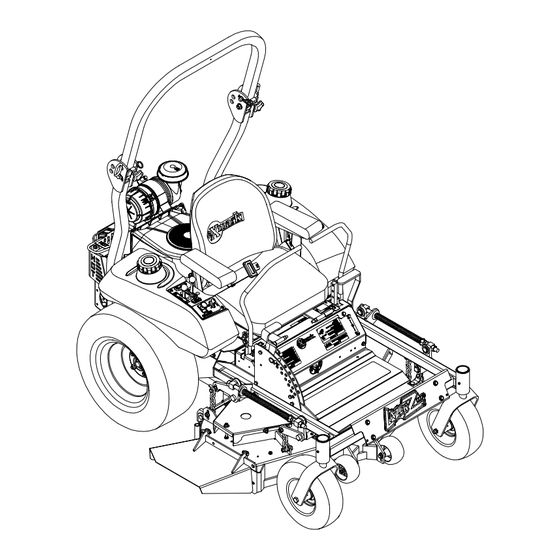

Exmark Lazer Z HP Operator's Manual

Lawn mower

Hide thumbs

Also See for Lazer Z HP:

- Operator's manual (60 pages) ,

- Operator and parts manual (32 pages) ,

- Parts manual (21 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Exmark Lazer Z HP

- Page 1 For Serial Nos. 670,000 & Higher Part No. 109-6439 Rev. A...

- Page 2 Replacements may be ordered through the engine manufacturer. Exmark reserves the right to make changes or add improvements to its products at any time without incurring any obligation to make such changes to products manufactured previously. Exmark, or its distributors and dealers, accept no responsibility for variations which may be evident in the actual specifications of its products and the statements and descriptions contained in this publication.

- Page 3 3. Exmark being unable to ship the part and the Exmark parts order is received by 3:00 p.m., central time, Exmark pays for the part and freight. 4. If the part does not arrive overnight due to the shipper (UPS), the shipper pays for the freight and Exmark pays for the part.

- Page 4 If additional information is needed, or should you require trained mechanic service, contact your authorized Exmark equipment dealer or distributor. All Exmark equipment dealers and distributors are kept informed of the latest methods of servicing and are equipped to provide prompt and efficient service in the field or at their service stations.

-

Page 5: Table Of Contents

TABLE OF CONTENTS 1. SAFETY PAGE Safety Alert Symbol ................1 Training ....................1 Preparation..................1-4 Operation ..................4-8 Maintenance & Storage ..............8-9 Safety Signs ..................9-11 2. SPECIFICATIONS Model Numbers ................12 Engine ....................12 Fuel System ..................12 Electrical System ................12 Operator Controls................12 Seat....................13 Hydrostatic Ground Drive System.............13 Tires &... -

Page 6: Safety Alert Symbol

MAY result in minor or moderate injury. 1.2 TRAINING 1.2.1 Regard the Exmark mower as a piece of power equipment and teach this regard to all who operate this unit. 1.2.2 Read the instructions carefully. Familiarize yourself with the controls and the proper use of the equipment. - Page 7 1.3.3 While mowing, always wear substantial footwear and long trousers. Do not operate equipment when barefoot or when wearing open sandals. 1.3.4 Thoroughly inspect the area where the equipment is to be used and remove all stones, sticks, wires, bones, and other foreign objects which may damage the equipment or cause personal injury to the operator or bystanders.

- Page 8 DANGER POTENTIAL HAZARD ♦ In certain conditions gasoline is extremely flammable and highly explosive. WHAT CAN HAPPEN ♦ A static charge can ignite gasoline vapors. A fire or explosion from gasoline can burn you, others, and cause property damage. HOW TO AVOID THE HAZARD ♦...

-

Page 9: Operation

WARNING POTENTIAL HAZARD ♦ Gasoline vapor can collect inside enclosed trailers and may be ignited by electrical sparks or hot engine/exhaust components. WHAT CAN HAPPEN ♦ Explosion and fire may occur, resulting in property damage, personal injury, and/or death. HOW TO AVOID THE HAZARD ♦... - Page 10 WARNING POTENTIAL HAZARD ♦ Hands, feet, hair, clothing, or accessories can become entangled in rotating parts. WHAT CAN HAPPEN ♦ Contact with rotating parts can cause traumatic amputation or severe lacerations. HOW TO AVOID THE HAZARD ♦ Do not operate the machine without guards, shields, and safety devices in place and working properly.

