Table of Contents

Summary of Contents for AirSep AS-20

- Page 1 Suggested List Price $75.00 (U.S.D.) ® AirSep Corporation PSA Oxygen Generator Models AS-20–1000 Instruction Manual MN011-1 A12/02 ® Corporation • 260 Creekside Drive • Buffalo, NY 14228-2075 USA AirSep Phone: (716) 691-0202 • Fax: (716) 691-1255...

- Page 3 Ownership Data ® Please take a moment to note below important information about your AirSep Corporation PSA Oxygen Generator. Retain this instruction manual, along with your invoice, to serve as a permanent record of your purchase. PSA Oxygen Generator Model Number:...

-

Page 5: Table Of Contents

4.1.2 Enclosure 4.1.3 Control Panel 4.1.4 Connections Manifold Components...............4-4 Installation ..................5-1 Handling and Unpacking..............5-1 Pre-installation Guidelines ..............5-2 Installation Instructions ..............5-3 Operation ..................6-1 Initial Start-up..................6-1 Operation ..................6-3 Shutdown..................6-3 Normal Start-up ................6-4 AS-20—1000 Instruction Manual table of contents - i... - Page 6 Product Warranty..................B-1 Limits of Liability ..................B-2 Returning the Oxygen Generator or a Component for Service ....B-2 Appendix Parts List................ C-1 AS-20 Parts ....................C-2 AS-45 Parts ....................C-3 AS-80 Parts ....................C-4 AS-160 Parts ....................C-5 AS-250 Parts ....................C-6 AS-450 Parts ....................

- Page 7 Figure 5-2 120 Gallon Oxygen Receiver ........... 5-5 Figure 7-1 Interior View of AS-45 and AS-80 Models ......7-3 Figure 1 General Arrangement Drawing – AS-20 ........ A-11 Figure 2 Flow Schematic – AS-20 ............A-12 Figure 3 Electrical Schematic – AS-20 (120V)........A-13 Figure 4 Electrical Schematic –...

- Page 8 Figure 16 Electrical Schematic – AS-450 through AS-750 (220V) ..A-23 Figure 17 General Arrangement Drawing– AS-1000 ......A-24 Figure 18 Electrical Schematic – AS-1000 (120V)......... A-25 Figure 19 Electrical Schematic – AS-1000 (220V)......... A-25 Figure 20 Flow Diagram – AS-1000............A-26 ii - list of illustrations AS-20—1000 Instruction Manual...

-

Page 9: Introduction

750, and AS-1000, as well as instructions for their installation, operation, and maintenance. The Appendix of this instruction manual also includes pertinent drawings and component literature. To ensure safe operation and proper maintenance of the oxygen generator, AirSep Corporation recommends that you keep this instruction manual readily available for reference. -

Page 10: Symbols

This instruction manual uses uppercase characters (e.g., ON/OFF switch) to refer to controls and indicators identified by tags or labels. Numbers inside parentheses (e.g., V-2) identify manually operated flow controls (e.g., manual valves). Refer to Chapter description oxygen generator components. AS-20—1000 Instruction Manual... -

Page 11: Safety

Oxygen is an invisible gas that is colorless, odorless, and tasteless. To ensure your safety, thoroughly read and familiarize yourself with this entire section of this instruction manual. In addition, AirSep Corporation strongly recommends that you review this section periodically. - Page 12 AirSep oxygen generators are sold for use in industrial applications only. Contact AirSep Corporation or an authorized AirSep representative before you use this unit for any medical application. Disconnect power before servicing oxygen generator.

-

Page 13: Safety Publications

Fire Protection Association; 1 Batterymarch Park; P.O. Box 9101; Quincy, Massachusetts 02269-9101 USA. “Oxygen;” Pamphlet G-4; Compressed Gas Association; 1725 Jefferson Davis Highway; Arlington, Virginia 22202-4102 USA. “Cleaning Equipment for Oxygen Service;” Pamphlet G-4.1; Compressed Gas Association; 1725 Jefferson Davis Highway; Arlington, Virginia 22202-4102 USA. AS-20—1000 Instruction Manual... -

