Table of Contents

Advertisement

Quick Links

Operator's Manual

Vantage

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

IM10494

| Issue D ate Jun-18

© Lincoln Global, Inc. All Rights Reserved.

®

435

For use with machines having Code Numbers:

12851

Need Help? Call 1.888.935.3877

to talk to a Service Representative

Hours of Operation:

8:00 AM to 6:00 PM (ET) Mon. thru Fri.

After hours?

Use "Ask the Experts" at lincolnelectric.com

A Lincoln Service Representative will contact you

no later than the following business day.

For Service outside the USA:

Email: globalservice@lincolnelectric.com

Advertisement

Table of Contents

Summary of Contents for Lincoln Electric Vantage 435

- Page 1 Operator’s Manual ® Vantage For use with machines having Code Numbers: 12851 Need Help? Call 1.888.935.3877 Register your machine: to talk to a Service Representative www.lincolnelectric.com/register Authorized Service and Distributor Locator: Hours of Operation: www.lincolnelectric.com/locator 8:00 AM to 6:00 PM (ET) Mon. thru Fri. Save for future reference After hours? Use “Ask the Experts”...

- Page 2 THANK YOU FOR SELECTING A QUALITY PRODUCT BY KEEP YOUR HEAD OUT OF THE FUMES. DON’T get too close to the arc. LINCOLN ELEC TRIC. Use corrective lenses if necessary to stay a reasonable distance away from the arc. READ and obey the Safety Data PLEASE EXAMINE CARTON AND EQUIPMENT FOR Sheet (SDS) and the warning label DAMAGE IMMEDIATELY...

- Page 3 W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 2.d. All welders should use the following procedures in order to 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199.

- Page 4 SAFETY ELECTRIC SHOCK ARC RAYS CAN BURN. CAN KILL. 3.a. The electrode and work (or ground) circuits are 4.a. Use a shield with the proper filter and cover plates to protect your electrically “hot” when the welder is on. Do eyes from sparks and the rays of the arc when welding or not touch these “hot”...

- Page 5 SAFETY WELDING AND CUTTING CYLINDER MAY EXPLODE IF SPARKS CAN CAUSE DAMAGED. FIRE OR EXPLOSION. 7.a. Use only compressed gas cylinders containing the correct shielding gas for the process used 6.a. Remove fire hazards from the welding area. If and properly operating regulators designed for this is not possible, cover them to prevent the welding sparks the gas and pressure used.

- Page 6 VANTAGE ® TABLE OF CONTENTS...

-

Page 7: Table Of Contents

VANTAGE ® TABLE OF CONTENTS Page Ground Stud .............B-8 Diagnostic Plug . - Page 8 VANTAGE ® NOTES...

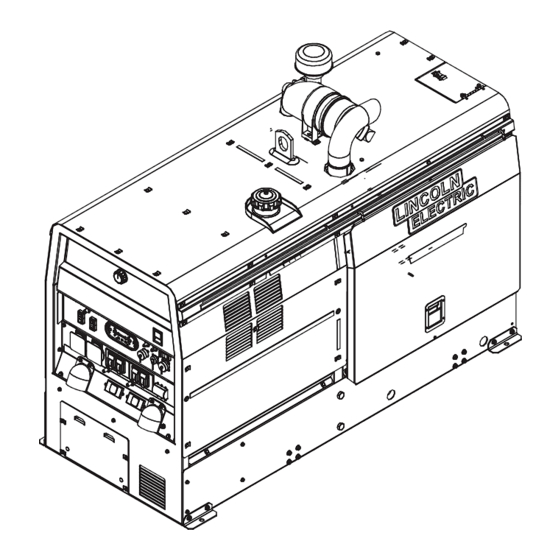

- Page 9 VANTAGE ® INSTALLATION GENERAL DESCRIPTION OUTPUT @ 104°F(40°C) - WELDER AND GENERATOR The Vantage ® 435 is a diesel engine-driven welding power Welding Range source. The machine uses a brush type alternating current gener- 30 - 520 Amps CC/CV ator for DC multi-purpose welding, for 120/240 VAC single phase and 240V three phase auxiliary standby power.

- Page 10 VANTAGE ® INSTALLATION SAFETY PRECAUTIONS With the VRD switch in the “OFF” position, the VRD lights are deactivated. WARNING FIGURE A.1 Do not attempt to use VANTAGE® 435 until you have thor- oughly read all operating and maintenance manuals supplied REMOVE 4 FRONT with your machine.

- Page 11 VANTAGE ® INSTALLATION ANGLE OF OPERATION HIGH TEMPERATURE OPERATION ® To achieve optimum engine performance the Vantage At temperatures above 104°F (40°C), output voltage derating may should be run in a level position. The maximum angle of operation be necessary. For maximum output current ratings, derate welder for the Deutz engine is 15 degrees in all directions.

