Summary of Contents for Miller Electric BLUE STAR 145 DX

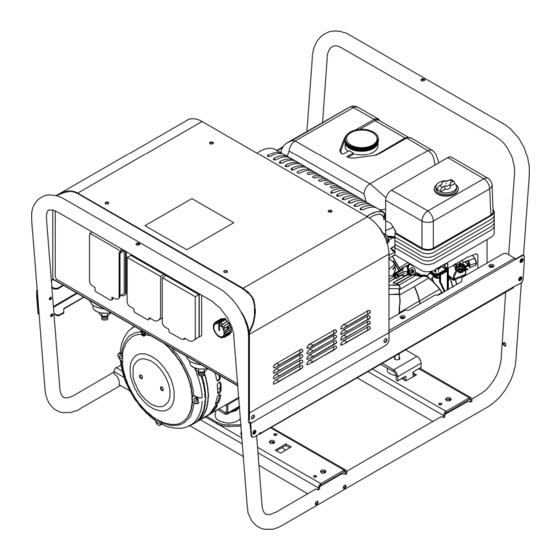

- Page 1 OM-4417 210 403C 2005−10 Processes Stick (SMAW) Welding Description Engine Driven Welding Generator Blue Star 145 Blue Star 145 DX File: Engine Drive Visit our website at www.MillerWelds.com...

- Page 2 ISO 9001:2000 Quality System Standard. particular model are also provided. Miller Electric manufactures a full line of welders and welding related equipment. For information on other quality Miller products, contact your local Miller distributor to receive the latest full line catalog or individual specification sheets.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SECTION 1 − SAFETY PRECAUTIONS − READ BEFORE USING 1-1. Symbol Usage ............... . 1-2. -

Page 5: Section 1 − Safety Precautions − Read Before Using

SECTION 1 − SAFETY PRECAUTIONS − READ BEFORE USING Y Warning: Protect yourself and others from injury — read and follow these precautions. 1-1. Symbol Usage Means Warning! Watch Out! There are possible hazards with this procedure! The possible hazards are shown in the adjoining symbols. -

Page 6: Engine Hazards

WELDING can cause fire or explosion. Welding on closed containers, such as tanks, drums, or pipes, can cause them to blow up. Sparks can fly off from the welding arc. The flying sparks, hot workpiece, and hot equipment can cause fires and burns. Accidental contact of electrode to metal objects can cause sparks, explosion, overheating, or fire. -

Page 7: Compressed Air Hazards

STEAM AND HOT COOLANT can burn. D If possible, check coolant level when engine is cold to avoid scalding. D Always check coolant level at overflow tank, if pres- ent on unit, instead of radiator (unless told otherwise in maintenance section or engine manual). D If the engine is warm, checking is needed, and there is no overflow tank, follow the next two statements. -

Page 8: California Proposition 65 Warnings

READ INSTRUCTIONS. D Use only genuine MILLER/Hobart replacement parts. D Perform engine and air compressor (if applicable) maintenance and service according to this manual and the engine/air compressor (if applicable) manu- als. H.F. RADIATION can cause interference. D High-frequency (H.F.) can interfere with radio naviga- tion, safety services, computers, and communica- tions equipment. -

Page 9: Section 2 − Consignes De Sécurité − Lire Avant Utilisation

SECTION 2 − CONSIGNES DE SÉCURITÉ − LIRE AVANT Avertissement: Protégez vous et les autres des blessures − lisez et suivez ces précautions. 2-1. Signification des symboles Signifie Mise en garde ! Soyez vigilant ! Cette procédure présente des risques de danger ! Ceux-ci sont identifiés par des symboles adjacents aux directives. -

Page 10: Dangers Existant En Relation Avec Le Moteur

LE SOUDAGE peut provoquer un in- cendie ou une explosion. Le soudage effectué sur des conteneurs fermés tels que des réservoirs, tambours ou des conduites peut provoquer leur éclatement. Des étincelles peuvent être projetées de l’arc de soudure. La projection d’étincelles, des pièces chaudes et des équipements chauds peut provoquer des incendies et des brûlures. -

