Summary of Contents for Canon imgaePRESS 1110+

- Page 1 1110+ Customer Expectations Document Version 3 Engineering Services and Solutions Division Business Imaging Solutions Group, Canon U.S.A., Inc.

-

Page 2: Table Of Contents

Contents 1. Introduction ......................5 2. Product Overview ....................5 Summary of Functions ..................6 Offset Press vs. Digital imagePRESS ............. 6 Image Stabilization Control ................7 Customer-Defined Image Quality Adjustments and Recommendations ..7 Notes on the Hard Disk ................... 7 Professional Input/Output Accessories ............ - Page 3 7. System Options ....................48 imagePRESS Printer Kit ................48 imagePRESS Server K200/K100 ..............49 PCI Bus Expansion Kit .................. 50 System Upgrade RAM .................. 50 Additional Memory Type C (512 MB) ............50 IPSec Board ....................50 Color Universal Send Kit ................50 Universal Send Security Feature Set-C1............

- Page 4 CONSEQUENTIAL DAMAGES CAUSED BY THE USE, MISUSE OR INABILITY TO USE THE PRODUCT, REGARDLESS OF THE LEGAL THEORY ON WHICH THE CLAIM IS BASED AND EVEN IF CANON OR ITS SUPPLIERS OR ANY AUTHORIZED SERVICE PROVIDER HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

-

Page 5: Introduction

Introduction The Canon imagePRESS 1110+ Customer Expectations Document contains information about the features and capabilities of the Canon imagePRESS 1110+. This document should be used as part of the presale and pre-installation planning process to help clarify the requirements and responsibilities associated with supporting, owning, and operating the imagePRESS 1110+. -

Page 6: Summary Of Functions

2.1 Summary of Functions Function imagePRESS 1110+ Output Speed (B&W) 110 ppm (LTR) Engine Resolution 1,200 x 1,200 dpi Gradations 256 levels B&W: 120 ipm (images per minute) Simplex Scan Speed Color: 80 ipm (LTR, 300 dpi) B&W: 200 ipm Duplex Color: 80 ipm Minimum... -

Page 7: Image Stabilization Control

2.3 Image Stabilization Control The imagePRESS 1110+ contains four separate skew adjustment rollers which ensure that an image is placed in the same location on every sheet of paper. Accurate front to back registration is actively adjusted during print runs, and consistency is maintained at high speeds with non-stop operation. -

Page 8: Professional Input/Output Accessories

2.6 Professional Input/Output Accessories The imagePRESS 1110+ features many robust input and output accessories that allow customers working in production environments to complete large jobs directly from the machine. An ARCnet (Attachable Resource Computer Network) communications cable is used to connect the accessories to the main unit. The ARCnet cable provides the main unit’s engine information about the accessories that are attached and if they are working properly. -

Page 9: Machine Dimensions And Space Requirements

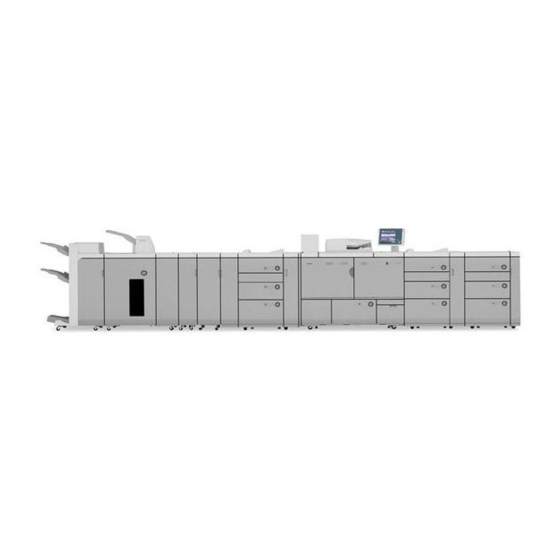

Machine Dimensions and Space Requirements 3.1 Dimensions The following table includes the width, height, and depth dimensions (in inches and millimeters) of the main unit and optional accessories. Unit Width Depth Height Main Unit 54.6” 1,387 mm 31.9” 809 mm 54.1”... -