- Page 11 FIGURE 1 • Progressively greater care is needed as the slope increases. • Always avoid sudden starting or stopping on a slope. If tires lose traction, disengage the blades and proceed slowly off the slope. • Avoid sudden starts when mowing uphill. Mower may tip backwards. •...

- Page 12 • Be certain that the seat belt can be released quickly if the machine is driven or rolls into ponds of water. • Check carefully for overhead clearances (i.e. branches, doorways, and electrical wires) before driving under any objects and do not contact them. 1.4.6 Use EXTREME caution when backing up.

-

Page 13: Maintenance & Storage

b) connect the negative or ground cable (-) from the negative post on the booster battery to any engine deck ground, preferably the engine block as far away from the battery as possible. c) disconnect battery cables in the reverse order after starting. 1.5 MAINTENANCE AND STORAGE 1.5.1 For engine maintenance, follow the engine manufacturer’s recommendations precisely as stated in the engine manual. -

Page 14: Safety Signs

When new components are installed, be sure that current safety signs are affixed to the replaced components. 1.6.4 New safety signs may be obtained from your authorized Exmark equipment dealer or distributor or from Exmark Mfg. Co. Inc. 1.6.5 Safety signs may be affixed by peeling off the backing to expose the adhesive surface. - Page 15 PART NO. 1-513742 PART NO. 98-5954 LOCATION: On Top of Mower LOCATION: Under Mower Deck Belt Shield(s) Deck Belt Shields, Left PART NO. 1-513748 and Right Sides LOCATIONS: Bottom of Floorpan PART NO. 109-0872 LOCATION: Top of Mower Deck, Front Left Edge near Area Shown PART NO.

- Page 16 PART NO. 109-1224 LOCATION: Left of Center on Mower Deck, Under Floor Pan PART NO. 109-1399 PART NO. 103-4930 LOCATION: Front Left Corner Top LOCATION: Right of Choke of Mower Deck Control on RH Fuel Tank PART NO. 1-653147 LOCATION: Lefthand Side of Cutting Height Adjustment Plate PART NO.

-

Page 17: Specifications

2. SPECIFICATIONS 2.1 MODEL NUMBER: Serial Nos. 670,000 & Higher: LHP19KA465; LHP19KA505; LHP23KA505; LHP23KA565; LHP27KC505; LHP27KC565 2.2 ENGINE: 2.2.1 Engine Specifications: See Your Engine Owner’s Manual 2.2.2 RPM: Full Speed: 3600 RPM (No Load) Idle: 1500 RPM 2.3 FUEL SYSTEM 2.3.1 Capacity: 11.2 gal. -

Page 18: Seat

2.6 SEAT 2.6.1 Type: Standard seat: high back, foam padded (internal spring suspension) with armrests. Optional seat accessories: • Custom ride suspension system to enhance Standard Seat. • Deluxe suspension seat with high back, low profile foam-in-place cushion (dampened, adjustable spring suspension) and armrests. 2.6.2 Mounting: Hinged to tilt up for access to hydraulic pumps, battery and other components. -

Page 19: Dimensions

2.9.7 Cutting Height Adjustment: an extra-long cushioned lever is used to adjust the cutting height from 1” (2.5 cm) to 4.5” (11.4 cm.) in 1/4” (.64 cm.) increments. The cutting height adjustment handle has a transport position and all adjustments can be made while the operator remains seated. -

Page 20: Operation Instructions

3. OPERATION INSTRUCTIONS 3.1 CONTROLS 3.1.1 Familiarize yourself with all controls before operating the mower. 3.1.2 Motion Control Levers: Located on each side of the console. The left lever controls the flow of hydraulic oil from the left hydrostatic pump to the left drive wheel motor. - Page 21 CAUTION POTENTIAL HAZARD ♦ Machine can spin very rapidly by positioning one lever too much ahead of the other. WHAT CAN HAPPEN ♦ Operator may lose control of the machine, which may cause damage to the machine or injury. HOW TO AVOID THE HAZARD ♦...

