Table of Contents

Advertisement

Quick Links

DRYPIX 7000

Operation Manual

11th Edition: July 2008

897N0324G (006-235-100)

This Operation Manual describes details on how to operate the

DRYPIX 7000 and cautions to be observed when operating it. Please

read the Operation Manual thoroughly before actually operating the

DRYPIX 7000 system. After reading this manual, store it nearby the

DRYPIX 7000 so that you can see it whenever necessary.

Advertisement

Table of Contents

Summary of Contents for FujiFilm Drypix 7000

- Page 1 11th Edition: July 2008 This Operation Manual describes details on how to operate the DRYPIX 7000 and cautions to be observed when operating it. Please read the Operation Manual thoroughly before actually operating the DRYPIX 7000 system. After reading this manual, store it nearby the DRYPIX 7000 so that you can see it whenever necessary.

- Page 2 We ask that first-time users read this manual thoroughly before actually using the DRYPIX 7000. After reading this manual, please store it nearby the DRYPIX 7000 so that it may be used to ensure that the machine is used under the best conditions.

- Page 3 Contents at a Glance Chapter 1 Introduction Chapter 2 System Overview Chapter 3 Basic Operation Chapter 4 Utility Operation Chapter 5 Troubleshooting Chapter 6 Regular Care and Maintenance Chapter 7 Specifications 006-235-30 2004.03...

-

Page 4: Table Of Contents

Contents Contents Chapter 1 Introduction 1.1 What is the DRYPIX 7000? .................. 1.2 System Features ....................1.3 Safety ........................1.4 Operational Precautions ..................1.4.1 Laser Handling Precautions ..............1.4.2 Preventing Electric Shock ................ 1.4.3 Ventilation Precautions ................1.4.4 Handling Precautions ................ - Page 5 Contents Chapter 4 Utility Operation 4.1 What is Utility? ..................... 4.2 Starting Up and Quitting the Utility ............... 4.2.1 Starting Up the Utility ................4.2.2 Quitting the Utility ..................4.3 Auto F.D.C......................4.4 Test Pattern ......................4.5 Unlock Tray ......................4-12 4.6 Print Queue ......................

- Page 6 Contents Chapter 6 Regular Care and Maintenance 6.1 Cleaning the Cleaning Roller with Water ............. 6.2 Cleaning the Suction Filter ................... Chapter 7 Specifications 1 System Components ....................Standard Components ..................Options ......................Supplies ......................2 Processing Capacity ....................3 Applicable Film ......................4 Recording Pixel Size ....................

-

Page 7: Chapter 1 Introduction

Chapter 1 Introduction 006-235-30 2004.03... -

Page 8: What Is The Drypix 7000

Introduction What is the DRYPIX 7000? The Fuji Medical Dry Laser Imager DRYPIX 7000 is a device that prints digital image data transferred via the DICOM network from the FCR Image Reader or CT, MRI and other imaging modalities onto dedicated film in the selected format. -

Page 9: Safety

Introduction Safety This section contains safety precautions required for the safe operation of this equipment. Carefully read and follow these precautions before using the equipment. If these precautions are not followed, injuries or damage to the equipment may occur. The safety precautions are marked as WARNING or CAUTION, and additional information “... -

Page 10: Operational Precautions

660 nm Maximum Output 50 mW (CW) The DRYPIX 7000 incorporates a Class 3B laser with a maximum output of 50mW. To prevent exposure to its laser beams, observe the following precautions. Never remove the protective covers. When opening the outer covers for coping with film jams, be sure to observe procedures set forth in the Operation Manual. -

Page 11: Electromagnetic Compatibility (Emc)

TIA/EIA-568 Cat5 or more. Straight cable of UTP type. • The DRYPIX 7000 should not be used adjacent to or stacked with other equipment. If adjacent or stacked use is necessary, the DRYPIX 7000 should be observed to verify normal operation in the configuration in which it will be used. - Page 12 Guidance and manufacturer’s declaration - electromagnetic emissions The DRYPIX 7000 is intended for use in the electromagnetic environment specified below. The customer or the user of the DRYPIX 7000 should assure that it is used in such an environment. Emissions test...

- Page 13 To assess the electromagnetic environment due to fixed RF transmitters, an electromagnetic site survey should be considered. If the measured field strength in the location in which the DRYPIX 7000 is used exceeds the applicable RF compliance, the DRYPIX 7000 should be observed to verify normal operation. If abnormal performance is observed, additional measures may be necessary, such as reorienting or relocating the DRYPIX 7000.