- Page 12 VANTAGE ® INSTALLATION TOWING ® The Vantage 435 is shipped with the engine crankcase filled with high Use a recommended trailer for use with Vantage® 435 for road, in- quality SAE 10W-30 Oil that meets classification CJ-4 for diesel engines. plant and yard towing by a vehicle(1).

- Page 13 VANTAGE ® INSTALLATION AIR CLEANER INSTALL EXHAUST OUTLET PIPE All parts below are shipped with the machine in a separate box Remove cap from DPF outlet pipe protruding from roof. attached to the crate.(See Figure A.2) Using the clamp provided secure the exhaust outlet pipe to the •...

- Page 14 VANTAGE ® INSTALLATION REMOTE CONTROL Warm Starting Procedure (See Figure B.3) This Vantage ® 435 is equipped with a 12-pin and a 14-pin con- 1. Same as steps 1 and 2 from cold start procedure. nector, along with a wireless remote control. To enable remote 2.

- Page 15 VANTAGE ® INSTALLATION For operation with a control cable wire feeder: TABLE A.2 With the CV-WIRE weld mode selector switch position and the OUTPUT CABLE GUIDELINES WELD TERMINALS ON switch in the REMOTE position, remote Percent Duty CABLE SIZES FOR COMBINED LENGTHS OF ELECTRODE AND WORK Amperes setting of the preset arc voltage is set through the 14 pin connec- Cycle...

- Page 16 VANTAGE ® INSTALLATION MACHINE GROUNDING FIGURE A.3 Because this portable engine driven welder creates its own power, it is AUXILIARY POWER RECEPTACLES not necessary to connect its frame to an earth ground, unless the machine is connected to premises wiring (home, shop, etc.). To prevent dangerous electric shock, other equipment powered by this engine driven welder must: a) be grounded to the frame of the welder using a grounded type...

- Page 17 VANTAGE ® INSTALLATION STANDBY POWER CONNECTIONS The Vantage ® 435 is suitable for temporary, standby or emer- 2. Take necessary steps to assure load is limited to the capacity of gency power using the engine manufacturer’s recommended the Vantage ® 435 by installing a 50 amp, 240 VAC double pole maintenance schedule.

- Page 18 VANTAGE ® INSTALLATION CONNECTION OF WIRE FEEDERS WITH CONTROL FIGURE A.5 CABLE (14 PIN) Set Polarity to WARNING match electrode Set to polarity Remote Shut off welder before making any electrical connections. Set weld terminals to ------------------------------------------------------------------ remotely controlled CONNECTION OF LF-72, LF-74, FLEX FEED 74 HT, Set to FLEX FEED 84, LN-25 PRO DUAL POWER TO THE Set mode to...

- Page 19 VANTAGE ® INSTALLATION CONNECTION OF ACROSS THE ARC WIRE FEEDERS FIGURE A.7 TO THE VANTAGE ® These connections instructions apply to both the LN-25 Pro and Activ8 models. These feeders have an internal contactor and the electrode is not energized until the gun trigger is closed. When the gun trigger is closed the wire will begin to feed and the welding process is started.

- Page 20 VANTAGE ® INSTALLATION CABLE INDUCTANCE AND ITS EFFECTS ON CONTROL CABLE CONNECTIONS WELDING General Guidelines Excessive cable inductance will cause the welding performance to Genuine Lincoln control cables should be used at all times (except degrade. There are several factors that contribute to the overall where noted otherwise).

- Page 21 VANTAGE ® NOTES A-13...

- Page 22 VANTAGE ® OPERATION OPERATION SAFETY INSTRUCTIONS RECOMMENDED APPLICATIONS Read and understand this entire section before operating WELDER your VANTAGE ® 435. The Vantage ® 435 provides excellent constant current DC welding WARNING output for stick (SMAW) and TIG (GTAW) welding. The Vantage ®...

- Page 23 VANTAGE ® OPERATION CONTROLS AND SETTINGS All welder and engine controls are located on the case front panel. Refer to Figure B.3 and the explanations that follow. FIGURE B.3 CASE FRONT PANEL CONTROLS ENGINE CONTROLS 1. STOP / (LOW IDLE/RUN) / (HIGH IDLE/RUN) SWITCH a.

- Page 24 VANTAGE ® OPERATION Idler Operational exceptions 4. OUTPUT CONTROL- The OUTPUT dial is used to preset the output voltage or current as displayed on the digital meters for When the WELDING TERMINALS switch is in the “Remotely the five welding modes. Controlled”...

- Page 25 VANTAGE ® OPERATION 6. DIGITAL OUTPUT METERS- The digital meters allow the preset arc voltage (CV-WIRE mode) or preset arc current (CC- STICK, DOWNHILL PIPE, ARC GOUGING and TIG modes) to be set prior to welding using the OUTPUT control dial. During welding, the meter display the actual output voltage (VOLTS) and current (AMPS).