Page 10: Weight

3.2 Weight The weights of the main unit, feeding and finishing options (in pounds and kilograms) are listed in the table below. Unit Weight Main Unit 1,103 lb 500 kg POD Deck-C1 498 lb 226 kg Secondary POD Deck-C1 498 lb 226 kg Color Image Reader-L1 w/Feeder 88 lb... -

Page 11: Minimum Space Requirements To Transport The Machine And Turn Hallway Corners

3.3.1 Minimum Space Requirements to Transport the Machine and Turn Hallway Corners The following table represents the minimum width that is necessary to turn hallway corners and transport the machine to its final installation site. IMPORTANT • The minimum doorway opening that the machine passes through prior to installation must be at least 36”... -

Page 12: Dimensions Diagrams

3.3.2 Dimensions Diagrams Approx. 31.9" Provide at least 3 feet on each side of the machine for unrestricted operation and for proper servicing. Approx. 54.1" Approx. 40.9" Approx. Approx. Approx. Approx. Approx. Approx. Approx. Approx. Approx. 95.6” 13.2” 39.3” 36.3” 39.3”... -

Page 13: Installation Space Diagrams

3.3.3 Installation Space Diagrams The approximate installation space requirements will differ, depending on how the machine is configured and the optional accessories attached. There must be enough space around the machine. The following diagrams show the minimum dimensions; whenever possible, be sure there will be more space than indicated. Minimum Configuration 144.7”... - Page 14 Maximum Configuration 457” 39.4” 39.4” [1] Main Unit [8] High Capacity Stacker-E1 [2] POD Deck-C1 [9] Secondary High Capacity Stacker-E1 [3] Secondary POD Deck-C1 [10] Perfect Binder-C1 [4] Secondary POD Deck-C1 (2nd Unit) [11] Paper Folding Unit-F1 [5] Multi Drawer Document Insertion Unit-A1 [12] Saddle Finisher-AK2 [6] Professional Puncher-B1 [13] Booklet Trimmer-D1...

-

Page 15: Recommended Floor Space Requirements

3.4 Recommended Floor Space Requirements For a fully configured imagePRESS 1110+, it is recommended that there be at least 45’ (W) x 12’ (D) of floor space. 45’ (13.7 m) 39.4” 456.6” 39.4” IMPORTANT • The imagePRESS 1110+ was created to be modular in design. Floor space, budget, monthly copy/print volume, and applications will determine which configuration works best. -

Page 16: Network Connectivity

3.6 Network Connectivity A standard 10/100Base-T Ethernet interface (RJ-45 jack) for device installation, monitoring, and Mail Box access, via the Remote UI, ships standard with all configurations. A USB 2.0 High-Speed interface port ships standard with all configurations for direct connection to centralized environments that want to drive all jobs through a single host PC. -

Page 17: Power Requirements For The Main Unit And Optional Accessories

4.1 Power Requirements for the Main Unit and Optional Accessories Power Supply Cord/Plug Length of Power Part or Accessory Power Supply Specifications Cord 1-Single Phase NEMA L14-30 9’ 8” (3 m) Main Unit 208 V/30 A outlet 1-208 V/15 A outlet NEMA 6-15 6’... - Page 18 IMPORTANT • Phase converters and step down transformers are not supported. • Canon USA strongly recommends that dedicated and properly grounded outlets be provided for the devices mentioned above. The ground connection serves to provide the internal electronics with a reference voltage. Faulty or poor ground sources will cause this reference voltage to fall into a range that no longer serves as a reliable reference voltage.