-

Page 14: Classification

The DRYPIX 7000 is intended for use in the electromagnetic environment in which radiated RF disturbances are controlled. The customer or the user of the DRYPIX 7000 can help prevent electromagnetic interference by maintaining a minimum distance between portable and mobile RF communications equipment (transmitters) and the DRYPIX 7000 as recommended below, according to the maximum output power of the communications equipment. -

Page 15: Precautions For Storing Or Handling The Di-Hl, Di-Hlc, And Di-Ml Films For The Fuji Medical Dry Laser Imager

Introduction Precautions for Storing or Handling the DI-HL, DI-HLc, and DI-ML Films for the Fuji Medical Dry Laser Imager 1.6.1 Precautions for Storing or Handling Unused Films 1 Use only the “Fuji Medical Dry Laser Imager Film DI-HL, DI-HLc, or DI-ML” that is compatible with this equipment. -

Page 16: Other Precautions For Using The Equipment

Introduction Other Precautions for Using the Equipment 1.7.1 Precautions for Inserting the Shutter Be sure to turn the power OFF first and then insert the shutter, because a system error may result. Note, however, that you do not have to turn the power OFF if an instruction is indicated on the operation panel to insert the shutter. -

Page 17: Location Of Each Label

Introduction Location of Each Label 1-11 006-235-100 2008.07... - Page 18 Introduction JAM Handling Label 1 JAM Handling Label 2 Caution Label 1-12 006-235-90 2007.03...

- Page 19 Introduction 1-13 006-235-100 2008.07...

- Page 20 Introduction 1-14 006-235-90 2007.03...

-

Page 21: Chapter 2 System Overview

Chapter 2 System Overview 006-235-30 2004.03... -

Page 22: System Configuration

System Configuration This system transfers and prints information of images exposed by the FCR Image Reader or CT, MRI and other imaging modalities to the DRYPIX 7000 (this equipment) via the DICOM network. Image data derived from the FCR Image Reader or image processor that is not connected to the DICOM network can be printed via the DRYPIX Link connected to the DICOM network. -

Page 23: Hardware Configuration

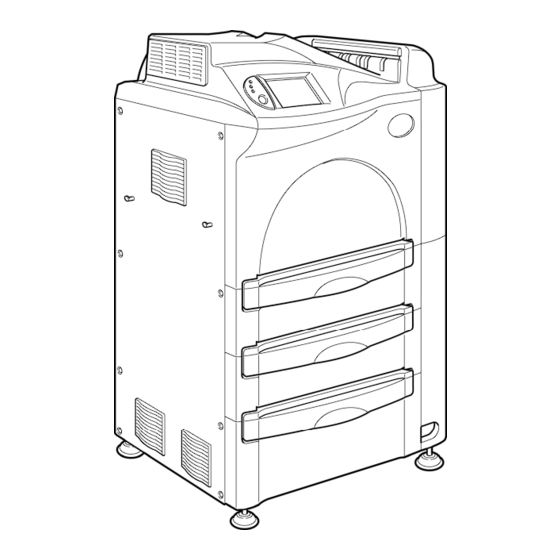

System Overview Hardware Configuration [1] DRYPIX 7000 Main Unit [Fig. 2.2] DRYPIX 7000 Main Unit [Table 2-1] Component Names and Functions Name Function Main Unit Operation Panel See pages 2-4 and 2-5 for details. Output Film Tray Ejected output films are stacked in this tray. -

Page 24: Operation Panel

System Overview [2] Operation Panel [Fig. 2.3] Main Unit Operation Panel [Table 2-2] Component Names and Function Name Function Power ON Switch Turns ON the power to the main unit. Lights green when the Main Power Switch has been turned ON. As the POWER Lamp Main Power Switch is basically left ON, the POWER Lamp will also basically be lit always. - Page 25 System Overview [Fig. 2.4] Main Unit Operation Panel (display layout: initial image) [Table 2-3] Component Names and Functions Name Function Ready (Green) Ready condition. Title/Message Displays screen titles or messages. Entering the Utility mode will display UTILITY in this area. For details, see Chapter 3, Basic Operation and Chapter 4, Utility Operation.

-

Page 26: System Overview

System Overview 006-235-30 2004.03... -

Page 27: Chapter 3 Basic Operation

Chapter 3 Basic Operation 006-235-30 2004.03... -

Page 28: Routine Operations

Basic Operation Routine Operations The following four steps constitute routine operations. Starting Up the System ................Page 3-3 Reading (Storing) Images ..........Page 3-5 Printing Images (film output) ..........Page 3-5 Shutting Down the System ..............Page 3-6 need not to be operated on this equipment because connected devices are responsible for those operations. -

Page 29: Starting Up The System

When the Power ON Switch is pressed, the initialization process starts. The software version as well as software ID will then appear on the DRYPIX 7000 main unit display. When the following right screen is displayed, the system has been started up normally. - Page 30 Basic Operation [Fig. 3.4] Startup UP Screen - 1 When this screen appears, imaging information can be transferred from an imaging modality to this equipment. [Fig. 3.5] Startup UP Screen - 2 This screen may not appear depending on the temperature inside the equipment, proceeding directly to [Fig.