Page 15: Plant Description

3.0 Plant Description General The AirSep Corporation PSA Oxygen Generator is a self-contained unit that utilizes Pressure Swing Adsorption (PSA) technology to produce oxygen on site. The oxygen generator uses compressed air as a feed gas to produce oxygen. The compressed air flows through a filter assembly before the air enters the adsorber vessels. -

Page 17: Component Descriptions

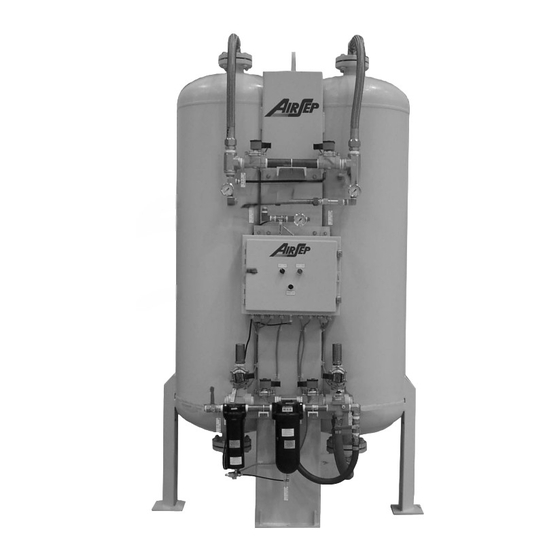

External Components Figure 4-1 below illustrates on two models the external components viewed from the front of the oxygen generator. Adsorbers Control Panel Enclosure AS-45 Model AS-750 Model Figure 4-1 External Components — Front View AS-20—1000 Instruction Manual... -

Page 18: Adsorbers

Examples of typical control panels are shown in figure 4-3. Not all components are available on every generator. On the AS-450 through AS-1000 models, the gauges are mounted directly on the manifolds and the hour meter is inside the control panel. AS-20—1000 Instruction Manual... -

Page 19: Connections

The manual drain button allows you to operate the automatic drain valve manually at any time during operation. Hour Meter (Not available on AS-20 model) The hour meter indicates the total number of hours the oxygen generator cycles. -

Page 20: Manifold Components

Coalescing Filter Muffler Feed Air Valves Manual Filter outlet Valve Equalization Valves Waste Valves Manual Air Inlet Pressure Switch Valve Product Valve Check Valves Flow Controller Filter Drain Valve Figure 4-3 Manifold Components — AS-160 and AS-250 Models AS-20—1000 Instruction Manual... - Page 21 The automatic feed air valves control the flow of the feed air as the air enters the adsorbers. Automatic Product Valve The automatic product valve controls the flow of product oxygen from the adsorbers. Automatic Waste Valves The automatic waste valves control the flow of waste gas as it exits the adsorbers. AS-20—1000 Instruction Manual...

- Page 22 Feed Air Regulator The feed air regulator is set at the AirSep Corporation factory. The feed air regulator controls the amount of air pressure at which the oxygen generator cycles.

- Page 23 The relief valves, one on each adsorber, ensure that the pressure in the adsorbers does not exceed the rated maximum pressure of the adsorbers. Transformer The transformer provides the proper voltage for the electrical components of the oxygen generator. AS-20—1000 Instruction Manual...

-

Page 25: Installation

5.0 Installation Handling and Unpacking AirSep Corporation ships the oxygen generator on a wooden skid covered by a container. The container also includes an accessory box containing all the accessories for the unit and an instruction manual needed to install the unit properly. -

Page 26: Pre-Installation Guidelines

(three feet)] to allow for cool air flow as well as to allow safe operation and maintenance. AirSep oxygen generators are sold for use in industrial applications only. Contact AirSep Corporation or an authorized AirSep representative before you use this unit for any medical application. AS-20—1000 Instruction Manual... -

Page 27: Installation Instructions

Refer to the Table 5.1 to determine the proper size for the feed air inlet connection and feed air hose for your model. AS-20—1000 Instruction Manual... - Page 28 1” NPT Female fitting next to V-2 1” ID minimum Table 5-1 Feed Air Connection Sizes and Hose Sizes Install your oxygen receiver. If AirSep Corporation provided your oxygen receiver, assemble the receiver as follows (See Figure 5-2.): AS-20—1000 Instruction Manual...