-

Page 19: Environmental Factors And Requirements

Environmental Factors and Requirements Optimum Temperature Range: Between 68°F (20°C) and 80.6°F (27°C)* Optimum Humidity Range: Between 30% and 70% Atmospheric Pressure: 810.6 to 1,013 hPa (0.8 to 1.0 atm) Noise (sound level): Standby: 68 dB; Operating: 83 dB Ozone Emissions: 0.01 ppm (parts per million) or less (initial startup) 0.35 ppm or less (after a short break-in period) * If the machine is operated in a low temperature... -

Page 20: Operating The Machine In A Low Temperature Environment

5.1.1 Operating the Machine in a Low Temperature Environment It is best to run the machine at a room temperature that falls within the optimal range (68°F to 80.6°F (20°C to 27°C)); however, if a low temperature environment cannot be avoided, and depending on the job criteria (either print speed or image quality), set the machine to account for the temperature of the room in which the machine is located. -

Page 21: Temperature Gradient

5.2 Temperature Gradient If a sudden temperature change occurs, may have an adverse affect on image positioning. Sudden temperature changes may cause the paper to bend or contract, cause the machine to malfunction, and form condensation. Every effort should be made to maintain consistent temperature and humidity levels in the operating environment at all times for the imagePRESS 1110+. -

Page 22: Elevation Limitations

5.4 Elevation Limitations Install this machine at an elevation below 13,123’ (4,000 m) and at an air pressure between 810.6 to 1,013 hPa (0.8 to 1.0 atm). 5.5 Lighting We recommend installing the machine in a location with at least 500 lux (29 1/2”... -

Page 23: Specifications

This chapter explains the specifications and any productivity impacts involving the main unit and optional accessories. Specifications are subject to change without notice for product improvement or future release. 6.1 Main Unit Item Specifications Name Canon imagePRESS 1110+ Type Console Printing Method Electronic Photography Color Supported Black-and-White Engine Resolution... - Page 24 Main Unit Table Continued Item Specifications Direct (sheets/minute) 13" x 19" Approximately 63 sheets/minute 12" x 18" Approximately 65 sheets/minute 12 5/8” x 17 3/4” Approximately 66 sheets/minute Copy Speed 11" x 17" Approximately 68 sheets/minute (20 lb bond (80 g/m Approximately 79 sheets/minute Approximately 110 sheets/minute LTRR...

-

Page 25: Color Image Reader-L1 With Feeder

6.2 Color Image Reader-L1 with Feeder The optional Color Image Reader-L1 with Feeder scans hard-copy documents to create a digital archive. The color image reader scans in color, and the feeder is extremely productive, since it can scan both sides of an original at the same time. The feeder can hold up to 300 originals (20 lb bond (80 g/m )) and scan up to 200 single- and double-sided sheets simultaneously per minute. - Page 26 Color Image Reader-L1 with Feeder Table Continued Item Specifications Regular paper size: Same Ratio Reduction 1:0.78 (LGL ➞ LTR) 1:0.73 (11" x 17" ➞ LGL, 11" x 15" ➞ LTR) 1:0.64 (11" x 17" ➞ LTR) 1:0.50 (11" x 17" ➞ STMT) Magnification 1:0.25 Enlargement...

-

Page 27: Pod Deck-C1/Secondary Pod Deck-C1

6.3 POD Deck-C1/Secondary POD Deck-C1 Up to three POD Decks can be attached to the machine (at least one POD Deck must be attached). When all three POD Decks are attached to the machine, a maximum of nine paper sources can be used for jobs with a maximum capacity of 14,000 sheets of paper. -

Page 28: Multi Drawer Document Insertion Unit-A1

6.4 Multi Drawer Document Insertion Unit-A1 The optional Multi Drawer Document Insertion Unit-A1 provides an additional three paper sources for sheet insertions and cover sheets. The upper and middle decks can hold up to 1,000 sheets (20 lb bond (80 g/m )) and the lower deck can hold up to 2,000 sheets (20 lb bond (80 g/m The Multi Drawer Document Insertion Unit-A1 and Document Insertion Unit-F1... -

Page 29: Document Insertion Unit-F1

6.5 Document Insertion Unit-F1 The optional Document Insertion Unit-F1 feeds up to 200 cover and insertion sheets for binding. The Document Insertion Unit-F1 and Multi Drawer Document Insertion Unit-A1 cannot be attached to the machine at the same time. IMPORTANT •... -