Page 11: Dangers Liés À L'air Comprimé

D Si le moteur est chaud et que le liquide doit être vérifié, opérer comme suivant. D Mettre des lunettes de sécurité et des gants, placer un torchon sur le bouchon du radiateur. D Dévisser le bouchon légèrement et laisser la vapeur s’échapper avant d’enle- ver le bouchon. -

Page 12: Proposition Californienne 65 Avertissements

LIRE LES INSTRUCTIONS. D Utiliser seulement les pièces de rechange d’origine. D Effectuer la maintenance du moteur et du compresseur (si applicable) suivant ce manuel et le manuel du moteur/ compresseur (si applicable). LE RAYONNEMENT HAUTE FRÉ- QUENCE (H.F.) risque de provoquer des interférences. -

Page 13: Section 3 − Definitions

SECTION 3 − DEFINITIONS 3-1. Symbol Definitions Engine Choke Engine Oil Positive Hours Circuit Protector SECTION 4 − SPECIFICATIONS 4-1. Weld, Power, And Engine Specifications Weld Welding Rated Output Mode Welding Output Range 145 A, 25 V, 20% Duty Cycle 100 A, 25 V, CC/DC 40 −... -

Page 14: Dimensions, Weights, And Operating Angles

4-2. Dimensions, Weights, And Operating Angles Dimensions Height 22-3/4 in (578 mm) Width 22-3/4 in (577 mm) Depth 31-5/8 in (803 mm) 31-5/8 in (803 mm) 10-9/16 in (268 mm) 13-25/64 in (340 mm) 22-3/4 in (577 mm) 1-9/16 in (40 mm) 19-5/8 in (498 mm) 13/32 in (10 mm) Dia. -

Page 15: Fuel Consumption

4-4. Fuel Consumption 1.00 0.80 0.60 0.40 0.20 IDLE 0.00 DC WELD AMPERES AT RATED DUTY CYCLE 1.00 0.80 0.60 0.40 0.20 IDLE 0.00 AUXILIARY POWER KW AT 100% DUTY CYCLE 220 637 OM-4417 Page 11... -

Page 16: Duty Cycle

4-5. Duty Cycle 100% Duty Cycle at 80 Amperes CC/DC 2 Minutes Welding 20% Duty Cycle at 145 Amperes CC/DC 4-6. Generator Power Curve OM-4417 Page 12 Continuous Welding 8 Minutes Resting % DUTY CYCLE 240 Volt 120 Volt AMPERES Duty cycle is the percentage of 10 minutes that unit can weld at rated load without overheating. -

Page 17: Section 5 − Installation

SECTION 5 − INSTALLATION 5-1. Installing Welding Generator Movement Y Always securely fasten welding generator Location 5-2. Grounding Generator To Truck Or Trailer Frame Electrically bond generator frame to vehicle frame by metal-to-metal contact. Y Bed liners, shipping skids, and some running gear insulate the welding generator from the ve- hicle frame. -

Page 18: Grounding Generator When Supplying Building Systems

5-3. Grounding Generator When Supplying Building Systems Use ground device as stated in electrical codes. 5-4. Engine Prestart Checks − Standard Model Fuel valve is shown in the open position. Always close fuel valve after stopping unit. Moving unit with fuel valve open may cause carburetor flooding and make starting difficult. -

Page 19: Engine Prestart Checks − Dx Model

5-5. Engine Prestart Checks − DX Model 1/2 in (13 mm) Full Gasoline Fuel valve is shown in the open position. Always close fuel valve after stopping unit. Moving unit with fuel valve open may cause carburetor flooding and make starting difficult. -