- Page 29 Connect the hex nipple to the oxygen outlet port on the oxygen receiver. Tighten the connection fully. Connect the oxygen regulator to the hex nipple at the oxygen outlet port on the oxygen receiver. Tighten the connection fully. AS-20—1000 Instruction Manual...

- Page 30 Teflon™ tape wrapping already applied. If AirSep Corporation did not provide your oxygen receiver, make sure your oxygen receiver is sized properly as specified in Appendix A of this instruction manual to meet the requirements of your oxygen generator model.

- Page 31 Provide proper voltage from a grounded outlet to the oxygen generator. Improper voltage causes damage not covered under the AirSep Corporation Product Warranty. The oxygen generator is now ready for operation. Refer to Chapter 6 of this instruction manual before you operate the oxygen generator.

-

Page 33: Operation

(refer to Figure 4-4 for location of valve). The manual product valve on these units has been configured to enable a predetermined amount of flow through the valve when closed. This allows the product pressure to build up even when the valve is closed. AS-20—1000 Instruction Manual... - Page 34 480 kPa (70 psig) and the peak cycle pressure should not exceed 480 kPa (70 psig). On the AS-450 through AS-1000 models, observe the readings on the two bed pressure gauges. AS-20—1000 Instruction Manual...

-

Page 35: Operation

Make sure the AUTO/MANUAL switch on the control panel is set to AUTO. Allow the oxygen receiver to repressurize fully. When the oxygen receiver repressurizes, after a time delay of five cycles, the oxygen generator stops cycling and the amber indicator light on the AUTO/MANUAL switch shuts off. AS-20—1000 Instruction Manual... -

Page 36: Normal Start-Up

Turn the oxygen generator off and disconnect power. Start-up after an Extended Shutdown After an extended shutdown or an unexpected shutdown, such as a loss of electrical power, you must purge the oxygen receiver of any low purity oxygen AS-20—1000 Instruction Manual... - Page 37 ® AirSep Corporation 12/02 before the oxygen generator can supply oxygen within purity specifications. To purge the oxygen receiver, follow all the steps in Section 6.1 — Initial Start-Up. AS-20—1000 Instruction Manual...

-

Page 39: Maintenance

Inspect the filter element(s). Replace any element(s) that appear damaged or excessively dirty. Reconnect the drain tubing to the bottom of the bowls. Add approximately two ounces of water to the filter bowls. Re-install the filter bowls, making sure the bowls lock firmly into place. AS-20—1000 Instruction Manual... -

Page 40: Removing The Front Cover Of The Enclosure (Not Available On As-450 - As-1000 Models)

Release the four latches on the sides of the cover by pulling the release levers towards the front of the unit. Carefully grasp the cover and slide it off the unit towards the front of the unit. The cover is freestanding, so it can be set aside in any location. AS-20—1000 Instruction Manual... -

Page 41: Depressurizing The Filters

Particulate filter (not provided on AS-20 model) Feed Air Regulator Filter Bowls Bowl Latches Manual Filter Outlet Valve Drain Tubing Connections Exhaust Muffler Manual Inlet Valve Pressure Switch Figure 7-1 Interior View of AS-45 and AS-80 Models AS-20—1000 Instruction Manual... -

Page 42: Changing Filter Elements

Changing Filter Elements The following procedure describes how to change the filter elements for either the particulate filter (not available on the AS-20 model) semi-annually or the coalescing filter annually. Depressurize the filter assembly and shut down the oxygen generator. (See Section 7.4, Depressurizing the Filters.) -

Page 43: Depressurizing The Oxygen Generator

Set the ON/OFF switch to ON and set the AUTO/MAN switch to MAN. Allow the unit to operate until gas no longer exhausts from the muffler and both the FEED AIR and CYCLE PRESSURE gauges indicate zero pressure. AS-20—1000 Instruction Manual... -

Page 44: Adjusting The Feed Air Regulator

Adjusting the Pressure Switch Although preset at the AirSep Corporation factory to the pressure switch minimum and maximum pressures specified in Appendix A of this instruction manual, the pressure switch may require adjustment if the pressure of the oxygen in the oxygen receiver registers outside the range specified in Appendix A. - Page 45 Turn either screw counterclockwise to decrease its pressure setting. To prevent damage to the pressure switch, do not force the adjustment screws past their stopping points. Set the AUTO/MAN switch on the oxygen generator control panel to AUTO. AS-20—1000 Instruction Manual...