-

Page 31: Reading (Storing) Images

Because operations, such as film output command, etc., are performed by DICOM- networked devices that enable the DICOM PRINT function, no specific operations are required on the DRYPIX 7000 main unit for film output purposes. However, be sure to observe the following cautions when outputting films from the DRYPIX 7000. -

Page 32: Shutting Down The System

Basic Operation Shutting Down the System 1 Make sure to confirm that the DRYPIX 7000 main unit has completed image recording and output processing and is in idle status. 2 Press the button on the Operation Panel. [Fig. 3.8] 3 When a screen appears prompting you to confirm the system shutdown, press button. -

Page 33: Supplying Film (Replacing The Film Pack)

Basic Operation Supplying Film (Replacing the Film Pack) When the film in the supply tray runs out, the screen background turns yellow and the button appears. Pressing this button will display the button. An attempt to output films in this status will sound the film supply alarm. * The alarm will not sound if it has been set to OFF. - Page 34 Basic Operation 3 The film tray has been unlocked. See the animation that appears on the display to fully pull the empty film tray out. [Fig. 3.13] Be sure to pull the tray out only after it has been unlocked. Doing so will result in damaging the tray unit.

- Page 35 Basic Operation 5 Place a new film pack in the empty tray following the procedure below. 5-1 Remove the film pack from the carton. 5-2 With the film pack arrow mark pointing upward, set it in place so that the mark on the label of the film pack is aligned with the mark on the tray as illustrated below.

- Page 36 Basic Operation 5-5 Replace the cutter in the position where it has been placed. 5-6 Slowly push the film tray in until it locks firmly. When locking the film tray, place the hand as illustrated below being careful not to pinch your fingers. [Fig.

- Page 37 Basic Operation 5-8 The display returns to the routine screen. This completes the film supply procedure. Note, however, that if you have selected By each film pack for AUTOMATED F.D.C. in the Utility mode, the Auto F.D.C. (automatic film density calibration) will be performed.

- Page 38 Basic Operation 6-2 When films of unspecified type were loaded When films of unspecified type are loaded, either screen will appear depending on the service setting. 1 When screen appears: To change the film, press the button. When the tray is unlocked, fully pull out the film tray toward you. Replace then the film and close the tray.

-

Page 39: Urgent Print

Basic Operation Urgent Print This function not only displays print jobs that have already been registered at the time when the Hard Disk Icon was pressed, but also processes urgent printing for specified films. The operation procedure is as follows. 1 Press the Hard Disk Icon on the operation panel. -

Page 40: Deleting A Print Job

Basic Operation Deleting a Print Job This function not only displays print jobs that have already been registered at the time when the Hard Disk Icon was pressed, but also deletes those jobs. The operation procedure is as follows. 1 Press the Hard Disk Icon on the operation panel. [Fig. - Page 41 Basic Operation 3-1 Pressing the button will display the [Fig. 3.27] Confirmation Screen, which prompts you to confirm the setup data. If the input setup data is correct, press the button. The display returns to the [Fig. 3.26] Job List Screen. Note that if you implement deletion processing, the image data will be erased.

-

Page 42: Print Job Details

Basic Operation Print Job Details This function not only displays print jobs that have already been registered at the time when the Hard Disk Icon was pressed, but also deletes those jobs or processes urgent printing. The operation procedure is as follows. 1 Press the Hard Disk Icon on the operation panel. - Page 43 Basic Operation 3-1 Pressing the button will display the [Fig. 3.30] Details Screen. [Fig. 3.30] Details Screen Use the buttons to move to the Details Screen of either the previous or following job. If you press the button, the job information will be updated to the newest. 3-1-1 Pressing the button will return the system to the [Fig.

- Page 44 Basic Operation 3-18 006-235-30 2004.03...

-

Page 45: Chapter 4 Utility Operation

Chapter 4 Utility Operation 006-235-30 2004.03... -

Page 46: What Is Utility

Utility Operation What is Utility? The DRYPIX 7000 offers Utility functions, which allow the users to operate processing such as film count checking and automatic film density calibration, etc. [Fig. 4.1] Utility Initial Screen (1/3) ......See page 4-4. Calibrates the output film density automatically. -

Page 47: Starting Up And Quitting The Utility

Utility Operation Starting Up and Quitting the Utility 4.2.1 Starting Up the Utility 1 Press the button that is on the upper right of the routine screen. After a while, the Utility initial screen will be displayed. [Fig. 4.2] Routine Screen [Fig. -

Page 48: Auto F.d.c

Utility Operation Auto F.D.C. This function is used to calibrate the film density. Output film density must correspond to the density gradation curve value that is determined by using the measured 24-step density data as reference. When the film manufacturing (lot) No. has been changed or when the output density has changed, use this function to calibrate the density in the system. - Page 49 Utility Operation 4 At the press of the button, the automatic film density calibration will be performed. Selecting the icon on [Fig. 4.6] Tray Select Screen will enable you to finely adjust a maximum density (Dmax) value. You can use this function when you wish to change the maximum density with respect to the setup value, depending on the view box luminance or room brightness.

- Page 50 Utility Operation For a failure that occurs in automatic film density calibration processing, see Chapter 5, Troubleshooting. [Fig. 4.8] [Fig. 4.9] 5 After approx. three minutes, a 24-step density test pattern film like the following will be output and the AUTO F.D.C will finish. [Fig.