Page 30: Professional Puncher-B1 And Professional Puncher Integration Unit-A1

6.6 Professional Puncher-B1 and Professional Puncher Integration Unit-A1 The optional Professional Puncher-B1 and Professional Puncher Integration Unit-A1 provide a variety of punching patterns. The punching patterns are available as die sets. The die sets are interchangeable and enable the customer to create off-line plastic spiral bound books. -

Page 31: Finisher-Ak1

6.7 Finisher-AK1 The optional Finisher-AK1 is equipped with the Collate, Group, Offset, and Staple modes, and contains improved stacking and alignment capabilities for the Non-Collate and Collate modes. The Finisher-AK1 and Saddle Finisher-AK2 cannot be attached to the machine at the same time. - Page 32 Finisher-AK1 Table Continued Item Specifications No Collating, Collate, or Group Mode Tray A: 13” x 19”, 12 5/8” x 17 3/4”, 12” x 18”, 11" x 17", LGL LTR, LTRR, EXEC, EXECR, and Irregular Size (4" x 7 1/8" to 13" x 19 1/4” (100 mm x 182 mm to 330.2 mm x 487.7 mm)): 1,000 sheets (or 5 3/4"...

- Page 33 Finisher-AK1 Table Continued Item Specifications Collate and Shift/Group and Shift Modes Set Tray A: 12” x 18”, 11" x 17", LGL LTR, LTRR, EXEC, EXECR, and Irregular Size (4" x 7 1/8" to 12" x 18” (100 mm x 182 mm to 305 mm x 457.2 mm)): 1,000 sheets (or 5 3/4"...

- Page 34 Finisher-AK1 Table Continued Item Specifications Staple (Double) Mode Set Tray B: LTR, EXEC, and Irregular Size (7 1/8” x 7 1/8” to 11 3/4” x 8 1/2” (182 mm x 182 mm to 297 mm x 216 mm)): 3,000 sheets/200 sets (or 16 5/8" (423 mm) in height) LTRR and Irregular Size (7 1/8”...

-

Page 35: Saddle Finisher-Ak2

6.8 Saddle Finisher-AK2 The optional Saddle Finisher-AK2 is equipped with the Collate, Group, Offset, Staple, and Saddle Stitch modes, and contains improved stacking and alignment capabilities for the Non-Collate and Collate modes. The Saddle Finisher can also V-fold up to five sheets without stapling. The Saddle Finisher-AK2 and Finisher-AK1 cannot be attached to the machine at the same time. - Page 36 Saddle Finisher-AK2 Table Continued Item Specifications No Collating, Collate, or Group Mode Tray A: 13” x 19”, 12 5/8” x 17 3/4”, 12” x 18”, 11" x 17", LGL LTR, LTRR, EXEC, EXECR, and Irregular Size (4" x 7 1/8" to 13" x 19 1/4” (100 mm x 182 mm to 330.2 mm x 487.7 mm)): 1,000 sheets (or 5 3/4"...

- Page 37 Saddle Finisher-AK2 Table Continued Item Specifications Collate and Shift/Group and Shift Modes Set Tray A: 12” x 18”, 11" x 17", LGL LTR, LTRR, EXEC, EXECR, and Irregular Size (4" x 7 1/8" to 12" x 18” (100 mm x 182 mm to 305 mm x 457.2 mm)): 1,000 sheets (or 5 3/4"...

- Page 38 Saddle Finisher-AK2 Table Continued Item Specifications Staple (Double) Mode Set Tray B: LTR, EXEC, and Irregular Size (7 1/8” x 7 1/8” to 11 3/4” x 8 1/2” (182 mm x 182 mm to 297 mm x 216 mm)): 3,000 sheets/200 sets (or 16 5/8" (423 mm) in height) LTRR and Irregular Size (7 1/8”...

- Page 39 Saddle Finisher-AK2 Table Continued Item Specifications Saddle Stitch: 25 sheets (20 lb bond (80 g/m )) (Including 1 cover sheet up to 300 g/m Saddle Fold: 5 sheets (20 lb bond (80 g/m Available Saddle Stitch Size: 13" x 19", 12" x 18", 12 5/8” x 17 3/4”, 11" x 17", LGL, LTRR, and Capacity /Paper Size Irregular Size (8 1/4"...

