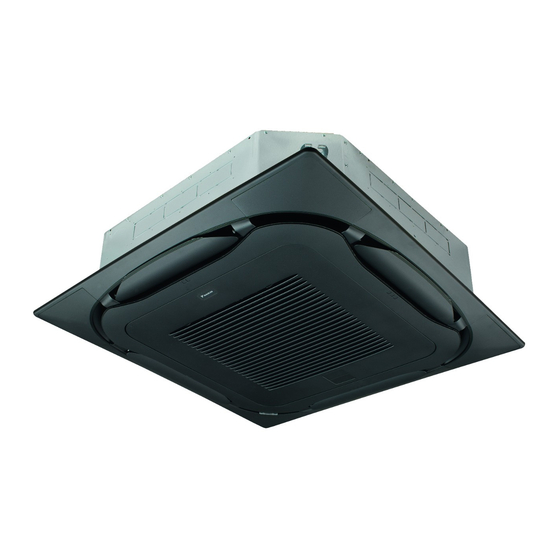

Summary of Contents for Daikin FCAG35BVEB

- Page 1 Installer and user reference guide Split system air conditioners FCAG35BVEB FCAG50BVEB FCAG60BVEB FCAG71BVEB FCAG100BVEB FCAG125BVEB FCAG140BVEB...

-

Page 2: Table Of Contents

Table of contents Table of contents 1 General safety precautions About the documentation .............................. 1.1.1 Meaning of warnings and symbols ........................ For the user..................................For the installer ................................1.3.1 General ................................1.3.2 Installation site ............................... 1.3.3 Refrigerant — in case of R410A or R32......................11 1.3.4 Brine................................ - Page 3 Table of contents 8 Commissioning Overview: Commissioning .............................. 47 Precautions when commissioning ..........................47 Checklist before commissioning............................. 48 To perform a test run..............................48 Error codes when performing a test run........................50 9 Hand-over to the user 10 Disposal 11 Technical data 11.1 Piping diagram: Indoor unit ............................

- Page 4 Table of contents 18.1.12 Symptom: The outdoor unit fan does not spin....................79 18.1.13 Symptom: The display shows "88"......................... 79 18.1.14 Symptom: The compressor in the outdoor unit does not stop after a short heating operation ....80 19 Relocation 20 Disposal 21 Glossary Installer and user reference guide...

-

Page 5: General Safety Precautions

General safety precautions 1 General safety precautions 1.1 About the documentation ▪ The original documentation is written in English. All other languages are translations. ▪ The precautions described in this document cover very important topics, follow them carefully. ▪ The installation of the system, and all activities described in the installation manual and in the installer reference guide MUST be performed by an authorised installer. -

Page 6: For The User

General safety precautions Symbol Explanation Before installation, read the installation and operation manual, and the wiring instruction sheet. Before performing maintenance and service tasks, read the service manual. For more information, see the installer and user reference guide. The unit contains rotating parts. Be careful when servicing or inspecting the unit. -

Page 7: For The Installer

Improper installation or attachment of equipment or accessories could result in electrical shock, short-circuit, leaks, fire or other damage to the equipment. Only use accessories, optional equipment and spare parts made or approved by Daikin. FCAG35~140BVEB Installer and user reference guide Split system air conditioners 4P561448-1B –... -

Page 8: Installation Site

General safety precautions WARNING Make sure installation, testing and applied materials comply with applicable legislation (on top of the instructions described in the Daikin documentation). CAUTION Wear adequate personal protective equipment (protective gloves, safety glasses,…) when installing, maintaining or servicing the system. - Page 9 WARNING Make sure installation, servicing, maintenance and repair comply with instructions from Daikin and with applicable legislation (for example national gas regulation) and are executed only by authorised persons. NOTICE ▪...

- Page 10 General safety precautions Installation space requirements WARNING If appliances contain R32 refrigerant, the floor area of the room in which the appliances are installed, operated and stored MUST be larger than the minimum floor area defined in table below A (m ).