-

Page 22: Pre-Start

Brake must be engaged, motion control levers out (neutral lock position) and PTO switch “OFF” to start engine. (It is not necessary for the operator to be in the seat to start the engine.) 3.1.9 Hour Meter: Located on the right fuel tank. The hour meter is connected to a pressure switch installed in the engine block and it records the number of hours that the engine has run. - Page 23 After starting a cold engine, gradually return choke to the “OFF” position as the engine warms up. On a warm engine, place the throttle midway between the “SLOW” and “FAST” positions and leave the choke in the “OFF” position. 3.3.4 Engaging PTO DANGER POTENTIAL HAZARD ♦...

-

Page 24: Transporting

Rotate ignition switch to “OFF” position. Remove the key to prevent children or other unauthorized persons from starting engine. Close fuel shut-off valve when machine will not be used for a few days, when transporting, and when the unit is parked inside a building. 3.4 TRANSPORTING 3.4.1 Transporting a Unit: Use a heavy-duty trailer or truck to transport the machine. - Page 25 WARNING POTENTIAL HAZARD ♦ Loading a unit on a trailer or truck increases the possibility of backward tip- over. WHAT CAN HAPPEN ♦ Backward tip-over of the unit could cause serious injury or death. HOW TO AVOID THE HAZARD ♦ Use extreme caution when operating a unit on a ramp.

-

Page 26: Maintenance & Adjustments

4. MAINTENANCE & ADJUSTMENTS WARNING POTENTIAL HAZARD ♦ While maintenance or adjustments are being made, someone could start the engine. WHAT CAN HAPPEN ♦ Accidental starting of the engine could seriously injure you or other bystanders. HOW TO AVOID THE HAZARD ♦... - Page 27 4.1.2 Clean engine air cooling system: Service Interval: Daily or more often in dry conditions CAUTION POTENTIAL HAZARD ♦ Excessive debris can cause the engine and hydraulic system to overheat. WHAT CAN HAPPEN ♦ Excessive debris around the engine cooling air intake and inside of the pump compartment can create a fire hazard.

- Page 28 Raise deck to the transport (4.5” (11.4cm) cutting height) position. Lift the front of unit and support unit using jack stands or equivalent support. CAUTION POTENTIAL HAZARD ♦ Raising the mower deck for service or maintenance relying solely on mechanical or hydraulic jacks could be dangerous.

- Page 29 HOW TO AVOID THE HAZARD ♦ Always install the original Exmark blades, blade bushings, spring disc washers, and blade bolts as shown. 4.1.6 Check safety interlock system.

- Page 30 4.1.7 Check rollover protections systems (roll bar) pins Service Interval: Daily a) Make sure latch pin and hair pin are fully installed and lanyard is in good condition. 4.1.8 Check seat belt Service Interval: Daily Visually inspect seat for wear, cuts, and proper operation of retractor and buckle.

- Page 31 (24°C). Fill to the appropriate level depending upon the temperature of the oil. For example: If the oil is about 150° F (65°C), fill to halfway between the “HOT” and “COLD” levels. If the oil is at room temperature (about 75° F (24°C)), fill only to the “COLD”...

- Page 32 Insert (1) bearing, (1) new seal into the wheel. NOTE: Seals (Exmark PN 103-0063) must be replaced. If the axle assembly has had both spacer nuts removed (or broken loose), apply a thread locking adhesive to (1) spacer nut and thread onto the axle with the wrench flats facing outward.

- Page 33 4.1.17 Lubricate seat switch actuator: Service Interval: 160 hrs. Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake. Unhook seat latch and tilt seat up. Lubricate switch actuator rod with spray type lubricant or light oil. 4.1.18 Lubricate brake handle pivot: Service Interval: 160 hrs.