-

Page 40: Puncher Unit-Bs1

6.9 Puncher Unit-BS1 The optional Puncher Unit-BS1 can be installed inside the optional Finisher-AK1 or Saddle Finisher-AK2, and can punch two to three holes (depending on the paper size). Item Specifications Size: Two holes: 11” x 17”, LGL LTR, LTRR, EXEC, EXECR, Irregular Size (7 1/8”... -

Page 41: Paper Folding Unit-F1

6.10 Paper Folding Unit-F1 The optional Paper Folding Unit-F1 can Z-fold, C-fold, Accordion Z-fold, Half-fold (LTRR only), and Double Parallel-fold paper for businesses that require letters, invoices, or brochures to be folded. The Paper Folding Unit must be attached to the optional Finisher-AK1 or Saddle Finisher-AK2. -

Page 42: Card Reader-C1

6.11 Card Reader-C1 The optional Card Reader-C1 automatically performs Department ID Management, and the customer does not have to enter the Department ID and password manually. The customer can also check the print totals and the remaining number of pages that can be printed on the touch panel display. Item Specifications Available Cards... -

Page 43: High Capacity Stacker-E1

6.12 High Capacity Stacker-E1 The optional High Capacity Stacker-E1 can stack up to 5,000 sheets of large size paper, or 10,000 sheets of LTR size paper. There is also a 1,000 sheet capacity proof tray located on top of the stacker. IMPORTANT •... -

Page 44: Perfect Binder-C1

The perfect binder uses hot glue technology and three-sided trimming to produce a nicely finished product. Canon U.S.A., Inc. recommends that imageWARE Prepress Manager be used for in-line perfect binding to create books, and easily design the spine of a book. -

Page 45: Booklet Trimmer-D1

Perfect Binder-C1 Table Continued Item Specifications Approximately 0.8 lb (380 g) (Enough for approximately 135 booklets Glue Capacity containing 100 bound sheets of 20 lb bond (80 g/m ) paper) 10 books containing 100 body pages (17 lb bond (64 g/m ) and one cover Tray Capacity sheet (32 lb bond (128 g/m... -

Page 46: Two-Knife Booklet Trimmer-A1

6.15 Two-Knife Booklet Trimmer-A1 If the optional Two-Knife Booklet Trimmer-A1 is attached to the optional Booklet Trimmer-D1, the customer can trim the fore edge and top/bottom edges of saddle stitched prints for neat output. Item Specifications Description Upper knife, reciprocating top-bottom trimmer Maximum Number of 100 sheets (20 lb bond (80 g/m Sheets... -

Page 47: Sdd Square Fold Booklet-Maker With Two-Knife Trimmer

6.16 SDD Square Fold Booklet-Maker with Two-Knife Trimmer The Square Fold Booklet-Maker with Two-Knife Trimmer offers an in-line finishing solution which creates a full bleed printed booklets, reports, brochures, manuals, and policy documents. The Two-Knife Trimmer is capable of trimming up to 25 sheets (20 lb bond (80 g/m Item Specifications... -

Page 48: System Options

System Options The functionality of the imagePRESS 1110+ can be expanded by installing system related optional accessories. This section describes the system related optional accessories and their functions. 7.1 imagePRESS Printer Kit The imagePRESS Printer Kit supports the PCL and PostScript printing solutions. The customer can print TIFF, JPEG, PDF, and PS files directly from their PC using the Remote UI. -

Page 49: Imagepress Server K200/K100

Fiery Pro80-III Fiery SP30-II System 10 PostScript 3 PCL6 PCL5 Canon iPR Server-K100-200 Ver1.0 (PS3) Driver’s Name Canon iPR Server-K100-200 PCL5e (PCL5e) Canon iPR Server-K100-200 PCL6 (PCL6) • Integrated Interface & Stand • Integrated Interface & Stand Kit (19” monitor) Kit (19”... -