-

Page 11: Refrigerant - In Case Of R410A Or R32

General safety precautions Ceiling-mounted Wall-mounted Floor-standing unit unit unit m (kg) m (kg) A m (kg) A ≤1.842 — ≤1.842 — ≤1.842 — 1.843 28.9 1.843 3.64 1.843 4.45 3.95 4.83 34.0 4.34 5.31 41.2 5.79 49.0 4.74 5.13 6.39 57.5 7.41 66.7... - Page 12 General safety precautions WARNING Take sufficient precautions in case of refrigerant leakage. If refrigerant gas leaks, ventilate the area immediately. Possible risks: ▪ Excessive refrigerant concentrations in a closed room can lead to oxygen deficiency. ▪ Toxic gas might be produced if refrigerant gas comes into contact with fire. DANGER: RISK OF EXPLOSION Pump down –...

-

Page 13: Brine

General safety precautions Then A siphon tube is present Charge with the cylinder upright. (i.e., the cylinder is marked with "Liquid filling siphon attached") A siphon tube is NOT present Charge with the cylinder upside down. ▪ Open refrigerant cylinders slowly. ▪... -

Page 14: Electrical

General safety precautions 1.3.6 Electrical DANGER: RISK OF ELECTROCUTION ▪ Turn OFF all power supply before removing the switch box cover, connecting electrical wiring or touching electrical parts. ▪ Disconnect the power supply for more than 10 minutes, and measure the voltage at the terminals of main circuit capacitors or electrical components before servicing. - Page 15 General safety precautions NOTICE Precautions when laying power wiring: ▪ Do NOT connect wiring of different thicknesses to the power terminal block (slack in the power wiring may cause abnormal heat). ▪ When connecting wiring which is the same thickness, do as shown in the figure above.

-

Page 16: About The Documentation

The original documentation is written in English. All other languages are translations. Technical engineering data ▪ A subset of the latest technical data is available on the regional Daikin website (publicly accessible). ▪ The full set of latest technical data is available on the Daikin Business Portal (authentication required). -

Page 17: For The Installer

For the installer FCAG35~140BVEB Installer and user reference guide Split system air conditioners 4P561448-1B – 2021.07... -

Page 18: About The Box

About the box 3 About the box 3.1 Overview: About the box This chapter describes what you have to do after the box with the indoor unit is delivered on-site. It contains information about: ▪ Unpacking and handling the unit ▪... -

Page 19: To Remove The Accessories From The Indoor Unit

About the box 3.2.2 To remove the accessories from the indoor unit 1× 1× 1× 8× 4× 7× 1× 4× 1× 1× 1× 1× a Paper pattern for installation (upper part of packing) b General safety precautions c Indoor unit installation and operation manual d Installation guide e Washers for hanger brackets f Screws (to temporarily attach the paper pattern for installation to the indoor unit) -

Page 20: About The Units And Options

About the units and options 4 About the units and options 4.1 Overview: About the units and options This chapter contains information about: ▪ Identifying the indoor unit ▪ Combining outdoor and indoor units ▪ Combining the indoor unit with options INFORMATION For year‑round cooling applications with low indoor humidity conditions, such as Electronic Data Processing rooms, contact your dealer or see the engineering... - Page 21 About the units and options In combination with R410A outdoor units Outdoor units Cooling Heating RXS35~60 –10~46°C DB –15~18°C WB 14~28°C WB 10~30°C DB 3MXS40~68 –10~46°C DB –15~18°C WB 4MXS68~80 14~28°C WB 10~30°C DB 5MXS90 RZQG71~140 –15~50°C DB –20~15.5°C WB 12~28°C WB 10~27°C DB RZQSG71~140 –15~46°C DB –15~15.5°C WB 14~28°C WB 10~27°C DB RZQ200~250 –5~46°C DB –15~15°C WB 14~28°C WB 10~27°C DB AZQS71...

