 Page 40 Return To Table Of Contents Y Stop engine and let cool. Y After servicing, start engine and check for fuel leaks. Stop engine, tighten connec- tions as necessary, and wipe up spilled fuel. Oil Filter Oil Drain Valve And Hose Oil Fill Cap... -

Page 45: Overload Protection

9-7. Overload Protection Return To Table Of Contents Y Stop engine. When a circuit breaker or fuse opens, it usually indicates a more serious problem exists. Contact Factory Authorized Service Agent. Fuse F1 Fuse F2 F1 and F2 protect the stator exciter winding from overload. -

Page 46: Diagnosing Causes Of Engine Fault Shutdowns

9-8. Diagnosing Causes Of Engine Fault Shutdowns Pre-Start Diagnostic Checks Turn Engine Control Switch To Run/Idle Position While Pressing Magnetic Shutdown Switch. Diagnostic Checks While Running Start Engine (With No Load Applied). OM-491 Page 42 Normal Condition: Oil Pressure Light On; Battery Charging, Fuel, And Temperature Lights Off. -

Page 47: Troubleshooting

9-9. Troubleshooting A. Welding − CC Models Trouble No weld output; generator power output Check position of Ampere Range switch. okay at ac receptacles. Check position of optional polarity switch. Place Amperage Adjust switch in Panel position, or place switch in Remote position and connect remote control to Remote Amperage Adjust receptacle RC13 (see Sections 5-10 and 6-1). - Page 48 B. Welding − CC/CV Models Trouble No weld output; generator power output Place Process/Contactor switch in a Electrode Hot position, or place switch in a Remote position and okay at ac receptacles. connect remote contactor to optional Remote 14 receptacle RC14 (see Sections 5-11 and 7-1). Check position of Ampere Range switch.

- Page 49 Trouble Min or max CV weld output only. Check position of Voltage/Amperage Adjust control and Voltage/Amperage Adjust switch. Repair or replace remote control device. Have Factory Authorized Service Agent check field current regulator board PC1. C. Standard Generator Power Trouble No generator power output at ac recep- Reset receptacle circuit breakers.

- Page 50 Trouble Engine cranks but does not start. Press Magnetic Shutdown switch MS1 when starting engine. Check fuel level. Reset circuit breaker CB13 (see Section 9-7). Have Factory Authorized Service Agent check engine wir- ing harness and components. Check battery and replace if necessary. Check engine charging system according to engine manual. Have Factory Authorized Service Agent check control relay CR2, and fuel solenoid FS1.

- Page 51 Notes Return To Table Of Contents OM-491 Page 47...

-

Page 52: Section 10 − Electrical Diagrams

SECTION 10 − ELECTRICAL DIAGRAMS Figure 10-1. Circuit Diagram For CC Welding Generator Return To Table Of Contents OM-491 Page 48... - Page 53 215 304-A Return To Table Of Contents OM-491 Page 49...

- Page 54 Figure 10-2. Circuit Diagram For CC/CV Welding Generator Return To Table Of Contents OM-491 Page 50...

- Page 55 215 305-A Return To Table Of Contents OM-491 Page 51...

-

Page 56: Section 11 − Run-In Procedure

SECTION 11 − RUN-IN PROCEDURE 11-1. Wetstacking OM-491 Page 52 Return To Table Of Contents run_in1 8/01 Y Do perform run-in procedure at less than 20 volts weld output and do not exceed duty cycle or equip- ment damage may occur. Welding Generator Run diesel engines near rated volt- age and current during run-in period... -

Page 57: Run-In Procedure Using Load Bank

11-2. Run-In Procedure Using Load Bank Return To Table Of Contents Y Stop engine. Y Do not touch hot exhaust pipe, engine parts, or load bank/grid. Y Keep exhaust and pipe away from flammables. Y Do perform run-in procedure at less than 20 volts weld output and do not exceed duty cycle or equip- ment damage may occur. -

Page 58: Run-In Procedure Using Resistance Grid

11-3. Run-In Procedure Using Resistance Grid OM-491 Page 54 Return To Table Of Contents Y Stop engine. Y Do not touch hot exhaust pipe, engine parts, or load bank/grid. Y Keep exhaust and pipe away from flammables. Y Do perform procedure at less than 20 volts weld output and do not exceed duty cycle or equip-... -

Page 59: Section 12 − Generator Power Guidelines

SECTION 12 − GENERATOR POWER GUIDELINES NOTE The views in this section are intended to be representative of all engine-driven welding generators. Your unit may differ from those shown. 12-1. Selecting Equipment 12-2. Grounding Generator To Truck Or Trailer Frame Electrically bond generator frame to vehicle frame by metal-to-metal contact. -

Page 60: Grounding When Supplying Building Systems

12-3. Grounding When Supplying Building Systems 12-4. How Much Power Does Equipment Require? AMPERES x VOLTS = WATTS EXAMPLE 1: If a drill uses 4.5 amperes at 115 volts, calculate its running power requirement in watts. The load applied by the drill is 520 watts. EXAMPLE 2: If three 200 watt flood lamps are used with the drill from Example 1, add the individual loads to calculate total load. - Page 61 12-5. Approximate Power Requirements For Industrial Motors Industrial Motors Split Phase Capacitor Start-Induction Run Capacitor Start-Capacitor Run Fan Duty 12-6. Approximate Power Requirements For Farm/Home Equipment Farm/Home Equipment Stock Tank De-Icer Grain Cleaner Portable Conveyor Grain Elevator Milk Cooler Milker (Vacuum Pump) FARM DUTY MOTORS Std.