Page 20: Connecting To Weld Output Terminals

5-7. Connecting To Weld Output Terminals Do not place anything between weld cable terminal and copper bar. Correct Installation 5-8. Selecting Weld Cable Sizes* Welding Amperes W ld O t Weld Output Terminals Terminals Y Turn off power before connecting to weld out- connecting to weld out- put terminals. - Page 21 Notes MATERIAL THICKNESS REFERENCE CHART 24 Gauge (.025 in) 22 Gauge (.031 in) 20 Gauge (.037 in) 18 Gauge (.050 in) 16 Gauge (.063 in) 14 Gauge (.078 in) 1/8 in (.125 in) 3/16 in (.188 in) 1/4 in (.25 in) 5/16 in (.313 in) 3/8 in (.375 in) 1/2 in (.5 in)

-

Page 22: Section 6 − Operating The Welding Generator

SECTION 6 − OPERATING THE WELDING GENERATOR 6-1. Controls (Standard Models) (See Section 6-2) 803 956−B / 803 594−B / 218 610 OM-4417 Page 18... -

Page 23: Description Of Controls (Standard Models) (See Section 6-1)

6-2. Description Of Controls (Standard Models) (See Section 6-1) Engine Switch Use switch to control ignition circuit. Turn switch to On position when starting engine. Turn switch to Off position to stop engine. En- gine cannot be started with switch in the Off position. -

Page 24: Controls (Dx Models) (See Section 6-4)

6-3. Controls (DX Models) (See Section 6-4) 803 596−A / 803 595−A / 218 610 OM-4417 Page 20... -

Page 25: Description Of Controls (Dx Models) (See Section 6-3)

6-4. Description Of Controls (DX Models) (See Section 6-3) Engine Switch Use switch to control ignition circuit. Turn switch to Start position for electric start. Turn switch to On position to start engine using starter handle (recoil). Turn switch to Off posi- tion to stop engine. -

Page 26: Section 7 − Operating Auxiliary Equipment

SECTION 7 − OPERATING AUXILIARY EQUIPMENT NOTE Set Current control to maximum for full generator power output at AC receptacles. 7-1. Generator Power Panel Receptacles Y If unit does not have GFCI recep- tacles, use GFCI-protected exten- sion cord. Generator power decreases as weld current increases. -

Page 27: Section 8 − Maintenance

SECTION 8 − MAINTENANCE NOTE Follow the storage procedure in the engine owner’s manual if the unit will not be used for an extended period. 8-1. Routine Maintenance n = Check Z = Change * To be done by Factory Authorized Service Agent Every Hours n Fuel Level... -

Page 28: Servicing Air Cleaner

8-2. Servicing Air Cleaner OM-4417 Page 24 Standard Model Shown Y Stop engine. Y Do not run engine without air cleaner or with dirty element. Precleaner Paper Element Do not wash paper element or clean with compressed air. Remove cover. Wash precleaner with soap and wa- ter solution. -

Page 29: Adjusting Engine Speed (Standard Models Only)

8-3. Adjusting Engine Speed (Standard Models Only) Tools Needed: After tuning engine, check engine speed. See table for proper no load speed. If necessary, adjust speed as follows: Start engine and run until warm. 3750 30 rpm (62 Hz) Adjustment Screw To increase speed, turn screw in (clockwise). -

Page 30: Adjusting Engine Speed (Dx Models Only)

8-4. Adjusting Engine Speed (DX Models Only) Tools Needed: OM-4417 Page 26 After tuning engine, check engine speed. See table for proper no load speed. If necessary, adjust speed as follows: 2500 100 rpm (42 Hz) Start engine and run until warm. Set Weld Output Control to Max. -

Page 31: Section 9 − Troubleshooting

SECTION 9 − TROUBLESHOOTING 9-1. Troubleshooting A. Welding Trouble No weld output or generator power out- Be sure all equipment is disconnected from receptacles when starting unit. put at ac receptacles. Have Factory Authorized Service Agent check brushes, slip rings, rotor, stator, integrated rectifier SR2, and Weld Output control R1. - Page 32 Trouble Low output at generator power ac Check Weld Output control setting. receptacles. Check engine speed, and adjust if necessary (see Section 8-3 or 8-4). Open circuit voltage is reduced as engine speed drops. Erratic output at generator power ac Check fuel level.