- Page 26 VANTAGE ® OPERATION • Alternate CV mode selection. Default CV mode will be non-syner- gic FCAW-SS (mode 6). Alternate settings will be non-synergic GMAW (mode 5) and non-synergic FCAW-GS (mode 7). The left display will show “CV” and “type” alternately at 0.5 second intervals.

- Page 27 VANTAGE ® OPERATION • Test Modes for grid load testing. The left display will show “tESt” and “LoAd” alternately at 0.5 second intervals. The right display will show “CC” (mode 200)(Figure B.11), “CV” (mode 201)(Figure B.12) or “OFF” (normal operation)(Figure B.13). This setting is not remembered between machine power cycles and will default to OFF at each power on.

- Page 28 VANTAGE ® OPERATION 7. WELD TERMINALS ON SWITCH 13. 12-PIN CONNECTOR Output is enabled when in the ON position. Output is remotely controlled For attaching optional remote control equipment. The ® when in the REMOTE position. This control is not active in ArcLink K2909-1 (12-pin to 6-pin) adapter cable is included for modes.

-

Page 29: 25. Ground Stud

VANTAGE ® OPERATION 18. 20A 120V AUXILIARY BREAKERS 24. CIRCUIT BREAKERS These circuit breakers provide separate overload current pro- 19. 50A 240V 3 PHASE BREAKER tection for each 120V circuit at the 240V single phase recepta- cle, each 120V single phase receptacle, the 240V three phase receptacle, the 120VAC in the 14-Pin connector, the 42VAC in 20. -

Page 30: 30. Status Led

VANTAGE ® OPERATION 30. STATUS LED (See Table B.1a) Status The status LED indicates system status. Normal oper- ation is a steady green light. Note: During normal power-up, the LED may flash red and/or green as the equipment performs self tests. -

Page 31: Welder Operation

VANTAGE ® OPERATION WELDER OPERATION TOUCH START TIG MODE The Vantage ® 435 can be used in a wide variety of DC TIG welding DUTY CYCLE applications. Duty cycle is the percentage of time the load is being applied in a 10 The TOUCH START TIG setting of the MODE switch is for DC TIG (Tungsten minute period. -

Page 32: Common Welding Procedures

If a length. Trim is adjustable from 0.50 to 1.50. 1.00 is the nominal special weld mode is desired, contact the local Lincoln Electric sales setting and is a good starting point for most conditions. - Page 33 VANTAGE ® OPERATION Most pulse welding programs are synergic. As the wire feed speed is adjusted, the Vantage ® 435 will automatically recalculate the waveform parameters to maintain similar arc properties. The Vantage ® 435 utilizes “adaptive control” to compensate for changes in the electrical stick-out while welding.

-

Page 34: Typical Current Ranges For Tungsten Electrodes

VANTAGE ® OPERATION SETTINGS WHEN USING THE K930-2 TIG MODULE • Set the WELD MODE switch to the “Touch Start TIG Setting”. • Set the STOP/AUTO IDLE/HIGH IDLE switch to the “AUTO/RUN” position. • Set the WELDING TERMINALS switch to the “Remotely Controlled”... -

Page 35: Cv-Wire Mode

VANTAGE ® OPERATION CV-WIRE MODE PARALLELING ® Connect a wire feeder to the Vantage 435 and set welder con- When paralleling machines in order to combine their outputs, all trols according to the instructions listed earlier in this section. units must be operated in the CC-STICK mode at the same output settings. - Page 36 VANTAGE ® OPERATION TABLE B.5 VANTAGE ® 435 DEUTZ SIMULTANEOUS WELDING AND POWER LOADS WELD 1 PHASE 3 PHASE BOTH 1 AND 3 PHASE AMPS WATTS AMPS WATTS AMPS WATTS AMPS 11,000 17,000 11,000 ------ 11,000 15,400 11,000 ------ PLUS 8000 13,000 8000...

- Page 37 VANTAGE ® OPERATION The following additional modes can be accessed via an ArcLink feeder Synergic CV Modes Metal Dia. Steel Stainless Core Flux Core Aluminum Argon Argon Argon inches Tri -Mix Argon Mix 4043 5356 .030 • • • • .035 •...