-

Page 22: System Layout

About the units and options In combination with R32 outdoor units Outdoor units Cooling Heating RZAG71~140 –20~52°C DB –20~24°C DB –20~18°C WB 17~38°C DB 10~27°C DB 12~28°C WB RZASG71~140 –15~46°C DB –15~21°C DB –15~15.5°C WB 20~38°C DB 10~27°C DB 14~28°C WB AZAS71~140 –5~46°C DB –15~21°C DB –15~15.5°C WB 20~38°C DB 10~27°C DB 14~28°C WB Indoor humidity ≤80% To avoid condensation and water dripping out of the unit. If the temperature or the humidity is beyond these conditions, safety devices may be put in action and the air conditioner may not operate. -

Page 23: Combining Units And Options

About the units and options 4.5 Combining units and options INFORMATION Certain options might not be available in your country. 4.5.1 Possible options for the indoor unit Make sure you have the following mandatory options: ▪ User interface: Wired or wireless ▪... -

Page 24: Preparation

Preparation 5 Preparation 5.1 Overview: Preparation This chapter describes what you have to do and know before going on-site. It contains information about: ▪ Preparing the installation site ▪ Preparing the refrigerant piping ▪ Preparing the electrical wiring 5.2 Preparing the installation site Choose an installation location with sufficient space for carrying the unit in and out of the site. - Page 25 Preparation ▪ Where the voltage fluctuates a lot ▪ In vehicles or vessels ▪ Where acidic or alkaline vapour is present NOTICE The equipment described in this manual may cause electronic noise generated from radio-frequency energy. The equipment complies to specifications that are designed to provide reasonable protection against such interference.

- Page 26 Preparation b 4-way air flow (with closed corners) (optional blocking pad kit required) c 3-way air flow (optional blocking pad kit required) ▪ Ceiling insulation. When conditions in the ceiling exceed 30°C and a relative humidity of 80%, or when fresh air is inducted into the ceiling, then additional insulation is required (minimum 10 mm thickness, polyethylene foam).

-

Page 27: Preparing Refrigerant Piping

Preparation 5.3 Preparing refrigerant piping 5.3.1 Refrigerant piping requirements INFORMATION Also read the precautions and requirements in the "1 General safety precautions" [ 5]. NOTICE The piping and other pressure-containing parts shall be suitable for refrigerant. Use phosphoric acid deoxidised seamless copper for refrigerant. ▪... -

Page 28: Preparing Electrical Wiring

Preparation 5.4 Preparing electrical wiring 5.4.1 About preparing electrical wiring INFORMATION Also read the precautions and requirements in the "1 General safety precautions" [ 5]. WARNING ▪ If the power supply has a missing or wrong N-phase, equipment might break down. ▪... -

Page 29: Installation

Installation 6 Installation 6.1 Overview: Installation This chapter describes what you have to do and know on-site to install the system. Typical workflow Installation typically consists of the following stages: Mounting the outdoor unit. Mounting the indoor unit (+ decoration panel). Connecting the refrigerant piping. -

Page 30: Guidelines When Installing The Indoor Unit

Installation 6.2.2 Guidelines when installing the indoor unit INFORMATION Optional equipment. When installing optional equipment, also read the installation manual of the optional equipment. Depending on the field conditions, it might be easier to install the optional equipment first. ▪ In case of installation with a fresh air intake kit. - Page 31 Installation a Centre of the unit b Centre of the ceiling opening c Paper pattern for installation (upper part of the packing) d Screws (accessories) ▪ Ceiling opening and unit: Make sure the ceiling opening is within the following limits: Minimum: 860 mm to be able to fit the unit.

-

Page 32: Guidelines When Installing The Drain Piping

Installation A In case of installation with standard decoration panel B In case of installation with fresh air intake kit C In case of installation with self-cleaning decoration panel D In case of installation with design decoration panel a Suspended ceiling b Installation guide (accessory) c Unit ▪... - Page 33 Installation 1~1.5 m a Hanging bar O Allowed X Not allowed ▪ Rising piping. If necessary to make the slope possible, you can install rising piping. Drain hose inclination: 0~75 mm to avoid stress on the piping and to avoid air bubbles.

