Summary of Contents for Titan TTL688HDC

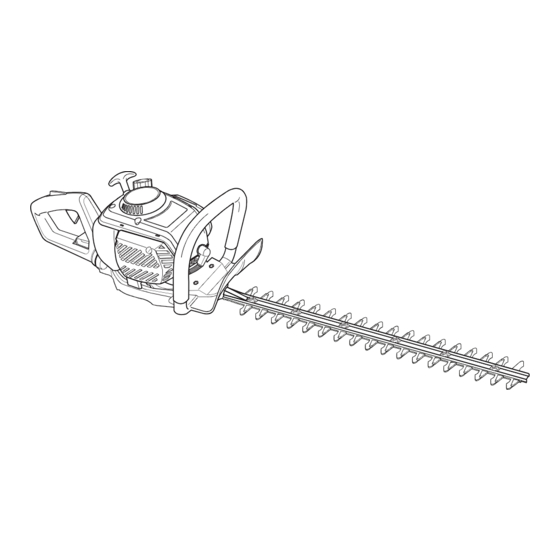

- Page 1 SAFETY AND OPERATING MANUAL Original Instructions V60920 / BX220IM 26CC PETROL HEDGE TRIMMER TTL688HDC...

- Page 2 Kingfisher International Products Limited or email cs@b-gr8.co.uk...

-

Page 3: General Safety Instructions

-If fuel is spilled, do not attempt to start the power source, but move the product away from the spillage before starting. -Always replace and securely tighten the fuel cap after refuelling. -If the fuel tank is drained, this should be done outdoors. 26CC PETROL HEDGE TRIMMER TTL688HDC... - Page 4 7.If the cutting mechanism strikes any foreign object or the product starts making any unusual noise or vibration, shut off the power source and allow the product to stop. Disconnect the spark plug wire from the spark plug and take the following steps. -Inspect for damage.

- Page 5 14.Follow the maintenance and repair instructions for this product. Never carry out any modifications of the product. Never change the pre-set rotary speed or the engine and product settings. Information about maintenance and repair is provided in this instruction manual. 26CC PETROL HEDGE TRIMMER TTL688HDC...

- Page 6 Fuel handling 1.Always switch the product off, disconnect the spark plug connector and let the product cool down, before refuelling it. Fuel and fuel vapour are highly flammable. Take care when handling fuel. Never smoke when you are refuelling the product. Do not refuel the product, if there is an open fire in the vicinity! 2.Always use suitable aids such as funnels and filler necks.

- Page 7 Maintain this tool in accordance with these instructions and keep well lubricated (where appropriate). Avoid using tools in temperatures of 10°C or less. Plan your work schedule to spread any high vibration tool use across a number of days. Health Surveillance. 26CC PETROL HEDGE TRIMMER TTL688HDC...

- Page 8 Health Surveillance All employees should be part of an employer's health surveillance scheme to help identity any vibration related diseases at an early stage, prevent disease progression and help employees stay in work. Emergency Familiarise yourself with the use of this product by means of this instruction manual. Memorise the safety directions and follow them to the letter.

- Page 9 Kilowatt cm³ Cubic centimetre min-¹ or /min per minute Millimetre Kilogram dB(A) Decibel (A-rated) m/s² Metres per second squared Litre yyWxx Manufacturing date code; year of manufacturing (20yy) and week of manufacturing (Wxx). 26CC PETROL HEDGE TRIMMER TTL688HDC...

- Page 11 Choke lever: Start (Close Position) - Run (Open Position) 26CC PETROL HEDGE TRIMMER TTL688HDC...

- Page 13 26CC PETROL HEDGE TRIMMER TTL688HDC...

- Page 14 615mm 27mm 5.6kg approx. 1230×250 260 × 106.9 2.32 The sound values have been determined according to noise test code given in EN ISO 10517, using the basic standards EN ISO 11201 and EN ISO 3744 Wear hearing protection! The sound intensity level for the operator may exceed 80 dB(A) and ear protection measures are necessary! The conformity assessment followed was according to Annex III of the directive for equipment listed in schedule 1 / article 13 the chosen conformity assessment route Internal cintrol of production (schedule...