-

Page 38: Accessories

Example: DC+ stick root pass on pipe and DC- Innershield ® self-shielded flux-cored wire for hot, fill and cap passes. 6 and 14-pin remote connec- tions can be made to this unit. For all Lincoln Electric Chopper Technology ® engine-driven welders. Mounts on roof with K2663-1 Docking Kit. K2642-1... -

Page 39: Wire Feeder Options

VANTAGE ® ACCESSORIES WIRE FEEDER OPTIONS ™ LN-25 IRONWORKER WIRE FEEDER Portable CV unit for flux-cored and mig welding with maxtrac ® wire drive system. includes digital meters for wire feed speed/amperage and voltage, gas solenoid, internal contactor and 5/64 in. (2.0 mm) drive roll kit for cored wire. -

Page 40: Maintenance

VANTAGE ® MAINTENANCE MAINTENANCE AIR FILTER SAFETY PRECAUTIONS WARNING CAUTION • Have a qualified technician do the maintenance and trou- • Excessive air filter restriction will result in reduced engine bleshooting work. life. • Turn the engine off before working inside the machine. WARNING •... - Page 41 VANTAGE ® MAINTENANCE Service Instructions Service Instructions Single- and Two-Stage Engine Air Cleaners Single- and Two-Stage Engine Air Cleaners Inspect the New Filter for Damage Inspect the New Filter for Damage Remove the Filter Remove the Filter Inspect the new filter carefully, paying attention to Unfasten or unlatch the the inside of the open end, which is the service cover.

-

Page 42: Fuel Filters

VANTAGE ® MAINTENANCE FUEL FILTERS BATTERY HANDLING WARNING WARNING When working on the fuel system GASES FROM BATTERY can explode. • Keep sparks, flame and cigarettes away from • Keep naked lights away, do not smoke! battery. • Do not spill fuel! ------------------------------------------------------------------ To prevent EXPLOSION when: The Vantage... -

Page 43: Charging The Battery

VANTAGE ® MAINTENANCE CHARGING THE BATTERY WELDER / GENERATOR MAINTENANCE When you charge, jump, replace, or otherwise connect battery STORAGE cables to the battery, be sure the polarity is correct. Improper Store the Vantage ® 435 in a clean, dry protected areas. polarity can damage the charging circuit. - Page 44 VANTAGE ® MAINTENANCE FIGURE D.2 Green Light GFCI TESTING AND RESETTING PROCEDURE The GFCI should be properly tested at least once every month or whenever it is tripped. To properly test and reset the GFCI: • If the GFCI has tripped, first carefully remove any load and check it for damage.

-

Page 45: Troubleshooting

HOW TO USE TROUBLESHOOTING GUIDE WARNING Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. - Page 46 VANTAGE ® TROUBLE SHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION ENGINE PROBLEMS Major Physical or Electrical Damage . Contact your Local Lincoln is Evident. Authorized Field Service Facility. Engine will not crank 1.

- Page 47 VANTAGE ® TROUBLE SHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION Battery does not stay charged. 1. Faulty battery. 2. Faulty engine alternator. 3. Loose or broken lead in charging circuit. 4.

- Page 48 VANTAGE ® TROUBLE SHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION FUNCTION PROBLEMS Engine goes to low idle but does not 1. Faulty Weld Control PCB or Idler stay at low idle. relay.

- Page 49 VANTAGE ® WIRING DIAGRAMS DIAGRAMS...

- Page 50 VANTAGE ® CONNECTION DIAGRAMS...

- Page 51 VANTAGE ® CONNECTION DIAGRAMS...

- Page 52 VANTAGE ® CONNECTION DIAGRAMS...

- Page 53 VANTAGE ® CONNECTION DIAGRAMS...

- Page 54 VANTAGE ® CONNECTION DIAGRAMS...

- Page 55 VANTAGE ® CONNECTION DIAGRAMS...

- Page 56 VANTAGE ® DIMENSION PRINT...

- Page 57 VANTAGE ® NOTES General Description COOLING SYSTEM STORING BATTERY HANDLING HIGH TEMPERATURE OPERATION WELDING OUTPUT CABLES CHARGING THE BATTERY OPERATION NAMEPLATES / WARNING DECALS MAINTENANCE RECOMMENDED APPLICATIONS STORAGE WELDER CLEANING GENERATOR BRUSH REMOVAL AND REPLACEMENT ENGINE CONTROLS TROUBLESHOOTING DUTY CYCLE DIAGRAMS STICK WELDING MODE TOUCH START TIG MODE...

- Page 58 WARNING Do not touch electrically live parts or Keep flammable materials away. Wear eye, ear and body protection. electrode with skin or wet clothing. Insulate yourself from work and AVISO DE ground. Spanish PRECAuCION No toque las partes o los electrodos Mantenga el material combustible Protéjase los ojos, los oídos y el bajo carga con la piel o ropa moja-...

- Page 59 WARNING Keep your head out of fumes. Turn power off before servicing. Do not operate with panel open or Use ventilation or exhaust to guards off. remove fumes from breathing zone. AVISO DE Spanish PRECAuCION Los humos fuera de la zona de res- Desconectar el cable de ali- No operar con panel abierto o piración.

- Page 60 Lincoln Electric for advice or information about their use of our products. We respond to our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such information or advice.