- Page 34 Installation 5 Wind the large sealing pad (= insulation) around the metal clamp and drain hose, and fix it with tie wraps. 6 Connect the drain piping to the drain hose. ≤4 mm A-A' a Drain pipe connection (attached to the unit) b Drain hose (accessory) c Metal clamp (accessory) d Large sealing pad (accessory)

-

Page 35: Connecting The Refrigerant Piping

Installation a Plastic watering can b Service drain outlet (with rubber plug). Use this outlet to drain water from the drain pan. c Drain pump location d Drain pipe connection e Drain pipe 5 Turn OFF the power. 6 Disconnect the electrical wiring. ▪... -

Page 36: Precautions When Connecting The Refrigerant Piping

Installation 6.3.2 Precautions when connecting the refrigerant piping INFORMATION Also read the precautions and requirements in the following chapters: ▪ General safety precautions ▪ Preparation DANGER: RISK OF BURNING/SCALDING CAUTION ▪ Do NOT use mineral oil on flared part. ▪ NEVER install a drier to this unit to guarantee its lifetime. -

Page 37: Guidelines When Connecting The Refrigerant Piping

Installation INFORMATION Do NOT open the refrigerant stop valve before checking the refrigerant piping. When you need to charge additional refrigerant it is recommended to open the refrigerant stop valve after charging. 6.3.3 Guidelines when connecting the refrigerant piping Take the following guidelines into account when connecting pipes: ▪... -

Page 38: To Connect The Refrigerant Piping To The Indoor Unit

Installation a Cut exactly at right angles. b Remove burrs. 3 Remove the flare nut from the stop valve and put the flare nut on the pipe. 4 Flare the pipe. Set exactly at the position as shown in the following figure. Flare tool for R410A or Conventional flare tool R32 (clutch type) -

Page 39: Connecting The Electrical Wiring

Installation a Insulation material (field supply) b Tie wrap (accessory) c Insulation pieces: Large (gas pipe), small (liquid pipe) (accessories) d Flare nut (attached to the unit) e Refrigerant pipe connection (attached to the unit) f Unit g Sealing pads: Medium 1 (gas pipe), medium 2 (liquid pipe) (accessories) 1 Turn up the seams of the insulation pieces. -

Page 40: Guidelines When Connecting The Electrical Wiring

Installation 6.4.3 Guidelines when connecting the electrical wiring Keep the following in mind: ▪ If stranded conductor wires are used, install a round crimp-style terminal on the end of the wire. Place the round crimp-style terminal on the wire up to the covered part and fasten the terminal with the appropriate tool. -

Page 41: To Connect The Electrical Wiring To The Indoor Unit

Installation Component Specification User interface cable Vinyl cords with 0.75 to 1.25 mm² sheath or cables (2‑core wires) Maximum 500 m H03VV-F (60227 IEC 52) 6.4.5 To connect the electrical wiring to the indoor unit NOTICE ▪ Follow the wiring diagram (delivered with the unit, located at the inside of the service cover). - Page 42 Installation 1~ 50 Hz 220-240 V ▪ Simultaneous operation system. 1 user interface controls 2 indoor units (indoor units operate simultaneously) 1~ 50 Hz 220-240 V ▪ Group control. 1 user interface controls up to 16 indoor units (all indoor units operate according to the user interface).

- Page 43 Installation 1~ 50 Hz 220-240 V a Interconnection cable b Power supply cable c Earth leakage circuit breaker d Fuse e1 Main user interface e2 Optional user interface 10~15 70~90 (mm) a Service cover (with wiring diagram on the back) b Opening for cables c Connection of interconnection cable (including earth) d Cable tie...

-

Page 44: Configuration

Configuration 7 Configuration 7.1 Field setting Make the following field settings so that they correspond with the actual installation setup and with the needs of the user: ▪ Ceiling height ▪ Design decoration panel (if applicable) ▪ Air flow direction ▪... - Page 45 Configuration a All-round air flow b 4-way air flow (all air outlets open, 2 corners closed) (optional blocking pad kit required) c 3-way air flow (1 air outlet closed, all corners open) (optional blocking pad kit required) Setting: Air volume when thermostat control is OFF This setting must correspond with the needs of the user.

- Page 46 Configuration Individual setting in a simultaneous operation system We recommend using the optional user interface to set the slave unit. Perform the following steps: 2 Change the second code number to 02 to perform individual setting on the slave unit. If you want to set the slave unit as…...