-

Page 33: Section 10 − Electrical Diagrams

SECTION 10 − ELECTRICAL DIAGRAMS 226 737-A Figure 10-1. Circuit Diagram For Standard Models OM-4417 Page 29... - Page 34 226 738-A Figure 10-2. Circuit Diagram for DX Models OM-4417 Page 30...

-

Page 35: Section 11 − Generator Power Guidelines

SECTION 11 − GENERATOR POWER GUIDELINES NOTE The views in this section are intended to be representative of all engine-driven welding generators. Your unit may differ from those shown. 11-1. Selecting Equipment 11-2. Grounding Generator To Truck Or Trailer Frame Electrically bond generator frame to vehicle frame by metal-to-metal contact. - Page 36 11-3. Grounding When Supplying Building Systems 11-4. How Much Power Does Equipment Require? AMPERES x VOLTS = WATTS EXAMPLE 1: If a drill uses 4.5 amperes at 115 volts, calculate its running power requirement in watts. The load applied by the drill is 520 watts. EXAMPLE 2: If three 200 watt flood lamps are used with the drill from Example 1, add the individual loads to calculate total load.

- Page 37 11-5. Approximate Power Requirements For Industrial Motors Industrial Motors Split Phase Capacitor Start-Induction Run Capacitor Start-Capacitor Run Fan Duty 11-6. Approximate Power Requirements For Farm/Home Equipment Farm/Home Equipment Stock Tank De-Icer Grain Cleaner Portable Conveyor Grain Elevator Milk Cooler Milker (Vacuum Pump) FARM DUTY MOTORS Std.

- Page 38 11-7. Approximate Power Requirements For Contractor Equipment Contractor Hand Drill Circular Saw Table Saw Band Saw Bench Grinder Air Compressor Electric Chain Saw Electric Trimmer Electric Cultivator Elec. Hedge Trimmer Flood Lights Submersible Pump Centrifugal Pump Floor Polisher High Pressure Washer 55 gal Drum Mixer Wet &...

- Page 39 11-8. Power Required To Start Motor Single-Phase Induction Motor Starting Requirements Motor Start Code KVA/HP kVA/HP x HP x 1000 VOLTS EXAMPLE: Calculate the starting amperage required for a 230 V, 1/4 HP motor with a motor start code of M. Volts = 230 HP = 1/4 11.2 x 1/4 x 1000...

- Page 40 11-10. Typical Connections To Supply Standby Power Y Properly install and ground this equipment according to its Owner’s Manual and national, state, and local codes. Utility Electrical Service Y Have only qualified persons perform these connections according to all applicable codes and safety practic- Y Properly install and ground this equipment according to its Owner’s Manual and national, state, and local...

- Page 41 11-11. Selecting Extension Cord (Use Shortest Cord Possible) Cord Lengths for 120 Volt Loads Y If unit does not have GFCI receptacles, use GFCI-protected extension cord. Current Load (Watts) (Amperes) 1200 1800 2400 3000 3600 4200 4800 5400 6000 *Conductor size is based on maximum 2% voltage drop Cord Lengths for 240 Volt Loads Y If unit does not have GFCI receptacles, use GFCI-protected extension cord.

-

Page 42: Section 12 − Stick Welding (Smaw) Guidelines

SECTION 12 − STICK WELDING (SMAW) GUIDELINES 12-1. Stick Welding Procedure Tools Needed: OM-4417 Page 38 Y Weld current starts when electrode touches work- piece. Y Weld current can damage electronic parts in vehicles. Disconnect both battery cables before welding on a vehicle. - Page 43 12-2. Electrode and Amperage Selection Chart 3/32 6010 5/32 & 3/16 6011 7/32 1/16 5/64 3/32 6013 5/32 3/16 7/32 3/32 5/32 7014 3/16 7/32 3/32 5/32 7018 3/16 7/32 3/32 5/32 7024 3/16 7/32 3/32 Ni-Cl 5/32 3/16 3/32 308L 5/32 12-3.