Page 50: Pci Bus Expansion Kit

7.3 PCI Bus Expansion Kit The PCI Bus Expansion Kit is necessary to install the IPSec Board. 7.4 System Upgrade RAM The System Upgrade RAM expands the memory capacity of the machine, and enables the customer to specify more functions for scanning and sending documents. -

Page 51: Universal Send Security Feature Set-C1

7.8 Universal Send Security Feature Set-C1 The Universal Send Security Feature Set-C1 enables the customer to encrypt PDF files and set a password to send them safely to a file server or e-mail address. It also enables the recipient of the PDF file to verify which device scanned it. NOTE To enable the functions of the Universal Send Security Feature Set-C1, it must be activated by registering a license key after the optional Color Universal Send... -

Page 52: Hdd Data Erase Kit-A1

7.13 HDD Data Erase Kit-A1 The HDD Data Erase Kit-A1 enables the customer to erase the data stored on the hard disk completely. 7.14 Encrypted Secure Print Software The Encrypted Secure Print Software enables the customer to encrypt print data sent from a computer using the Secured Print function and decrypt it at the machine. -

Page 53: Installation Review

Installation Review This chapter describes the necessary number of technicians required to install the machine properly, the time required to install the main unit and optional equipment, and customer installation responsibilities. 8.1 Installation Time The time required to install the imagePRESS 1110+ depends on the options and accessories to be installed, and the number of technicians performing the installation. - Page 54 The table below indicates the estimated length of time needed to install the main unit and optional accessories from the time the machine is unpacked to when it is installed, and calculated from the average amount of manpower hours. The estimated installation times are based on four (4) experienced technicians.

-

Page 55: Customer Responsibilities

8.2 Customer Responsibilities Item Comment Identify location for equipment. Area meets space and service space requirements. Verify strength of floor and level. Certified by structural engineers. Ensure that the equipment can be Path is clear and unobstructed. delivered to the site. Confirm proper electrical outlets and Dedicated power, and enough outlets for equipment power are available. -

Page 56: Consumables

Therefore, consumable parts do not have a warranty, and Canon U.S.A., Inc. cannot guarantee a minimum life. 9.1.1 Estimated Life of Consumables The table below states the estimated life expectancy yields based on LTR size paper. -

Page 57: Toner Bottle And Hopper Unit Yields

10. Toner Bottle and Hopper Unit Yields A toner bottle holds approximately 5 lb (2.3 kg) of toner, and will yield approximately 69,000 impressions at 6% coverage on LTR size paper. The hopper unit holds approximately 4.2 lb (1.89 kg), and will yield approximately 47,000 impressions. -

Page 58: Estimated Performance Standards

• If the machine is maintained and serviced by a Canon authorized service technician • If only Genuine Canon service and consumable parts are used... -

Page 59: Optimum Monthly Product Performance

13. Optimum Monthly Product Performance The table below describes the differences between the optimum PCV (Print Copy Volume) and maximum PCV. Please note that the numbers in the table are for reference purposes only, and depend strongly on the type of media selected and environmental conditions. -

Page 60: Machine Reliability And Productivity

• The installation and operating environment meets the specifications detailed in this document and other Canon service documentation. • Service is provided by a Canon authorized service technician. • Single sided, uncoated, letter size sheets (20 lb bond (80 g/m )) are used. -

Page 61: Print Speed

14.1 Print Speed One of the key features of the imagePRESS 1110+ is its print speed technology. The imagePRESS 1110+ prints a letter-sized sheet of bond paper weighing 14 lb bond (52 g/m²) at 110 ppm. Also, the same sized sheet (single sided) at 110 lb cover (300 g/m²) prints at 110 ppm. - Page 62 Print Speed Table (2 of 3) Productivity (ppm) Embossed Bond Vellum Coated Paper 1 Mode Size Vellum 28 to 35 lb bond Transparency 14 to 24 lb bond 20 to 28 lb bond (106-128 g/m (52-90 g/m (80-105 g/m LTR-Tab EXEC EXECR LTRR...

- Page 63 Print Speed Table (3 of 3) Productivity (ppm) Coated Coated Coated Paper 6 Coated Paper 2 Coated Paper 3 Paper 4 Paper 5 Mode Size 47 lb bond to 24 to 32 lb bond 32 to 35 lb bond 35 to 40 lb 40 to 47 lb 90 lb cover (91-120 g/m...