- Page 51 Utility Operation 6 The screen will change to the following (Fig. 4.11). Press the button to return to the Utility initial screen. [Fig. 4.11] AUTO F.D.C. Completed Screen At the press of the button, the display returns to the [Fig. 4.6] Tray Select Screen.

-

Page 52: Test Pattern

Utility Operation Test Pattern This function outputs test pattern films. Use this function to output test pattern films as required to make sure that images are printed correctly. The operation procedure is as follows. 1 Start up the Utility. (Refer to section 4.2.1.) 2 Press the button on the Utility initial screen (1/3). - Page 53 AE title. Use the button to select one device registered to DRYPIX 7000. A test pattern will be printed based on the imaging conditions of the selected device. The output parameter select screen appears as follows. Select a desired number of frames (1, 2, 4, 6, 8 or 12) and lookup table curve (LUT nos.

- Page 54 Utility Operation 6 On the Interpolation select screen that appears, select a desired interpolation type and interpolation algorithm/method. Press then the button. [Fig. 4.16] Interpolation Select Screen If “NONE” is selected for the Interpolation algorithm/method, output test pattern films may not be subjected to interpolation processing and images may be printed smaller in relation to the...

- Page 55 Utility Operation 8 When the test pattern film is output after a while, make sure that image has been printed correctly. [Fig. 4.18] Standard Test Pattern (SMPTE) - Example: For an output image When the Service Setting has been performed, a user-defined test pattern can be selected.

-

Page 56: Unlock Tray

Utility Operation Unlock Tray When you wish to remove the tray for any reason, you can unlock and remove the tray by using this function. The operation procedure is as follows. 1 Start up the Utility. (Refer to section 4.2.1.) 2 Press the button on the Utility initial screen (1/3). - Page 57 Utility Operation 4 On the tray select screen in step 3 above, select a tray you wish to unlock and press the button. The tray will be unlocked. 5 Confirm that the screen has changed to the following. Remove then the tray to conduct necessary work.

- Page 58 Utility Operation 6 After completing the work, insert the tray carefully and confirm that the tray has been locked correctly, and then remove the shutter. When locking the film tray, be careful not to pinch your fingers. [Fig. 4.24] 7 Hang the tray on the specified position (on the left-side or rear cover) for storage. [Fig.

-

Page 59: Print Queue

Utility Operation Print Queue You can use this function to delete registered print jobs or handle urgent print processing. The operation procedure is as follows. 1 Start up the Utility. (Refer to section 4.2.1.) 2 Press the on the Utility initial screen (1/3). [Fig. - Page 60 Utility Operation 4 If the button is pressed, jobs selected in step 3 above will be printed urgently. button is pressed, screens like those shown below will appear prompting you to confirm. Press the button. [Fig. 4.28] When the DELETE button was pressed [Fig.

-

Page 61: Set Counters

Utility Operation Set Counters This function is used to display (confirm) and/or reset the no. of films output from each tray. The operation procedure is as follows. 1 Start up the Utility. (Refer to section 4.2.1.) 2 Press the button on the Utility initial screen (1/3). [Fig. - Page 62 Utility Operation Press the button, and the following screen appears. The number of films used since it was cleared off the last and the total number of films used will be displayed respectively for each tray. If the button is pressed on the right hand side of the screen, the number of films used for each tray since it was cleared off the last (displayed at the top) will be cleared off, resetting thus the film count to 0 (zero).

- Page 63 Utility Operation 6 Press the button, and the following screen will appear. [Fig. 4.34] 7 With the button, change the display list. 8 Pressing the button will return to the Set Counters screen [Fig.4.32]. The used film count in the Display List will not be cleared off even if the count is actually cleared off.

-

Page 64: Economy Mode

Utility Operation Economy Mode Economy Mode that consists of the following three patterns is available for saving power consumption by the equipment. Screen Saver Puts off the backlight of the screen and turns the screen OFF. This mode pattern becomes available around-the-clock if you input a specific time period on the “Transition Time”... - Page 65 Utility Operation 4.8.1 Transition Time Set a time period in which the system proceeds from the routine status to Economy Mode as follows. If the operation panel is not touched or no data comes from the outside exceeding a predetermined time period, the system proceeds automatically to the Economy Mode. The Stand-By/Sleep mode pattern will be activated if settings necessary for “Scheduler”...

- Page 66 Utility Operation 4 When a screen like that shown below appears, press the button. [Fig. 4.37] Details Screen When the button is selected, the display changes to the [Fig. 4.38] screen. If the operation panel is not touched or no data comes from the outside exceeding a time period predetermined on this screen, the system proceeds automatically to the Economy Mode.

- Page 67 Utility Operation CAUTION If you have activated power conservation in “Scheduler” or “Time of Office Closed” and the equipment restored from Economy Mode, the system goes again into Economy Mode when the time preset on the “Transition Time” screen elapses. If you use the system on holidays or at night for emergency purposes, we recommend that you set the “Transition Time”...

- Page 68 Utility Operation 4.8.2 Scheduler Use the “Scheduler” function to apply Economy Mode at night during weekdays. This function makes it possible to set up a weekly time period for which Economy Mode is to be activated. The time period thus set up will be the “Time Period Where Economy Mode is Activated”.

