Advertisement

Quick Links

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

Visit the Viking website for the latest edition of this technical data page www.vikinggroupinc.com

1. DESCRIPTION

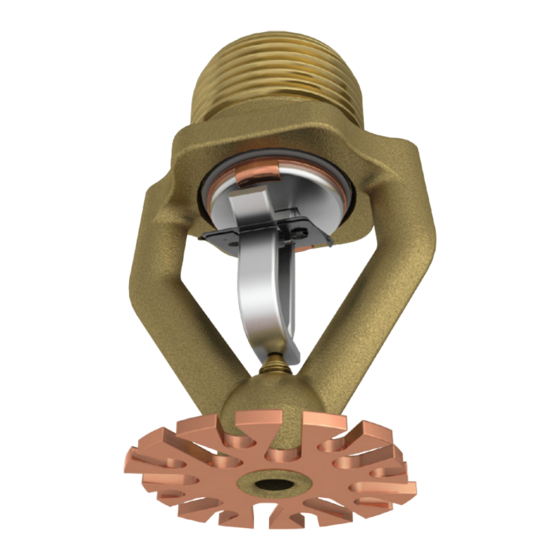

Viking Early Suppression Fast Response (ESFR) Pendent Sprinkler VK514

incorporates the capability to suppress specific high-challenge fires. The larger

K-Factor allows protection of higher hazard commodities at greater ceiling heights

with lower end-head pressures. K28.0 sprinklers can:

• Provide flexibility of fire protection designs.

• Eliminate the use of in-rack sprinklers when protecting high piled storage of

certain specified materials up to:

UL (Refer to Table 4): 43 ft. (13,1 m) with ceilings up to 48 ft. (14,6 m)*

FM (Refer to Table 5): 50 ft. (15,2 m) with ceilings up to 55 ft. (16,76 m)*

NFPA 13 (Refer to Table 6): The VK514 is a Special Sprinkler as defined by

the National Fire Protection Association (NFPA 13, 2022 Ed.-Section 15.2).

Viking ESFR Pendent Sprinklers VK514 are primarily intended to protect the

following types of storage, which tend to produce severe-challenge fires: palletized

and solid pile storage and single, double, and portable open rack storage (no

open-top containers or solid shelves). The VK514 is listed to utilize a minimum

aisle width of 6'-0" (UL - 43' storage or FM - 45' storage) or 8'-0" (FM - 50' storage).

Viking ESFR Pendent Sprinklers VK514 provide protection of most common

storage materials, including:

• Encapsulated or unencapsulated Class I, II, III, and IV commodities*.

• UL Listed for protection of cartoned nonexpanded** Group A plastic

commodities*.

• FM Approved for protection of cartoned unexpanded** plastic commodities.*

* Refer the Approval Chart and Commodity Selection and Design Criteria Overview for Listing

and Approval requirements that must be followed.

** The terms nonexpanded and unexpanded are equivalent.

2. LISTINGS AND APPROVALS*

UL Listed: Category VNWH (Listed as an ESFR Sprinkler)

FM Approved: Class 2035

* Refer the Approval Chart and Commodity Selection and Design Criteria Overview for Listing and Approval requirements that must be followed.

3. PATENT INFORMATION

Please refer to PATVK.COM for all appropriate patents and patent information pertaining to the Model VK514 ESFR Sprinkler.

4. TECHNICAL DATA

Specifications:

Maximum Working Pressure: 175 psi (12 bar). Factory tested hydrostatically to 500 psi (34.5 bar).

Thread size: 1" NPT or 25 mm BSPT (Refer to Table 2)

Nominal K-factor: 28.0 U.S. (404 metric*)

* Metric K-factor measurement shown is in bar. When pressure is measured in kPa, divide the metric K-factor shown by 10.0.

Overall Length: 3-3/16" (81 mm)

Deflector Diameter: 1-3/4" (45 mm)

Material Standards:

Frame Casting: Brass UNS-C84400 or CW602N

Deflector: Phosphor Bronze UNS-C51000

Seat: Copper UNS-C11000 and Stainless Steel UNS-S30400

Belleville Spring Sealing Assembly: Nickel Alloy, coated on both sides with PTFE Tape

Compression Screw: Stainless Steel UNS-S31603

Trigger and Support: Stainless Steel UNS-S31600

Fusible Element Assembly: Beryllium nickel coated with a black epoxy, polyurethane (FM only), or acrylic paint

Ordering Information: Refer to Table 2

Form No. F_102422

Rev 01

TECHNICAL BULLETIN

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

45 ft. (13,5 m) with ceilings up to 50 ft. (15,2 m)*

October 2022

OR

ESFR PENDENT SPRINKLER

UL: SPECIFIC APPLICATION ESFR SPRINKLER

FM: STORAGE SPRINKLER

NFPA: SPECIAL SPRINKLER

VK514 (K28.0)

TABLE 1

SPRINKLER GENERAL INFORMATION

Item

Sprinkler Identification

Number (SIN)

K-factor, gpm/psi

(lpm/bar

)

½

½

Thread Size

Sprinkler Orientation

Maximum Working Pressure

Page 1 of 6

Description

VK514

28.0 (404)

1" NPT (25 mm)

Pendent

175 psi (12 bar)

Advertisement

Summary of Contents for Viking VK514

- Page 1 * Refer the Approval Chart and Commodity Selection and Design Criteria Overview for Listing and Approval requirements that must be followed. 3. PATENT INFORMATION Please refer to PATVK.COM for all appropriate patents and patent information pertaining to the Model VK514 ESFR Sprinkler. 4. TECHNICAL DATA Specifications: Maximum Working Pressure: 175 psi (12 bar).

-

Page 2: Installation

D. Use ONLY sprinkler wrench 13635W/B (shown in Figure 1) for installing VK514. With the sprinkler contained in the protective cap, install the sprinkler onto the piping by applying the sprinkler wrench to the sprinkler wrench flats only, while taking care not to damage the sprinkler operating parts. - Page 3 Refer to the Authorities Having Jurisdiction for minimum replacement requirements. 8. AVAILABILITY The Viking Model VK514 Sprinkler is available through a network of domestic and international distributors. See The Viking Corporation web site for the closest distributor or contact The Viking Corporation. 9. GUARANTEE For details of warranty, refer to Viking’s current list price schedule or contact Viking directly.

- Page 4 VK514 (K28.0) The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058 Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com Visit the Viking website for the latest edition of this technical data page www.vikinggroupinc.com Wrench Flat Protective Sprinkler 1-9/16”...

- Page 5 The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058 Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com Visit the Viking website for the latest edition of this technical data page www.vikinggroupinc.com TABLE 4: COMMODITY SELECTION AND DESIGN CRITERIA OVERVIEW FOR...

- Page 6 The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058 Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com Visit the Viking website for the latest edition of this technical data page www.vikinggroupinc.com TABLE 6: COMMODITY SELECTION AND DESIGN CRITERIA OVERVIEW FOR...