-

Page 47: Commissioning

Commissioning 8 Commissioning 8.1 Overview: Commissioning This chapter describes what you have to do and know to commission the system after it is installed. Typical workflow Commissioning typically consists of the following stages: Checking the "Checklist before commissioning". Performing a test run for the system. 8.2 Precautions when commissioning INFORMATION During the first running period of the unit, the required power may be higher than... -

Page 48: Checklist Before Commissioning

Commissioning 8.3 Checklist before commissioning After the installation of the unit, first check the items listed below. Once all checks are fulfilled, the unit must be closed. Power-up the unit after it is closed. You read the complete installation instructions, as described in the installer reference guide. - Page 49 Commissioning Action Turn ON power for at least 6 hours before starting operation to protect the compressor. On the user interface, set the unit to cooling operation mode. 2 Start the test run Action Result Go to the home menu. Cool Set to °C Press at least 4 seconds.

-

Page 50: Error Codes When Performing A Test Run

Commissioning 5 Stop the test run. Action Result Press at least 4 seconds. The Service Settings menu is displayed. Select Test Operation. Service Settings Test Operation Maintenance Contact Field Settings Demand Min Setpoints Differential Group Address Return Setting Press. The unit returns to normal operation, and the home menu is displayed. -

Page 51: Hand-Over To The User

Hand-over to the user 9 Hand-over to the user Once the test run is finished and the unit operates properly, please make sure the following is clear for the user: ▪ Make sure that the user has the printed documentation and ask him/her to keep it for future reference. -

Page 52: Disposal

Disposal 10 Disposal NOTICE Do NOT try to dismantle the system yourself: dismantling of the system, treatment of the refrigerant, oil and other parts MUST comply with applicable legislation. Units MUST be treated at a specialised treatment facility for reuse, recycling and recovery. FCAG35~140BVEB Installer and user reference guide Split system air conditioners... -

Page 53: Technical Data

Technical data 11 Technical data ▪ A subset of the latest technical data is available on the regional Daikin website (publicly accessible). ▪ The full set of latest technical data is available on the Daikin Business Portal (authentication required). 11.1 Piping diagram: Indoor unit... - Page 54 Technical data Symbol Colour Symbol Colour Blue Pink Brown PRP, PPL Purple Green Grey White Yellow Symbol Meaning Printed circuit board Pushbutton ON/OFF, operation switch BZ, H*O Buzzer Capacitor AC*, CN*, E*, HA*, HE*, HL*, HN*, HR*, Connection, connector MR*_A, MR*_B, S*, U, V, W, X*A, K*R_*, NE D*, V*D Diode...

- Page 55 Technical data Symbol Meaning n=*, N=* Number of passes through ferrite core Pulse-amplitude modulation PCB* Printed circuit board Power module Switching power supply PTC* PTC thermistor Insulated gate bipolar transistor (IGBT) Circuit breaker Q*DI, KLM Earth leak circuit breaker Overload protector Thermo switch Residual current device Resistor...

- Page 56 Technical data Symbol Meaning Electronic expansion valve coil Y*R, Y*S Reversing solenoid valve coil Ferrite core ZF, Z*F Noise filter FCAG35~140BVEB Installer and user reference guide Split system air conditioners 4P561448-1B – 2021.07...

-

Page 57: For The User

For the user FCAG35~140BVEB Installer and user reference guide Split system air conditioners 4P561448-1B – 2021.07... -

Page 58: About The System

About the system 12 About the system The indoor unit of this split system air conditioner can be used for heating/cooling applications. NOTICE Do NOT use the system for other purposes. In order to avoid any quality deterioration, do NOT use the unit for cooling precision instruments, food, plants, animals, or works of art. -

Page 59: Information Requirements For Fan Coil Units

Heating capacity rated,h Total electric power input elec Sound power level (per speed setting, if applicable) Contact details: DAIKIN INDUSTRIES CZECH REPUBLIC s.r.o. U Nové Hospody 1/1155, 301 00 Plzeň Skvrňany, Czech Republic FCAG125 8.71 3.39 13.50 0.17 FCAG140 8.68... -

Page 60: User Interface

User interface 13 User interface CAUTION ▪ NEVER touch the internal parts of the controller. ▪ Do NOT remove the front panel. Some parts inside are dangerous to touch and appliance problems may happen. For checking and adjusting the internal parts, contact your dealer. -