- Page 62 12-7. Approximate Power Requirements For Contractor Equipment Contractor Hand Drill Circular Saw Table Saw Band Saw Bench Grinder Air Compressor Electric Chain Saw Electric Trimmer Electric Cultivator Elec. Hedge Trimmer Flood Lights Submersible Pump Centrifugal Pump Floor Polisher High Pressure Washer 55 gal Drum Mixer Wet &...

-

Page 63: Power Required To Start Motor

12-8. Power Required To Start Motor Single-Phase Induction Motor Starting Requirements Motor Start Code KVA/HP kVA/HP x HP x 1000 VOLTS EXAMPLE: Calculate the starting amperage required for a 230 V, 1/4 HP motor with a motor start code of M. Volts = 230 HP = 1/4 11.2 x 1/4 x 1000... - Page 64 12-10. Typical Connections To Supply Standby Power Y Properly install and ground this equipment according to its Owner’s Manual and national, state, and local codes. Utility Electrical Service Y Have only qualified persons perform these connections according to all applicable codes and safety practic- Y Properly install and ground this equipment according to its Owner’s Manual and national, state, and local...

-

Page 65: Selecting Extension Cord (Use Shortest Cord Possible)

12-11. Selecting Extension Cord (Use Shortest Cord Possible) Cord Lengths for 120 Volt Loads Y If unit does not have GFCI receptacles, use GFCI-protected extension cord. Current Load (Watts) (Amperes) 1200 1800 2400 3000 3600 4200 4800 5400 6000 *Conductor size is based on maximum 2% voltage drop Cord Lengths for 240 Volt Loads Y If unit does not have GFCI receptacles, use GFCI-protected extension cord. -

Page 66: Section 13 − Parts List

SECTION 13 − PARTS LIST Hardware is common and not available unless listed. 108 (FIG 13-4 OR 13-5) OM-491 Page 62 112 (FIG 13-7) 104 FIG 13-2 OR 13-3) 101 (CC ONLY) 103 (CC ONLY) Figure 13-1. Main Assembly Return To Table Of Contents... - Page 67 46 (FIG 13-6) Big Blue 502, 602 Only 50 51 Return To Table Of Contents OM-491 Page 63 802 265-G...

- Page 68 Item Dia. Part Mkgs....189 824 ....199 294 ..

- Page 69 Item Dia. Part Mkgs....010 875 ....193 314 .

- Page 70 Item Dia. Part Mkgs....191 610 ....190 180 .

- Page 71 Figure 13-2. Control Box Assembly − CC Models Item Dia. Part Mkgs. Figure13-2. Control Box Assembly − CC Models (Figure 13-1 Item 104) ..F1, F2 *085 874 ....046 432 .

- Page 72 Item Dia. Part Mkgs. Figure 13-2. Control Box Assembly − CC Models (Continued) ....190 260 ..PLG3 .

- Page 73 Item Dia. Part Mkgs. Figure 13-3. Control Box Assembly − CC/CV Models (Figure 13-1 Item 104) ..F1, F2 *085 874 ....046 432 .

- Page 74 Hardware is common and not available unless listed. Figure 13-4. Panel, Front w/Components − CC Models Item Dia. Part Mkgs. Figure 13-4. Panel, Front w/Components − CC Models (Figure 13-1 Item 108) ....202 705 .

- Page 75 Item Dia. Part Mkgs. Figure 13-4. Panel, Front w/Components − CC Models (Continued) ... . . 011 609 .......

- Page 76 Hardware is common and not available unless listed. Figure 13-5. Panel, Front w/Components − CC/CV Models Item Dia. Part Mkgs. Figure 13-5. Panel, Front w/Components − CC/CV Models (Figure 13-1 Item 108) ....202 706 .

- Page 77 Item Dia. Part Mkgs. Figure 13-5. Panel, Front w/Components − CC/CV Models (Continued) ... . . 193 118 ... . 193 234 .

- Page 78 Item Dia. Part Mkgs. Figure 13-5. Panel, Front w/Components − CC/CV Models (Continued) ..FUEL . . . 191 242 ... . . 118 058 .

- Page 79 Item Dia. Part Mkgs....132 053 ....183 387 .

- Page 80 Hardware is common and not available unless listed. Item Dia. Part Mkgs....201 747 ..203 381 ..

- Page 81 Warranty Questions? Call LIMITED WARRANTY − Subject to the terms and conditions below, Miller Electric Mfg. Co., Appleton, Wisconsin, warrants 1-800-4-A-MILLER to its original retail purchaser that new Miller equipment sold for your local after the effective date of this limited warranty is free of defects in material and workmanship at the time it is shipped by Miller.

-

Page 82: Owner's Record

File a claim for loss or damage during shipment. For assistance in filing or settling claims, contact your distributor and/or equipment manufacturer’s Transportation Department. 2003 Miller Electric Mfg. Co. 1/03 Miller Electric Mfg. Co. An Illinois Tool Works Company 1635 West Spencer Street Appleton, WI 54914 USA International Headquarters−USA...

Need help?

Do you have a question about the Big Blue 602P and is the answer not in the manual?

Questions and answers