Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Datalogic Gryphon GFE4400

- Page 1 Gryphon™ GFE4400 Fixed Area Imaging Bar Code Scan Engine Integration Guide...

- Page 2 Disclaimer Datalogic has taken reasonable measures to provide information in this man- ual that is complete and accurate, however, Datalogic reserves the right to change any specification at any time without prior notice. Datalogic and the Datalogic logo are registered trademarks of Datalogic S.p.A.

-

Page 3: Table Of Contents

Demo Kit ......................2 Unpacking the Scan Engine ................2 Scan Engine Care ....................3 Technical Support ......................3 Datalogic Website Support ................. 3 Telephone Technical Support ................3 Mounting the Scanner ..................... 4 General Considerations ..................4 Mounting ........................4 Mounting the Scanner Standalone ............ - Page 4 NOTES...

-

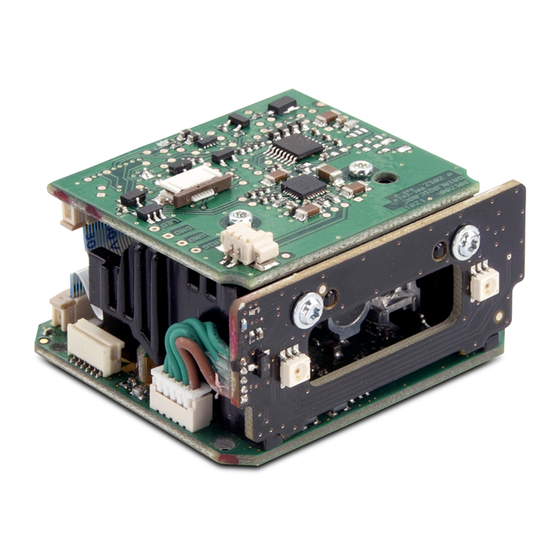

Page 5: Gryphon™ Gfe4400 Integration Guide

Gryphon™ GFE4400 Integration Guide This document gives instruction, mechanical details, and design consid- erations to integrate the Gryphon™ GFE4400 model (designated as “scan engine” or “OEM scan engine” in this manual) specifically into equipment-integrated scanning applications. Overview The GFE4400 OEM scan engine is a compact decoding omni-direction- al imaging scan engine for fixed position OEM integration, such as price verifiers, kiosks, vending machines, point-of-sale (POS) terminals, and other equipment-integrated scanning applications. -

Page 6: Demo Kit

Details on the Configuration Settings and Programming are found in the GFS4400 Product Reference Guide (PRG). The Datalogic Aladdin Con- figuration Utility (available free from the Datalogic website) can also be used to modify settings. Demo Kit... -

Page 7: Scan Engine Care

Telephone Technical Support If you do not have internet or email access, you may contact Datalogic technical support at (541) 349-8283 or check the back cover of your manual for more contact information. -

Page 8: Mounting The Scanner

Mounting the Scanner Mounting the Scanner This section describes how to design the mounting for optimum scanner performance. General Considerations A typical system uses the scanner mounted inside a host enclosure, with an opening for the scanning pattern to exit and read bar codes. The open- ing should be the size of the scanner field of view at a minimum, but only exposing as much of the scanner as necessary. -

Page 9: Scan Engine Electrical Connections

Mounting the Scanner Scan Engine Electrical Connections The GFE4400 scan engine has three application ports for device integra- tion, as indicated below, a Host (J1), User (J2), and Good Read Beep In- terface. Figure 1. Scan Engine Application Ports J3 Beep Interface J2 User Interface J1 Host Interface Host Interface... - Page 10 Mounting the Scanner Table 1. J1 Connector Pins Assignment Pin Number Pin Functionality USB D+ USB D- USB Shield USB Shield EXT_TRIGGER_IN; (input to the base of a transistor, pull high to activate) RS232 TXD (output from scanner) RS232 RTS (output from scanner) RS232 RXD (input to the scanner) RS232 CTS (input to scanner) DIGITAL_OUT (open collector)