- Page 69 Utility Operation A select screen like that shown below appears. Press the button. [Fig. 4.40] Set Economy Mode Screen When the following screen appears, press the button. [Fig. 4.41] Details Screen 4-25 006-235-30 2004.03...

- Page 70 Utility Operation The display then changes to a screen like that shown below, where you can set up a time period for Economy Mode and None Economy by the day of the week. [Fig. 4.42] Details Scheduler Screen If the operation panel is not touched or no data comes from the outside exceeding the time period specified so that the Transition Time is effective, the Economy Mode function will be performed.

-

Page 71: Calendar

Utility Operation 4.8.3 Calendar Use the “Calendar” mode function if you wish to save power on office closing days. By using this mode function, you can set up a time range that enables power conservation on a daily basis. This setting also belongs to “Time Period Where Economy Mode is Activated”. - Page 72 Utility Operation The operation procedure is as follows. (If the system has already been proceeded to Economy Mode, you need not to perform steps 1 and 2 below.) 1 Start up the Utility. (Refer to section 4.2.1.) Perform settings necessary for Economy Mode. Press the button on the Utility initial screen (1/3).

- Page 73 Utility Operation The display then changes to the following. [Fig. 4.47] Calendar Screen (1) Press a date of the calendar, and the color of the date thus specified will change, meaning of which are as follows. Repeat touching the screen until the color you want appears.

- Page 74 Utility Operation Time of Office Closed mode settings Each mode pattern (Closing all day, Closing afternoon, or Closing morning) available for office closing days can be set up as follows. [Normal office day] *An example of a normal office day with Economy Mode activated from 8:00 to 18:00, according to the Scheduler mode.

- Page 75 Utility Operation The operation procedure is as follows. (If the system has already been proceeded to Economy Mode, you need not to perform steps 1 and 2 below.) 1 Start up the Utility. (Refer to section 4.2.1.) Perform settings necessary for Economy Mode. Press the button on the Utility initial screen (1/3).

- Page 76 Utility Operation The display then changes to the following, where press the button. [Fig. 4.50] Details Screen A screen like that shown below appears. [Fig. 4.51] Time of Office Closed Screen (1) Press a time period value you want to change. Background of a value thus selected will turn white.

-

Page 77: Save Power

Utility Operation 4.8.4 Save Power Use this mode function when you wish to perform power saving immediately. Pressing the button will enable you to proceed immediately to Economy Mode independent of any time periods determined in Economy Mode. The operation procedure is as follows. Start up the Utility. - Page 78 Utility Operation The display then changes to the following screen. Select Stand-By or Sleep mode pattern as necessary. [Fig. 4.54] Save Power Screen : At the press of this button, you can enter Stand-By mode immediately. The screen will then disappear and the power save lamp goes on. To return from the Stand-By mode, touch the operation panel.

-

Page 79: Set Alarm

Utility Operation Set Alarm Use this function when you wish to turn ON/OFF or adjust the alarm and button touch tone. The operation procedure is as follows. 1 Start up the Utility. (Refer to section 4.2.1.) 2 Press the button on the Utility initial screen (2/3). [Fig. - Page 80 Utility Operation [Fig. 4.57] [Fig. 4.58] When was selected. When was selected. Set the button touch tone and volume, then Set the alarm and volume, then press the press the button to determine the button to determine the setup data. setup data.

-

Page 81: Automated F.d.c

Utility Operation 4.10 Automated F.D.C. Use this function to set the timing for achieving automatic film density calibration when supplying a new film pack. The operation procedure is as follows. 1 Start up the Utility. (Refer to section 4.2.1.) 2 Press the button on the Utility initial screen (2/3). -

Page 82: Set Date/Time

Utility Operation 4.11 Set Date/Time The date and time of the clock incorporated in this equipment can be set with this function. The operation procedure is as follows. 1 Start up the Utility. (Refer to section 4.2.1.) 2 Press the button on the Utility initial screen (2/3). - Page 83 Utility Operation [Fig. 4.63] [Fig. 4.64] When was selected. When was selected. Enter a two-digit year (lower two digits of a Enter an hour (two digits) and minutes (two dominical year: 20XX), month (two digits), and digits). Press then the button.

-

Page 84: Software Version

Utility Operation 4.12 Software Version Use this function to display the software version. The operation procedure is as follows. 1 Start up the Utility. (Refer to section 4.2.1.) 2 Press the button on the Utility initial screen (2/3). [Fig. 4.65] 3 The display changes to the software version screen like that shown below. -

Page 85: Reprint

Utility Operation 4.13 Reprint Images stored in the hard disc of the equipment can be reprinted. To use this function, images on the connected equipment to be stored for reprinting purpose must be set up in advance at Service setup. The operation procedure is as follows. - Page 86 Utility Operation The User ID Input screen will appear. Input your User ID (four digits), and press the button. [Fig. 4.69] User ID must be registered at Service setup mode. The Print ID Input screen will appear. Input your Print ID (four digits), and press the button.

