Table of Contents

Advertisement

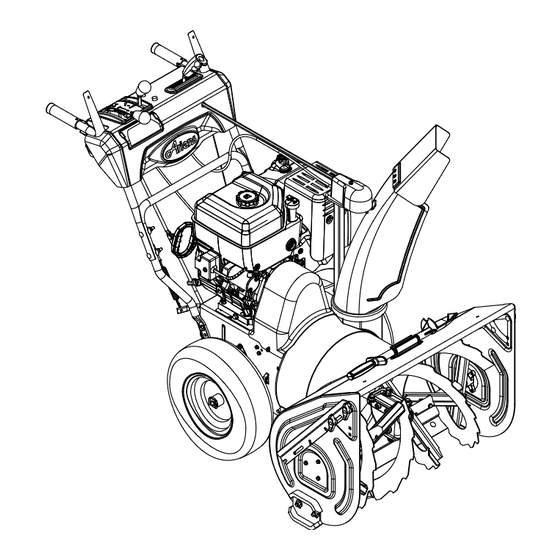

Owner/Operator Manual

Manuel Du Propriétaire/Utilisateur

E10

926 Series

Sno-Thro

The use of any gasoline exceeding 10% ethanol (E10) or

10% MTBE will void the product warranty.

L'utilisation d'une essence contenant plus de 10% d'éthanol

(E10) ou de 10% de MTBE annulent la garantie.

ENGLISH

FRANÇAIS

®

Models

926038 – Pro 28

(SN 095000 +)

926039 – Pro 32

(SN 095000 +)

926040 – Pro 36

(SN 095000 +)

926042 – Pro 28 Track

(SN 095000 +)

04337400G 4/13

Printed in USA

Advertisement

Table of Contents

Summary of Contents for Ariens Sno-Thro Pro 28 926038

- Page 1 926 Series Sno-Thro ® Owner/Operator Manual Manuel Du Propriétaire/Utilisateur Models 926038 – Pro 28 (SN 095000 +) 926039 – Pro 32 (SN 095000 +) 926040 – Pro 36 (SN 095000 +) 926042 – Pro 28 Track (SN 095000 +) The use of any gasoline exceeding 10% ethanol (E10) or 10% MTBE will void the product warranty.

-

Page 2: Table Of Contents

PRODUCT REGISTRATION package. They are printed on a serial number label, located on the frame of your unit. The Ariens dealer must register the product at the time of purchase. Registering the product will help the company process warranty claims or contact you with the latest service information. -

Page 3: Safety

4. Review recommended lubrication, maintenance and adjustments. 5. Review Limited Warranty Policy. 6. Fill out a Product Registration Card and return the card to the Ariens Company or go to www.ariens.com. SAFETY WARNING: To avoid injury to hands DANGER: IMMINENTLY... -

Page 4: Practices And Laws

PRACTICES AND LAWS 1. DANGER! Practice usual and customary safe working precautions, for the benefit of yourself and others. Understand and follow all safety messages. Be alert to unsafe conditions and the possibility of minor, moderate, or serious Danger! injury or death. Learn applicable rules and laws in your area. -

Page 5: Emission Control System

(CARB) regulations. Tampering with emission controls and components by unauthorized personnel may result in severe fines or penalties. Emission controls and components can only be adjusted by an Ariens Company dealer or an authorized engine manufacturer's service center. Contact your Ariens Company Equipment Retailer concerning emission controls and component questions. - Page 6 DO NOT operate unit without wearing Do not operate in reverse unless absolutely adequate winter outer garments. Wear necessary. ALWAYS back up slowly. Always adequate safety gear, including safety look down and behind before and while glasses with side shields, and protective backing.

- Page 7 NO smoking, NO sparks, NO flames. ALWAYS keep protective structures, guards, ALWAYS allow engine to cool before and panels in good repair, in place and servicing. securely fastened. NEVER modify or remove NEVER fill fuel tank when engine is running safety devices.

-

Page 8: Assembly

ASSEMBLY IMPORTANT: Be careful not to damage cable spring hooks when rotating handlebars WARNING: AVOID INJURY. Read upward. and understand the entire Safety section before proceeding. 5. Install and tighten all hardware on the handlebar assembly and shift rod. WARNING: Dropping or tipping over boxed unit could result in personal injury or damage to unit. - Page 9 Install Discharge Chute, Chute Control and Chute Rod (Figures 5, 6 and 7) 1. Grease underside of discharge chute ring (if not already greased). 2. Remove mounting hardware from auger housing. 3. Install discharge chute over opening in the auger housing. Finger tighten the mounting hardware removed in step 2.

