Table of Contents

Advertisement

Quick Links

Instruction Manual

D102178X012

May 2010

Fisherr V260 Rotary Pipeline Ball Valve

Contents

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

Scope of Manual

This instruction manual provides installation,

operation, maintenance, and parts information for

the Fisher V260 control valve. Refer to separate

manuals for information concerning the actuator,

positioner, and accessories (see figure 1).

Do not install, operate, or maintain a V260 valve

without being fully trained and qualified in valve,

actuator, and accessory installation, operation, and

maintenance. To avoid personal injury or property

damage, it is important to carefully read, understand,

and follow all the contents of this manual, including

all safety cautions and warnings. If you have any

questions about these instructions, contact your

Emerson Process Management sales office before

proceeding.

www.Fisher.com

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . .

1

1

1

2

2

4

5

5

5

6

8

10

10

10

10

12

W6365-2/IL

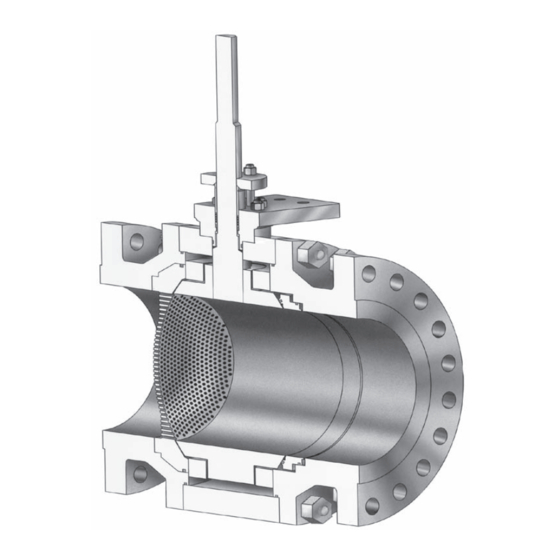

Figure 1. Fisher V260 Sectional View

Description

V260 throttling ball valves are available in

single-seal, double block-and-bleed, dual-seal, and

bidirectional flow constructions with or without

attenuators. Valves with dome-style attenuators

combine the efficiency of a rotary valve with the

noise reducing capability of a special trim (figure 4).

Valves without attenuators present little or no

restriction to flow at full travel.

V260 Valve

Advertisement

Table of Contents

Summary of Contents for Emerson Fisher V260

-

Page 1: Table Of Contents

Introduction Scope of Manual This instruction manual provides installation, operation, maintenance, and parts information for the Fisher V260 control valve. Refer to separate manuals for information concerning the actuator, W6365-2/IL positioner, and accessories (see figure 1). Figure 1. Fisher V260 Sectional View... -

Page 2: Specifications

1. The pressure-temperature limits in this instruction manual and any applicable standard or code limitation for valve should not be exceeded. 2. PTFE stands for Polytetrafluorethylene, and PEEK stands for Polyetheretherketone. 3. Temperature limits of PTFE/PEEK is limited due to standard nitrile O-ring. Contact your Emerson Process Management sales office for higher temperature options, up to 232_C (450_F). Installation... - Page 3 Note D Check with your process or safety Standard Fisher V260 valve packings engineer for any additional measures (key 105) are composed of: that must be taken to protect against D Conductive packing ring (graphite process media.

-

Page 4: Maintenance

Instruction Manual V260 Valve May 2010 D Do not remove the actuator from the valve while the valve is still pressurized. D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal injury. D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. -

Page 5: Packing Maintenance

Instruction Manual V260 Valve May 2010 D Avoid injury by keeping hands, lines (or other power source) to the power actuator, release pressure from the actuator, and disconnect tools, and other objects away from the the pressure lines from the actuator. Use lock-out ball while stroking the valve. -

Page 6: Seal Ring Maintenance

Instruction Manual V260 Valve May 2010 Figure 3. Packing Arrangement Details a. If the packing housing (key 16) is mounted 2. For standard packing arrangements, install the on the valve: Use a formed wire hook with a new packing parts using the parts sequence shown sharp end to pierce the packing rings, and pull in figure 3. - Page 7 Instruction Manual V260 Valve May 2010 from the valve body cavity. If a. If the valve does not have an attenuator dome, lift the valve and place it on its side with either necessary, disassemble the valve in a tailpiece flange resting on the flat surface. Be safe area for cleaning.

-

Page 8: Assembly

Instruction Manual V260 Valve May 2010 the attenuator dome from rotating with respect to the WARNING tailpiece. 3. Install the inlet end attenuator dome (key 28 In the next step, be sure to secure the or 10) into the tailpiece (key 6). Use the lifting lugs in bearing plates on the ball to prevent the two threaded holes for ease of handling. - Page 9 Instruction Manual V260 Valve May 2010 8. Lift the ball with a nylon sling through the bore Table 3. Torque Values and turn the ball until the port and trunnions are VALVE BODY MOUNTING VALVE horizontal. HEX NUT FLANGE HEX PRESSURE SIZE, (KEY 19)

-

Page 10: Actuator Mounting

Always refer to the valve requirements could damage the valve serial number when corresponding with your and impair safe operation. Emerson Process Management sales office 26. Refer to the Packing Maintenance section to regarding spare parts or technical information. When install the packing parts. - Page 11 Instruction Manual V260 Valve May 2010 E0816 HI-DENSITY CHARACTERIZED ATTENUATOR ATTENUATOR Figure 4. Ball Attenuator Construction Details E0817 Figure 5. Exploded View of Dome, Ball, Tailpiece and Bearing Plates...

-

Page 12: Parts List

If you need a valve body as a replacement part, order the NPS 16 1C7729X0012 valve size, pressure rating, serial number, and desired NPS 20 17B7413X012 material. Contact your Emerson Process Management NPS 24 17B7413X012 sales office. Body Hex Nut Drive Shaft Inlet Tailpiece Actuator Mounting Cap Screw (4 req’d) - Page 13 Instruction Manual V260 Valve May 2010 Description Part Number Description Ball Thrust Washer (2 req’d) Packing Stud (2 req’d for NPS 8 12, 4 req’d for NPS 8 17B1342X012 NPS16 24) NPS 10 17B1344X012 Packing Nut (2 req’d for NPS 8 12, 4 req’d for NPS 12 17B1346X012 NPS16 24)

- Page 14 Instruction Manual V260 Valve May 2010 Keys 10* & 28* Attenuator Dome, S17400 SST ATTENUATOR DOME PART NUMBER VALVE SIZE, Key 28 For single seal constructions Key 10 For dual seal constructions VALVE Characterized High Density Characterized High Density 47B1312X012 47B1309X012 48B0916X012 48B0915X012...

- Page 15 Instruction Manual V260 Valve May 2010 STANDARD FLOW DIRECTION ATTENUATOR DOME WITH NO SEAL NOTE: KEY NUMBERS 25, 33, AND 34 ARE NOT SHOWN. 54B9811-D/DOC Figure 6. Fisher V260 Valve Assembly...

- Page 16 May 2010 Fisher and ENVIRO SEAL are marks owned by one of the companies in the Emerson Process Management business division of Emerson Electric Co. Emerson Process Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.