Page 61: Before Operation

Before operation 14 Before operation WARNING This unit contains electrical and hot parts. WARNING Before operating the unit, be sure the installation has been carried out correctly by an installer. CAUTION It is unhealthy to expose your body to the air flow for a long time. CAUTION To avoid oxygen deficiency, ventilate the room sufficiently if equipment with burner is used together with the system. -

Page 62: Operation

Operation 15 Operation 15.1 Operation range Use the system in the following temperature and humidity ranges for safe and effective operation. In combination with R410A outdoor units Outdoor units Cooling Heating RR71~125 –15~46°C DB — 12~28°C WB — RQ71~125 –5~46°C DB –10~15°C WB 12~28°C WB 10~27°C DB RXS35~60 –10~46°C DB... -

Page 63: Operating The System

Operation In combination with R32 outdoor units Outdoor units Cooling Heating RXM35~60 –10~46°C DB –15~24°C DB –15~18°C WB 14~28°C DB 10~30°C DB 3MXM40~68 –10~46°C DB –15~24°C DB 4MXM68~80 –15~18°C WB 5MXM90 18~37°C DB 10~30°C DB 14~28°C WB RZAG35~60 –20~52°C DB –20~24°C DB –21~18°C WB 17~38°C DB 10~27°C DB 12~28°C WB RZAG71~140 –20~52°C DB –20~24°C DB –20~18°C WB 17~38°C DB 10~27°C DB 12~28°C WB RZASG71~140 –15~46°C DB... -

Page 64: About Cooling, Heating, Fan Only, And Automatic Operation

Operation 15.2.2 About cooling, heating, fan only, and automatic operation ▪ The air flow rate may adjust itself depending on the room temperature or the fan may stop immediately. This is not a malfunction. 15.2.3 About the heating operation It may take longer to reach the set temperature for general heating operation than for cooling operation. -

Page 65: Using The Dry Program

Operation 15.3 Using the dry program 15.3.1 About the dry program ▪ The function of this program is to decrease the humidity in your room with minimal temperature decrease (minimal room cooling). ▪ The micro computer automatically determines temperature and fan speed (cannot be set by the user interface). -

Page 66: Active Circulation Airflow

Operation ▪ Automatic and desired position . WARNING Never touch the air outlet or the horizontal blades while the swing flap is in operation. Fingers may become caught or the unit may break down. NOTICE ▪ The movable limit of the flap is changeable. Contact your dealer for details. (only for double-flow, multi-flow, corner, ceiling-suspended and wall-mounted). - Page 67 Operation Check if Air Volume/direction is set Air Volume/direction Air Volume Direction to automatic. If not set to Auto Auto automatic. Return Return Setting Setting 2 Turn on the unit by the user interface. FCAG35~140BVEB Installer and user reference guide Split system air conditioners 4P561448-1B –...

-

Page 68: Energy Saving And Optimum Operation

Energy saving and optimum operation 16 Energy saving and optimum operation Observe the following precautions to ensure the system operates properly. ▪ Adjust the air outlet properly and avoid direct air flow to room inhabitants. ▪ Adjust the room temperature properly for a comfortable environment. Avoid excessive heating or cooling. -

Page 69: Maintenance And Service

Maintenance and service 17 Maintenance and service 17.1 Precautions for maintenance and service CAUTION: Pay attention to the fan! It is dangerous to inspect the unit while the fan is running. Be sure to turn off the main switch before executing any maintenance task. CAUTION Do NOT insert fingers, rods or other objects into the air inlet or outlet. -

Page 70: To Clean The Air Filter

Maintenance and service 17.2.1 To clean the air filter When to clean the air filter: ▪ Rule of thumb: Clean every 6 months. If the air in the room is extremely contaminated, increase the cleaning frequency. ▪ Depending on the settings, the user interface can display the TIME TO CLEAN AIR FILTER notification. -

Page 71: To Clean The Suction Grille

Maintenance and service 4 Dry the air filter in the shadow. 5 Reattach the air filter and close the suction grille. 6 Turn ON the power. 7 Press the FILTER SIGN RESET button. Result: The TIME TO CLEAN AIR FILTER notification disappears from the user interface. -