- Page 46 13) Slowly turn the low adjustment screw clockwise in ¼-turn increments until the oxygen generator starts to cycle and the amber indicator light on the AUTO/MAN switch illuminates. 14) Fully close the oxygen vent valve on the oxygen receiver. AS-20—1000 Instruction Manual...

- Page 47 ® AirSep Corporation 12/02 15) Close the front cover of the enclosure and resume normal operation of the oxygen generator. AS-20—1000 Instruction Manual...

-

Page 49: Troubleshooting

USA or Canada, call 1-800-320-0303. Outside the USA or Canada, call (716) 691- 0202. Send fax inquiries anytime to (716) 691-1255. Address written inquiries to: AirSep Corporation, 260 Creekside Drive, Buffalo, NY 14228-2075 USA, Attention: Commercial Products Service Department. Problem... - Page 50 275 kPa (40 psig). Inadequate cycle Adjust or replace feed air pressure. regulator. Oxygen demand exceeds Check oxygen usage or oxygen generator check unit and oxygen capacity. hoses and piping for leaks. AS-20—1000 Instruction Manual...

- Page 51 Clean or rebuild valve. Worn valve core. Rebuild valve. Defective EMI filter. Replace EMI filter. Very low oxygen output Leaking check valves. Clean or replace check (21–50%). valves. Plugged muffler. Replace muffler. Contaminated molecular Replace molecular sieve. sieve in adsorbers. AS-20—1000 Instruction Manual...

- Page 52 (No power output to valve.) Filter drain valve energizes Drain valve obstructed or Clean or replace valve. with unit pressurized, but no stuck in closed position. air exhausts. Clean or replace tubing. Drain tubing obstructed or pinched. AS-20—1000 Instruction Manual...

-

Page 53: Specifications

Technical Data Specifications Data in this section refer to standard AS-20 through AS-1000 model oxygen generators. The oxygen generators may use feed air at specifications outside those shown; however, use of such feed air may require modification of the oxygen generators at the AirSep Corporation factory to ensure the product oxygen meets the design specifications. - Page 54 240 VAC, 50 Hz, Single Phase, 60 W, 0.25 Amp 240 VAC, 60 Hz, Single Phase, 60 W, 0.25 Amp *SCF (standard cubic foot) gas measured at 1 atmosphere and 70°F. **Nm (normal cubic meters) gas measured at 1 atmosphere and 0°C. AS-20—1000 Instruction Manual...

- Page 55 240 VAC, 50 Hz, Single Phase, 60 W, 0.25 Amp 240 VAC, 60 Hz, Single Phase, 60 W, 0.25 Amp *SCF (standard cubic foot) gas measured at 1 atmosphere and 70°F. **Nm (normal cubic meters) gas measured at 1 atmosphere and 0°C. AS-20—1000 Instruction Manual...

- Page 56 240 VAC, 50 Hz, Single Phase, 60 W, 0.25 Amp 240 VAC, 60 Hz, Single Phase, 60 W, 0.25 Amp *SCF (standard cubic foot) gas measured at 1 atmosphere and 70°F. **Nm (normal cubic meters) gas measured at 1 atmosphere and 0°C. AS-20—1000 Instruction Manual...

- Page 57 240 VAC, 50 Hz, Single Phase, 60 W, 0.25 Amp 240 VAC, 60 Hz, Single Phase, 60 W, 0.25 Amp *SCF (standard cubic foot) gas measured at 1 atmosphere and 70°F. **Nm (normal cubic meters) gas measured at 1 atmosphere and 0°C. AS-20—1000 Instruction Manual...

- Page 58 240 VAC, 50 Hz, Single Phase, 60 W, 0.25 Amp 240 VAC, 60 Hz, Single Phase, 60 W, 0.25 Amp *SCF (standard cubic foot) gas measured at 1 atmosphere and 70°F. **Nm (normal cubic meters) gas measured at 1 atmosphere and 0°C. AS-20—1000 Instruction Manual...

- Page 59 240 VAC, 50 Hz, Single Phase, 60 W, 0.25 Amp 240 VAC, 60 Hz, Single Phase, 60 W, 0.25 Amp *SCF (standard cubic foot) gas measured at 1 atmosphere and 70°F. **Nm (normal cubic meters) gas measured at 1 atmosphere and 0°C. AS-20—1000 Instruction Manual...