-

Page 11: Usb

Mounting the Scanner For USB setup, the recommended wiring is the following. Figure 3. USB Cabling It is important that connections 7/8/9 be wired together for USB Auto Detection. Integration Guide... -

Page 12: External Trigger And Digital Output

Mounting the Scanner RS-232 For RS-232 serial setup, the recommended wiring is shown below. Figure 4. RS-232 Cabling External Trigger and Digital Output The interface allows the user's adapting interface to trigger the scan engine if not set for Automatic Reading Mode. Also, a programmable digital out- put signal is available, which indicates a good read/decode. - Page 13 Mounting the Scanner Figure 5. Connections Output Connection Vext 14Vdc max GFE44X0 USER INTERFACE 12 GND Input Trigger Using GFE44X0 Power GFE44X0 EXT TRIGGER TRIGGER 12 GND Input Trigger Using External Power GFE44X0 EXT TRIGGER Vext 5 Vdc TRIGGER 12 GND Integration Guide...

-

Page 14: User Interface

Mounting the Scanner User Interface The User Interface connection (J2) provides the integrator a means to monitor scan engine status (LEDs), and offers an additional mechanism for manually triggering the device. The user connection (J2) uses a Molex part number, 0527460671, 0.50mm (.020") Pitch FFC/FPC Connector, Right Angle, SMT, ZIF, Bottom Contact Style, 6 Circuits, Gold Contact Plating. - Page 15 Mounting the Scanner Table 2. J2 Connector Pins Pin Number Pin Functionality LED1 Ctrl Signal, Trigger (active low) LED2 Ctrl Signal, Status (open collector active low) LED3, Power, (hard wired to VCC internally) VCC_Out (5v for LED supply) Trigger Switch+ Trigger Switch- (ground) The following table outlines scan engine status assigned to each LED (with recommended colors).

- Page 16 Mounting the Scanner The following is an example of a possible connection scheme for the User Interface: Figure 7. Sample Connection Scheme Gryphon™ GFE4400...

-

Page 17: Good Read Beep Interface

Mounting the Scanner Good Read Beep Interface The Beep Interface connection (J3) provides the integrator a means to tap the engine's good read beep signaling and interface with an external audio device. The Beep Connection (J3) is a Molex part number, 53261-0271, 1.25mm Pitch PicoBlade™... -

Page 18: Scanner Ventilation

Mounting the Scanner Figure 8. Beeper Connection Scheme Scanner Ventilation When mounting the scanner inside an enclosure, it is important to have proper ventilation to ensure that the scanner temperature does not exceed the maximum range as listed in "Technical Specifications" on page 19. -

Page 19: Integrating The Scanner To Read At The Proper Distance

Mounting the Scanner Integrating the Scanner to Read at the Proper Dis- tance When deciding how to mount the OEM scanner, there are many criteria that must be considered. First, there are minimum and maximum dis- tances that the bar code can be from the front of the scanner to be prop- erly read, depending on the size of the bar code. -

Page 20: Design Of The Scanner Opening

Mounting the Scanner Design of the Scanner Opening The design and placement of the scanner opening within a host enclosure are critical for optimum system performance. A typical system uses the scanner mounted inside a host enclosure, with an opening to allow the scanner Field of View to exit the scanner window and read bar codes. -

Page 21: Integrating The Scanner Behind A Window

Mounting the Scanner Integrating the Scanner Behind a Window The addition of a host enclosure window could degrade scanner performance. This is due to the optical reflective surfaces that will cause interfer- ence with the imaging technology. CAUTION It is recommended to conduct scan performance testing with any win- dow to determine if the performance level is acceptable for the applica- tion. -

Page 22: Esd Protection

Mounting the Scanner ESD Protection The host enclosure design must provide adequate ESD protection for the scanner. Ideally, static discharge should not be allowed contact with the scanner. The preferred method to prevent static discharge is to provide a long discharge path to all circuits. The scanner is intended to be mounted inside a host enclosure. -