Page 72: To Clean The Air Outlet And Outside Panels

Maintenance and service Design panel: 3 Remove the air filter. 4 Clean the suction grille. Wash with a soft bristle brush, and water or neutral detergent. If the suction grille is very dirty, use a typical kitchen cleaner, leave it on for 10 min, then wash it with water. 5 Reattach the air filter (step 3 in reverse order). -

Page 73: Maintenance Before A Long Stop Period

Maintenance and service 17.4 Maintenance before a long stop period E.g., at the end of the season. ▪ Let the indoor units run in fan only operation for about half a day in order to dry the interior of the units. Refer to "15.2.2 ... -

Page 74: After-Sales Service And Warranty

Maintenance and service WARNING R410A is a non-combustible refrigerant, and R32 is a mildly flammable refrigerant; they normally don’t leak. If the refrigerant leaks in the room and comes into contact with fire from a burner, a heater, or a cooker, this may result in a fire (in case of R32), or the formation of a harmful gas. -

Page 75: Shortened Maintenance And Replacement Cycles

Maintenance and service Component Inspection Maintenance cycle cycle (replacements and/or repairs) Electric motor 1 year 20,000 hours 25,000 hours Heat exchanger 5 years Sensor (thermistor, etc.) 5 years User interface and switches 25,000 hours Drain pan 8 years Expansion valve 20,000 hours Solenoid valve 20,000 hours... - Page 76 Maintenance and service Recommended replacement cycle of wear parts Component Inspection Maintenance cycle cycle (replacements and/or repairs) Air filter 1 year 5 years High efficiency filter 1 year Fuse 10 years Pressure containing parts In case of corrosion, contact your local dealer. NOTICE ▪...

-

Page 77: Troubleshooting

Troubleshooting 18 Troubleshooting If one of the following malfunctions occur, take the measures shown below and contact your dealer. WARNING Stop operation and shut off the power if anything unusual occurs (burning smells etc.). Leaving the unit running under such circumstances may cause breakage, electric shock or fire. -

Page 78: Symptoms That Are Not System Malfunctions

Troubleshooting If after checking all above items, it is impossible to fix the problem yourself, contact your installer and state the symptoms, the complete model name of the unit (with manufacturing number if possible) and the installation date (possibly listed on the warranty card). -

Page 79: Symptom: The User Interface Reads "U4" Or "U5" And Stops, But Then Restarts After A Few Minutes

Troubleshooting 18.1.6 Symptom: The user interface reads "U4" or "U5" and stops, but then restarts after a few minutes This is because the user interface is intercepting noise from electric appliances other than the air conditioner. The noise prevents communication between the units, causing them to stop. -

Page 80: Symptom: The Compressor In The Outdoor Unit Does Not Stop After A Short Heating Operation

Troubleshooting 18.1.14 Symptom: The compressor in the outdoor unit does not stop after a short heating operation This is to prevent refrigerant from remaining in the compressor. The unit will stop after 5 to 10 minutes. FCAG35~140BVEB Installer and user reference guide Split system air conditioners 4P561448-1B –... -

Page 81: Relocation

Relocation 19 Relocation Contact your dealer for removing and reinstalling the total unit. Moving units requires technical expertise. FCAG35~140BVEB Installer and user reference guide Split system air conditioners 4P561448-1B – 2021.07... -

Page 82: Disposal

Disposal 20 Disposal NOTICE Do NOT try to dismantle the system yourself: dismantling of the system, treatment of the refrigerant, oil and other parts MUST comply with applicable legislation. Units MUST be treated at a specialised treatment facility for reuse, recycling and recovery. FCAG35~140BVEB Installer and user reference guide Split system air conditioners... -

Page 83: Glossary

Optional equipment Equipment made or approved by Daikin that can be combined with the product according to the instructions in the accompanying documentation. Field supply Equipment NOT made by Daikin that can be combined with the product according to the instructions in the accompanying documentation. - Page 84 4P561448-1B 2021.07 Verantwortung für Energie und Umwelt...