- Page 60 240 VAC, 50 Hz, Single Phase, 60 W, 0.25 Amp 240 VAC, 60 Hz, Single Phase, 60 W, 0.25 Amp *SCF (standard cubic foot) gas measured at 1 atmosphere and 70°F. **Nm (normal cubic meters) gas measured at 1 atmosphere and 0°C. AS-20—1000 Instruction Manual...

-

Page 61: Operating Data

® AirSep Corporation 12/02 Operating Data AS-20—1000 Instruction Manual... -

Page 62: Drawings

® 12/02 AirSep Corporation Drawings A-10 AS-20—1000 Instruction Manual... - Page 63 ® AirSep Corporation 12/02 Figure 2 General Arrangement Drawing – AS-20 AS-20—1000 Instruction Manual A-11...

- Page 64 ® 12/02 AirSep Corporation Figure 3 Flow Schematic – AS-20 A-12 AS-20—1000 Instruction Manual...

- Page 65 ® AirSep Corporation 12/02 Figure 4 Electrical Schematic – AS-20 (120V) Figure 5 Electrical Schematic – AS-20 (220V) AS-20—1000 Instruction Manual A-13...

- Page 66 ® 12/02 AirSep Corporation Figure 6 General Arrangement Drawing – AS-45 A-14 AS-20—1000 Instruction Manual...

- Page 67 ® AirSep Corporation 12/02 Figure 7 General Arrangement Drawing – AS-80 AS-20—1000 Instruction Manual A-15...

- Page 68 ® 12/02 AirSep Corporation Figure 8 General Arrangement Drawing – AS-160 A-16 AS-20—1000 Instruction Manual...

- Page 69 ® AirSep Corporation 12/02 Figure 9 General Arrangement Drawing – AS-250 AS-20—1000 Instruction Manual A-17...

- Page 70 ® 12/02 AirSep Corporation Figure 10 Flow Diagram – AS-45 through AS-250 A-18 AS-20—1000 Instruction Manual...

- Page 71 ® AirSep Corporation 12/02 Figure 11 Electrical Diagram – AS-45 through AS-250 (120V) Figure 12 Electrical Diagram – AS-45 through AS-250 (220V) AS-20—1000 Instruction Manual A-19...

- Page 72 ® 12/02 AirSep Corporation Figure 13 General Arrangement Drawing – AS-450 A-20 AS-20—1000 Instruction Manual...

- Page 73 ® AirSep Corporation 12/02 Figure 14 General Arrangement Drawing – AS-750 AS-20—1000 Instruction Manual A-21...

- Page 74 ® 12/02 AirSep Corporation Figure 15 Flow Diagram – AS-450 through AS-750 A-22 AS-20—1000 Instruction Manual...

- Page 75 ® AirSep Corporation 12/02 Figure 16 Electrical Schematic – AS-450 through AS-750 (120V) Figure 17 Electrical Schematic – AS-450 through AS-750 (220V) AS-20—1000 Instruction Manual A-23...

- Page 76 ® 12/02 AirSep Corporation Figure 18 General Arrangement Drawing– AS-1000 A-24 AS-20—1000 Instruction Manual...

- Page 77 ® AirSep Corporation 12/02 Figure 19 Electrical Schematic – AS-1000 (120V) Figure 20 Electrical Schematic – AS-1000 (220V) AS-20—1000 Instruction Manual A-25...

- Page 78 ® 12/02 AirSep Corporation Figure 21 Flow Diagram – AS-1000 A-26 AS-20—1000 Instruction Manual...

-

Page 79: B Appendix Warranty/Returns

Each unit of equipment for which a warranty claim is asserted shall, at the request of AirSep, be returned on a prepaid basis with proof of purchase date to the AirSep factory specified by AirSep at the expense of the original purchaser. Replacement parts shall be warranted as stated above for the unexpired portion of the original warranty. -

Page 80: Limits Of Liability

Returning the Oxygen Generator or a Component for Service If the oxygen generator or a defective part requires service, contact your distributor. If instructed by your distributor to contact AirSep Corporation, follow the procedure below to return the oxygen generator or a component for service or credit. - Page 81 Corporation. Return item(s) in their original packaging material. Pack merchandise for a safe return. AirSep Corporation assumes no responsibility for damage that occurs in transit. Any damage to the oxygen generator or a component because of failure to follow this procedure is the sole responsibility of the customer.