Page 23: Technical Specifications

Technical Specifications Technical Specifications Item Description Physical Characteristics Height 28.2mm (1.11") Dimensions Length 42mm (1.65") Width 48 mm (1.89") Weight (without cabling) Approximately 51.2 g (1.8 oz) Electrical Characteristics 5 VDC ± 5% Input Voltage Overvoltage tolerant to 14VDC External Trigger Input : 1V - 5V Current Consumption for 1V = 2mA max 5V = 10mA max Min Pulse Duration = 25ms *... - Page 24 Technical Specifications Item Description Good Read Beep Output Output Type Open Collector Maximum Sink Current 200mA Maximum Sink Voltage 5V (ESD protection limit) Current & Power Consumption Input current at 5V in Automatic (Object Sense) Reading Mode 175 mA (OnLine & Serial OnLine Modes) Operating (typical) 165 mA (Automatic Object Sense Mode) Operating (max)

- Page 25 Technical Specifications Depth of Field (Typical) NF = Near Field inches FF = Far Field Code 39 5mil 16.8 Code 39 10mil 32.3 12.7 Code 39 20mil 48.3 19.0 EAN 7.5mil 26.4 10.4 EAN 13mil 41.0 16.1 PDF-417 6.6mil 14.5 PDF-417 10mil 23.0 PDF-417 15mil...

- Page 26 (Italian Pharmacode 39); Code 128; Code 128 ISBT; Interleaved 2 of 5 ; Standard 2 of 5; Interleaved 2 of 5 CIP (HR); Industrial 2 of 5; Discrete 2 of 5; Datalogic 2 of 5 (China Post Code/Chinese 2 of 5); IATA 2of5 Air cargo code;...

-

Page 27: Rs-232 Electrical Connections

Technical Specifications RS-232 Host Interface supported USB (full speed) User Environment Operating Temperature -4° to 122° F (-20° to 50° C) Storage Temperature -4° to 158° F (-20° to 70° C) Humidity Operating: 5% to 90% relative humidity, non condensing Ambient Light immunity Up to 100,000 Lux Regulatory... -

Page 28: Indicators

Technical Specifications Indicators The reader’s green LED L2 of J2 illuminates to indicate various functions or errors. An optional “Green Spot” also performs useful functions. The following tables list these indications. One exception to the behaviors list- ed in the tables is that the reader’s functions are programmable, and so may or may not be turned on. -

Page 29: Error Codes

Indicator Description LED L2 of J2 Flash Memory Occurs while update is in progress Blue LED blinks Update Except when in sleep mode or when a Good Read LED Duration other than 00 is selected Error Codes Upon startup, if the reader’s LED2 and Green Spot are blinking alter- nately, this means the reader has not passed its automatic Selftest and has entered FRU (Field Replaceable Unit) isolation mode. -

Page 30: Mechanical Specifications

Mechanical Specifications Mechanical Specifications Physical Properties Parameter Specification 42.0mm x 48.0mm x 28.2mm Dimensions (1.65" x 1.89" x 1.11" Weight ~51.2 g (1.8 oz) Scanner Dimensions TOP VIEW Gryphon™ GFE4400... - Page 31 Mechanical Specifications Scanner Dimensions (continued) BOTTOM VIEW SIDE VIEW Integration Guide...

-

Page 32: Clearance Required For Integration

Mechanical Specifications Clearance Required for Integration TOP VIEW SIDE VIEW Gryphon™ GFE4400... - Page 33 Mechanical Specifications NOTES Integration Guide...

- Page 34 Mechanical Specifications NOTES Gryphon™ GFE4400...

- Page 36 ©2012-2013 Datalogic ADC, Inc. • All rights reserved. Datalogic and the Datalogic logo are registered trademarks of Datalogic S.p.A. in many countries, including the U.S.A. and the E.U. Datalogic ADC, Inc. 959 Terry Street Eugene |OR 97402 Telephone: (1) 541-683-5700...