Table of Contents

Advertisement

Advertisement

Table of Contents

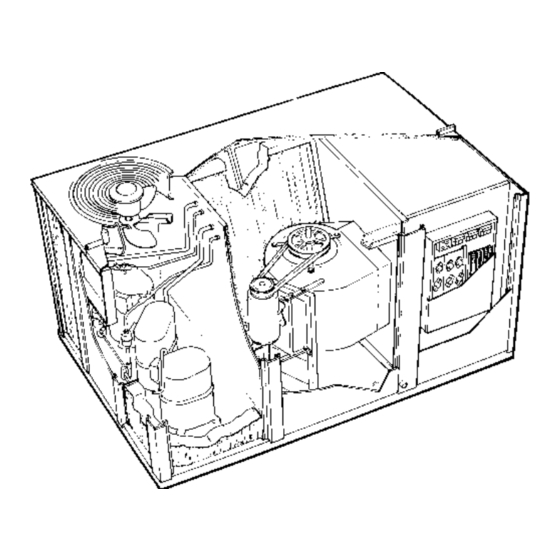

Summary of Contents for Lennox CHA16

- Page 1 Page 1...

- Page 2 Page 2...

- Page 3 Page 3...

- Page 4 Page 4...

- Page 5 Page 5...

- Page 6 Page 6...

- Page 7 Page 7...

- Page 8 Page 8...

- Page 9 Page 9...

- Page 11 Page 11...

- Page 12 Page 12...

- Page 13 Page 13...

- Page 14 Page 14...

- Page 15 Page 15...

- Page 16 Page 16...

- Page 17 NOTE-Contactor K1 is energized by the thermostat control system. Depending on the control system installed, the contactors may or may not be immediately energized upon demand. Refer to the operation se quence for the control system installed. Page 17...

- Page 18 Page 18...

- Page 19 NOTE-Compressor monitors must be disconnected if optional low ambient kit is used. Page 19...

- Page 20 Page 20...

- Page 21 Page 21...

- Page 22 Page 22...

- Page 23 Page 23...

- Page 24 NOTE-Refer to wiring diagram section B9 for specif ic unit operation. Page 24...

- Page 25 Page 25...

- Page 26 Page 26...

- Page 27 NOTE-If owner complains of insufficient cooling, the unit should be gauged and refrigerant charge checked. NOTE-The following is a generalized procedure and does not apply to all thermostat control systems. Elec tronic and ramping thermostat control systems may op erate differently. Refer to the operation sequence sec tion of this manual for more information.

- Page 28 Make sure thermometer wells are filled with oil be fore checking. IMPORTANT - Block compressor compartment with access panel so air will not by-pass the coils. NOTE-The following is a generalized procedure and does not apply to all thermostat control systems. Page 28...

- Page 29 NOTE-Tension new belt after 24-48 hours of operation. This will allow belts to stretch and seat in grooves. To increase belt tension, loosen two locking bolts and pull mounting plate. Tighten motor mounting plate in verti cal position. NOTE-Filters must be U.L.C. certified or equivalent for use in Canada.

- Page 30 Page 30...

- Page 31 Page 31...

- Page 32 Page 32...

- Page 33 Page 33...

- Page 34 Page 34...

- Page 35 Fuse F3 Fuse F3 Fuse F3 Fuse F3 Fuse F3 2nd Stage 3rd Stage 4th Stage 5th Stage 1st Stage (3 Fuses) (3 Fuses) (3 Fuses) (3 Fuses) (3 Fuses) 60 Amp 208/230V 250V 30 Amp 600V 460 & 575V 60 Amp 208/230V 250V...

- Page 36 T2 TRANSFORMER RATINGS Electric Heat Internal Secondary Primary Unit Fuse 50VA 208/230V Red Tap 208V Blue Tap 24VAC Exc. 75kW Orange Tap 230V 2.5A Yellow Tap Common Black Tap Common 70 VA Red Tap 208V 208/230V Blue Tap 24VAC Orange Tap 230V 75kW 3.5A Yellow Tap Common...

- Page 37 Contactor K17 Contactor K16 1st Stage Heat Demand Contactor K18 3rd Stage 2nd Stage Contactor K15 Pilot Relay K9 4th Stage (40kW and 50 kW 1st Stage (all units) (208/230v 30kW and 2nd Stage Heat Demand (50 kW 208/230v units) 208/230V units only) all 40 kW &...

- Page 38 Contactor K17 Contactor K16 3rd Stage 2nd Stage Contactor K15 Contactor K18 (45kW and 60kW (208/230v 30kW and 1st Stage (all units) 4th Stage 208/230V units only) all 45kW and 60kW units) (60kW 208/230V only) Primary Limit S15 (208/230V only) Redundant Limit S63 (460 &...

- Page 39 5th Stage Heat Electric Heat 1st Stage Heat Demand 2nd Stage Heat Demand Contactor K75 Transformer T2 Pilot Relay K9 Pilot Relay K19 75kW Only 5th Stage Heat K9 K19 Fuse F3 75kW Only 4th Stage Heat DL18 Time Delay DL18 4th Stage Heat Fuse F3 75kW Only...

- Page 40 Page 40...

- Page 41 REMD16M-185 (horizontal application) CHA16 1853 Unit Outdoor Air Dampers Air Filters Return Air Duct Gravity Exhaust Dampers REMD16M-185 (downflow application) Outdoor CHA16-1853 unit Air Dampers Air Filters Gravity Exhaust Dampers Optional Power Exhaust Dampers Page 41...

- Page 42 Page 42...

- Page 43 Page 43...