- Page 10 Remote Deflector Control (Figure 8) Connect the cable end to the cable anchor on the discharge deflector before clipping the cable to the cable bracket on the discharge chute. 1. Route deflector remote cable along the left side of the chute pedestal. 2.

- Page 11 Check Function of Dual Handle Check Engine Crankcase Oil Interlock IMPORTANT: The engine may be shipped with oil in crankcase. Refer to Engine Manual Without the engine running, press down for detailed instructions. (engage) both clutch levers. Release attachment clutch lever. Attachment clutch Fill Fuel Tank should remain engaged until traction clutch Fill fuel tank.

-

Page 12: Controls And Features

CONTROLS AND FEATURES Figure 9 1. Skid Shoes 11. Chute Rod 2. Clean-Out Tool 12. Handlebar Hardware 3. Remote Discharge Chute Deflector 13. Heated Handles 4. Belt Cover 14. Drift Cutters 5. Headlight 15. Height Adjuster Trigger (926042) 6. Auger 7. - Page 13 Figure 10 1. Oil Drain 12. Speed Selector 2. Fuel Shut-Off Valve 13. Traction Drive Clutch Lever 3. Primer Bulb 14. Deflector Remote Control 4. Recoil Starter Handle 15. Chute Control 5. Throttle 16. Muffler Guard 6. Choke Control Knob 17.

-

Page 14: Operation

OPERATION Attachment Clutch – WARNING: AVOID INJURY. Read Right Hand Lever and understand the entire Safety section before proceeding. Squeeze Attachment Clutch Lever against handlebar (1) to WARNING: To avoid injury to hands engage attachment. and feet, always disengage Release both clutch clutches, shut off engine, and wait levers (2) to disengage for all movement to stop before... - Page 15 Speed Selector Snow Clean-Out Tool (Figure 11) Position the Speed Selector in the appropriate speed notch to WARNING: Hand contact with the control forward and reverse rotating impeller is the most travel. common cause of injury associated Forward: with snow throwers. Never use your (6) Fastest hand to clean out the discharge (1) Slowest...

- Page 16 Drift Cutters (Figure 13) Drift cutters break up snow drifts that are taller than the auger housing and direct the snow into the auger. Store the drift cutters on the auger housing when not in use. Install them as shown below so they are taller than the snow to be cleared.

- Page 17 NOTICE: All gasoline is not the same. If the Normal engine experiences starting or performance problems after using a new gasoline, switch to a different fuel provider or fuel brand. IMPORTANT: Excessively oxygenated or reformulated fuels (fuels blended with alcohols or ethers) can damage the fuel system or cause performance problems.

-

Page 18: Pre-Start

The fuel shut-off valve TO STOP IN AN EMERGENCY has two positions: Immediately release both control levers to Open (1): Use this stop unit in an emergency. Stop engine, position to run the unit. remove key and wait for all rotating parts to stop before leaving operator’s position. -

Page 19: Snow Removal

Electric Start (120V) SNOW REMOVAL 1. Connect extension cord to starter. IMPORTANT: Allow unit and engine to adjust to the outdoor temperature before clearing IMPORTANT: Prevent damage to unit. Know snow. voltage of your starter and only use matching outlets. NOTICE: Attachment clutch should be engaged before traction drive clutch when 2. -

Page 20: Maintenance

MAINTENANCE Ariens Dealers will provide any service or MAINTENANCE SCHEDULE adjustments which may be required to keep The chart below shows the recommended your unit operating at peak efficiency. Should maintenance schedule that should be engine service be required, contact an Ariens performed on a regular basis. -

Page 21: Check Tire Pressure

NOTICE: Inspect seal washer for wear or rubber deterioration and replace as needed. CHECK ENGINE OIL IMPORTANT: Use only Ariens L3 synthetic severe duty gear lube (Part Number The engine crankcase oil should be checked 00068800). Use of other lubricants will void every 5 hours of operation. -

Page 22: General Lubrication

Shear get on friction disc, friction plate or belts. Bolts on page 23. Apply grease at the grease NOTICE: Apply Ariens Hi-Temp Grease or zerks and then turn the auger assemblies on equivalent to the lubrication fittings. See the auger shaft. -

Page 23: Service And Adjustments

SHEAR BOLTS WARNING: AVOID INJURY. Read (Figure 19) and understand the entire Safety IMPORTANT: Use only Ariens OEM shear section before proceeding. bolts for replacement. Use of any other type of shear bolt may result in severe damage to SCRAPER BLADE unit. - Page 24 HANDLEBAR HEIGHT REMOTE DEFLECTOR CONTROL (Figure 20) (Figure 21) Deflector must stay in selected position while CAUTION: AVOID INJURY. Adjust throwing snow. the attachment clutch, speed If deflector does not stay in set position: selector and traction clutch after 1. Tighten nut beneath control panel to changing the handlebar height.