- Page 34 Service Interval: After First 250 hrs. Then yearly thereafter NOTE: Use only Exmark Part No. 109-4180 for Summer use above 32° F (0°C) or Part No. 1-523541 for Winter use below 32° F (0°C). Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

-

Page 35: Adjustments

4.1.27 Thread locking adhesives such as “Loctite 242” or “Fel-Pro, Pro-Lock Nut Type” are used on the following fasteners: Pump drive sheave setscrews. Square head setscrews on Hydro pump control arms. Sheave retaining bolt in the end of engine crankshaft. Caster wheel spacer nuts (See Section 4.1.15) Fuel tank bulkhead fitting threads. - Page 36 installed with the spring disc washer between head of the bolt and mounting bracket. Torque hardware as specified, or loss of roller may result. Torque the 3/8 nyloc nut to 30-35 ft-lbs. (41-47 N-m). Torque the 3/8-24x2 Gr 8 hex capscrew to 50-55 ft-lbs (68-75 N-m) FIGURE 6 4.2.2 Deck Leveling: Position mower on a flat surface.

- Page 37 10 1/2" (26.7 cm) for 46" deck 10" (25.4 cm) for 50" deck 9 1/2" (24.1 cm) for 56" deck FIGURE 7 Recheck that blocks fit just snugly under the deck skirt and that the tension on all the chains are approximately equal. Make sure all chain attachment bolts are tight.

- Page 38 FIGURE 8 4.2.7 Brake Adjustment. a) Check for brake link 2.75” (7.0 cm) measurement as described in section 4.2.6. b) Engage brake lever (lever up). c) Measure the distance between the trunion roller and the rod collar as shown in Figure 8A. Measurement should be 1/4” (6.4 mm) to 5/16” (7.9 mm) (See Figure 8).

- Page 39 4.2.10 Motion Control Linkage Adjustment. WARNING POTENTIAL HAZARD ♦ Engine must be running and drive wheels must be turning so motion control adjustment can be performed. WHAT CAN HAPPEN ♦ Contact with moving parts or hot surfaces may cause personal injury. HOW TO AVOID THE HAZARD ♦...

- Page 40 REVERSE TURN BOLT INDICATOR HERE END OF SLOT LOOSEN HERE YOKE TURN HERE LOOSEN HERE TO ADJUST LOOSEN HERE (RIGHTHAND THREAD) (LEFTHAND THREAD) FIGURE 9 f) Start engine. Brake must be engaged and motion control levers out to start engine. Operator does not have to be in the seat because of the jumper wire being used.

-

Page 41: Waste Disposal

4.2.11 Caster pivot bearings pre-load adjustment. a) Remove dust cap from caster and tighten nyloc nut until washers are flat and back off 1/4 of a turn to properly set the pre- load on the bearings. If disassembled make sure the spring washers are reinstalled as shown in Figure 11. -

Page 42: Trouble Shooting

NOTE: After carefully checking the above steps, attempt to start the engine. If it does not start, contact your authorized Exmark service dealer. IMPORTANT: It is essential that all operator safety mechanisms be connected and in proper operating condition prior to mower use. -

Page 43: Electrical Diagrams

7. ELECTRICAL DIAGRAM – KAWASAKI UNITS... -

Page 44: Electrical Diagrams

ELECTRICAL DIAGRAM – KOHLER UNITS... -

Page 45: Hydraulic Diagram

8. HYDRAULIC DIAGRAM... -

Page 46: Warranty

This warranty extends only to replace or adjust any part manufactured by Exmark and found turf equipment operated under normal conditions. You by us (in the exercise of our reasonable discretion) to be... - Page 47 NOTES...

- Page 48 NOTES...

- Page 49 NOTES...

-

Page 50: Service Record

SERVICE RECORD Date Description of Work Done Service Done By... - Page 51 ALIGN THIS EDGE WITH A VERTICAL SURFACE (TREE, BUILDING, FENCE POST, POLE ETC.)

- Page 52 The engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm. © 1997-2007 EXMARK MFG. CO. INC. PART NO. 109-6439 REV. A INDUSTRIAL PARK BOX 808 (402) 223-6300...