- Page 87 Utility Operation The screen Reprint details will appear. [Fig. 4.71] (1) Use the button to set the number of copies. (2) Pressing the button will start registration for print job and display the following screen. [Fig. 4.72] 4-43 006-235-30 2004.03...

- Page 88 Utility Operation (3) When the registration is finished, the Reprint Registration Completed screen will appear. [Fig. 4.73] : Return to the Utility screen. : Returns to the Print ID registration screen. (4) Exit the utility to return to routine mode. When the system has returned to routine mode, reprinting will start.

-

Page 89: Time Interval Determined For Animation Display

Utility Operation 4.14 Time Interval Determined for Animation Display This function changes time interval for display of animation that prompts you to take necessary action such as film loading. The operation procedure is as follows. 1 Start up the Utility. (Refer to section 4.2.1.) 2 Press the button on the Utility Initial screen (3/3). - Page 90 Utility Operation 4 Use the buttons to adjust the animation display speed, and press the button. The animation will then be displayed at a specified speed. 5 If you press the button, the display will change to the ANIMATION (PREVIEW) Screen [Fig. 4.76]. The film loading animation will be displayed as a test at a specified speed.

-

Page 91: Chapter 5 Troubleshooting

Chapter 5 Troubleshooting 006-235-30 2004.03... -

Page 92: Items To Be Confirmed First

When the following failure occur, check the items listed below first and take appropriate countermeasures Error Check Items Countermeasures DRYPIX 7000 1 Whether the Main Power If the Main Power Switch has been turned OFF, turn it ON Switch on the bottom front of does not start up. - Page 93 Check Items Countermeasures The alarm Confirm the operation panel display An error window like the following is sounds. of the DRYPIX 7000. displayed. Press the button to silence the alarm. Then, take an appropriate measure following the error message displayed.

-

Page 94: Error Window

Troubleshooting Error Window When an error occurs disabling routine processing to continue, the alarm sounds and an error window like that shown below appears on the display. Press the button to silence the alarm. Jot down the error code and error details code displayed, and then press the button to turn OFF the power. -

Page 95: When The Film Jams

Troubleshooting When the Film Jams If the film jams inside the DRYPIX 7000, the alarm will sound and an illustration (seven patterns) that shows the jamming position and then an operation guide animation will appear in the main unit operation panel. - Page 96 Troubleshooting [Table 5-1-2] Illustration Illustration JAM Handling Reference Page for (ALARM ON) (ALARM OFF) Label 1 or 2 Countermeasure Label 1 Page 5-15 Label 1 Page 5-17 Label 2 Page 5-23 − Page 5-25 006-235-30 2004.03...

- Page 97 Troubleshooting Jamming Position: Tray1 1 The animation starts when the alarm is stopped at the press of the button. See the animation to take appropriate countermeasures. To start the animation while the alarm is set to OFF, press the button. See the animation to take appropriate countermeasures.

- Page 98 Troubleshooting 4 Press the button. [Fig. 5.5] 5 Pull out Tray 1 toward you to remove the jammed film. [Fig. 5.6] Film jams that can be presumed. (1) Part of a film remains outside the tray because it was caught between the tray and the shutter.

- Page 99 Troubleshooting 6 Insert Tray 1 to make sure that it is locked firmly. Close then the front cover. [Fig. 5.7] 7 Remove the shutter and put it back again on the left-hand side or rear of the equipment. [Fig. 5.8] 006-235-30 2004.03...

- Page 100 Troubleshooting Jamming Position: Tray2 1 The animation starts when the alarm is stopped at the press of the button. See the animation to take appropriate countermeasures. To start the animation while the alarm is set to OFF, press the button. See the animation to take appropriate countermeasures.

- Page 101 Troubleshooting 4 Press the button. [Fig. 5.11] 5 Pull out Tray 2 toward you to remove the jammed film. [Fig. 5.12] Film jams that can be presumed. (1) Part of a film remains outside the tray because it was caught between the tray and the shutter.

- Page 102 Troubleshooting 6 Insert Tray 2 to make sure that it is locked firmly. Close then the front cover. [Fig. 5.13] 7 Remove the shutter and put it back again on the left-hand side or rear of the equipment. [Fig. 5.14] 5-12 006-235-30 2004.03...

- Page 103 Troubleshooting Jamming Position: 1 The animation starts when the alarm is stopped at the press of the button. See the animation to take appropriate countermeasures. To start the animation while the alarm is set to OFF, press the button. See the animation to take appropriate countermeasures. 2 Open the front cover.

- Page 104 Troubleshooting 3 As the animation shows, rotate the handle clockwise to remove the jammed film, then close the front cover. [Fig. 5.16] 5-14 006-235-30 2004.03...

- Page 105 Troubleshooting Jamming Position: 1 The animation starts when the alarm is stopped at the press of the button. See the animation to take appropriate countermeasures. To start the animation while the alarm is set to OFF, press the button. See the animation to take appropriate countermeasures. 2 Open the front cover.