- Page 44 If the enthalpy control is set at setpoint A" as shown in figure 45, the following situation could occur.A cooling demand when the outside air is at 75 and 20 percent humidity would drive the economizer outdoor air dampers open to utilize outdoor air for cooling.The compressor cooling circuit would be disabled.Howev er, if the outdoor air should change to 70 F (a drop in temperature) and 70 percent humidity (a dramatic rise...

- Page 45 Page 45...

- Page 46 NOTE Late production CHA16 units are equipped with factory installed cycle controls. Page 46...

- Page 47 CYCLE CONTROL KIT WIRING DIAGRAM...

- Page 48 NOTE- See CAUTION. Compressor monitor (Low Ambient Lockout Switch) S3 cannot be used with optional low ambient kit.Com pressor monitor MUST be disconnected before allow ing low ambient kit to be used. Electrical shock hazard. Low ambient kit wiring changes depending on unit size. Depending on the application, low ambient controls may be wired to low voltage or line voltage.

- Page 49 Page 49...

- Page 50 Jack J25 / (opt. Plug P25) (used in 15 ton and larger units only) Jack J2 / (opt. Plug P2) Jack J33 / (opt. Plug P34) (used in 15 ton and larger units only) Jack J35 / Plug P35 (used in 12.5 ton and smaller units only) Jack J3 / Plug P3 Jack J36 / Plug P36 (used in 15 ton and larger units only)

- Page 51 D5 Wiring Diagram - Modulating Economizer Model Number REMD16M-185 Warm-Up Kit Page 51...

- Page 52 C2 1 Wiring Diagram Wiring Diagram C1 Wiring Diagram Page 52...

- Page 53 July 1989 and is not shown in the CHA16-1853. However, Flexstat remains a valid matchup to commercial CHA16 units of all sizes until inventories are depleted. You may find some CHA16-1853 units using it.

- Page 54 C14-1 Wiring Diagram C8 1 diagram C12 Wiring Diagram C8-1 Wiring Diagram C12-2 Wiring Diagram *NOTE-Some clocks may be 120VAC while most are 24VAC. Be sure to check clock motor rating and wire clock according to its rating. Page 54...

- Page 55 Page 55...

- Page 56 C1 diagram with B9 and A16 diagrams basic thermostat with CHA16 1853, with typical electric heat and without economizer...

- Page 58 C1 diagram with D5 diagram electromechanical thermostat with modulating economizer...

- Page 59 NOTE-In this operation sequence the unit diagram has been omitted in order to concen trate on the interaction between thermostat and economizer. NOTE-Relay K9 is part of the ECH16 electric heater used with the CHA16 unit for heating. NOTE-K11 relay is part of the REMD16M 185 economizer.

- Page 60 C2-1 diagram with D5 diagram electromechanical thermostat with modulating economizer and warm-up...

- Page 61 1 - The warm-up kit requires the use of optional time clock CMC3-1. 2 - Optional night thermostat S12 must be installed. 3 - The warm-up kit can only be installed in CHA16 units with REMD16 economizer. NOTE-This operation sequence emphasizes warm up kit operation. Unit diagram has...

- Page 62 B41 diagram with C1 diagram CHA16-2553, 2753, 3003 Operating Sequence...

- Page 64 B9 diagram with C1 diagram CHA16-1853 Operating Sequence...

- Page 66 B2 diagram with C1 diagram CHA16-1603 Operating Sequence...

- Page 67 B2 diagram with C1 diagram CHA16-1353 Operating Sequence...

- Page 68 B1 diagram with C1 diagram CHA16-823 / 953 Operating Sequence...

- Page 69 A1 diagram with B2 diagram ECH16-82/95/135/160 10kW & 15kW 208/230V Sequence...

- Page 70 A2 diagram with B2 diagram ECH16-82/95/135/160 20kW & 30kW 208/230V Sequence...

- Page 71 A3 diagram with B2 diagram ECH16-82/95/135/160 40kW 208/230V Operating Sequence...

- Page 72 A4 diagram with B2 diagram ECH16-82/95/135/160 50kW 208/230V Operating Sequence...

- Page 73 A5 diagram with B2 diagram ECH16-82/95/135/160 10kW & 15kW 460V & 575V Sequence...

- Page 74 A6 diagram with B2 diagram ECH16-82/95/135/160 20kW & 30kW 460V & 575V Operating Sequence...

- Page 75 A7diagram with B2 diagram ECH16-82/95/135/160 40kW 460V & 575V Operating Sequence...

- Page 76 A8 diagram with B2 diagram ECH16-82/95/135/160 50kW 460V & 575V Operating Sequence...

- Page 77 A15 diagram with B9 diagram ECH16-185 15kW 208/230V Operating Sequence...

- Page 78 A16 diagram with B9 diagram ECH16-185/255/275/300 30kW 208/230V Operating Sequence...

- Page 79 A17 diagram with B9 diagram ECH16-185/255/275/300 45kW 208/230V Operating Sequence...

- Page 80 A18 diagram with B9 diagram ECH16-185/255/275/300 60kW 208/230V Operating Sequence...

- Page 81 A19 diagram with B9 diagram ECH16-185/255/275/300 75kW 208/230V Operating Sequence...

- Page 82 A20 diagram with B9 diagram ECH16-185 15kW 460V & 575V Operating Sequence...

- Page 83 A21 diagram with B9 diagram ECH16-185/255/275/300 30kW 460V & 575V Sequence...

- Page 84 A22 diagram with B9 diagram ECH16-185/255/275/300 45kW 460V & 575V Sequence...

- Page 85 A23 diagram with B9 diagram ECH16-185/255/275/300 60kW 460V & 575V Sequence...

- Page 86 A24 diagram with B9 diagram ECH16-185/255/275/300 75kW 460V & 575V Sequence...