-

Page 83: C Appendix Parts List

Parts List Use the following lists to order parts for the oxygen generator. To order, please contact your distributor. If instructed by your distributor to contact AirSep Corporation, contact the AirSep Commercial Products Service Department as described in Chapter 8, Troubleshooting. If the list does not contain the part you require, please provide a precise description of the part when you call. -

Page 84: Parts

® 12/02 AirSep Corporation AS-20 Parts Model AS-20 Spare Parts Item Qty Per Part Number 8,000 Hour Kit/1 Year KI180-1 Microalescer Element FI019-1 16,000 Hour Kit/2 Year KI181-1 Microalescer Element FI019-1 1/4" Feed Valve Rebuild Kit VA089-1 1/4" Waste Valve Rebuild Kit VA089-1 1/4"... - Page 85 3/8" Waste Valve Rebuild Kit VA096-1 3/8" Equalization Valve Rebuild Kit VA095-1 1/8" Product Valve VA009-1 1/8" Drain Valve VA009-2 PC Board CB039-2 3 Amp Fuse FU004-1 Check Valve VA141-2 1/4" Feed Valve Coil VA110-1 3/8" Waste,Equalization Valve Coil VA112-1 AS-20—1000 Instruction Manual...

-

Page 86: Parts

VA096-1 3/8" Equalization Valve Rebuild Kit VA095-1 1/4" Product Valve Rebuild Kit VA088-1 1/8" Drain Valve VA009-2 PC Board CB039-3 3 Amp Fuse FU004-1 Check Valve VA141-2 1/4" Product Valve Coil VA110-1 3/8" Feed,Waste,Equalization Valve Coil VA112-1 AS-20—1000 Instruction Manual... -

Page 87: As-160 Parts

3/4" Waste Valve Rebuild Kit VA101-1 3/4" Equalization Valve Rebuild Kit VA100-1 3/8" Product Valve Rebuild Kit VA095-1 1/8" Drain valve VA009-2 PC board CB039-4 3 Amp Fuse FU004-1 Check Valve VA027-1 3/8" Feed,Waste,Equalization,Product Valve Coil VA112-1 AS-20—1000 Instruction Manual... -

Page 88: As-250 Parts

1 1/2" Equalization Valve Rebuild Kit VA104-1 3/8" Product Valve Rebuild Kit VA095-1 1/8" Drain valve VA009-2 PC board CB039-5 3 Amp Fuse FU004-1 Check Valve VA027-1 3/8" Feed,Product Valve Coil VA112-1 1 1/2" Waste,Equalization Valve Coil VA115-1 AS-20—1000 Instruction Manual... -

Page 89: As-450 Parts

1" Feed Valve Rebuild Kit VA103-1 1 1/2" Waste Valve Rebuild Kit VA104-1 1 1/2" Equalization Valve Rebuild Kit VA104-1 1/8" Drain valve VA009-2 PLC Timer CM084-1 3 Amp Fuse FU004-1 Check Valve VA027-1 1 1/2" Feed,Waste,Equalization Valve Coil VA360-1 AS-20—1000 Instruction Manual... -

Page 90: As-750 Parts

1 1/2" Waste Valve Rebuild Kit 1 VA104-1 1 1/2" Equalization Valve Rebuild Kit 1 VA104-1 1/8" Drain valve 1 VA009-2 PLC Timer 1 CM084-1 3 Amp Fuse 4 FU004-1 Check Valve 1 VA027-1 1 1/2" Feed,Waste,Equalization Valve Coil 1 VA360-1 AS-20—1000 Instruction Manual... -

Page 91: As-1000 Parts

1 1/2" Equalization Valve Rebuild Kit 1 VA104-1 1/8" Drain valve 1 VA009-2 PLC Timer 1 CM084-1 3 Amp Fuse 4 FU004-1 Check Valve 1 VA027-1 1 1/2" Feed,Waste,Equalization Valve Coil 1 VA360-1 Supplemental Equipment Oxygen Analyzer 1 AN009-1 AS-20—1000 Instruction Manual...