- Page 106 Troubleshooting 3 As the animation shows, rotate the handle counterclockwise to remove the jammed film, then close the front cover. [Fig. 5.18] 5-16 006-235-30 2004.03...

- Page 107 Troubleshooting Jamming Position: 1 The animation starts when the alarm is stopped at the press of the button. See the animation to take appropriate countermeasures. To start the animation while the Alarm is set to OFF, press the button. See the animation to take appropriate countermeasures. 2 Open the front cover and/or jam clear cover.

- Page 108 Troubleshooting 3 As the animation shows, open the front cover and/or the small upper cover to remove the jammed film, then close it. [Fig. 5.20] 5-18 006-235-30 2004.03...

- Page 109 Troubleshooting 3-1 If you find a jammed film around the position where you have just opened the jam clear cover, press the button. See then the animation to remove the jammed film. [Fig. 5.21] 5-19 006-235-30 2004.03...

- Page 110 Troubleshooting 3-2 If you find a jammed film in the thermal development unit, press the button and see the animation to remove the jammed film. [Fig. 5.22] 5-20 006-235-30 2004.03...

- Page 111 Troubleshooting 3-3 If you find jammed films both around the position where you have just opened the jam clear cover and in the thermal development unit, press the button. See then the animation to remove the jammed films. [Fig. 5.23] 5-21 006-235-30 2004.03...

- Page 112 Troubleshooting 3-4 If you do not find any film, press the button, and then see the animation to locate and remove a jammed film. [Fig. 5.24] 5-22 006-235-30 2004.03...

- Page 113 Troubleshooting Jamming Position: 1 The animation starts when the alarm is stopped at the press of the button. See the animation to take appropriate countermeasures. To start the animation while the alarm is set to OFF, press the button. See the animation to take appropriate countermeasures. 2 Open the front cover.

- Page 114 Troubleshooting 3 As the animation shows, rotate the handle clockwise to remove the jammed film, then close the front cover. [Fig. 5.26] 5-24 006-235-30 2004.03...

- Page 115 Troubleshooting Ejection Unit Jamming Position: 1 The animation starts when the alarm is stopped at the press of the button. See the animation to take appropriate countermeasures. To start the animation while the alarm is set to OFF, press the button.

- Page 116 Troubleshooting 3 See the animation to remove the jammed film, then close the jam clear cover. [Fig. 5.28] 5-26 006-235-30 2004.03...

-

Page 117: Failing In Reading A Barcode

Troubleshooting Failing in Reading a Barcode back When a film pack is replaced, this equipment reads a barcode affixed on the of the film pack and manages the film lot number and other information. [Fig. 5.29] If, for any reason, the equipment fails in reading the barcode, an error window like that shown below appears. - Page 118 Troubleshooting Press the button to make sure again that a film pack has been set correctly. [Fig. 5.31] [Fig. 5.32] When screen [Fig. 5.32] is displayed, proceed to the following steps on the next page. 5-28 006-235-30 2004.03...

- Page 119 Troubleshooting 1 Input a 20-digit barcode of the label affixed on the back of the bag that contains films, and press the button. [Fig. 5.33] 2 If the barcode thus input has been recognized correctly, the display changes to that shown below.

-

Page 120: Failing In Loading Films

Troubleshooting Failing in Loading Films For a failure in film replenishment, countermeasures to be taken will differ case by case. Follow the procedures shown below and load films again. 5.5.1 When the tray was closed without placing a new film pack: [Fig. - Page 121 Troubleshooting 5.5.3 When a new film pack was loaded and the tray closed, but the positioning was wrong: [Fig. 5.36] will appear. Since the tray has not been locked, pull out the tray. Place the film pack in the correct position and pull out the film end, and close the tray. [Fig.

- Page 122 Troubleshooting 5.5.5 A new film pack was placed front side back, and the film pack was pulled out of the tray by tearing the label. The bottom of the film pack was then cut, and the tray closed: Since the wrong part was cut off, the film pack cannot be removed. [Fig.

- Page 123 Troubleshooting 5.5.6 When films other than DI-HL, DI-HLc, and DI-ML were placed: (A label on the pack is other than red or green (DI-ML).) (1) Before the film pack is removed: Confirm the color of the film pack label outside of the film tray. If it is not red or green (DI-ML), the film cannot be used in this equipment.

-

Page 124: Failing In Auto F.d.c. (Automatic Density Calibration)

Troubleshooting Failing in Auto F.D.C. (Automatic Density Calibration) If fails in automatic density calibration processing for any reason, an error window like that shown below appears. [Fig. 5.44] Press the button to perform automatic density calibration processing again. If the same failure recurs after Auto F.D.C. processing is performed again, a film will be printed by using a density table before the failure has occurred. -

Page 125: Failing In Placing A Cleaning Roller

Troubleshooting Failing in Placing a Cleaning Roller When a cleaning roller was not put inside the equipment by mistake, the following error screen ([Fig. 5.46] or [Fig. 5.47]) will appear. The instruction to be displayed on the panel will be different according to the alarm setup. [Fig. - Page 126 Troubleshooting 2 When the front cover is opened, the following animation screen [Fig. 5.49] will appear. [Fig. 5.49] 3 Place a cleaning roller and then close the front cover. When the startup ready screen is displayed, the print function will be started. If the error code below is displayed, take the relevant countermeasure to cope with the problem.