-

Page 64: Mixed Paper Weight Job Productivity

14.2 Mixed Paper Weight Job Productivity The imagePRESS 1110+ is capable of processing jobs that contain paper with different paper weights. However, during the processing of jobs with mixed paper weights, the machine adjusts its fixing temperature, resulting in a slight processing delay. -

Page 65: Paper, Toner, And Waste Toner Replacement

14.4 Paper, Toner, and Waste Toner Replacement The imagePRESS operator can maintain productivity by removing, replacing, and refilling the paper, toner, and waste toner while the machine is running. The paper trays can also be opened and refilled during operation. The tray that is being used by the machine during production, however, will be locked. -

Page 66: Media Usage/Compatibility

‘1,200 x 1,200 dpi’. However, if the customer wants to perform transactional printing or print from the Canon PS printer driver, and the profile is set to ‘Default Settings’, the customer must manually change the machine’s default printing resolution from ‘600 dpi’... -

Page 67: Device Management Settings

15.2.1 Device Management Settings The Device Management Settings mode is for customers who want to make fine adjustments to the printed image. There is a special menu that must be activated by an authorized service dealer. For more information on specifying the Device Management Settings modes, see “Device Management Settings,”... -

Page 68: Paper Handling And Storage

To obtain the Specialty Media Handling Guide for the imagePRESS 1110+, please contact a local authorized Canon dealer. Canon U.S.A., Inc. also publishes a Paper Orientation and Driver Setting Guide. The Paper Orientation and Driver Setting Guide includes information on how to place and orient paper in the correct way to achieve desired finishing results. -

Page 69: Paper Grain And Curl

15.5 Paper Grain and Curl Paper grain and curl can dramatically affect the reliability of machines utilizing an electrostatic process like the imagePRESS 1110+. Paper used in an offset press is usually cut for short edge feeding. This type of paper is not as reliable as paper made for machines utilizing an electrostatic process, which is cut for long edge feeding. -

Page 70: Note For Customers Who Cut Their Own Paper

15.7 Media Feed Locations As with all Canon copiers, certain feed locations within the device are capable of feeding specific media sizes and weights. When considering media, make sure the media is within the proper size and weight parameters of the feed location. - Page 71 The default paper types registered in the machine are shown in the table below. : Available - : Unavailable Paper Source POD Deck- Paper Decks of the Main Multi Drawer Document C1/Secondary POD Paper Type Unit Insertion Unit-A1 Deck-C1 (Paper Weight) (14 lb bond to (14 lb bond to...

- Page 72 Default Paper Types Table Continued : Available - : Unavailable Paper Source POD Deck- Paper Decks of the Main Multi Drawer Document C1/Secondary POD Paper Type Unit Insertion Unit-A1 Deck-C1 (Paper Weight) (14 lb bond to (14 lb bond to (14 lb bond to 110 lb cover 110 lb cover...

- Page 73 Default Paper Types Table Continued : Available - : Unavailable Paper Source POD Deck- Paper Decks of the Main Multi Drawer Document C1/Secondary POD Paper Type Unit Insertion Unit-A1 Deck-C1 (Paper Weight) (14 lb bond to (14 lb bond to (14 lb bond to 110 lb cover 110 lb cover...

-

Page 74: Paper Sizes And Feed Location Chart

Default Paper Types Table Continued : Available - : Unavailable Paper Source POD Deck- Paper Decks of the Main Multi Drawer Document C1/Secondary POD Paper Type Unit Insertion Unit-A1 Deck-C1 (Paper Weight) (14 lb bond to (14 lb bond to (14 lb bond to 110 lb cover 110 lb cover... -

Page 75: Responsibility Matrix

16. Responsibility Matrix Responsibility Action Customer Dealer Ensure adequate space and power to properly install the machine. Verify floor strength and level. Ensure that the equipment can be delivered to the site, and that the path is clear and unobstructed. Unpack all delivered items.