-

Page 15: Intended Use

4.Ensure that you have all the accessories and tools needed for assembly and operation. This also includes suitable personal protective equipment. BLADE COVER 1.Remove the blade cover (17) from the cutting device (1) before operation (Fig. 1). 26CC PETROL HEDGE TRIMMER TTL688HDC... -

Page 16: Handle Adjustment

NOTE: Always attach the blade cover (17) when the product is not in use, for storage and transportation. To attach the blade cover, align and push the blade cover onto the cutting device (1). HANDLE ADJUSTMENT Adjust the handle to fit the application. 1.Pull the unlock lever (9) backward and hold it in position (Fig. -

Page 17: Fuel And Engine Oil

NOTE: Never mix fuel and oil directly in the tank of the product. Use a fuel mixing container that helps to ensure the correct mixing ratio. Shake gently to ensure a thorough mix of fuel and oil. 26CC PETROL HEDGE TRIMMER TTL688HDC... -

Page 18: Handle Controls

6.Unscrew and remove the fuel tank cap (12). 7.Fill correctly mixed fuel/oil into the tank using a fuel funnel fitted with a filter to avoid debris entering the tank. Do not overfill. Leave a minimum 5 mm of space between the top of the fuel and the inside edge of the tank (11) to allow for expansion (Fig. -

Page 19: General Operation

2.Set ignition switch (10) to “I” (ON) position. 3.Press the primer (13) 5-6 times. 4.Move the choke lever (16) to “ start” position. 5.Hold the top cover firmly with your left hand and put your right knee onto the rear handle (5). 26CC PETROL HEDGE TRIMMER TTL688HDC... - Page 20 6.Pull the recoil starter handle (4) lightly until you feel resistance, then pull it briskly 3-4 times. The engine would normally not start at this stage. WARNING! Allow the rope to return slowly and in a controlled manner each time it is pulled! 7.Move the choke lever (16) to “...

- Page 21 1.Cut and remove branches exceeding the cutting capacity of this product using a proper pruner before operation. 2.Adjust the handle so that it fits the intended cut. WARNING! When operating the product, keep the exhaust outlet (20) away from your body (Fig. 15-20). 26CC PETROL HEDGE TRIMMER TTL688HDC...

- Page 23 NOTE: When shaping it is advisable to achieve a trapezoidal shape (Fig. 23). A trapezoidal cut corresponds to the natural growth of plants and results in optimal hedge growth, as it will expose more light to the lower end of the hedge. Fig.23 26CC PETROL HEDGE TRIMMER TTL688HDC...

-

Page 24: After Use

WARNING! TO STOP THE ENGINE IN AN EMERGENCY: Press and hold the ignition switch (10) to “STOP” position until engine stops. AFTER USE 1.Switch the product off, allow the engine to cool down and then remove the spark plug connector. 2.Check, clean and store the product as described below. -

Page 25: Maintenance And Care

1.Keep the cutting device (1) clean and free of debris. Remove trimmings 2.Apply a small amount of suitable lubricant on the cutting device (1) to retain a good cutting performance (Fig. 24). 26CC PETROL HEDGE TRIMMER TTL688HDC... -

Page 26: Air Filter

3.Keep the cutting device (1) sharp. Have a worn or damaged cutting device replaced with a new one of the same type by a qualified specialist. 4.Tighten loose nuts on the cutting device (1) with a proper wrench with 5 N.m min, 7 N.m max. to ensure safe operation of your product (Fig. -

Page 27: Fuel Filter

5.Remove debris from the electrode with a soft wired brush; avoid heavy cleaning of the electrode. 6.Dry the spark plug (18) with a soft cloth if it is wet from fuel. 7.Check the spark plug gap; it should be 0.6 – 0.7 mm (Fig. 29). 26CC PETROL HEDGE TRIMMER TTL688HDC... - Page 28 8.Replace with a new spark plug (18) if either the electrode or the insulation is damaged. 9.When replacing the spark plug (18) first screw it in hand tight and then lightly tighten it with the multi tool (24). GEAR BOX 1.Lubricate the gear box every 30 hours or more frequent at heavy use.

- Page 29 26CC PETROL HEDGE TRIMMER TTL688HDC...

-

Page 30: Recycling And Disposal

STORAGE 1.Drain all fuel from tank into a container. Run engine until it stops. Always drain the fuel tank outdoors. 2.Switch the product off and disconnect the spark plug connector. 3.Clean the product as described above. 4.Attach the blade cover. 5.Store the product and its accessories in a dry, frost-free place. -

Page 31: Troubleshooting

1. Engine does not start 2. Engine stops 3. Engine starts but will not accelerate 4. Engine does not reach full speed and emits excessive smoke 5. Unsatisfactory result 6.Excessivevibration /noise or exhaust 26CC PETROL HEDGE TRIMMER TTL688HDC... - Page 32 Kingfisher International Products B.V. Rapenburgerstraat 175E 1011 VM Amsterdam The Netherlands EN ISO 10517:2019 EN ISO 14982:2009 The RoHS Directive 2011/65/EU and its amendments (EU) 2015/863 and (EU)2017/2102 The Regulation of Non-Road Mobile Machinery Emissions (EU) 2016/1628, and its supplemented regulations Engine model number: SL34 03/09/2019 Eric Capotummino / Group Quality Director...