-

Page 127: Storing The Equipment Operation History

Troubleshooting Storing the Equipment Operation History This equipment is available for storing the operation history in a hard disc incorporated in it. Basically, this function is set to OFF. However, in order to analyze causes of failure, it may be set to ON in service setup mode. 1 Press the LCD unit on the operation panel. -

Page 128: Failing In Turning The Power Switch Off After Pressing The Shutdown Button

Troubleshooting Failing in Turning the Power Switch OFF After Pressing the SHUTDOWN Button If the power switch does not turn OFF even when 10 minutes have passed after “System Shut Down” appears, turn the main power switch OFF at the lower right corner on the front of the equipment. -

Page 129: Chapter 6 Regular Care And Maintenance

Chapter 6 Regular Care and Maintenance 006-235-30 2004.03... -

Page 130: Cleaning The Cleaning Roller With Water

Regular Care and Maintenance 6.1 Cleaning the Cleaning Roller with Water We recommend that you wash the cleaning roller with water once every week to secure print image quality. When white spots or traces of lint appear on the output film, also clean the cleaning roller with water according to the following procedure. - Page 131 Regular Care and Maintenance 3 Lower the lever and remove the cleaning roller together with its receive. [Fig. 6.2] Removing the Cleaning Roller When removing the cleaning roller, hold it with both hands paying attention not to drop it. Remove the cleaning roller while slightly raising the receive.

- Page 132 Regular Care and Maintenance Use a gauze moistened with alcohol or ethanol anhydride to wipe off water remaining on the roller. The cleaning roller will be dried in a few minutes. Put the roller back to its original position and close the front cover. Do not raise the lever with hand, otherwise a problem such as damages to gears or film stuck may occur with the equipment.

-

Page 133: Cleaning The Suction Filter

Regular Care and Maintenance 6.2 Cleaning the Suction Filter 1 Remove the filter from the left-side cover and use a vacuum cleaner to remove dirt or dust accumulated inside. [Fig. 6.5] Open the front cover and remove the black filter at the bottom. Remove then dirt or dust accumulated inside with a vacuum cleaner. - Page 134 Regular Care and Maintenance 006-235-90 2007.03...

-

Page 135: Chapter 7 Specifications

Chapter 7 Specifications 006-235-30 2004.03... -

Page 136: System Components

Specifications 1 System Components 1.1 Standard Components (1) DRYPIX 7000 main unit ............1 (One-tray, two-tray and three-tray specification types are available.) (2) Image buffer memory board 256MB ........1 1.2 Options Supply film tray, 8"×10" film kit, Add-on memory (256MB), Sorter 1.3 Supplies... -

Page 137: Maximum Density

Specifications 7 Maximum Density For the DI-HL and DI-HLc, select one of 2.64, 3.0, 3.3 and 3.6. For the DI-ML, select 3.6 or 4.0. * Note that 3.6 and 4.0 are for mammography use only. 8 Power Supply Conditions Input voltage AC 200/220/230/240V ±10% Phase Single... -

Page 138: External View And Weight

10 External View and Weight 10.1 External Dimensions and Weight Model Name Width (mm) Depth (mm) Height (mm) Weight (kg) DRYPIX 7000 1240 (including two trays) * Dimensions and weight are approximate and are subject to change without prior notice. [Fig. 7.1] 006-235-40 2006.05... -

Page 139: Internal Construction

Specifications 10.2 Internal Construction [Fig. 7.2] * Depending on the equipment specification, Tray 2 is provided as a standard. 006-235-40 2006.05... - Page 140 Specifications 006-235-30 2004.03...

-

Page 141: Maintenance And Inspection

Maintenance and Inspection During maintenance and inspection, strictly observe precautions contained in “1.3 Safety” (page 1-3) and “1.4 Operational Precautions” (page 1-4) in this manual for you to use the DRYPIX 7000 system under best conditions. 1 User’s Maintenance and Inspection Items... - Page 142 Maintenance and Inspection 006-235-30 2004.03...

- Page 143 • Restricted Functionality. You are licensed to use the SOFTWARE to provide only the limited functionality (specific tasks or processes) for which the DEVICE has been designed and marketed by [FUJIFILM Corporation]. This license specifically prohibits any other use of the SOFTWARE, or inclusion of additional software programs or functions, on the DEVICE.

- Page 144 SOFTWARE after the date you obtain your initial copy of the SOFTWARE (“Supplemental Components”). • If [FUJIFILM Corporation] provides or makes available to you Supplemental Components and no other EULA terms are provided along with the Supplemental Components, then the terms of this EULA shall apply.

- Page 146 FUJIFILM MEDICAL SYSTEMS U.S.A., INC. 419 WEST AVENUE, STAMFORD CT 06902, U.S.A...