- Page 44 12-5. Positioning Electrode Holder End View of Work Angle End View of Work Angle 12-6. Poor Weld Bead Characteristics 12-7. Good Weld Bead Characteristics OM-4417 Page 40 10 -30 Side View of Electrode Angle GROOVE WELDS 10 -30 Side View of Electrode Angle FILLET WELDS S-0060 Large Spatter Deposits...

-

Page 45: Conditions That Affect Weld Bead Shape

12-8. Conditions That Affect Weld Bead Shape NOTE Weld bead shape is affected by electrode angle, arc length, travel speed, and thickness of base metal. Angle Too Small Too Short Slow 12-9. Electrode Movement During Welding NOTE Normally, a single stringer bead is satisfactory for most narrow groove weld joints; however, for wide groove weld joints or bridging across gaps, a weave bead or multiple stringer beads work better. - Page 46 12-10. Butt Joints 12-11. Lap Joint Or Less Single-Layer Fillet Weld 12-12. Tee Joint OM-4417 Page 42 1/16 in (1.6 mm) Or Less Multi-Layer Fillet Weld Or Less Tack Welds Prevent edges of joint from drawing together ahead of electrode by tack welding the materials in position be- fore final weld.

- Page 47 12-13. Weld Test 2 To 3 in (51-76 mm) 1/4 in (6.4 mm) 12-14. Troubleshooting − Porosity Possible Causes Arc length too long. Damp electrode. Workpiece dirty. 12-15. Troubleshooting − Excessive Spatter Possible Causes Amperage too high for electrode. Arc length too long or voltage too high. 2 To 3 in (51-76 mm) Porosity −...

- Page 48 12-16. Troubleshooting − Incomplete Fusion Possible Causes Insufficient heat input. Improper welding technique. Workpiece dirty. 12-17. Troubleshooting − Lack Of Penetration Lack of Penetration Good Penetration Possible Causes Improper joint preparation. Improper weld technique. Insufficient heat input. 12-18. Troubleshooting − Excessive Penetration Excessive Penetration Good Penetration Possible Causes...

- Page 49 12-19. Troubleshooting − Burn-Through Possible Causes Excessive heat input. 12-20. Troubleshooting − Waviness Of Bead Possible Causes Unsteady hand. Use two hands. Practice technique. 12-21. Troubleshooting − Distortion Base metal moves in the direction of the weld bead. Possible Causes Excessive heat input.

-

Page 50: Section 13 − Parts List

SECTION 13 − PARTS LIST OM-4417 Page 46 Figure 13-1. Main Assembly Standard Model Hardware is common and not available unless listed. 803 795−B... - Page 51 Item Dia. Part Mkgs..AC−Z ..218767 Reactor ....099255 Terminal, Pwr Output Neutral ....217125 Base, Control Box .

- Page 52 Hardware is common and not available unless listed. Item Dia. Part Mkgs....217125 ... . 201936 .

- Page 53 Item Dia. Part Mkgs....221007 Bracket,Support Fuel Tank ....223079 Tank, Fuel 5.0 Gal .

- Page 54 OM-4417 Page 50...

- Page 55 Warranty Questions? Call LIMITED WARRANTY − Subject to the terms and conditions below, Miller Electric Mfg. Co., Appleton, Wisconsin, warrants to 1-800-4-A-MILLER its original retail purchaser that new Miller equipment sold after for your local the effective date of this limited warranty is free of defects in material and workmanship at the time it is shipped by Miller.

- Page 56 File a claim for loss or damage during shipment. For assistance in filing or settling claims, contact your distributor and/or equipment manufacturer’s Transportation Department. 2005 Miller Electric Mfg. Co. 10/05 Miller Electric Mfg. Co. An Illinois Tool Works Company 1635 West Spencer Street Appleton, WI 54914 USA International Headquarters−USA...

Need help?

Do you have a question about the BLUE STAR 145 DX and is the answer not in the manual?

Questions and answers

ISE cambio de aceite pero aún marca la luz de aceite y no enciende

The Miller Electric BLUE STAR 145 DX shows the oil light and does not start after an oil change if the engine oil level is too low. The engine cannot be restarted until sufficient oil is added.

This answer is automatically generated