-

Page 25: Speed Selector Adjustment

DISCHARGE CHUTE CONTROL d. Stop unit. e. Shift speed selector into first (Figure 22) reverse speed. If chute does not stay in position while f. Engage the traction clutch. Unit throwing snow or if chute does not rotate should move backward. freely, adjust the cable under the gear cover g. - Page 26 Check Attachment Idler Arm Roller Clearance (Figure 26) NOTICE: It will be difficult to check the measurement inside the frame. Use a 1/2" (12.7 mm) minimum spacer as a gauge to check the clearance between the roller and the frame. 1.

-

Page 27: Traction Drive Clutch Adjustment

Check Attachment Brake Check belt finger clearance here. With the (Figure 27) attachment clutch engaged, there should 1. With the clutch lever disengaged, brake be less than 1/8" (3 mm) clearance pad must contact attachment belts. With between the belts and the belt finger. The clutch lever engaged, brake pad must be belt finger should not touch the belts. - Page 28 ATTACHMENT DRIVE BELTS REPLACEMENT (Figure 29) Remove old attachment drive belts 1. Shut off engine, remove key, disconnect spark plug wire and allow unit to cool completely. 2. Loosen hardware securing belt cover to unit (Figure 29). NOTICE: Do NOT completely remove the hardware from unit.

-

Page 29: Traction Drive Belt Replacement

TRACTION DRIVE BELT FRICTION DISC REPLACEMENT REPLACEMENT (Figure 31) 1. Place unit into service position. (Figure 30) 2. Remove bottom cover by removing six NOTICE: Replacement will be easier with hex bolts. housing and frame tipped apart and bottom cover off. 3. -

Page 30: Storage

TRACK TENSION ADJUSTMENT Pin on overtravel arm (926042) makes slight contact with end of slot. (Figure 32 and 33) Check the track tension by applying pressure on the track midway between the upper and rear track rollers. Deflection should be approximately 3/8"... -

Page 31: Service Parts

These deposits can damage the carburetor Part No. Description and the fuel hoses, filter and tank. Prevent 00036800 Ariens Hi-Temp Grease (3, 3 oz deposits from forming in the fuel system cartridges) during storage by adding a quality fuel 00592900 Fuel Stabilizer (4 oz.) stabilizer to the fuel. -

Page 32: Troubleshooting

TROUBLESHOOTING PROBLEM PROBABLE CAUSE CORRECTION Engine will not 1. Fuel tank is empty. 1. Fill fuel tank (see Filling Fuel Tank on page 17). crank/start. 2. Fuel shut-off valve closed. 2. Open fuel shut-off valve. 3. Build up of dirt and residue 3. -

Page 33: Specifications

SPECIFICATIONS Model Number 926038 926039 926040 926042 Description Pro 28 Pro 32 Pro 36 Pro 28 Track Engine Engine Model Briggs & Stratton Polar Force Pro 2100 Gross Torque* – ft-lbs (N-m) 21.0 (28.5) *Engine output stated in gross torque per SAE J1940 as rated by engine manufacturer Displacement –... -

Page 34: Warranty

® ® Sno-Thro , Sno-Tek Chore Performing Equipment Limited Warranty Ariens Company (Ariens) warrants to the original purchaser that Ariens, Gravely, Parker, and Countax ® ® brand chore performing equipment (including Sno-Thro and Sno-Tek equipment) purchased on or after 1/1/2013 will be free from defects in material and workmanship for the time period noted in the chart below. - Page 35 Register the product immediately at the time of sale. If the dealer does not register the product, the customer must complete the product registration card in the literature package and return it to Ariens Company, or register the unit online at www.ariens.com, www.gravely.com, www.countax.com or www.parkersweeper.com.

- Page 36 Exclusions – Items Not Covered by This Warranty • Parts that are not genuine Ariens, Gravely, Parker or Countax service parts are not covered by this warranty and may void the warranty. • Damages resulting from the installation or use of any part, accessory, or attachment which is not approved by the Ariens Company for use with product(s) identified herein are not covered by this warranty.

- Page 38 Ariens 655 West Ryan Street Brillion, WI 54110 920-756-4688 www.ariens.com...

Need help?

Do you have a question about the Sno-Thro Pro 28 926038 and is the answer not in the manual?

Questions and answers